Introduction

All projects are subject to a certain lifecycle as indicated by the inherent limitations of the project itself and, as such, it becomes important to determine whether the team either contributed towards meeting deadline objectives, going over the deadline or even completing the project earlier than expected. It is based on this that this paper delves into issues related to the Harcourt Master plan Project which was a road infrastructure project that was awarded to Enoc Civil Pty Ltd in May 2013. By the end of the project life cycle, the total amount spent on the project ballooned to $376,425.16 which amounts to a $92,595.16 project overrun cost. This was indicative of a quality failure on the part of the project manager and the various parties involved since it did not adhere to the projected and set cost for the road improvement. Overall, it can be stated that the main problem with the project was that there were no process controls in place that should have prevented unneeded variations in the project plan from being put into effect. First and foremost, it was noted that there was a lack of documentation on the part of the project manager to support the site inspections that were supposedly conducted. Other identified issues come in the form of poor communication between the project manager and the contractor.

This can clearly be seen in the project wherein it went over and beyond the initial goals resulting in the incorporation of project variances that are possibly not needed. Another problem that was encountered when examining the various issues surrounding the project was the lack of financial checking by the project manager which resulted in the unneeded project variations being included. When examining the processes that were put in place in the Harcourt Master plan Project, it is evident that a certain degree of managerial incompetence was in play given that the project manager allowed unilateral project add-ons without taking into consideration the proper financial ramifications of such actions. Upon examining the Harcourt Master plan Project, it was evident that formal documentary procedures were not in place to limit and observe the various activities of the contractor. This led to the unilateral implementation of operations that resulted in the project going over budget. What this shows is that proper documentary procedures are a necessity in ensuring that a project stays on track from a process and financial operations perspective. To resolve the issues surrounding the Harcourt project, this report advocated the implementation of internal information systems and process changes so as to address the various issues that were identified resulting in the creation of a better project process that can be implemented in the future to reduce instances where projects exceed their outlined costs without sufficient justification behind the variation.

Context and background

The Harcourt Master plan Project was a road infrastructure project that was awarded to Enoc Civil Pty Ltd in May 2013. The projected value of the project was set at $284,000 by the local council with $237,735.20 (GST exclusive) being the winning project bid. 10 percent of the total project value ($23,773.50) was also set aside under the discretion of the project superintendent for possible additional costs that may come up during the construction process. By the end of the project life cycle, the total amount spent on the project ballooned to $376,425.16, which is indicative of a $92,595.16 project overrun cost. Further investigation into the reason behind the increased costs associated with the project revealed that there were insufficient tracking mechanisms in place related to variations that were outside the original scope of the project that was utilized as a means of justifying the increased cost.

Combined with the unilateral signing off of increased expenditure for services and materials by the contractors along with the lack of proper documentary procedures when it came to creating a means for approval and recording costs, the end result was the apparent use of services and resources that may have been unneeded by the original project scope which led to the significant cost increase that could have been avoided if proper oversight was implemented in the first place. Taking these factors into consideration, it can be seen that what was necessary to improve the quality of the project in reference to its adherence to its original budget was the necessity of proper communication between the project manager and the contractor, the implementation of documentary procedures involving the execution of the project, implementation of effective financial oversight by the project manager and lastly, formal authorization through proper documentation involving the necessity of variations to the original contract due to unexpected circumstances.

Definition of quality appropriate to the process identified

Based on the work of Parasuraman, Zeithaml, Berry (1985), the following is the qualities that have been deemed appropriate to the process that has been identified. The basis behind this choice is explained through the succeeding section on the processes inherent in the construction industry.

After examining the possible approaches to defining “quality” when it comes to the given construction project, the value-based approach was chosen as the most viable. The reasoning behind this is quite simple, under the analysis of Golob, Bastič & Pšunder, it was stated that most construction projects utilize a value-based approach due to the perceived cost versus intended outcome ratio that is inherent in every construction project (Golob, Bastič & Pšunder 2013). To better clarify the concept given by Golob, Bastič & Pšunder, it is important to note the following when it comes to a construction project:

- Unlike a consumer product (ex: ice cream, cake, etc.) construction projects tend to have either significant increases or decreases in cost based on the inherent efficiency of the approach utilized.

- Cost from the construction point of view is influenced by the type of materials utilized, the rate by which they are used and the time it takes to put together a particular building.

- While the cost of materials can become a set value, the efficiency of construction is not and can often vary from what was planned.

- Longer construction times due to the inherent inefficiency of the approach results in higher costs which impacts the viability of the project since higher costs can affect the price by which a project is sold to consumers. In a worst-case scenario, longer construction times can even lead to penalties for the company that is constructing the building in the first place which could result in the cost of penalties exceeding the amount paid for services rendered.

