Introduction

The primary goal of a company is to attain profits through the sale of products and services. One particular industry that focuses on quality service provision due to the sensitivity and confidentiality of goods involved is the express logistics industry. The industry entails the provision of courier services regionally and internationally in a swift manner that is facilitated by air and sea transport. A notable company in the industry is DHL Express, which specialises in the provision of local and international mail delivery services.

The reputable name created by the company can be traced down to the quality of its services. However, the emergence of other players in the market seeking a fair share of the market implies that it is essential for DHL to improve the quality of service delivery in a bid to cement its position in the industry. This report will focus on the DHL’s background, workflow issues, requirements for quality improvement, and an evaluated plan for the development of the workflow.

Company Background

DHL was born in 1969 and it started offering airmail services between California and Hawaii. The company has extended its services to over 220 countries across the world with over 325,000 employees. For this reason, the Deutsche Post DHL Group has worked hard to become the largest logistics and postal group in the world as manifested by its operations in over 70,000 destinations whereby small and bulky parcels are delivered (DHL, 2015c).

Vision and Mission

The vision of DHL is to become a logistics company for the entire world (DHL, 2015a). Their vision can be termed as viable since their presence has been felt in over 220 countries resulting in confidence in their services. The mission of DHL comprises four components. The first aspect of the company’s mission is to streamline the lives of its customers. This aspect implies that the organisation strives to improve the lives of its clients by satisfying their mailing and logistics needs. Secondly, the company seeks to add up to the success of their customers, employees, and investors.

Again, their activities seek to satisfy both their clients and workers in a bid to attract investors. Thirdly, DHL intends to play a central role in the world’s success. Showing respect when trying to meet the company’s targets is the fourth element of DHL’s mission. In this light, the company’s vision and mission are geared towards the collective success of the parties involved in the industry (DHL, 2015a).

Strategic Objectives

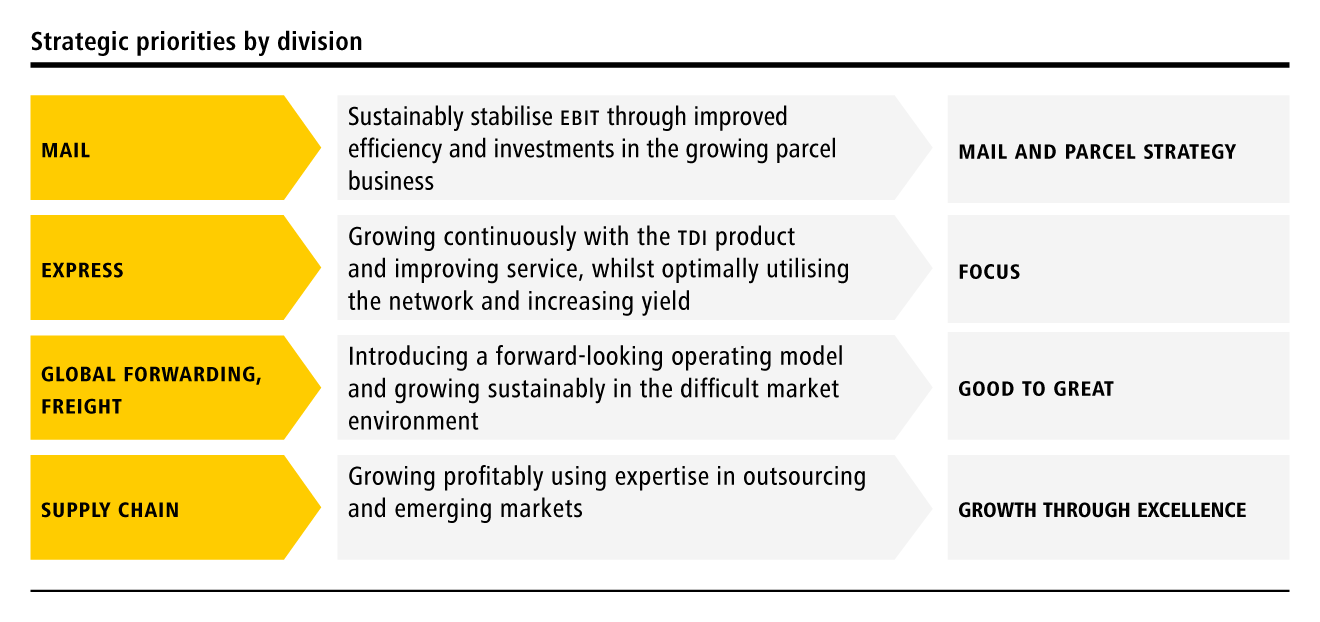

The attainment of the laid down vision and mission statements necessitates the need for a strategic plan guided by a number of set objectives. DHL announced Strategy 2015 back in 2009, which stipulated the intended approaches for each of its four divisions (Deutsche Post DHL, 2015). The four departments forming the DHL Group include the Express, Mail, Global Forwarding, Freight, and Supply Chain. The company has the following departmental strategies that seek to deal with challenges that may arise.

