Definitions and overview

Project management as a practice today draws a lot of attention based on the benefits that accrue from its successful application. As business processes keep changing there is a need for a defined process to initiate, plan, execute and monitor these processes (Schwalke 2005; Nicholas 2000). This discipline normally presents itself through project management.

During project management all the activities should be within the project constraints which include time, cost and quality and project management help organizations to achieve this and hence ensure the success of their projects.

Project management requirements are significant and planned by a well-defined team which has the technical capacity to work within the defined discipline. However when these disciplines are not clearly followed the project is likely to slip or all together fail resulting in loss of money and a dented reputation.

This paper elaborates a project management process involving the development of a touch screen customer order processing system. The project should be developed in three phases to plan, develop and manage the installation of a touch screen customer ordering system in each of the company’s retail outlets.

The proposed product must be shown to be user-friendly and sufficiently robust to withstand end user abuse without failure, it is intended that this touch screen system will require minimal assistance by the retail stores sales staff. To this end the sales model used by Argos stores is cited as a successful and appropriate for the range of goods sold by Benhams.

Benhams is Britain’s second-biggest department store chain selling garments, it trades from 160 stores in Britain, Ireland and Denmark, reported an 18.6% increase in profit before tax to £123.6m, however this retail business only ranks a fourth place in the UK’s top retail clothing stores.

Benhams Board of Directors, after reading a recent market research report which indicated that many buyers found their size of clothing was waiting to be restocked; in this situation the customer visited a rival retail store to purchase a similar garment.

The sales department basing on the directive by Benhams chief executive produced a project brief on behalf of the Board of Directors which was subsequently passed to the project team to evaluate the viability of such a proposal, and if approval by the board, proceed with the installation of this product ordering system in each of the UK stores.

The stages in this product development are

Undertake market research to estimate market demand, then to determine the total cost of the project including all of the installation work to our retail outlets in the UK, and plan if this proposed work can be completed in time for August 2013 sales.

Set up a singular mock prototype ordering system to be tested out at the retail store by staff and selected shoppers, a feedback facility is to be incorporated into the prototype which will report the success rate of this new shopping method.

It is expected the prototype web based ordering system will be successful, and further funding will be release to implement this new customer ordering system on a trial basis at two of the companies’ retail outlets. A target date for these two new ordering systems to be complete and in use is before the summer of 2013. Funding for the project will be available from September 2011. To support this work the board will release development funding for the project installation work and project management costs.

Purpose

The purpose of the project is to provide a web-based interface for the customer order processing system to enable them to place orders while allowing the management at Benhams Company to monitor the process and keep a record of the same.

Objectives of the project

The objectives of the project will include the following:

- To improve Benhams managers’ monitoring process and improve decision-making.

- To centrally avail Benhams clients’ data and information to facilitate effective order processing thereby meeting the deadlines.

- To provide the client with a state of the art method of placing orders online.

Scope

The scope of this project will cover the head office and a number of the company’s branches dispersed across the nation. It will also incorporate external stakeholders who will have a portal into the intranet.

Undertaken will be a market research to estimate market demand, then to determine the total cost of the project including all of the installation work to our retail outlets in the UK, and advise/plan if this proposed work can be completed in time for August 2012 sales.

Eventually a singular mock prototype ordering system will be set up to be tested out at the retail store by staff and selected shoppers, a feedback facility is to be incorporated into the prototype which will report the success rate of this new shopping method.

It is expected the prototype web based ordering system will be successful, and further funding will be released to implement this new customer ordering system on a trial basis at two of the companies’ retail outlets. A target date for these two new ordering systems to be complete and in use is before the summer of 2012.

Project funding commences in September 2011. To support this work the board will release development funding for the project installation work and project management costs.

