Executive Summary

Driving value through the procurement process enhances the identification of all needs within the company. The paper discusses the acquisition of equipment by Abu Dhabi National Oil Company (ADNOC), an oil and gas holding company in Abu Dhabi as a tool to improve the quality and effectiveness of the institution. The procedure involved is critical in ensuring the maximization of profits and the reduction of the cost of production. The importance of writing the article is to analyze the vital gaps for improving the system in establishing modern techniques of procurement. The main findings in the paper are that communication and involvement of the stakeholders is one major aspect of adding value to the process.

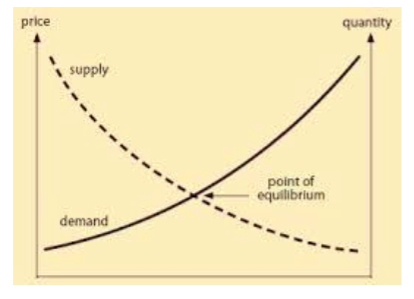

Other factors affecting the procurement system in the company are the demand and supply of drilling and production chemicals, gaskets, valves, and safety equipment for engineers on the different sites operated by ADNOC. There is a need to enhance the purchasing cycle to make provision for efficient sourcing of goods that are delivered in time without compromising the quality of products. The effectiveness of the procurement department is critical in improving companies’ efficiency and achieving the goals set. The equipment has high demand in the institution, but limited suppliers due to their high cost or the lack of availability from a quality perspective. The price mechanisms applied must conform to the situation of the industry and have the ability to control the costs. Different elements in the market render the systems expensive to purchase. The high demand and insufficient supply of material and equipment for engineers are major aspects that influence the prices. Finally, the paper sums up with a conclusive paragraph that discusses the important elements discussed.

Introduction

The modern procurement and sourcing processes have the capability to focus on lowering the costs of supplies. The processes have shifted the subject to major business needs with the aim of accomplishing the goals by taking into account important aspects such as product quality and reliability. Moreover, through the emphasis on the vital categories within the business, organizations can manage and build supplier relationship that is perceived to enhance delivery results. Supply chain management has become a major concern in different companies. As the world’s market becomes competitive, the profitability depends less on raising the prices. Consequently, there is the need for enhancement of productive innovation, faster response to time, and higher quality. Similarly, there is the need to grow the cross-collaboration as a way to drive the modern generation to more advanced strategies. Implementation of diverse methods is critical in resolving challenges facing organizations. Procurement is a process of obtaining products by making decisions of when and how much to purchase. The procedure at the procurement department of ADNOC in Abu Dhabi ensures that the appropriate quality and quantity of materials and equipment are acquired at the lowest cost and suitable source.

Driving Value through Procurement and Supply

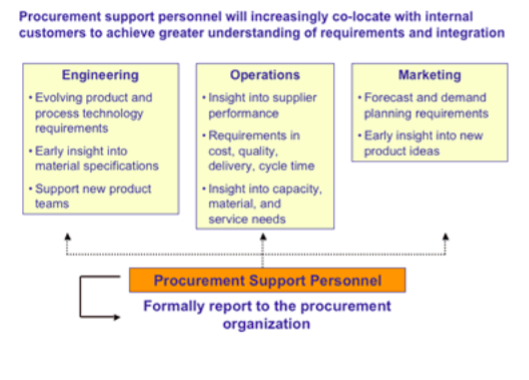

The purchasing cycle in the organization makes provision for all departments to have a link to information about the functions and other related operations. The services have been enhanced through a reliable association of long-lasting affiliation with both international and local vendors. Consequently, the involvement of an experienced team provides the clients with the best equipment suited for most of their needs. In the modern world, optimization of procurement is considered as a host of most benefits and added tremendous value. From a company’s perspective, the obvious advantages of efficiency within this department are the maximization of financials (Chima, 2011). Managing the procurement process enables an organization to gain immediate upfront cost savings by attaining services, contracts, and other items. In order to apprehend the process of procurement, see Figure 1 below.

