Direct and indirect causes of the accident

Direct causes

The worker did not secure the steel sheets as expected with cables through the traveling crane. The worker was not within the designated area, thus exposing himself to harm. The traveling crane has not been serviced for a long period of time, and the safety alarm signal was not functional. The safety regulations which prohibit any employee from walking under the moving crane were not handed to the employee despite having been in the company for more than two months. Lastly, the operator of the crane lacked specific training in handling the hoisting crane.

Indirect Causes

The employee was disturbed by the incidence of the previous day when he refused to sign the disciplinary notice for absenteeism. This state of disturbance might have resulted in his safety neglect in delivering services at the company. Besides, the employee was trusted with a dangerous duty despite having been in the company for less than three months. This might not be enough time for proper handling of dangerous assignments such as the one which nearly turned fatal.

Steps to take and the remedial measures to be implemented the next day

Risk assessment process

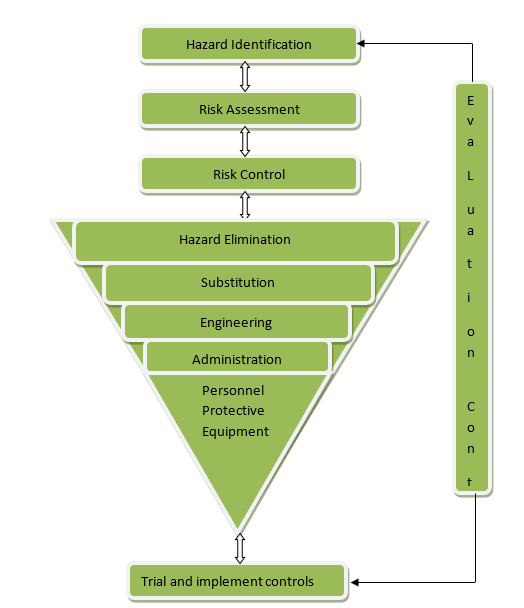

Occupational health and safety must be managed in a systematic way. The following procedures should be immediately followed in risk assessment:

- Identify the hazards-establish what might be the cause of the harm

- Asses the risks if necessary-understanding the nature of the harm and how severe the harm could be and the likelihood of it reoccurring.

- Control risks-engage the most efficient control measure to curb the harm.

- Review control measures-this is done to ascertain that the measures are working as required by OHS standards.

The safety regulations should be issued to all employees to ensure that everyone is aware of what is expected of them in terms of safety. The company should outsource a maintenance team to fix the crane in the shortest time possible, especially the movement alarm. The operator of the crane should be subjected to quick refresher lessons to ensure that the hoisting apparatus is well operated. Lastly, the injured employee should be kept off the premises of the company until full recovery is recorded.

Recommendations to be applied over the next three months

Revision of the Safety Policy

- Ensure the organization has an up-to-date policy on health and safety and that each employee is orientated on the same.

- Ensuring that the content of the policy is made available to all employees of the company.

- Establishing clear reporting, investigation, and resolution procedures.

Revision of the Safety Standards and Performance

- Should include the provision of appropriate workstation equipment in the company.

- Establish effective work standards that must be followed by all employees

- Ensure environmental safety

- Carry out a comprehensive risk assessment and management

- Spell out emergency actions

- Ensuring personal safety

Adoption of a Comprehensive Hazard Management Approach

Implementation of Hazard control system

- Application of appropriate control measures

- The evaluation of the measures to identify areas of weaknesses

- Application of corrective measures to curb the identified faults in the system.