Constraints

The following are the likely constraints of this project:

- Lack of technical manpower to develop and optimize the web application

- Inadequate financial resources

Assumptions

The following are some assumptions for the project:

- That the funds allocated for this project a total of £ 233155.725 will be enough

- That the project will proceed and complete as scheduled with the team working 7 days a week

Project planning and documentation

Project management has a defined framework identified by a number of constraints. This covers the cost of the project, time it will take, quality and scope (Duncan 1996; Maylor 2010).

Project planning therefore involves the process of managing each of these constraints in a disciplined fashion to ensure that the process meets and exceeds the stakeholders’ expectations. A project management plan must therefore address pertinent management aspects related to scope, integration, communication, risk, time, cost, procurement and change.

Project integration management

This process describes all the processes required in ensuring that all project elements are well coordinated. This process has an aim of meeting stakeholder expectations. This process considers inputs such as organization’s policy. This can be subjected to various tools and techniques such as the project management information system (PMIS) to produce a project plan.

Project scope management

This covers all the processes that are necessary for the successful completion of a project. During this process, a written scope statement is developed and becomes the reference for future project decisions. The strategic plan of the organization can be the input in this case. Historical information may also be considered at this point. Relying on expert judgment a project charter would be one of the outputs from this process.

Project time management

This covers the activities that ensure timely project completion. This process relies on the work break down structure (WBS) (See appendix) which is then decomposed to output the activity list and work break down structure updates.

Project cost management

This covers the processes needed to guarantee that the project’s completion is within a definite budget. Among the inputs to this process are the work break down structure (WBS) and the scope statement. These inputs are subjected to expertise judgment to give the resource requirements in the form of a budget (See appendix).

Project quality management

This covers the activities ensuring that the project meets its need. These activities are intended to uphold the quality policy throughout the whole project. Quality policy and the scope statement may be part of the inputs into the process. Flowcharting and the cost benefit analysis are some of the techniques and tools used within this process to develop a quality management plan as the output (Duncan 1996).

Project risk management

This process covers the identification, analysis and response of project risk occurrences. This process involves optimizing the positive event effects while reducing the effects of the adverse events (Maylor 2010). One typical input within this process is the product description. The tools and techniques in use within this process include checklists, interviewing and flowcharting. This process identifies the risk sources, plan (See appendix) events and symptoms as output.

Project procurement management

This involves the activities supporting goods and services acquisition. The scope statement and product description acts as a part of the input to the process. Contract type selection is then carried out to give a procurement management plan.

Project communications management

This are the activities that generate, store and disseminate information related to a project. The inputs for this process are like the communications requirements which undergo a stakeholder analysis giving rise to a communications management plan.

Project human resource management

This involves all the activities that make optimal use of the people resources within the project. This covers all the project’s stakeholders. The inputs during this process include the project’s interface. The tools and techniques used here will include stakeholders’ analysis (See appendix), templates and a human resource practices which can be used to develop a staff management plan or an organizational chart.

Schedule control

This process involves the following activities:

- Adjusting schedule related factors to bring beneficial change

- Ensuring a change of schedule.

- Manage the schedule change when it occurs.

One of the main inputs to the schedule control process is the project schedule. The work break down structure for this project will suffice as an input for this process.

While the project progress performance reports and change requests can also be incorporated as input into the schedule control process, tracking and feedback system must be in place to synthesize the inputs (Marchewka 2009). While assessing the performance measurement it will be vital to note the schedule variations requiring corrective action.