ADNOC is the seventh biggest oil producer in the world. It is also one of the companies with the lowest costs of operations per barrel due to the characteristics of its onshore and offshore sites. A fully functioning department of procurement ensures that products and services required by their engineers on the different sites (rigs) are bought through an efficient and cost-effective method. Moreover, having a clear understanding of the spending allows the management to have higher bargaining power with the vendors (Srivastava & Verma, 2012). With this added benefit, the company can fully maximize the profits by acquiring what seems to be unavailable to it. Visibility into budgets and spending patterns makes a provision for an organization to leverage any additional cash flow. A fully operational department can contribute to greater preparedness and efficiency. Besides, many perceive the procurement process as a single-dimensional procedure within the company (Daniel, Keen, & McPherson, 2010).

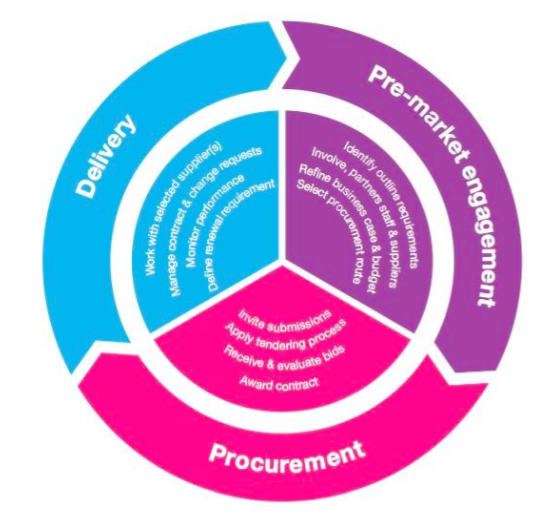

An optimized purchasing cycle makes provision for efficient sourcing of goods that are delivered in time. Updating the department of procurement in ADNOC ensures that the supply chain can navigate through unforeseen challenges such as volatility of commodities. Moreover, it creates an avenue of distinguishing between successful sellers from underachieving vendors. Any competitive edge of this institution makes a difference between new customers and levels of sale (Chima, 2011). A progressive procurement procedure can allow the business to seek more innovative products and services. Besides, entrusting the procurement department enables it to source modern equipment and chemicals with high efficiency of achieving the intended purpose (Ross, 2011). For a better understanding, see Figure 2 below.

Recommendations for Improvement of Procurement System

An effective procurement procedure has room for improving the companies’ efficiency and bottom line. However, to improve the performance of this department, it is critical to have a strategic plan that aims at achieving the set goals. The first technique of success in ADNOC is to provide the team with the required procurement tools that enhance the process. Consequently, it is imperative to incorporate a strategic sourcing procedure. Oil and gas organizations aim at offsetting the barriers of expensive systems and equipment. It is important to note that new products are not the solution to achieving efficiency (Mumford, 2012). With a proper organization of operations, ADNOC can be equipped to enhance innovation, keep the costs low, and have an improved response to the customer’s name, the engineers on sites, and their client overseas ultimately. In reality, continuous competitiveness and growth in this industry will require the management to enhance the alignment of functions in the procurement department especially with the current crop of oil prices.

Areas of Improvement for ADNOC

ADNOC can achieve benefits that apply to most facets of the oil and gas companies. Benefits such as reliability, quality, environmental performance, and safety can help to improve the position of the institution within the global market. Reliability is an important factor in the supply chain since it makes the provision of timing and quality. Buying materials or contracting services for engineers on different sites influences the productivity of the company. If the operations of the institutions are delayed as a result of the poor procurement process, the profit margins are reduced. It is important to improve the diversity of selecting vendors. The equipment and services purchased must have the ability to enhance safety in the drilling operations.

Improvements and refining the procurement process make a provision for the management to focus on the stakeholders’ engagement. In the modern business environment, traditional techniques are perceived as time-consuming, expensive, and harbor major drawbacks. The key priority of planning within this department in ADNOC is to audit and improve the communication with the bidders. In some cases, the purchase of materials for engineers on different sites can be tedious, and the strategy to acquire quality products renders it important to involve the major stakeholders before making decisions. Moreover, the contact between the buyer and seller makes provision for a full trial that enhances accountability throughout this process (Walker & Brammer, 2009). It is important to ensure that all vital roles within the supply chain are met.