Mail Division

This department focuses on costs flexibility through adaptation, cutting costs, and investments. Additionally, DHL strives to provide quality services and observing environmental sustainability. Workforce motivation is another strategy for empowering the human factor. The company also seeks to venture into new markets through innovative measures such as digital communication.

Express Division

This division specialises in managing revenue and costs, the management of sales and pricing, network management, and motivation of employees.

Global Forwarding, Freight Division

This division focuses on establishing new solutions for customers, creating an extensive transport system, and streamlining an accepted process of operations navigation.

Supply Chain Division

The DHL’s supply chain division focuses on a regular enhancement of existing business and strengthening of the focus sectors for profitable growth.

SWOT Analysis for DHL

The need to identify the strengths, weaknesses, opportunities, and threats encompassing DHL is significant for the improvement of its service provision. This requirement is necessary given the presence of competitors the United States Postal Service (USPS) and the Federal Express (FedEx) (MbaSkool, 2015). A SWOT analysis highlights the effect that the DHL’s departmental strategies have with respect to internal and external factors. The following table is a SWOT analysis intended to evaluate the DHL’s environment in relation to its operations.

Figure 2: A SWOT analysis for DHL

Workflows issues in DHL’s Business Organisation

The efficient delivery of the DHL’s products and services entails a sequence of activities that work interdependently for the success of the whole. The allocation of responsibilities and resources enhances the workflows within the business organisation. For this reason, the need for quality management (QM) is required in order to stay competitive.

In the express logistics industry, a number of QM tools can be applied to the achievement of efficient management of organisational processes. The tools that can be used for the case of DHL include Control charts, Cause-and-effect diagrams, Check sheets, Pareto charts, Scatter diagrams, Histograms, and Stratification. The proposed tools for enhancement of workflows at DHL entail the use of Cause-and-effect diagrams, Check Sheets, and Pareto charts. In this light, the mentioned QM tools are expected to be in line with the strategies that each division of DHL has put forward.

