New advancements in technology and globalization demand constant adaptation and evolution of the manufacturing process. The cloud-based approach aims to reform modern manufacturing practices making them more flexible and responsive to the growing customer demands. This paper will analyze the literature available on the subject of cloud-based systems and summarize the findings exploring the history, applications, and perspectives offered by this method.

The article “Cloud manufacturing: Strategic vision and state-of-the-art” by Wu, Greer, Rosen, and Schaefer offer a comprehensive review of the cloud manufacturing strategy. The main theme of the paper is the potential of cloud manufacturing and the current developments in that field. The article describes how this system will allow the customers, application providers, and physical resource providers (PRPs) to coordinate their efforts to create the desired product. Customers will be able to use the applications to submit their requirements for costs, design, and performance while the cloud system will process their data and determine how the order can be completed in the most efficient way (Wu, Greer, Rosen and Schaefer 2). The order will then be distributed among the PRPs after the applications determine which providers can handle it and how they can cooperate to speed up the process. The article describes the benefits of this approach. It will be consumer-oriented, providing decreased costs and higher efficiency. Cloud-based manufacturing will be much more flexible and adaptable allowing for quick adjustments to the process. The following picture from the article illustrates the basic structure of cloud manufacturing.

It will be able to streamline even highly personalized individual orders. That means that orders will no longer be rejected based on the complications of creating unique items in the mass-production environment (Wu et al. 4). The article also describes the history and the current state of the cloud-based systems. It covers the first precursors to the idea. The authors mention an article by Goldhar and Jelinek from 1990. That paper proposed that the factories will start to integrate computers into the workflow and create networks with other factories. An article from 1998 by Rajagopalan is also mentioned as one of the first pieces considering the Internet and network integration as part of the manufacturing process development.

The authors also cover the companies working to implement cloud strategies at this time, such as ManuCloud and Quirky. These firms create modern integrative solutions which lay the path for the true cloud manufacturing. The article discusses the future of cloud manufacturing in great detail. The authors mention the requirements for the future solutions, including flexibility, ability to rapidly expand available resources, and adaptive algorithms for data management. The paper also covers the potential impact of such systems, including easier access to design information, improved efficiency, and access to new marketing channels, like user co-creation. All of the claims in the article are supported by the evidence from the peer-reviewed journals. The paper provides an extensive overview of the cloud manufacturing strategy, its future prospects, necessary technologies and business strategies.

