Introduction

Supply chains in the agri-food sector are highly complex systems involving a large number of stakeholders. Such complexity contributes to the emergence of issues and barriers. The following technical report provides an overview of two major issues of the meat supply chain and outlines the opportunities for improvement in the identified areas.

Supply Chain Description

When viewed against similar systems in the agri-food industry, the meat supply chain can be considered a relatively complex entity. The first major reason for this is the involvement of strict quality standards because meat as a product is inherently more prone to processes that may compromise its quality (Bedard 2017). The second aspect is the reliance on animals as a source of meat, which raises several ethical concerns, leading in some cases to major scandals in the media.

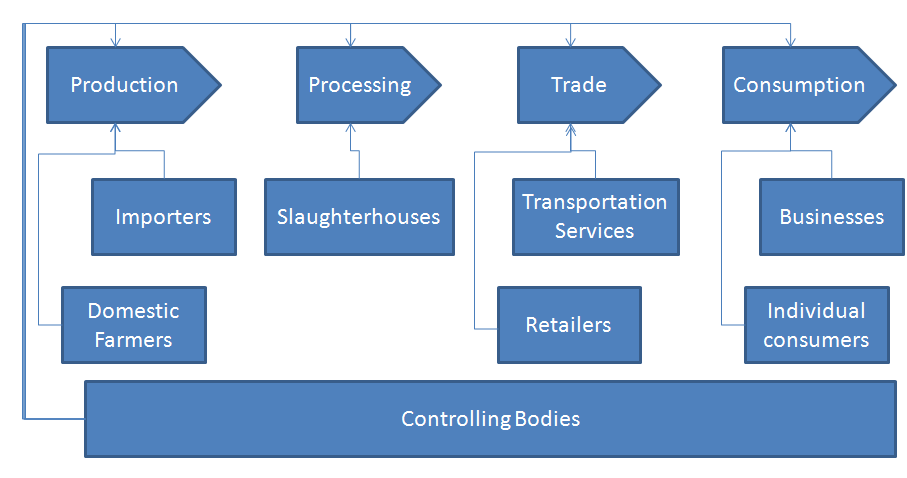

In the most basic terms, the meat supply chain can be divided into four major phases. The first phase is the production. At this stage, cattle are being grown on farms. The majority of meat is grown in industrial feedlots, with insignificant amounts being contributed by private ranches that use free-roaming feeding processes. Only a small proportion of cattle is grown domestically, with the bulk of meat being imported from China, Argentina, and Brazil (Rousseau 2016).

The second phase is processing, during which the cattle get slaughtered, and the meat undergoes various processing procedures preparing it for sales and consumption. Meatpacking is performed in slaughterhouses, also referred to as meatpacking plants. After the meat is packed, it is transported to distributors and retailers, at which point the trade phase is initiated. Depending on the scale of operations, a varying number of distributors participate in the procedure.

From the retailers’ perspective, this phase also involves marketing and transportation. Finally, during the fourth phase, consumption, meat is bought by the consumers, either for home use or in the restaurant. Importantly, the first three phases involve quality control. However, due to the comprehensive nature of controlling efforts, this aspect of the supply chain is not confined to a single phase.

Existing Issues

Quality Control

Due to the complexity of the described process and the involvement of numerous parties, the meat supply chain harbors several issues. The most apparent one is the existence of gaps in the quality control process. In its current form, controlling entities act in separation and have limited control over some of the elements of the supply chain (Pucar 2014). Also, some phrases contain more elements where the safety and quality of the product can be compromised.

For instance, during the production phase, the livestock can be infected with pathogens that render their meat unsuitable for human consumption. To minimize this risk, it is necessary to conduct regular checks by qualified professionals. While these checks are currently considered a standard in the industry, evidence exists that at least in some cases they are performed with insufficient diligence (Wasley 2018). Another important aspect of quality control during production is the feeding process oversight. The food provided to animals is expected to be consistent with the nutritional requirements of the livestock.