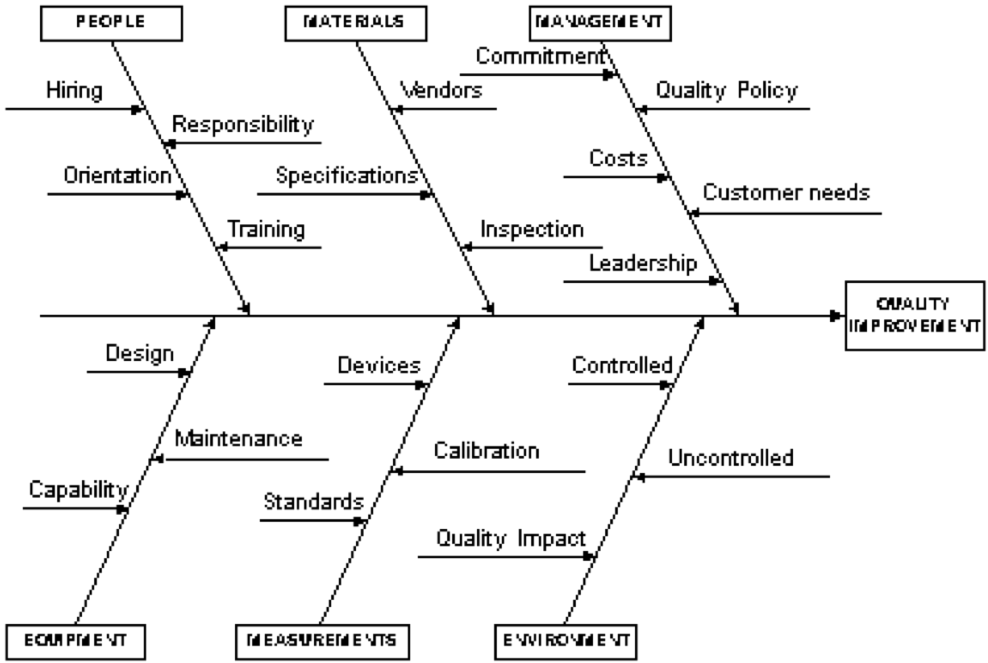

Cause-and-effect diagrams

The Cause-and-effect diagrams, which are also referred to as the Ishikawa diagrams, are used to identify the underlying causes of a problem in an organisation. The implementation of the QM tools at DHL could help to enhance decision-making concerning the several aspects of its functionality. The four main steps involved when using this tool entail the identification of the issue, working out the major factors involved, the identification of probable causes, and analysis of the diagram. Below is an Ishikawa diagrams that could be used to explain how the company can enhance operations in line with Strategy 2015.

Since DHL endeavours to become the logistics company across the globe, it is essential to prevent any challenges that may cause the derailment towards the attainment of the vision. In this regard, the threats to the company’s success need to be analysed considering the departmental strategies. Challenges faced in foreign countries due to unfavourable government policies and taxation could be a potential threat to the organisation’s workflows.

The primary factors identified could be the intention to protect local firms in the industry. An analysis of the diagram then proceeds whereby strategies in line with the core competencies are put forward to alleviate the situation. For instance, the Global Forwarding Freights division could implement strategies aimed at influencing favourable government policies that would allow operations in foreign markets.

Check Sheets

A Check Sheet is a QM tool that facilitates data collection in real-time. Check sheets could be used by DHL to enhance data analysis using other tools such as the Ishikawa diagrams. Therefore, challenges inhibiting DHL from attaining its vision could be collected and classified before the solutions are proposed.

One of the core strategies for the Mail division at DHL is to provide high-quality services to customers. Qualitative methods could be applied when conducting studies aimed at achieving the customers’ views on the company’s services. Questionnaires could be provided to clients and then later be used to check items in the Check Sheet. Consequently, processes within the different departments would be streamlined, thus leading to improved functionality of the DHL’s management.

Pareto Charts

The company’s competitiveness can be analysed through the Pareto Charts as earlier proposed. This QM tool is characterised by bar charts and line graphs indicating the distribution of items. This tool operates under the 20/80 rule implying that 20% of issues usually cause 80% of problems (ASQ, 2015). In this regard, the DHL’s competitiveness in the market can be evaluated by determining the problems that lead to the inefficiency in its operations. For instance, when analysing the frequency of problems facing the Supply Chain division, issues inhibiting the growth of focus areas could be identified.

Thus, 20% of defects appearing in supplied goods could be the reason for 80% of problems encountered in the department. Focus on the most serious problems causing the greatest impact is thus prioritised. Consequently, the strategic plans in the Supply Chain department are geared towards the gainful growth of particular sectors such as the Technical Services.

The Implementation of ISO 9001 certification

The ISO 9001 focuses on various elements of quality management. As an ISO certified company, it implies that DHL has to adhere to some accepted standards in its operations. The ISO 9001:2008 Certification provides principles that enhance quality management. The certification advocates for customer satisfaction, motivation of the workforce, and impacts of the principle management, organisational processes, and continuous improvements (ISO, 2015). Therefore, the various workflows present at DHL need to consider the provisions for quality management in an effort to ensure that the company navigates within the required standards.

DHL has been accredited with ISO 9001, ISO 14001, TS 16949, among other certifications (DHL, 2015b). The company is competent in providing timely and quality services without shipment errors through clear communication with clients. As DHL competes with rivals for a substantial market share, compromising the quality of its products and services could lead to legal repercussions, hence failure.

In a bid to avoid the occurrence of such scenarios, DHL upholds its Quality Assurance mechanisms and complies with the regulatory requirements for quality management and operations (DHL, 2015c). Accordingly, the various workflows in the four departments at DHL have to conduct their undertakings in respect to the ISO certification requirements in order to be in line with the quality management standards.

Improving Quality at DHL

The need for continual improvement of the quality of products and services offered by DHL is significant for its growth. Sound leadership is essential for the successful implementation of change in an organisation. Leadership factors such as transformational skills, creativity, change initiation, and sound management need to be prioritised for the practical improvement of the delivery of parcels internationally.

