Introduction

Fashion is never static; it embodies popular trends that keep on changing depending on consumer tastes and preferences. Globalisation has had a big impact on the European fashion industry, as firms seek to expand to overseas markets in China, the US, and Japan, among others. Thus, competition in the fashion industry is intense, and companies have to implement effective business models, designs, and marketing strategies in order to remain competitive on the global stage. Unlike other fashion companies, Zara’s target market is wide. Its business strategy is unparalleled in the industry.

Zara handles up to 40% of its production, which means that only a few operations are contracted out. This allows it to maintain a flexible inventory system and exercise effective control of its supply chains. The company regulates its production through sequence control, which allows it to create an ‘unsatisfied’ demand for its fashion products. It uses a vertical integration strategy to manage scarcity and production of its fashion items. It allows the firm to save time and reduce operating costs by minimising its distribution channels. Thus, compared to its competitors, Zara’s production and supply chains are shorter and more efficient (Gustafson, Schmiesing-Korff, and Ng Para. 4).

As aforementioned, the firm produces and sells its items in small batches because of the vertical integration strategy. This allows it to adjust its production and supply chains to suit the current trends and tastes in a fast and efficient manner. The strategy also enables the company to manage its logistics, product design (style), and distribution. Thus, Zara’s competitiveness is attributable to its sequence control strategy. This study will focus on how Zara uses the sequence control strategy to manage its supply chains.

Background of the Research Problem

While Zara’s ‘unique’ shops used to be in Italy, nowadays, the firm has shops located in major cities in Europe, the Centre Eastern, and Japan. The organisation launched its first store in the Russian Federation on Aug 28, 2013. In 2012, Inditex reported complete product sales of € 15.9 Billion ($20.7 Billion dollars) (Loeb Para. 5). In comparison, in the same year, Zara recorded a 66% of the rise incomplete product sales, which translated to €10.5 Billion ($13.6 Billion dollars), and 120 shops worldwide (Loeb). Other, more compact, sections include Take & Keep, Massimo Dutti, Bershka, Stradivarius, Oysho, Zara Home, and Uterque.

Zara targets particular groups of developers and product supervisors. They manage the style by seeking and manufacturing a specific category of products such as outfits or female’s sportswear. They are responsible for both the preliminary selection and in-season reaction. Significant to its success, Zara develops its fashion styles based on trending customer tastes. This approach shortens the fashion design and development process. Zara has the ability to design, manufacture, and bring to the market a new fashion product within a fortnight. The organisation usually spends almost nothing on marketing and uses its profits to support production in Italy. This allows the organisation to generate what the clients want. Moreover, marketing, design, and production at Zara’s plants, such as the La Coruna subsidiary, involve distinct departments. This allows the firm to adapt quickly to market changes.

Relevant Literature and Researches

What improves the complexity of the provide sequence is the dependency on exports from other manufacturing countries. Almost 30% of all outfits created on the globe are released to markets in other countries (Loeb Para. 2). Hence, there is a huge cost involved in moving components and completed products. Zara has managed to take a leading position as an innovator in the outfits market because of its exclusive sequence techniques. Zara uses the following three concepts to increase its net income and provide brands that are both stylish and cost-effective:

- Quick reaction to customer requirements – Zara follows a ‘take’ design in their stock and provides a sequence control. It creates up to 1000 styles every month, depending on shop sales and current trends (Loeb Para. 5). The firm monitors the clients’ purchases to assess and know their tastes and then accordingly, design styles that reflect future market trends.

- Small group shows – Zara generates fast revenues; it gets a small profit from every item it sells. This gives the firm an opportunity to know what styles are effective. It is also a great way to discover a new style and gauge its approval rate in the market. This also immensely decreases the risk of generating excess products that may not be absorbed into the market. Although investing in different styles is costly, Zara reaps from the new designs by using the same content in multiple product offerings.