These requirements may differ depending on the breed of the animals and their intended purpose. These variables can be overlooked or omitted by irresponsible controlling entities (Shams 2014). At this point, it is worth mentioning that for some types of livestock, such as cattle, the phase is further fragmented as a result of the differentiation between breeding and rearing, or fattening. The latter phase is initiated to prepare animals for the processing phase by moving them to fatten farms. Understandably, the conditions on the breeding and fattening farms differ considerably, which requires the adjustment of the controlling procedure. Such fragmentation further complicates the audit and documentation process.

Finally, it is necessary to recognize the recent increase in attention to ethical considerations in the industry. In recent years, the recognition of the issue of animal welfare has reached global status, with a significant proportion of the consumers displaying awareness on the conditions of breeding (Smithers 2018). Consequently, the new criterion of “cruelty-free” meat was introduced to the market, which identifies a sufficient degree of welfare maintained by the producers. As a result, animal welfare has been included in the list of categories under inspection, further complicating the process.

Once the livestock arrives at a slaughterhouse, the available documentation is verified by the facility staff in collaboration with the inspectors. The processing and packaging of meat are overseen to ensure compliance with sanitary norms. Nevertheless, some of the aspects of the meatpacking process, such as restraint and stunning procedures, can remain outside the scope of the assessment, which introduces the risk of product contamination or other violations through negligence or deliberate fraud (Processing Staff 2013). Also, the assessment of meat quality and quantity can be performed by unqualified personnel, which, in some cases, may produce inconsistent results. For example, the verification of cattle carcasses, which is commonly done by eye, harbors a significant margin of error for an unqualified specialist.

As is apparent from the information above, the quality control procedures within the industry are numerous and fragmented. Also, they are often performed by separate third parties, which complicates the documentation-related procedures. Finally, several gaps exist that are actively exploited by dishonest stakeholders. In some cases, these gaps conceal unintentional flaws and errors. However, at least in some cases, they are taken advantage of by dishonest producers for obtaining cheap meat through livestock theft, illegal and undocumented slaughter, and misdescription of animals used for meat production. To minimize the identified risks, it is necessary to develop a consistent assessment procedure. The procedure should involve surveillance, audit, and certification aspects, preferably with one of the recognized quality management systems as its basis.

Operational Aspects

The second major issue pertinent to the meat supply chain is the operational aspects of its functioning. As was noted in the previous section, the involvement of a large number of stakeholders creates barriers to the efficiency of interactions within the system. The lack of transparency and accountability requirements combined with poor interoperability of the data used in the process makes consistent monitoring of meat nearly impossible.

Essentially, retailers do not have the means of ascertaining the quality of the products offered to consumers or verifying the underlying processes responsible for the validity of the producers’ claims. For instance, as was demonstrated in the recent incident known as the 2 Sisters case, it is trivial for a large-scale producer of meat to modify the expiration dates of its products and thus sell the potentially harmful product to consumers.

Importantly, such a practice does not require the retailer’s involvement it is extremely difficult for the latter to identify the dishonest practice due to the absence of monitoring means. At this point, it should be mentioned that the desired monitoring procedure is not impossible. Some retailers, such as Walmart, have developed systems intended to trace the life cycle of shipped foods, including meats, back to their point of origin (Jing 2017).

With this system, it becomes possible to verify some of the information related to product quality and consistency of practices behind it. Nevertheless, in their current state, these systems are inefficient, as it may take up to a week to run the full verification process. In at least some cases, such speed would be insufficient since, by the time of its completion, the product would already be received. More importantly, the system in question is designed to be used by the retailer, which means that the findings will not necessarily be available to the end consumer. In other words, the system can only partially resolve the issue of insufficient transparency, and the time constraints limit its use to a relatively narrow number of cases.

As can be seen, the identified issue has a detrimental impact on several stakeholders in the supply chain. In addition to the apparent harm to consumers of food of questionable quality, the unfair practices are damaging for the reputation of other stakeholders, most notably the retailers, who may be perceived responsible without their actual involvement while at the same time incur losses as a result of product recalls. The same can be said about the controlling entities, whose reputation depends on the ability to detect inconsistencies and report them to the end-user. Thus, the current state of the operational side of the meat supply chain harbors an opportunity for improvement.