Gavin (1984) states that the value-based approach is: “a quality product provides performance at an acceptable price, or conformance at an acceptable cost” (Gavin 1984). This means that the measure of worth for a construction project is based on its adherence to an acceptable price and conformance to an acceptable cost for its creation. Under such a concept, this means that the construction project that was presented did not follow the value-based approach at all since not only did it not conform to the concept of acceptable price (it exceeded the set price by nearly 1/4th of the original cost) but it also did not conform to the concept of acceptable costs (the receipts showed several nonconforming works to the project which exceeded the initial outline of development without sufficient justification behind their implementation) (Gavin 1984).

It is under this context that the definition of ISO 9000 standards comes into play which states that quality can be defined as the degree to which a set of inherent characteristics fulfills a predetermined requirement (British standard ). The requirement under the context of the construction project in question refers to its adherence to set guidelines of conformity, budget, communication and financing. All of which were not followed as needed (British standard 2006, p.7). Taking this into consideration, it can thus be stated that quality standards in reference to IS0 9000 were not followed given the level of variance between what was expected and the resulting outcome of the project.

Through the section explaining ISO 9000 standards, it can be reasoned that quality, when it comes to a project, is related to its conformance to its expected outcome. Basu’s model of quality in project management supports this claim by stating that “quality is the consistent conformance to customer expectations” (Basu 2012). Basu goes on further to explain that “project quality is the philosophy of the adherence of standards to fulfill acceptable delivery objectives throughout the life cycle of a project and there are three clear dimensions of project quality given by design quality, process quality and organization quality” (Basu 2012, p. 47). From the perspective of Basu, the Harcourt Master plan Project can be considered as a failure since it fails all three of the dimensions of quality that were stated as necessary when it comes to project outcomes (Basu 2012, p. 47). From a process quality standpoint which is defined as “the degree to which the product or service, which is made available to the customer, conforms to specification”, the project is a failure since it does not conform to the original specifications that were outlined (Basu 2012, p. 47). For example, the article “Keys to Success in Megaproject Management in Mexico and the United States: Case Study” explains that while it may be true that it is infeasible to believe all aspects of a project will go exactly as planned, there is still the necessity of adhering to as close to the desired specifications as possible when it comes to creating project outcomes.

Failure to do so without sufficient justification behind it (as seen in the Harcourt Master plan Project) can be considered a failure on the part of the project process despite the fact that the project outcome was achieved (though it did go significantly over budget) (Keys to Success in Megaproject Management in Mexico and the United States: Case Study 2014). It is based on this that the project can be stated as failing another dimension of Basu’s model of quality management in that it did not conform to the intended design quality that was supposed to be implemented (Basu 2012, p. 47). Basu states that design quality is: “the degree to which the specification of the product or service satisfies customer requirements” (Basu, 2012). Under this context, the design quality of the project is a failure since it goes beyond the original specifications that were outlined in the original project details which resulted in the significant added costs of the project (Basu, 2012). Lastly, from an organizational quality standpoint, it can be stated that the project lacked sufficient organizational oversight in terms of proper documentation, committee evaluation of proposed project variations as well as sufficient financial management on the part of the project manager. Basu states that organizational quality is “the quality of the organization and people-related issues”, under this context the project organization was ineffective due to the lack of sufficient process controls that should have been in place to prevent unneeded project variations from being implemented (Basu 2012, p. 47).

Taking all the factors that have been mentioned into consideration, it can be stated that the definition of quality, when applied to the Harcourt Master plan Project, would have been adherence to the original scheme of the project, implementation of proper process controls to ensure proper documentation and budgeting, as well as the use of better methods of communication between the project manager, contractor and committee in charge of the project to ensure that variations to the project would have been discussed and implemented with full knowledge regarding the necessity of the intended changes instead of the unilateral changes that were implemented.

Describe the existing process

The existing process is actually pretty straightforward; the local council outlines the need for the road and creates an estimate regarding the cost. The project team on the other hand develops the means by which the plan can be implemented and bids out the project as well as supervises the construction of the road by the contractor. Lastly, the contractor handles the building of the road itself and creates requisitions to the project manager involving variances to the initial construction design due to various issues that were encountered. Upon examination of the case, it can be stated that the contractor was actually practicing proper due diligence when it came to the work that was being done since they were trying to make sure that “all the bases were covered” so to speak when it came to the construction. However, the article “Analysis of Disruptions Caused by Construction Field Rework on Productivity in Residential Projects” explains that contractors are inherently profit motivated in that when it comes to construction projects they tend to “discover” variances in the project that were not found before. This usually comes in the form of additional support structures needed, the necessity of disposing of materials in an environmentally proficient manner as well as other such issues that “come up” during the construction process (Arashpour, Wakefield, Blismas & Lee 2014).