- Central Submission Centre – Zara has very powerful IT systems for distribution management. All the outfits are delivered to Italy, which is the central assembly location (Loeb). From Italy, they are allocated to different countries and shops depending on individual specifications and needs of the area. Zara has established itself as a market leader in the fashion sector due to its exclusive sequence design. However, as more opponents enter the market, will Zara sustain its competitive advantage through its sequence control strategy?

Zara’s sectors in Italy and France, the other agents, and the Poultry generate its coolest outfits, which often epitomise the newest styles in the fashion industry. They account for about half of Zara’s stock (Loeb Para. 2). Its more primary T-shirts, sweatshirts, and the likes are requested on a conventional routine, about six to a few weeks in advance, from sectors in Japan, where work costs are often less expensive and sent to Italy. Zara invests in R&D, which allows the company to develop new designs and styles that are unique in the market. According to Pokharel, at the beginning of each year, a common store places an order for at least 80% of the outfits it will offer (Para. 7). The sequence chooses only about 50% of its styles in advance. Thus, this system facilitates the development of new brands and innovative designs within a short time.

ZARA changes its styles twice in a week, whereas Represents and Spencer do this less frequently. Products of Zara are very popular with young women (aged between 24 and 25). The firm’s item profile consists of outfits for men, women, and children (ZARA KIDS), shoes, and beauty products. The company invests in new stores to expand its market presence as opposed to spending on brand promotion. Currently, Zara runs 1671 shops all over the globe (Pokharel Para. 4). The industry leader is a “fashion imitator” organisation; it changes more than 2000 styles per year. In 2012, its income from its sales stood at 7 billion dollars (Pokharel).

Infrastructure

Zara’s manufacturing plant is located in La Coruna, France. It is a small town with the cheapest labour in the country. However, compared to countries in South Asia, labour costs are higher in France. The location offers versatility and speed, which allows new styles and features to be developed quickly.

Human Resource Management

ZARA employs school leavers and fresh undergraduates who begin their career at the company. The firm prefers fresh, dynamic, and youthful individuals because they do not have family responsibilities and thus, can focus more on their work.

Technological Development

Zara invests heavily in fashion development. It sends providers to nightclubs and social activities (fashion shows) to check out new styles and send back images using modern technological platforms. The manufacturer then designs new items based on these images, with minor variations in style.

Operations

Zara’s factory in France is equipped with versatile production systems for a quick turnaround in style and fashion. However, labour is not as cheap as the company lays more emphasis on product quality and performance. This extends its production lead times (Gustafson, Schmiesing-Korff, and Ng Para. 4).

Marketing and Sales

Zara rarely promotes its products on the press; however, occasionally, the company erects a large poster on a new development or construction project. As the project nears completion, the poster becomes more noticeable to its target audience.

Facilities

Zara increases its market presence by positioning their shops in strategic town-centre places. By decreasing the produced volume of each style, Zara creates an ‘unsatisfied’ demand and decreases the risk of having inventory it cannot sell. Zara supplies its items in small batches and thus, manages to keep the demand for its products high. Zara discount rates stand at 18% of its inventory, which is half the regular value in the industry (Loeb).

Inventory Stores

The retail shops place purchases twice weekly, and the provider of completed products is recorded (Loeb). Manufacturing is then improved or reduced in the most versatile plants depending on the level of demand. Demand-based production indicates there is very little inventory in Zara, which results in much lower distribution costs.

Procurement/Inbound Logistics

Zara purchases its raw materials from France and Portugal. The aim is to reduce costs and promote certain product features. Suppliers provide much of the services within the country of production. As such, incoming materials are often transported by road (mainly trucks).

Pricing

Since manufacturing is carried out in Italy, which has high labour costs compared to parts of East Asia, prices are bound to be high. The huge salaries paid to workers impacts on the prices of the final products.

Delivery

An item ordered from the industry is usually delivered after two days. The delivery involves the use of trucks. The new outfits are displayed in the retail shops ready for sale.