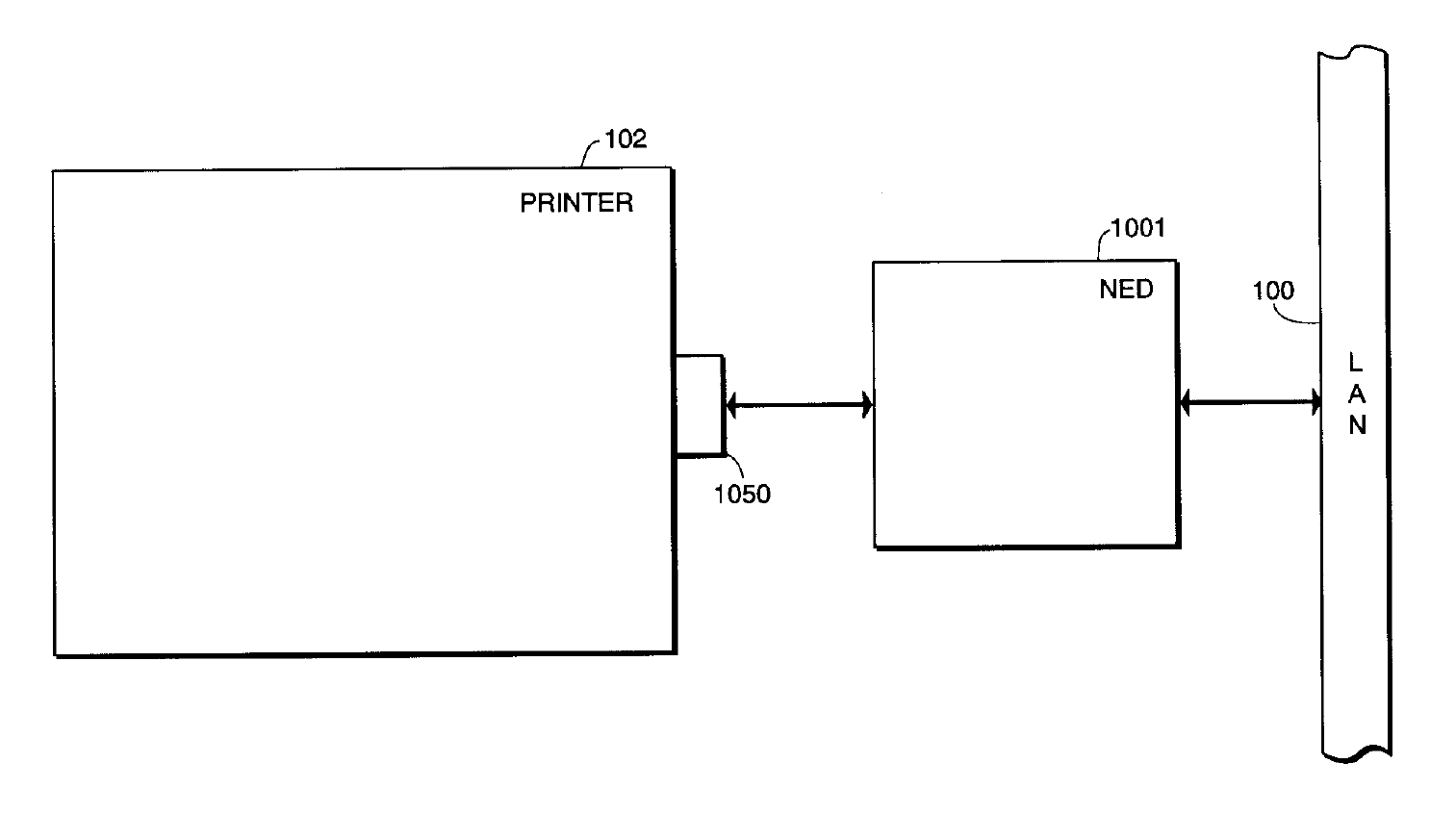

Two patent papers included in this review illustrate the concept of cloud systems on a smaller scale. The first one by Barrett, Russell, and Danknick describes “interface device connected between LAN and a printer for outputting formatted debug information about the printer to the printer.” The patent describes the device and its design in great detail. The main purpose of the device is to aggregate the network debug information and print it out on the connected image forming device avoiding the need for a computer. This piece of the technology can be viewed as an early example of a cloud-based technology since it aggregates the debug data from the entire network and stores it on various drives creating a “dump” useful for diagnostic and other purposes (Barrett, Russell and Danknick 2). This can be viewed as a cloud of sorts gathering information for further analysis. Since 1998, this device has become obsolete, and the modern cloud applications are much more advanced. However, the patent presents an example of an early cloud system. While the approach does not utilize the full potential of cloud networks, that design philosophy later evolved to become modern integrated systems.