Kelly, Edkins, Smyth & Konstantinou state that this practice is especially true when it comes to government-funded projects which often balloon in cost due to “added services” that are often tacked on to the initial contract. Such a case does not appear often in commercial contracts due to set budget constraints and meticulous project oversight strategies that companies implement to ensure that projects do not go over budget (Kelly, Edkins, Smyth & Konstantinou 2013). These particular practices were unfortunately not present in the project and this led to the considerable increase in the project price. Further examination of the project details reveals that it utilized a “top-down” organizational structure wherein instructions from the council that authorized the construction of the road were then relegated to the project manager and from there given to the contractor. While this is one of the most common organizational structures, it does have considerable issues in relation to proper oversight. The article “Proactive Productivity Management at Job Sites: Understanding Characteristics of Assumptions Made for Construction Processes during Planning Based on Case Studies and Interviews” explains that oversight when it comes to the “top-down” organizational structure is effective only if the “executive” in charge of the operation is actually performing their duty. This means that tasks are properly assigned, project control mechanisms are in place and the “executive” is more hands-on in terms of controlling and mitigating the various issues that crop up (Gao, Ergan, Akinci, & Garrett 2014). Unfortunately, this was not the case when it came to the Harcourt Master plan Project due to the lack of sufficient oversight by the project manager in charge of the operation which led to the various issues that cropped up.

Identify problems with the existing process and try to identify causes of the problems

Overall, it can be stated that the main problem with the project was that there were no process controls in place that should have prevented unneeded variations in the project plan from being put into effect. Aside from this, the following are the identified issues that have been identified as being the source of the other problems in the project.

Lack of sufficient documentation

First and foremost it was noted that there was a lack of documentation on the part of the project manager to support the site inspections that were supposedly conducted. This can either mean that the project manager did not do the site inspections at all or was negligent in his/her duties resulting in mismanagement of the project (Puerto & Shane, 2014). The article “Selection of Third-Party Relationships in Construction” delves more into the issue of proper documentation by explaining that documentation of site inspections ensures that everything is moving along on schedule and that the project is adhering to the specifics that were originally outlined. Without proper documentation detailing whether the project is on time or that the requirements were followed to exact specifications, this can often lead to issues related to delays in the construction schedule or the incorporation of unneeded processes which increases the cost of the project (Palacios, Gonzalez, & Alarcón, 2014). Evidence of this can be seen in the 19 non-conforming works that were identified in the project and are indicative of the contractor overstepping their bounds in terms of additional work done without sufficient consultation regarding their necessity.

Lack of proper communication between the project manager and the contractor

Other identified issues come in the form of poor communication between the project manager and the contractor. Chou & Yang state that a lack of proper communication between a project manager and a contractor is indicative of issues in the project process. Supposedly, communication helps to align the goals of the project with the intended outcome and, as such, is an essential aspect in the “checks and balances” system that is inherent in most projects (i.e. determining the current needs of the project versus the outlined specifics that need to be done) (Chou & Yang 2012). The end result of miscommunication is often a project that is misaligned from its intended goals and, as a result, has poor quality in terms of possible negligence or issues related to improper processes in construction. This can clearly be seen in the project wherein it went over and beyond the initial goals resulting in the incorporation of project variances that are possibly not needed.

Lack of Sufficient Financial Checking

Another aspect that should be taken into consideration is the lack of financial checking by the project manager. The study of Chou, Irawan & Pham stated that financial checking procedures are an essential aspect of all project processes since adherence to a budget helps to determine both the quality and the success of a project. Going over budget or being unable to complete a project due to improper financial management is indicative of a failure on the part on the part of a financial manager to ensure that a project becomes successful (Chou, Irawan & Pham 2013). It is based on this that the lack of financial checking is indicative of the absence of a proper formal template that was developed in order to ensure that the project conforms to a particular set of financial boundaries that help to limit unneeded financial expenditures. It is within this context that when examining the processes that were put in place in the Harcourt Master plan Project, then it is evident that a certain degree of managerial incompetence was in play given that the project manager allowed unilateral project add-ons without taking into consideration the proper financial ramifications of such actions. This may in part be due to the fact that there is little evidence to support that he had actually visited the site and ensured that everything was proceeding as planned.