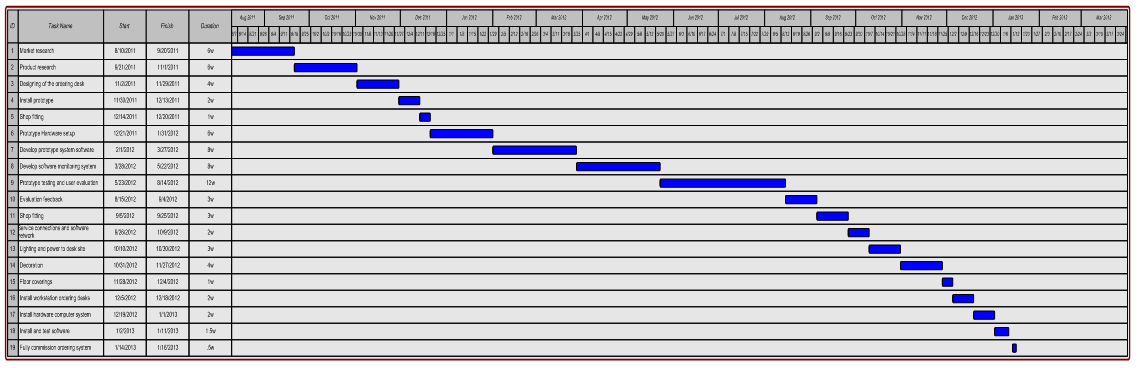

This calls for understanding the overall effect on the project schedule when a critical activity to the project evaluation and review technique (PERT) diagram is changed. The project management software will be used to ensure the schedule control is implemented. The main output from the schedule control process includes Gantt chart (See appendix), corrective action and revisions as well as schedule updates.

Cost control

Cost control includes the following activities:

- Adjusting factors in order to create beneficial change to the project cost baseline.

- Identifying whether the project cost baseline has changed.

- Manage the change when and as it occurs. The cost management plan is the input during this process. The project budget (See appendix) can also be used

Earned value analysis (EVA) is one of the ways in which the cost control for this project can be achieved. EVA is a process of measuring progress and provides schedule and budget variance within the project forecast.

EVA involves carrying out a comparison for the planned and accomplished work as far as its schedule and cost is concerned. Using EVA behind schedule activities and blotted budget occurrences can be identified and rectified.

The work breakdown structure (WBS) will be an important input during this process.

EVA has a number of derivatives highlighted here below:

- Budgeted cost of work scheduled (BCWS) indicates the total amount relating to work performed by a certain date.

- Actual cost of work performed (ACWP) cover the cost incurred up to the current project state.

- Budgeted cost of work performed (BCWP) includes the anticipated cost for completion of the work carried out.

- A number of metrics can be derived from EVA.

- Schedule variance (SV) represents the difference from BCWP and BCWS. A negative figure shows the project is slipping.

- Cost variance (CV) is the difference from the BCWP and ACWP whereby a negative cost variance indicates an over budgeted project.

Other metrics used in determining project cost control are like the schedule performance index (SPI) which is budgeted cost of work performed over budgeted cost of work scheduled. If this result is less than 1, this indicates that the project has slipped and therefore behind schedule.

Alternatively the cost performance index (CPI) is the result obtained from budgeted cost of work performed divided by the actual cost of the work performed whereby a result that is less than 1 indicates that the project is over budgeted.

References List

Duncan, W.R. 1996. A guide to the project management body of knowledge. Sylva, NorthCarolina: Project Management Institute.

Nicholas, J.M., 2000. Project Management for Business and Technology: Principles and Practice. 2nd ed. New Jersey: Upper Saddle River: Prentice Hall.

Marchewka, J.T. 2009. Information technology project management 3rd ed. London: Wiley & sons.

Maylor, H. 2010. Project Management. 4th ed. London: The Financial Times Prentice Hall.

Schwalke, K., 2005. Information Technology Project Management. 4th ed. Cambridge: Course Technology.

Appendix

Appendix 1: Benhams’ touch screen customer order processing system project WBS

Assumptions: Work will be carried on seven days a week (8.00am to 4.00pm) every day.

Appendix 2: Benhams’ touch screen customer order processing system project Budget

Appendix 3: Benhams’ touch screen customer order processing system Risk evaluation

Appendix 4 Benhams’ touch screen customer order processing system Stakeholder analysis and communication plan

Appendix 5 Benhams’ Project Gantt Chart