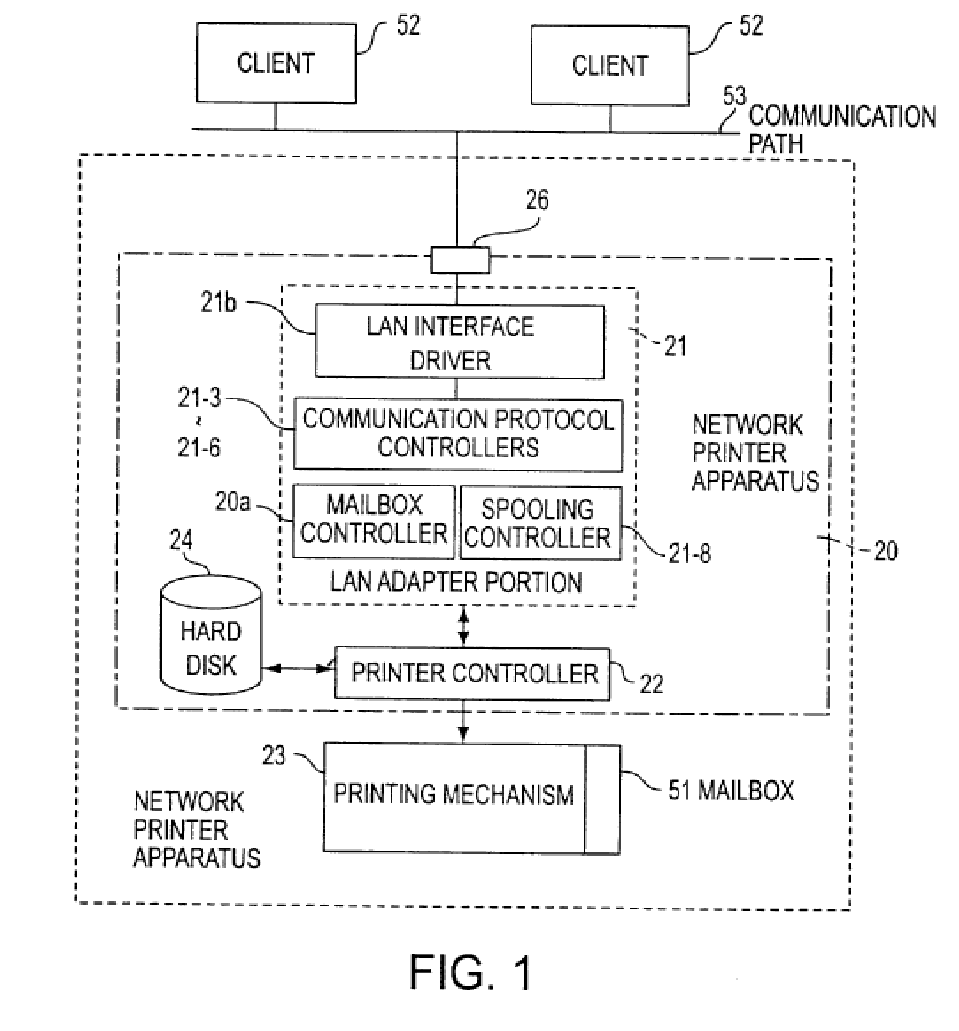

The second patent by Mori, Abe, Ishiguro, Ueyama, Ito, Saitoh, Sato, and Kida describes “network printer apparatus and LAN network system.” The patent goes into great detail on the inner working of the device. This apparatus was designed in order to streamline the printing process and avoid the unnecessary load on the network servers. It also helps to avoid the conflicts between various communication protocols (Mori et al. 2). This device can be viewed as an example of the comparatively advanced cloud technology. It creates a mediator akin to the cloud application in the manufacturing process which helps allocate resources efficiently and coordinate the printing process to avoid conflict and achieve desirable results. These two inventions are prototypes of the currently widespread cloud-based solutions. While the modern networking technology allows for much more complex systems, the devices described in the patents demonstrate how the applications developed over time.

This apparatus was created in 2001. The scheme demonstrates that it was much more intricately integrated into the network than the previous one. It represents an improvement on the functionality of the first device. The apparatus from 1998 was designed as simple data storage with the printer output functionality. The more recent one acts as a coordinator for the printer usage in the network. This discrepancy demonstrates the advancements in the cloud-related ideas and applications.

The article “Distributed Collaborative Design and Manufacture in the Cloud—Motivation, Infrastructure, and Education” by Schaefer, Thames, Wellman, and Wu presents an overview of the cloud-based technology, its perspectives and the education programs connected to it. The paper explores the current projects utilizing the cloud computing capabilities. It aims to relate the importance of the recent advancement in the cloud technologies to the educators to ensure they provide adequate knowledge to their students. The article describes the modern cloud networks in detail. It elaborates that in this context, “cloud” means having too many interconnected elements to map efficiently (Schaefer, Thames, Wellman and Wu 5). The authors also describe how such networks are presently utilized. It covers the systems, allowing engineers to use remote resources for computer-assisted development projects and 3D rendering.