Strengths

Zara generates about 11,000 unique products yearly in contrast to 2,000 to 4,000 items produced by its key opponents (Handfield Para. 11). Due to low lead-times, Zara takes a short time to design, manufacture, and supply new items into the market. The firm can replace all the items on offer in its shops within a fortnight. By reducing an item’s life cycle, Zara achieves greater success in meeting customer choices and tastes. Its Italian shops receive return visits from several local and international clients. On average, a client can visit its stores up to 17 times a year. About 50% of Zara’s products are made in Italy, 26% in other European nations, and 24% in Asian and African nations (Handfield).

Based on Zara’s provide sequence, the writer concludes that the system allows the firm to come up with innovative styles for its outfits. Moreover, the location of Zara’s main factory in Italy has also helped it to integrate its operations vertically. An essential fact that has enhanced Zara’s competitiveness is the regular circulation of information between its suppliers, clients, developers, professionals, and retail shops.

Problem and Its Key Terms

In the past, the outfits industry was classified as more of a force design where the store sites offered new designs and outfits to the market. However, the same technique is ineffective nowadays because the industry has become highly competitive with new and innovative fashions being introduced into the market daily. Thus, it is important for fashion companies to identify what appeals to the clients and quickly respond to their needs. Additionally, every geographical location varies in terms of spending styles, design preferences, and household incomes, among others. Therefore, it is important for industry players to assess the demand that will be available in every market segment.

The key predictors of demand in the fashion industry include customer tastes and preferences, and trends in the market. Demographic factors can also indicate future demand trends. Consumer demand depends on age, gender, income level, and geographical location. Fashion firms should focus their business strategies on these key variables.

Objectives/Question of the Study

The objectives of this study are as follows:

- To evaluate the level of sequential control as applied in Zara’s operations

- To find out if the current provide sequence control is effective and how it has contributed to Zara’s success

- To recognise the key control components of Zara’s provide a sequence

Scope of the Study

This study will examine Zara’s sequence control framework to identify the techniques it uses in supply chain management. Therefore, the study will be limited to Zara’s supply chain in the fashion industry.

Motivation

As a student, the researcher aims to study the sequence control in Zara and apply it to scenarios that he is involved in to comprehend the concept completely. The student intends to comprehend how big companies apply control in their operations and how this makes them industry leaders.

Research Design

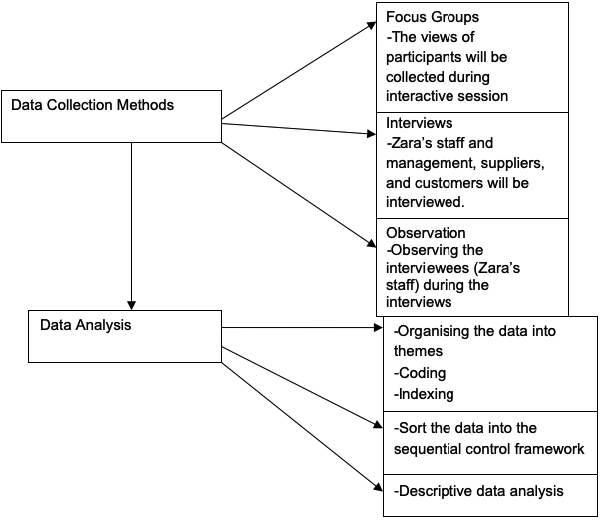

The study will involve a qualitative research design. Primary data will be collected using survey questionnaires, field notes, and interview recordings. The research will also rely on secondary sources, such as published articles, books, and online resources, for qualitative data. The data collection methods that will be used in this research include interviews, observation, and focus group discussions.

Data analysis will involve the organisation of the data into themes representing common points, coding, and indexing of related variables. The descriptive analysis method will be used to analyse the sorted data based on the sequential control framework. The process that will be used in qualitative data collection and analysis is presented in the flow diagram below.

Works Cited

Gustafson, Annika, Alice, Schmiesing-Korff, and Sze, Ng 2004, A Time Efficient Supply Chain Model for an Apparel Company. Web.

Handfield, Robert. What is Supply Chain Management?. 2011. Web.

Loeb, Walter. Zara’s secret to success: The news science of retailing. 2013. Web.

Pokharel, Manju. Supply chain management of Zara. 2013. Web.