Definition

A hydraulic pump is a pressure dependent device that is designed and built to drive fluids (particularly liquids) in open-loop hydraulic-driven systems or to re-pressurize fluids through a driven motor in a closed-loop, and delivers power mechanically to machinery through the pump’s rotation. There are several types and a majority of them are adjustable in order to regulate the amount of pressure delivered by the pump – few are not; depending on whether the pumps are hydrostatic or hydrodynamic. The pumps are built to varying specified parameters in accordance with engineering or industrial usage.

Several hydraulic pumps have been known to be of use to primordial Greeks, Romans, and the Chinese – by the 9th century, the interest of Islamic inventors s in the usage of hydraulic pumps brought in a lot of innovation for compactable, functional, efficient, and more productive hydraulic pumps when Al Khzini, and other reformed the devices.

Characteristics of Hydraulic Pumps

Hydraulic pumps are characterized by pump volumetric efficiencies, pump-horsepower, as well as the general efficiency. The following formulae are applicable in determining same in piston used pumps:

- Volumetric output of fluid = area of piston X RPM X piston stroke X number of pistons

- Theoretical output =area x piston stroke X number of pistons

Cycle:

- Volumetric efficiency % = Actual volumetric output x 100

Theoretical Output:

- Pump horsepower = Pressure X rate of Flow X 0.000583

Efficiency:

- Overall efficiency = Volumetric efficiency X Mechanical efficiency

Types of Hydraulic Pumps

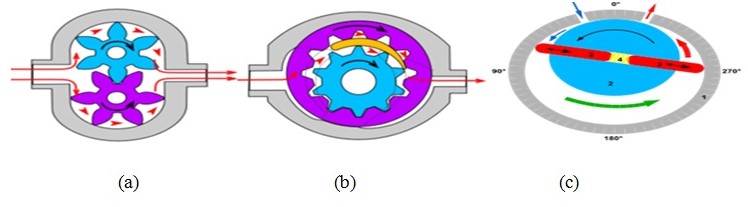

Figure 1 presents a number of commonly found hydraulic pumps.

Gear Pumps

These types of pumps could either be of the type with external teeth or could possess internal teeth; the earlier is in a very simplified structure and offers high economy to usage. For external teeth, the swept-volume is within the ranges of a cm3 and 200cm3 creating a mesh of its gear-teeth that exacts a pressure on fluids through the outlets. A number of these are really very noisy during operations- although recently developed ones are very reliable and operate with reduced noise.

Rotary Vane Pumps

These constitute fixed and simplified adjustable pumps with a comparable higher efficiency than gear-pumps- except their usage is confined to mid-pressure that is limited to 180 bars, generally. Certain vane pumps are capable of changing the vane-body’s center resulting to the ability to adjust the pumps. The vanes usually offer constant-pressure or constant-power.

Screw Pumps

These are fixed displacement in nature and have replicated Archimedes screws, and are closed. Otherwise, the body has two screws fitted to it. Screw pumps are made use of at instances whereby increased flow and a reduced pressure of not more than a hundred bars are needed. The pumps are of great use on ship-boards in maintaining the pressure of hydraulic-systems. The reduction in noise during operation of a screw pump constitutes one of the most pronounced merits about it, though they are not quite efficient.

Gerotor Pumps

Gerotor pumps refer to the group of internal gear pumps with no crescent. These constructions are applied for low-pressure purposes in lubrication or oil filtration system; they can also be used for hydraulic operations with moderate pressures. The major advantages of gerotor pumps consist in high speed, two-direction operation, and presence of only two moving parts and one stuffing box.

Radial Piston Pumps

Radial piston pumps work in radial direction around the drive shaft. Each piston motion is initiated by a drive shaft or external tappet. It is distinguished by high pressure and high efficacy, reliability and low noise level. The pump can be used for machine tools, test rigs, high-pressure units, automatic transmission, and for generating wind energy. All these applications entail that the pump is used for a wide range of purposes.

Peristaltic Pumps

Peristaltic pumps refer to positive replacement pumps that are applied for pumping a great number of fluids. The most common applications involve pumping fluids through aggressive chemicals, infusion devices and other substances where isolation from the outer environment is critical. The major advantage of the pump lies in producing no contamination because the inside surface do not interact the eternal fluids.

Other commonly found pumps include bent axis pumps axial-piston pumps radial-piston pumps peristaltic pumps, and others. All hydraulic pumps must be kept free of contaminations throughout the flow path for them to function very efficiently. In whole, each type of pump has its benefits and drawback with regard to the purposes and applications. Therefore, my task is to distinguish clearly between those and know which kind will suit a particular construction project. In addition, it is also necessary to know different types of fluid that may be engaged into the process of energy generation and which one are the most effect and the leas expensive.

Major Emphasis

Throughout the history, people have been striving to construct effective hydraulic system for obtaining energy and for creating a regular cycle at the manufactures. Over the three past decades, the operating and performance of hydraulic equipment have been advanced significantly which influence the operating costs and level of services. In this respect, I want to enter this sphere to optimize the work of hydraulic equipment and minimize the expenditures. I admit that the process in the sphere of energy management is, indeed, challenging, but this is the future of our planet whose resources are not endless. More importantly, because water is one of the most abundant resources on Earth, there will be a great problem to introduce a new model of perpetual motion machine that will work with the help of water.

While learning more about hydraulic pumps, I have realized that this science is quite complicated and challenging to conceive. At the same time, it provides a wide range of professional perspective for me to choose. Beside the actual penetration to the construction process, I also more interested into being engaged with specific construction management projects to oversee the phases of accomplishment, coordinate all design processes, and participate in the conceptual development of the project. The occupation also involves the communication and interaction with architects, engineers, and owners that can provide me with valuable experience. In whole, this multi-facet occupation is really exciting and engaging because it will allow to advance my knowledge about hydraulic pumps construction and find out new trends and tendencies of project management development in this sphere. More importantly, this knowledge can be used in future for modernizing and improving the current hydraulic systems.

Works Cited

Akers, Avena R, et al. Hydraulic Power System Analysis. New York: Taylor & Francis, 2006. Print.