The DHL leadership has facilitated the training of employees in a bid to enhance the development of its qualities. A section of the workers at DHL was trained and attained apprenticeship qualifications in Team Leadership and Management, Customer Service, and Business Administration. The top management saw the essence of building the capacity of its employees by enrolling them at Weston College. Empowering the employees enabled the company to strengthen the potential of its leadership. Consequently, quality management systems could be attained hence fostering improvement in quality of the express services

The motivation of the workforce at DHL is paramount for the enhancement of service delivery. This assertion holds because the human factor contributes majorly to output that facilitates goal attainment. In a bid to motivate the employees, DHL introduced the Upstairs scholarship program for its workers’ children. The adoption of this policy was intended to promote employee loyalty and facilitate equal opportunities for education for the workers’ children. In this way, the motivation effect necessities improved workflows that are in line with the company’s strategic plans.

The changing customer needs contribute substantially to the adjustment of how services are delivered at DHL. Understanding the dynamic needs of the clients is essential for the improvement of the services offered. In June 2008, the Deutsche Post DHL conducted a study dubbed “Delivering Tomorrow – Customer Needs in 2020 and Beyond” in a bid to foresee the future changes affecting its customer base (Deutsche Post DHL, 2015). The study sought to analyse the effects that globalisation, economic changes, environment, technology, and logistics to its clients by 2020 and beyond.

The identified issues include sustainability, corporate social responsibility, and education. A key finding was that in the future, the purchase of goods and services would not be based on price and quality, but on the impact that the product has on the environment (Deutsche Post DHL, 2015). In this light, DHL has come up with a mechanism to promote environmental consciousness. Consequently, this move would facilitate the sustainability of both the environment and DHL.

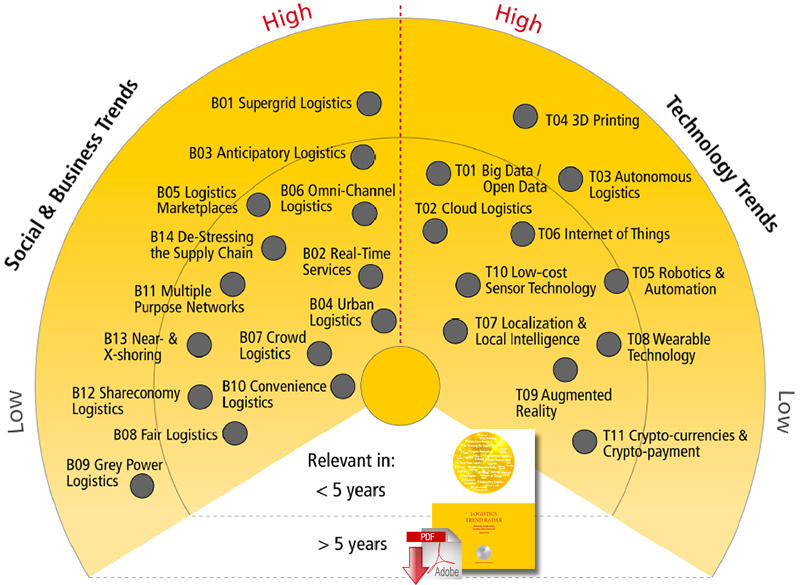

Efficient decision making in the management of DHL is vital for the implementation of strategies aimed at improving operations and services. The company has utilised various analytical tools designed to monitoring trends that would help the managerial team to make decisions and plan for the future. DHL facilitates its qualitative and quantitative studies through its Trend Research team. According to the Deutsche Post DHL (2015), the logistics team developed the Trend Radar analytical tool, which aims at helping management systems formulate new strategies to promote innovative projects.

Workflow Improvement Plan with justification and evaluation

The improvement of workflows at DHL is essential for the competitiveness of the company and the realisation of its goals. For the improvement of quality to be achieved, qualitative and quantitative tools of analysis have to be utilised in an effort to identify the inhibitors to streamlined workflows. Through the implementation of the Trend Radar for the analysis of the current customer needs with respect to future trends, DHL has focused on the future in relation to sustainability, technological changes, and education (DHL, 2015a). Additionally, the company uses the Big Data report for the improvement of workflows.

The implementation of the QM tools to enhance operations gathers both structured and unstructured data. The Big Data analysis then follows whereby further tests are carried out to identify aspects that would trigger change. In its findings, the Big Data analysis uncovered the need to exploit data from three primary sources, viz. “operational efficiency, customer experience, and new business models” (DHL, 2015c, par. 6). The Pareto charts could be used in line with this aspect for the analysis of the variations in different aspects of the Big Data.