Several solutions have been put forward to address the described situation. Currently, the most viable of the suggested approaches is the implementation of a tracking mechanism based on Blockchain technology. The proposed system has a major advantage in terms of speed of execution, requiring several seconds to complete a request (Safaryan 2017). At the same time, the solution increases the accountability of actions by introducing an immutable and transparent ledger of operations.

By logging each of the transactions associated with the product throughout its life cycle, it becomes possible to establish its current location through a single request, removing the limitation of a lengthy and infrequently updated procedure. The technology permits creating a traceable imprint of the totality of transactions underwent by each batch of meat. The imprint can be represented in the form of a unique line of symbols and converted into a consumer-friendly format such as a QR-code (Gelsky 2018). Thus, it will be possible for any interested party to perform a verification procedure using a simple scanner and access to the database.

The database in question can be made fully or partially available for public access while at the same time preserving the sensitive information related to the commercial activities of the involved intermediaries. The database can also be adjusted to include any information considered relevant for the purpose, including breeding conditions, feeding practices, location of vendors involved in meat processing and transportation, their track record in terms of compliance with rules and regulations, and other relevant data. The information can be accumulated as the log is modified at each subsequent phase. Once the technology is adopted by all main participants, it can also contribute to the seamless nature of operations without introducing the possibility of dishonesty.

It is also worth mentioning that the proposed solution has the potential of addressing the interoperability aspect of the issue. The automated nature of the Blockchain-based systems allows for converting data between different formats or using a universal protocol across several systems. Finally, and, perhaps, most importantly, it provides the consumers with direct access to the information. While not intended as a primary goal of the innovation in question, this aspect of the solution makes it more attractive both for the end-users and the controlling entities and policymakers The former will obtain the opportunity of verifying the important consumer information whereas the latter will benefit from additional transparency and compliance with requirements.

Conclusion

Supply chains in the agri-food segment tend to include a large number of diverse stakeholders and, as a result, are noticeably more complex compared to the majority of industries. Importantly such complexity creates numerous barriers to maintaining sound business practices. First, the supply chain is prone to the introduction of unsafe practices through negligence. Second, it allows certain dishonest stakeholders to resort to fraud. In most cases, insufficient transparency and accountability do not allow real-time monitoring without significant time and resource allocation. Thus, quality control in the segment is of limited availability and utility.

Nevertheless, several opportunities for improvement can be identified within the system. First, it is possible to address the situation of fragmented and piecemeal quality control by developing an encompassing evaluation and audit framework. Such a framework would incorporate the principles of accepted quality management systems and cover the majority of known gaps. Simultaneously, the operational aspect of the supply chain can be addressed by taking advantage of the Blockchain technology. In this way, it would be possible to achieve the desired level of transparency and accountability while at the same time improve and streamline its components.

Reference List

Bedard, M 2017, 7 Stages of quality control checks for meat and poultry. Web.

Gelsky, J 2018, Future of blockchain technology. Web.

Jing, M 2017, ‘Here’s a peek at Wal-Mart’s game-changing plan to trace food from China’s farms to store shelves’, South China Morning Post. Web.

Processing Staff 2013, Major food safety violations discovered at Mississippi meat processing plants. Web.

Pucar, S 2014, Where are we now and where should we go? Gap analysis of food sector. Web.

Rousseau, O 2016, Beef imports rise as China’s growth cools. Web.

Safaryan, A 2017, Food you trust: how blockchain will reinvent the supply chain. Web.

Shams, S 2014, Meat scandal highlights China’s negligence. Web.

Smithers, R 2018, ‘Animal welfare groups call for higher standards for farmed chickens’, The Guardian. Web.

Wasley, A 2018, ‘Dirty meat: Shocking hygiene failings discovered in US pig and chicken plants’, The Guardian. Web.