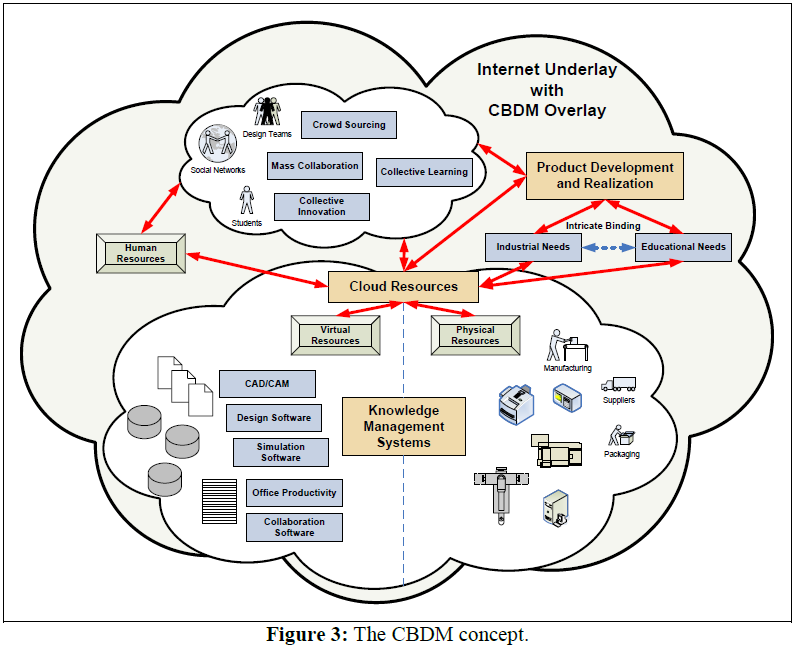

The authors also note the convenience of the pay-as-you-go model which allows the companies to avoid buying costly software licenses. Storing data in the same cloud where the software is running can also be beneficial as it reduces the necessary traffic and cuts waiting times. On the other hand, the article also notes that modern cloud systems can present an unacceptable amount of response lag which can be disruptive to the workflow. The authors describe that in the future, cloud-based manufacturing and design can be advanced dramatically. The following diagram illustrates how the article represents the future of cloud manufacturing. It is a deeply integrated system with various organizations and individuals performing their tasks independently and achieving the desired outcomes through the use of various cloud resources and programs which streamline and organize the process without excessive supervision. The concept borders on the idea of self-management which describes each employee independently playing his role in the company. The described network allows for similar results on the organizational scale.

The new paradigm will allow for a complex and efficient system integrating CAD programs, communication tools and automated application into a cohesive centralized system allowing the designers to quickly and efficiently prototype their ideas and optimize the overall workflow (Schaefer et al. 7). The article also mentions the need for new education programs teaching students to work in an integrated environment of cloud-based manufacturing. The authors present a study course which is aimed at presenting the advanced concepts of the cloud systems to the students. It also provides information on the crowdsourcing, mass collaboration, distributed virtual product creation and other topics related to the cloud applications. If “Cloud manufacturing: Strategic vision and state-of-the-art” focuses more on the history and general aspects of cloud manufacturing, this article describes specific actions and technology advancements that are required to make the cloud-based applications a market standard. It presents a detailed overview of the technology used and offers a comprehensive course, which is already being offered to the students around the world.

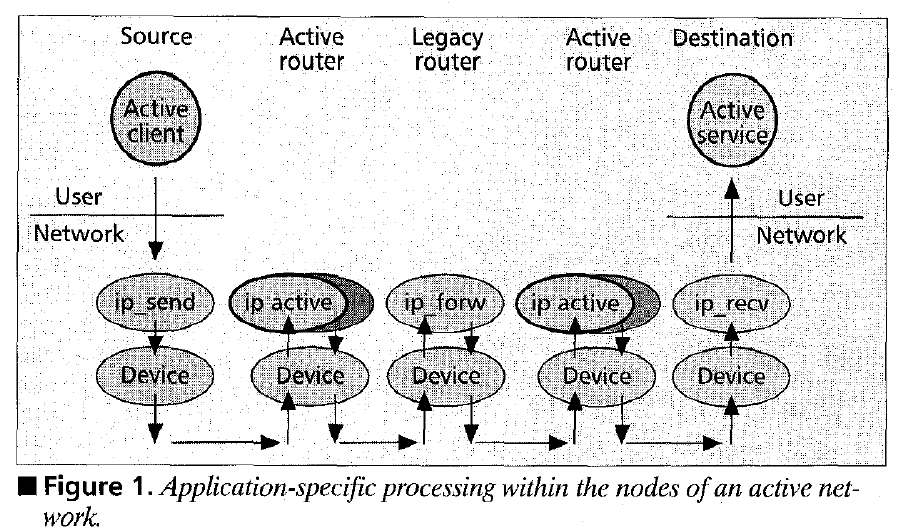

“A Survey of Active Network Research” is an article by Tennenhouse, Smith, Sincoskie, Wetherall, and Miden. It presents the concept of active networking in an understandable format while covering the research on the subject. Active networking is a software-intensive approach to network design. It has repeatedly been discussed, but the authors argue that recent technological advancements make this approach viable at that time (Tennenhouse, Smith, Sincoskie, Wetherall and Miden 85). The following illustration represents the basic operation of the active networks. It shows the active network components processing the data packet instead of simply forwarding it.

The article focuses on two approaches to the active networks realization. The first one utilizes programmable switches. These devices combine the functions of traditional switches with the ability to execute programs. This design keeps the data distribution separate from the management functionality. A program simply reads the packet’s header and processes it appropriately. Capsule approach is much more innovative and radical. In the capsule networks, every packet is a program possibly containing embedded data. The contents of such capsules are executed in a transient environment allowing for more flexible data management. The authors argue in favor of the integrated environment which will allow all platforms and their users to communicate efficiently. They also describe the contemporary research in the field of active networks.