Big Data analysis indicated that for operational efficiency, real-time optimisation of routes, crowd pick up and consignment, and planning for network, and operational capacity. In this light, an evaluation of these aspects was crucial for DHL to safeguard its vision and handle competition efficiently (Deutsche Post DHL, 2015).

On the other hand, customer experience required the facilitation of customer loyalty, unceasing services enhancement, innovative strategies, and risk evaluation. New business models were also classified as potential for streamlined workflows. New operational trends would consider environmental changes, market intelligence, analytics in demand and supply, and the verification of addresses. Therefore, risk mitigation is covered in the DHL’s logistics division translating into a streamlined navigation of workflows.

DHL Process Improvement Programs

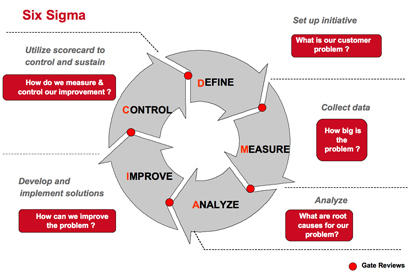

The supply chain division strives for perfection of its service delivery in a bid to consolidate efficient supply chain processes with its clients. In a bid to attain this goal, DHL utilises proven methodologies that aim at giving scientific solutions to issues that cause incompatibilities. DHL uses the DMAIC model (Define, Measure, Analyse, Implement, and Control) for the analysis of improvement requirements (DHL, 2015b). The model uses the six sigma approach and lean manufacturing to identify the vital aspects that would improve processes at various levels.

Continual employee involvement and management engagement are important aspects at DHL. The aim is to create strong formal and informal relationships within the organisation since the human element in an organisation is essential for the implementation of changes. After Ken Allen assumed duties as the DHL CEO in 2009, he introduced the bespoke employee engagement program under a budget of €100m (DHL, 2015a). Additionally, he introduced the Certified International Specialist program (CIS) for its 100,000 workers based in over 220 countries.

The program elicited remarkable results indicating a 9% increase in employee engagement between 2010 and 2012. The €1bn profits attained in 2012 were attributed to the employee engagement programs that Ken Allen introduced to DHL (DHL, 2015c). In this regard, the participation of workers created motivation among them, thus leading to desirable output as portrayed in the profits during that period. The program shifted the notion that it is the HR’s responsibility to motivate people to the idea that top management should engage employees.

The launch of a system for tracking orders (Lots) aimed at providing clients with real-time information is another process improvement program initiated by DHL in 2010 (DHL, 2015a). The system uses a Lots tool, which is web-based, to enable customers to view information about their orders. The company’s costs have been cut since then, thus enabling the Supply Chain division operate economically.

The tools involved in this program are technology-based since online programming platforms were utilised. Thus, GPS gadgets were incorporated into vehicles to track movement and delivery speeds. The tool uses trucks delivery vehicles through Geofence GPS platforms and automatically notifies the client via text messages (DHL, 2015c). In this light, the company’s move towards embracing technology in its Supply Chain division using statistical measurements was a critical step for operational efficiency.

Conclusion

DHL has been a leading company in the express industry driven by its vision to become the top logistics company across the world. Its departmental strategic objectives have enabled it to enhance workflows that aim at improving the standards of the products and services that it provides. Since DHL is ISO certified, it utilises quality management tools such as the Pareto charts and Ishikawa diagrams to enhance management systems.

The company’s sound leadership has also been accredited for its initiation of policies that are geared towards understanding the changing customer needs using qualitative and quantitative analytical tools. Various workflows improvement plans including the CIS and the Upstairs program have been implemented in a bid to streamline operations at different levels.

This goal was accomplished through the adoption of various quality management tools such as Sigma. Analytical strategies such the use of Big Data has also enabled the anticipation of the customers’ future needs. Therefore, DHL has done a commendable task in trying to improve workflows in the organisation, hence its success.

References

ASQ: Pareto Chart. (2015). Web.

Deutsche Post DHL: Deutsche Post DHL Presents Study of Future Trends. (2012). Web.

Deutsche Post DHL: Objectives and Strategies. (2015). Web.

DHL: Company Portrait. (2015a). Web.

DHL: Process Improvement: How We Work. (2015b). Web.

DHL: Trend Research. (2015c). Web.

ISO: ISO 9000 – Quality management. (2015). Web.

MbaSkool: DHL: Transport and Logistics. (2015). Web.