Lack of Formal Documentary Procedures

Through the analysis of Chou, Irawan & Pham, it was noted that formal documentary procedures were an essential aspect in all project management processes since it creates a “paper trail” so to speak regarding what was implemented, how much did it cost, and the justification behind the implementation. Through proper documentation, a project manager can oversee why a project is going over budget, determine what can be done to resolve it and can “nip it in the bud” when it comes to eliminating excessive processes that may not be needed in order to complete a project. Chou, Irawan & Pham go into more detail regarding this by explaining that documentation acts as a “limiter” to particular actions wherein either the personnel or the needed budget are not given without prior approval to the documentary procedures that were implemented (Chou, Irawan & Pham 2013). This helps to limit unneeded operations from being accomplished through the use of a committee that evaluates the necessity of the requested operation and decides whether it is necessary for the project to be completed. Upon examining the Harcourt Master plan Project, it was evident that such a process was not in place and led towards the unilateral implementation of operations that resulted in the project going over budget. What this shows is that proper documentary procedures are a necessity in ensuring that a project stays on track from a process and financial operations perspective.

Recommended process improvements and describe the improved process

Project Process Approval for Identified Issues and Modifications

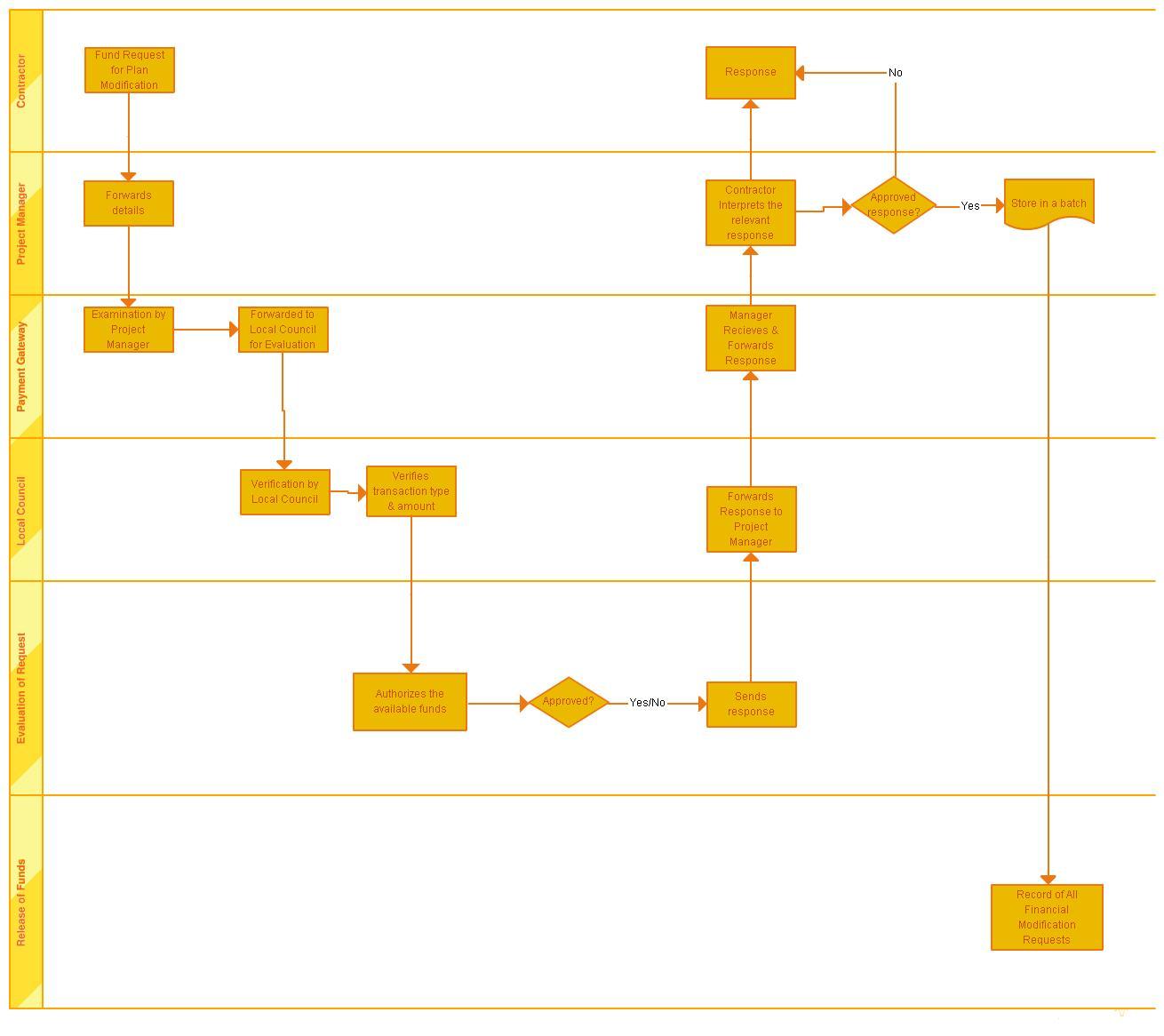

Swim lane flow chart for Fund Request

To resolve the issues surrounding the Harcourt project, this report advocates the implementation of internal information systems and the process changes outlined above as a means of creating a better method of managing the various nuances associated with the construction project.