Collaboration with Stakeholders

To ensure that a virtuous cycle operates effectively, there is a need to guarantee the continuity of efficient communication throughout the procurement processes. ADNOC uses common tools that permit the company to all other interested parties when they are required. Consequently, the application of collaborative solutions gives the stakeholders access to definitive information about the institution. It is important to bring a combination of supply-side and buyer-side parties at all stages of the procedures (Goodwin, Harris, Nelson, Roach, & Torres, 2013). By promoting this, the organization has better chances of acquiring quality equipment that encompasses innovation and the right specification. For instance, organized meetings between end-users and suppliers in the chosen company have shown an interesting result with regards to the timely delivery. Indeed, as suppliers are able to understand the full requirements from our end users, the time required to procure the products or services is lower as well as better matching the needs and requirements.

Collaboration is an effective tool that builds a stronger, transparent affiliation between the company and its partner (Mumford, 2012). It is a critical benefit for the delivery of quality products for efficient operations in the organization.

Collaboration is perceived as the preferred method of driving greater value through sourcing. The investments in ADNOC ensure that it fosters both internal and external involvement of the stakeholders as a game-changer in the procurement department. Moreover, specific features such as automated centralization, workflows, and functions need to be established for the purpose of enhancing compliance, enterprise performance, and risk mitigation (Forgues & Koskela, 2009). Engagement with stakeholders can improve the delivery of services and achievements of the goals. Consequently, the development of a proper guide of the procurement process renders it easier to communicate to the relevant parties. Besides, it is important for the management to define the engagement objectives to enhance accountability.

The process makes provision for selecting the best method to involve the players and influential stakeholders to interact. Similarly, the organization can have a strategy to develop metrics of its success by ensuring that the efforts are focused on the important issues affecting the procurement process (Mumford, 2012).

Organizational Policies and Procedures

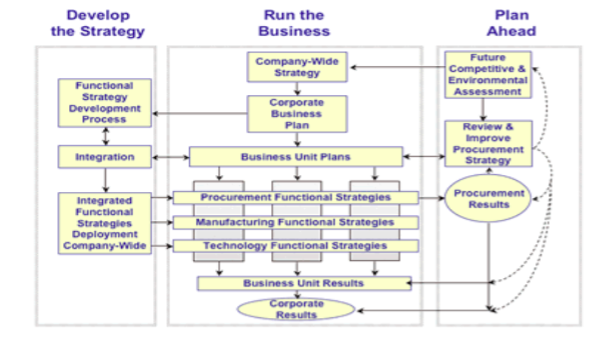

In the modern business environment, it is critical to reducing the costs of procuring equipment and enhancing the results despite the challenges faced by a company. Consequently, there is the need to establish a governed supply chain (Ponte, 2009). Acquiring better services from a team of experts leads to the improvement of commitment and endorsement of leadership within an organization. Moreover, the alignment of the staff maximizes the effectiveness and develops a commensurate benefit to the institution (Monczka, Handfield, Giunipero, & Patterson, 2015). The adoption of a hybrid approach allows a combination of strategic plans and decentralized execution of enhancing the services. See detailed information in Figure 4 below.

Setting the conditions for the procurement process is one way to enhance accountability and reliability in ADNOC. Moreover, it is the responsibility of the team members to commit their effort in ensuring quality that determines reliability. Enhancement of confidentiality is a major aspect of promoting transparency. Besides, adhering to the company’s values is vital in achieving the goals of this department (Arnaboldi, Azzone, & Giorgino, 2015). Similarly, it is a way to enhance safety for the staff operating the equipment. The success of ADNOC relies on both internal (engineers) and external stakeholders (Government of the UAE and other governments) (Amina, Baazaoui, & Abdellatif, 2015).

