When a piece of conductive metal is under strenuous force, it broadens and decreases in length. If the stresses stay within the elastic limit, then such strip can work as a gauge for measuring physical force. Strain gauge measures stresses from machinery e.g. in aircraft parts (Irwin and Robert 20).

Bonded wire strain gauge is the most common usually less than one inch long in measurement. Engineers use bonded wire strain gauge to show the measurement of changes that have taken place on large surfaces. Bonded wire strain gauge consists of a bendable features and a strain gauge that joins the bendable parts. If the bendable part moves, then the strain gauge changes resistance.

Bonded wire strain gauge typically has codes which consist of a contact point for the lever arm. Any movement in the lever arm results into contact with the point of contact. The resulting contact creates a complete electrical circuit. This generates signals. Conversely, if the lever arm leaves the contact point, then electrical circuit breaks and generation of signals stops.

Types

Bonded wire strain gauges exist in three forms, namely, metal foil, fine wire, and semi-conductor gauge. These gauges rely on direct pasting or bonding on the surface of object under measurement. An application of stress on the bonded strain gauge causes the electric resistance to change end-to-end (Hibbeler 120).

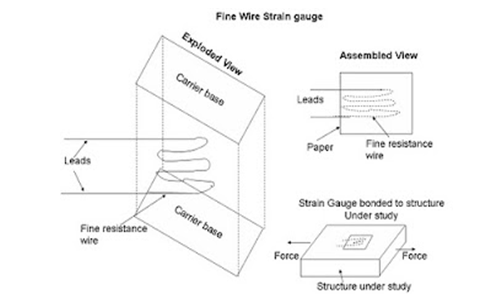

Fine wire strain gauge has a thin bended wire of 0.025 mm diameter. The wire ensures an equal distribution of stress. The wire is usually between two carrier bases connected to each other.

They protect the gauge from any possible damages. It mainly consists of nichrome at 80%, constantan of 45%, nickel, platinum, and isoelastic of 36%. Fine wire strain gauge has a high accuracy, a range of positive or negative 0.3 percent of strain, and a linearity of positive or negative one percent.

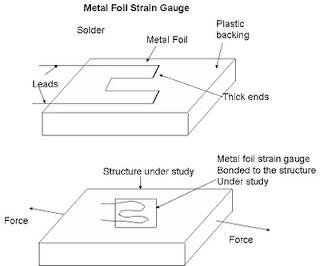

Engineers use printed circuit method to produce metal foil strain gauge. Lead electrically joins the strain gauge to an instrument of measurement which is a wheat stone bridge. The advantages of a metal foil is that its shape is flexible, produces a perfect bonding, stands pressure for a long time, and is sensitive even under the extreme high temperatures.

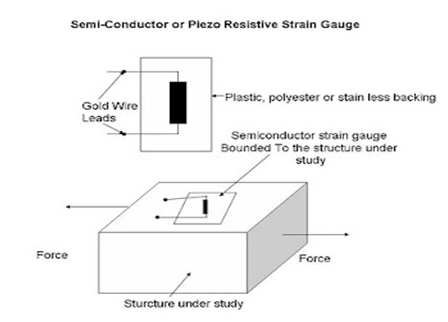

Semi-conductor strain gauge takes the form a wafer from geranium or silicon crystals. Additional of boron creates preferred properties in a process known as doping that produces a doped crystal. This is the sensor which lies on stainless steel or plastic backing. Gold-coated lead electrically connects sensing materials with the strain gauge for measuring objects.

This model has both negative and positive sensing element with reference to tensile strain. It measures extremely small strains, and their sizes can also be extremely small. It has a higher accuracy of 2.3 percent, high frequency of giving results and a longer life with perfect hysteresis properties.

Problem

Bonded wire strain gauge cannot be “detached and used again because of the bond” (Irwin and Robert 25). Likewise, point of contact and the lever usually wear off, which produce poor electrical signals resulting into erroneous interpretation of signal, thus, gives garble the results.

The system is also mechanically complex consisting of moveable parts of balls or needle bearing, which are expensive and difficult to manufacture. Some gauges are brittle and cannot withstand large strains. There are also others with poor linearity, as others are sensitive to extremely high temperatures.

Works Cited

Hibbeler, Russell C. Mechanics of Materials, 8th ed. New Jersey: Prentice Hall, 2010. Print.

Irwin, J. David and Robert M. Nelms. Basic Engineering Circuit Analysis. New York: John Wiley, 2004. Print.