Information systems can be described as the interface between people, organizations and technology enabling the business to accomplish a specific task or action. Developing proper information systems is an essential aspect of a project for without it a company will be unable to properly deal with the buying, selling and utilization of resources across various locations. Due to the varied and often complicated nature of project operations, it becomes a necessity to streamline and integrate product delivery processes, methods of operation, customer service and various other operational capacities. An organization cannot just simply construct a project without taking into consideration how best to allocate specific resources, which operation needs it most, how will information returns be processed and how HR services will deal with salaries for the myriad employees within a company. A company requires an efficient and up-to-date information system in order to integrate the factors mentioned into an efficient and effective operational strategy so as to better serve its clients. The larger an organization gets the more hectic and haphazard its operations to tend to become, especially in instances where its operations are located in different areas. Organizations need to understand how to properly allocate resources to specific international locations, how suppliers can be contacted, what are the limits of production on a daily basis and how will each branch location contact each other. It is based on this that the recommended processes which will be explained in the next section integrate information systems so as to facilitate better operational standards and address the various issues that were brought up earlier.

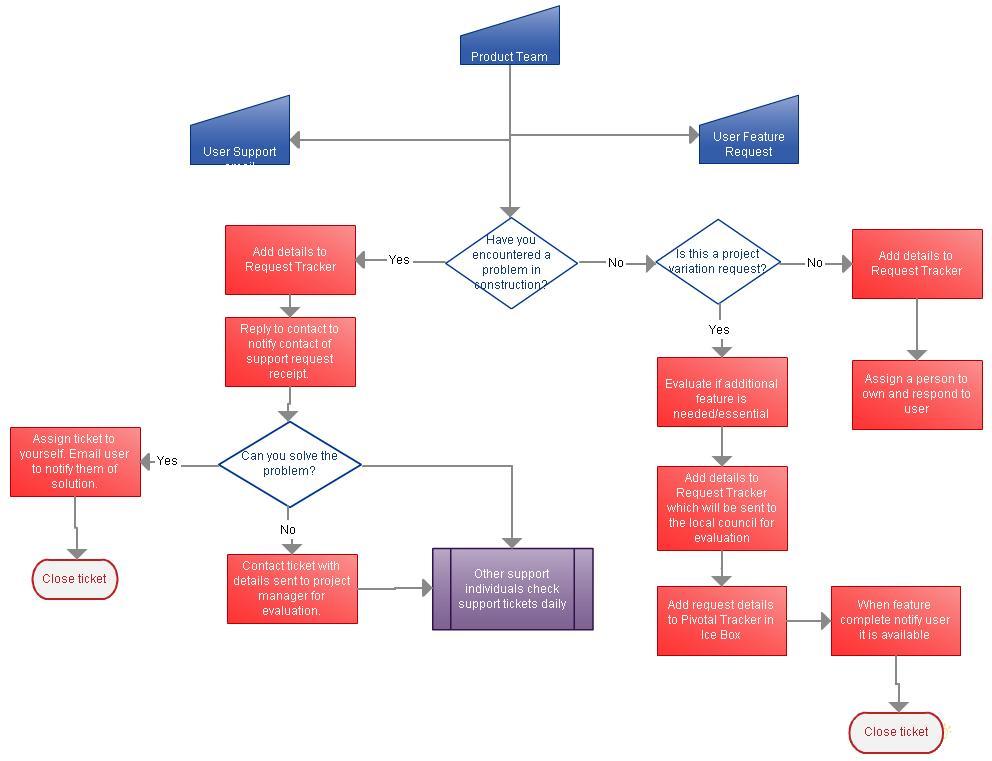

Decision Process Chart

The first flow chart delves into the proposed process to resolve the issues involving process approval for identified variances and modifications to the original project outline. As it can be seen, the process now has a decision matrix that will be incorporated into an internal communication system that will be essential in tracking order requests and creating a proper method of documentation to showcase the reasons behind modifications and additional financing for the project. The first aspect of the decision-making process involves a question regarding issues encountered during the project. This manifests as the question “have you encountered a problem in construction?” This enables the information system to determine whether the issue is construction-related or variance-related in the form of requests to add additional variances to the project itself. Under the construction-related issue, the decision-making process requires the contractor to outline the problems encountered after which it is forwarded to the project manager for evaluation at which point a response will eventually be given directing the contractor towards a particular set of actions. This “ticket” system ensures that all issues that have been encountered throughout the construction process are documented along with the decision that was done in order to resolve it. Doing so, ensures that the project manager is aware of all issues that crop up and will be able to address them.