The review mentions works by the MIT specialists seeking to realize capsule approach, the University of Pennsylvania scholars working towards programmable switches and other related projects (Tennenhouse et al. 83). Most of the data presented is completely outdated at this point. However, the article describes an approach to networking which is relevant to the cloud-based system creation. The mechanisms of information management within a network are required for efficient data processing in the cloud, as well as for its uninterrupted operation. Currently, most companies use software-defined networks to manage their dataflow. This technique expands on the ideas used in the initial active networks research described in the article. It decouples data plane and control plane completely, creating a convenient environment for the overall network management. The article describes the origins of this idea and allows for better understanding of the technologies which support cloud manufacturing.

The article “The density algorithm for pairwise interaction testing” by Bryce and Colbourn describes an innovative algorithm design for network compatibility tests. Such tests are utilized in the network architecture to ensure that various end-user system components are properly addressed by it. Exhaustive testing would be an ideal solution as the authors state, but the number of variables prevents it from being viable (Bryce and Colbourn 160). Since every single test can only return either “true” or “false” result, it must address a certain set of parameters. An average computer can have more than a million combinations of various operating systems, browsers, and connection types. For that reason, networks use interaction tests.

That is done by organizing values into interactions. Then the interactions appear in each test suite. Then the interaction can return a “false” which will be represented in the results. The article describes the creation of a new efficient algorithm which is designed to optimize the compatibility testing (Bryce and Colbourn 180). Interaction tests are a crucial part of ensuring efficient device communication within the network. The algorithm described in the article can be used in cloud manufacturing to ensure efficient data exchange. Cloud networks connect a multitude of devices using software and hardware of various manufacturers. The article highlights the importance of the end-user testing. It is crucial to maintaining efficiency and ensuring that no errors occur. The article allows some insight into the complexity of cloud networks, and the challenges network administrators face creating and servicing them.

The literature on review presents a comprehensive and complete look at the problems and challenges of the network manufacturing. The articles “Cloud manufacturing: Strategic vision and state-of-the-art” and “Distributed Collaborative Design and Manufacture in the Cloud—Motivation, Infrastructure, and Education” present an overview of the system and how it can be implemented. The papers also cover the perspectives and potential future designs of cloud-based solutions in manufacturing, design, and computing. The patent papers present information about early projects which essentially implemented clouds on the individual network level.

They allow for deeper understanding of the origins of the cloud technology and how it has developed over time. “Survey of Active Network Research” is a comprehensive article describing the topics of network management. While most research is not relevant at this point, the article presents the history of technology which made cloud networks possible. Finally, “The density algorithm for pairwise interaction testing” describes the problems of compatibility within networks. The article focuses on the specific issue of interaction testing. However, the findings can be extrapolated for a better understanding of the network management issues which are inevitable in the cloud environment. Overall, the literature discussed in this paper covers both the history and the future of the cloud manufacturing.

Works Cited

Barrett, Lorraine, William Russell and Daniel Danknick. “United States Patent № 5,828,863.” United States Patent and Trademark Office. Web.

Bryce, Renée C. and Charles J. Colbourn. “The Density Algorithm For Pairwise Interaction Testing”. Software Testing, Verification and Reliability 17.3 (2007): 159-182. Print.

Mori, Yoshio, Fumitake Abe, Keiji Ishiguro, Satoru Ueyama, Mari Ito, Toshmi Sato, Yasushi Saitoh and Yasunari Kido. “United States Patent № 6,292,267 B1.” United States Patent and Trademark Office. Web.

Schaefer, Dirk, Lane Thames, Robert Donald Wellman and Dazhong Wu. “AC 2012-3017: Distributed Collaborative Design and Manufacture in the Cloud – Motivation, Infrastructure, and Education.” American Society for Engineering Education. Web.

Tennenhouse, David, Jonathan Smith, David Sincoskie, David Wetherall and Gary Minden. “A Survey Of Active Network Research.” IEEE Communications Magazine 35.1 (1997): 80-86. Print.

Wu, Dazhong, Matthew John Greer, David W. Rosen, and Dirk Schaefer. “Cloud Manufacturing: Strategic Vision And State-Of-The-Art”. Journal of Manufacturing Systems 32.4 (2013): 564-579. Print.