Literature on the spoiled dates biomass in Saudi Arabia

Saudi Arabia is the home of the Phoenix dactylifera plant. According to Al-Abdoulhadi et al. (2011), “Saudi Arabia has about 23 million palm trees, which produce about 780 thousand tons of dates per year” (Al-Abdoulhadi et al. 2011). Every year, tons of biomass waste from date palm is generated in the procedure of date palm fruit processing.

The date seeds accounts for almost a third of the weight of the dates. These seeds are never used during the date palm processing hence, forming part of the spoiled date biomass. Thus, the date seeds can be exploited and processed to produce energy or be part of the numerous value addition elements in chemical products. Little has been done to optimally utilize the spoiled dates and the seeds to produce biomass energy. Despite the fact that Madison et al. (2004) succeeded in “producing bio-oil and activated carbon from date palm seeds in a fixed bed reactor using pyrolysis technique” (Madison et al. 2004), there has never been a commercialised venture to exploit this potential form of energy in Saudi Arabia.

Processing bio-refinery to get a bio-fuel from the spoiled date biomass

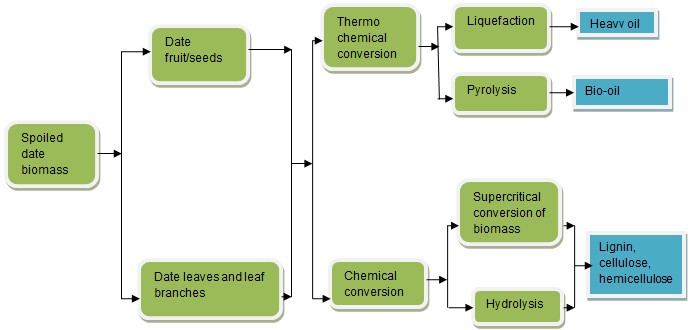

In order to understand the potential of the spoiled dates in energy production, it is necessary to review the types of date seeds to determine their chemical composition. Bridgwater (2012) and Briones et al. (2011) found it that it is possible to produce the active polyol through chemical modification of the date seeds via a simultaneous liquefaction and oxypropylation processes. These processes involve incorporation of compatible organic agents such as carbon dioxide. After the incorporation of an organic agent, the process is further subjected to a thermo-chemical to rejuvenate the spoiled date biomass into energy.

Upon obtaining the spoiled date biomass, the wastes are passed through distilled water to wash the dirt before being dried evenly at room temperature. This is followed by crushing and grinding the spoiled date seeds and fruits to obtain a powdered form the raw material for production of energy (Grammelis et al. 2009). In the initial step of cleaning other parts of the spoiled date such as the leaf stem and leaves, they are washed in distilled water, dried and shredded. This step is followed by breaking down the biomass material through hydrolysis (Cai & Chen 2012).

After completely breaking down the biomass into simple sugars, fermentation process follows to produce series of bio-fuels. In order to make the bio-fuels pure, the final product is passed through a dehydration cylinder to free it from excess water. The bio-fuels produced from spoiled date biomass have prospective future, because these fuels are carbon-neutral with all the CO2 discharged through use of the fuel (Demirbas 2004). This is summarised in flow chart below.

Since most of the manufacturing companies now heavily relied on the bio-ethanol and other bio-fuel considering their responsibility to save the environment from adverse impact of carbon emission, this type of energy forms part of the green energy to ensure sustainability (Fisher et al. 2002).

Conclusion

Conclusively, it is apparent that the spoiled date biomass materials have similar combustion and pyrolysis traits. Besides, the spoiled date biomass has relatively low explosive matter and high content of moisture. This makes the biomass from spoiled dates ideal for a simultaneous thermo-chemical process in energy production. When reacted at an ideal temperature, the biomass from spoiled date can be transformed into different forms of bio-fuel.

References

Al-Abdoulhadi, I.A., Dinar, H.A., Ebert, G., & Buttner, C. (2011). Effect of salinity on leaf growth, leaf injury and biomass production in date palm cultivators. Indian J.Sci. Technol, 4 (11), 1542– 1546

Bridgwater, A.V. (2012). Review of fast pyrolysis of biomass and product upgrading. Biomass Bioenergy, 38, 68–94.

Briones, R., Serrano, L., Younes, R. B., Mondragon, I., & Labidi, J. (2011). Polyol production by chemical modification of date seeds. Ind. Crop. Prod, 34 (1), 1035–1040.

Cai, J., & Chen, Y. (2012). Iterative linear integral isoconversional method: Theory and application. Bioresour. Technol, 103 (1), 309–312.

Demirbas, A. (2004). Combustion characteristics of different biomass fuels. Prog.Energy Combust, 30, 219–230.

Fisher, T., Hajaligol, M., Waymack, B., & Kellogg, D. (2002). Pyrolysis behavior and kinetics of biomass derived materials. J. Anal. Appl. Pyrol, 62, 331–349.

Grammelis, P., Basinas, P., Malliopoulou, A., & Sakellaropoulos, G. (2009). Pyrolysis kinetics and combustion characteristics of waste recovered fuels. Fuel, 88 (1), 195–205.

Madison, W. I., Besbes, S., Blecker, C., Deroanne, C., Drira, N. E., & Attia, H. (2004). Date seeds: chemical composition and characteristic profiles of the lipid fraction. Food Chem, 84 (4), 577–584.