The second aspect of the decision-making process delves into whether or not a project variation request is being made. If it is a variation request, the decision making process is different wherein instead of forwarding it to the project manager it is instead given to the local council (i.e. the ones who started the Harcourt project in the first place) in order for them to decide on the merits of the proposed changes. By doing so shifts the responsibility from the project manager to the local council and helps to ensure that any proposed changes have full approval and can be effectively incorporated into the budget without any complaints. However, if the proposed variances to the project have been deemed “inappropriate” or not necessary by the local council then the funds needed for its implementation will not be released and the project will go forward as outlined. This decision-making process that incorporates information systems, ensures that proper documentation and acknowledgment is incorporated into every aspect for proposed modifications to the original project plan and ensures that only approved changes are implemented.

Resolving Fund Request through Swim Lane Chart

One of the identified issues in the project was the application of project variances without sufficient explanation or effective prior approval before their implementation. The fact that the documentation process behind the process was faulty showed the necessity of a proper process behind fund release and approval of project variances. This is where the swim lane project process plan comes into effect, it can be considered as a continuation of the earlier decision-making process yet delves deeper into developing a proper method behind documenting the release of funds for the project. First off, the process works by having the project manager examine the context behind the fund request for the plan modification. After it has been examined and various comments have been made, it is then forwarded to the local council that approved the road project in the first place for it to be verified and the request to be examined. If the request is acceptable and in accordance with reasonable modifications, the funds are released via proper documentary procedures after which it is acknowledged by the project manager and then sent to the contractor for verification. Such a process helps to resolve the various issues related to a lack of documentation or a lack of knowledge on the part of the project manager involving finances for additions to the road project.