Demand and Supply Factors Affecting Procurement

The purchase of drilling and production chemicals, gaskets, valves, and safety equipment for engineers on the different sites in the oil and gas industry is a sensitive task to undertake. The demand for the equipment within the organization is high since they are used to run everyday operations. Moreover, by viewing the procurement system, decisions must be made to award the supply tenders to the appropriate contractors. Equipment remains critical in the drilling process of ADNOC, and the procurement department must ensure its existence. On the other hand, oil and gas companies require a large amount of capital that renders the industry more restricted. For this reason, institutions dealing with the necessary tools are fewer, and this aspect lowers their availability. Such elements in the market make the systems expensive to purchase (Daniel et al., 2010). Therefore, it is important to have a strategic plan for acquiring the products by ensuring that quality goods are delivered to the company.

The current pricing mechanisms render it effective for the industry to control the cost of drilling equipment. Nonetheless, a careful examination of all the products and services needs to be done for the purpose of establishing a standardized value. Moreover, the risk can be undertaken by experts within the procurement department. By regulating demand for the tools, prices can be lowered to a suitable level where the cost of production is minimized. Similarly, the strategy can be used for improving their quality.

Conclusion

Driving value through the procurement process ensures that deployed procedures are effective in delivering quality products within the company. Moreover, purchased techniques and tools enhance competitiveness in the market. The challenges involved include both external and internal changes that render it hard for the organization to drive the costs down. The company’s performance in the oil and gas industry can be examined through the help of a competitive benchmark. Besides, properly implemented and planned programs in the sourcing procedures enhance the effectiveness of the business and the quality of products and services. Furthermore, this route of attaining advantage by pioneering procurement is important for institutions in this industry bearing in mind that the equipment is expensive. Commercializing and developing new ideas is achieved through strategic decisions within this department. To be clear, the process within ADNOC is critical in ensuring cost reduction and profit maximization. The application of leadership qualities in managing the department makes provision for improving the effectiveness of the institution. So, procurement is a key step in the value chain for quality assurance and competitiveness. The margin generated is the difference between the value given to the product or service and the costs associated with its creation until its commercialization.

References

Amina, R., Baazaoui, A., & Abdellatif, T. (2015). The influence of internal marketing on the behavior of the expatriate employee and on the determination of the external customer satisfaction. Humanistic Management Network, 21(15), 1-20.

Arnaboldi, M., Azzone, G., & Giorgino, M. (2015). Performance measurement and management for engineers. New York, NY: Elsevier.

Chima, C. M. (2011). Supply-chain management issues in the oil and gas industry. Journal of Business & Economics Research (JBER), 5(6), 27-36.

Daniel, P., Keen, M., & McPherson, C. (2010). The taxation of petroleum and minerals. New York, NY: Routledge.

Forgues, D., & Koskela, L. (2009). The influence of a collaborative procurement approach using integrated design in construction on project team performance. International Journal of Managing Projects in Business, 2(3), 370-385.

Frazier, D. (2014). A survival guide for government contractors. Raleigh, NC: Lulu Publishing.

Goodwin, N., Harris, J. M., Nelson, J. A., Roach, B., & Torres, M. (2013). Microeconomics in context. New York, NY: Routledge.

Monczka, R. M., Handfield, R. B., Giunipero, L. C., & Patterson, J. L. (2015). Purchasing and Supply Chain Management. New York, NY: Cengage Learning.

Mumford, M. D. (2012). Handbook of organizational creativity. San Diego, CA: Elsevier.

Ponte, S. (2009). Governing through quality: conventions and supply relations in the value chain for South African wine. Sociologia Ruralis, 49(3), 236-257.

Ross, D. F. (2011). Introduction to supply chain management technologies. Boca Raton, FL: CPR Press.

Srivastava, R. M., & Verma, S. (2012). Strategic management: Concepts, Skills, and Processes. New Delhi: PHI Learning.

Walker, H., & Brammer, S. (2009). Sustainable procurement in the United Kingdom public sector. Supply Chain Management: An International Journal, 14(2), 128-137.