Provide a rationale for the improvements chosen

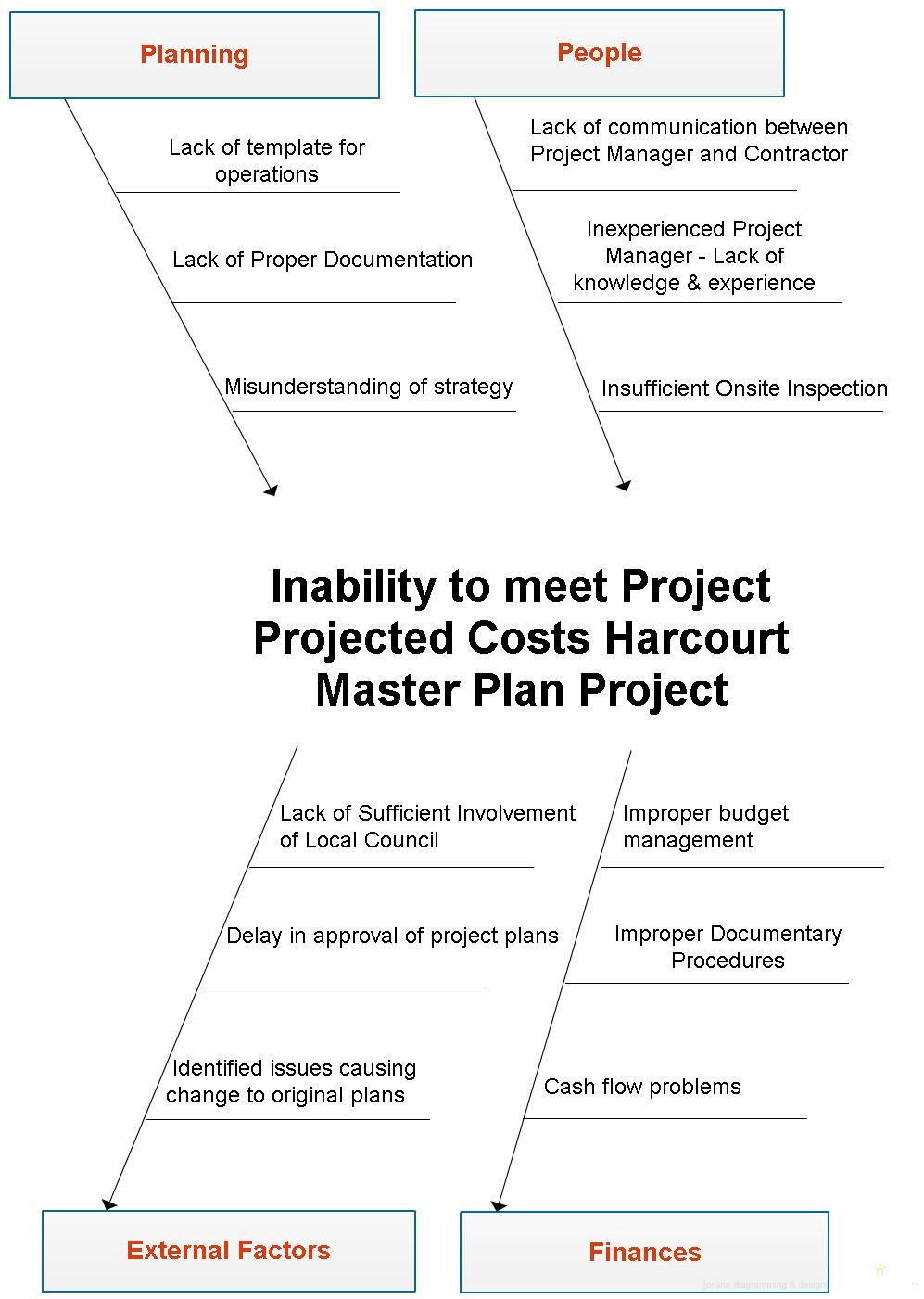

Fishbone Chart of Inability of Project to Meet Projected Costs

The Fishbone chart shown above helps to shed light on the various reasons behind the increased costs associated with the project. Through the analysis, it was revealed that there were insufficient tracking mechanisms in place related to variations that were outside the original scope of the project that was utilized as a means of justifying the increased cost. Combined with the unilateral signing off of increased expenditure for services and materials by the contractors along with the lack of proper documentary procedures when it came to creating a means for approval and recording costs, the end result was the apparent use of services and resources that may have been unneeded by the original project scope which led to the significant cost increase that could have been avoided if proper oversight was implemented in the first place. Taking these factors into consideration, it can be seen that what was necessary to improve the quality of the project in reference to its adherence to its original budget was the necessity of proper communication between the project manager and the contractor, the implementation of documentary procedures involving the execution state of the project, implementation of effective financial oversight by the project manager and lastly, formal authorization through proper documentation involving the necessity of variations to the original contract due to unexpected circumstances.

When comparing the rationale for the improvements chosen with the data from the Fishbone chart, it can be seen that the new operational processes that are advocated help resolve the identified issues. For example, the decision-making process for resolving construction-related issues helps to resolve problems involving proper documentation and inspection by the project manager of the site. Through its integration into an information system, this helps to create a documentary procedure that outlines the decision-making process of the manager and the recommendations of the contractors and helps to showcase the basis behind a decision that was implemented. Not only that, through the decision-making process this helps to resolve issues related to proper financial oversight since it is the local council that oversees proper disbursal of funds and gives the needed authorization for new variances in the project. The Swim lane diagram creates a more “in-depth” perspective regarding the need for authorization and documentation by creating a better process by which funds are released. The diagram shows how the approval process is conducted, how the money is released and the acknowledgment of each party involved regarding either compliance to the original project outline or the implementation of variance based on the recommendations of the contractor. Through the Fishbone diagram, greater levels of oversight and documentation are implemented which helps to limit unnecessary spending and project variance without prior approval. The proposed systems are thus the most effective solution to all the identified issues and help to ensure that the project continues along with its original outline plan.

Briefly describe a process change strategy

One process change strategy that could be implemented would be for individual members of the project team to submit daily documentary reports regarding the progress of the project. This way, this helps to create a documentary trail and helps to ensure that the project is proceeding as planned.

Describe the expected quality outcomes

The expected quality outcome of the proposed process change strategy comes in the form of better oversight involving future road construction projects. This comes in the form of ensuring that the actions of contractors are limited based on the project outline with variances being incorporated only after sufficient evaluation by both the project manager and the local council that brought about the road construction plan in the first place. Other expected quality outcomes come in the form of better documentary procedures wherein changes to the project, site inspections as well as issues related to needed variances to the project are properly documented. This helps to create sufficient justification behind actions that were implemented should an evaluation be conducted regarding the quality of the project.

Conclusion

All projects are subject to a certain lifecycle as indicated by the inherent limitations of the project itself and as such it becomes important to determine whether the team either contributed towards meeting deadline objectives, going over the deadline or even completing the project earlier than expected. Taking all the factors that have been mentioned in this paper into consideration, it can be stated that the definition of quality, when applied to the Harcourt Master plan Project, would have been adherent to the original scheme of the project, implementation of proper process controls to ensure proper documentation and budgeting as well as the use of better methods of communication between the project manager, contractor and committee in charge of the project to ensure that variations to the project would have been discussed and implemented with full knowledge regarding the necessity of the intended changes instead of the unilateral changes that were implemented. Unfortunately, none of these processes were evident which resulted in the issues that came up.

As examined by Xiang, Zhou, Zhou & Ye (2012), construction-based projects need to conform to set resource and time limits from creation to completion. Project teams that expend more resources and time than what is legitimately necessary can thus be categorized as inefficient and negligent since it is their responsibility to ensure that projects are able to stay within set limits (Xiang, Zhou, Zhou & Ye 2012).

Thus, in evaluating a project team on the basis of life cycle achievement it is important to determine whether they sufficiently utilize project management tools as indicated by the article “Selection of Construction Methods for Construction Projects: A Knowledge Problem” which are necessary aspects in ensuring proper project completion. This can come in the form of financial planning tools, timesheets, completed project milestones, daily reports and logistics software which combines all this data in order to determine the current rate of project completion versus the rate at which the project team should have been working (Ferrada, Serpel, & Skibniewski, 2014). By examining the data from such tools it will be easy to evaluate whether the team was able to properly meet and accomplish specific project milestones within a given time frame and if it was able to meet the project deadline that was created during the project planning stage.

Reference List

Arashpour, M, Wakefield, R, Blismas, N, & Lee, E. ‘Analysis of Disruptions Caused by Construction Field Rework on Productivity in Residential Projects’ 2014, Journal Of Construction Engineering & Management, vol. 140, no. 2, p. -1,

Basu, R 2012, Managing Quality in Projects, Ashgate Publishing Ltd, Farnham.

Chou, J, & Yang, J 2012, ‘Project Management Knowledge and Effects on Construction Project Outcomes: An Empirical Study’, Project Management Journal, vol. 43, no. 5, pp. 47-67.

Chou, J, Irawan, N, & Pham, A 2013, ‘Project Management Knowledge of Construction Professionals: Cross-Country Study of Effects on Project Success’, Journal Of Construction Engineering & Management, vol.139, no. 11, p. 1.

Garvin, A. D 1984, ‘What Does “Product Quality” Really Mean?’, Sloan Management Review (pre-1986), vol. 26, no. 1, pp. 25.

Golob, K, Bastič, M, & Pšunder, I 2013, ‘Influence of Project and Marketing Management on Delays, Penalties, and Project Quality in Slovene Organizations in the Construction Industry’, Journal Of Management In Engineering, vol. 29, no. 4, pp. 495-502.

Kelly, N, Edkins, A, Smyth, H, & Konstantinou, E 2013, ‘Reinventing the role of the project manager in mobilizing knowledge in construction’, International Journal Of Managing Projects In Business, vol. 6, no. 4, pp. 654-673.

Puerto, C. L. & Shane S.J. (2013)’Keys to Success in Megaproject Management in Mexico and the United States: Case Study’ , Journal Of Construction Engineering & Management, vol. 140, no. 4, p. 1.

British Standard, Quality Management Systems – Fundamentals and Vocabulary, EN ISO 9000:2000, International Organizational for Standardization, Geneve.

Parasuraman, A, Zeithaml, VA & Berry, LL 1985, ‘A Conceptual Model of Service Quality and Its Implications for Future Research’, Journal of Marketing, vol. 49, no. 4, pp. 41-50.

Gao, T Ergan, S Akinci, B & Garrett, J. 2014, ‘Proactive Productivity Management at Job Sites: Understanding Characteristics of Assumptions Made for Construction Processes during Planning Based on Case Studies and Interviews’, Journal Of Construction Engineering & Management, vol. 140, no. 3, p. 1.

Palacios, J Gonzalez, V & Alarcón, L. 2014, ‘Selection of Third-Party Relationships in Construction’, Journal Of Construction Engineering & Management, vol. 140, no. 4, p. 1.

Ferrada, X, Serpel, A, & Skibniewski, M, ‘Selection of Construction Methods for Construction Projects: A Knowledge Problem’ 2014, Journal Of Construction Engineering & Management, vol. 140, no. 4, p. -1.

Xiang, P, Zhou, J, Zhou, X, & Ye, K 2012, ‘Construction Project Risk Management Based on the View of Asymmetric Information’, Journal Of Construction Engineering & Management, vol. 138, no. 11, pp. 1303-1311.