Need for Clean Energy & Water

- Global Warming.

- Energy Shortages.

- Water Shortages.

- Third World Disease.

One Solution for Several Problems

Binary Fluid Ejector Refrigeration System Designed by May-Ruben Technologies:

- Refrigeration cycle capable to be driven by low grade energy, substituting gas-phase ejector used in conventional mechanical compressor.

- Can run on low grade thermal energy such as solar, waste heat, or geothermal.

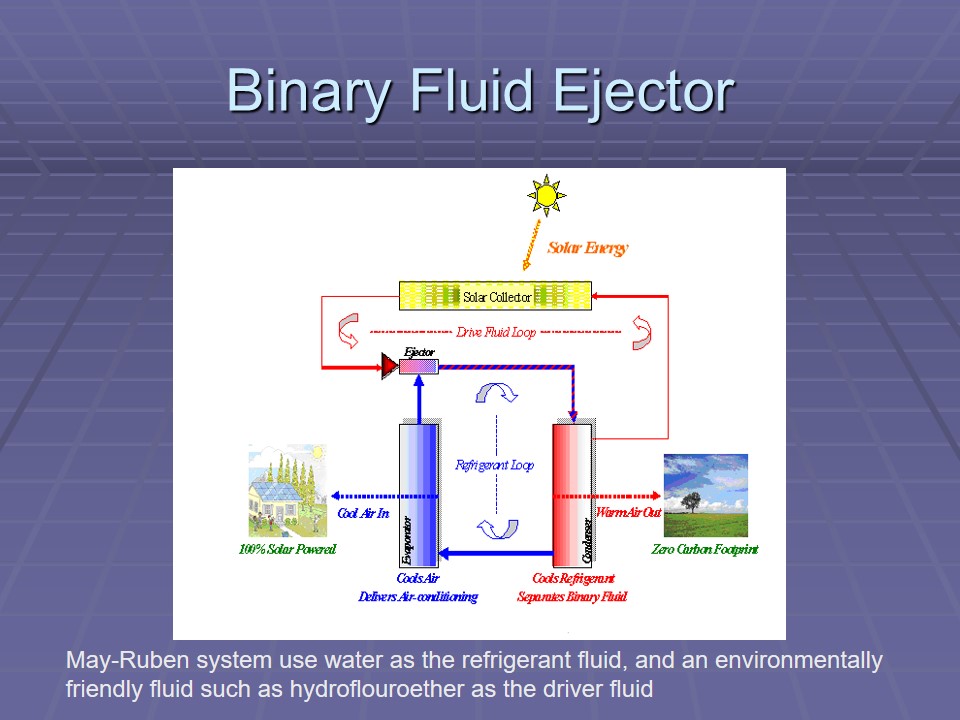

Binary Fluid Ejector

- Unique use of a binary fluid comprised of two different fluid components.

- One optimized to serve as a driver that collects thermal energy and transfers it through compression to the second fluid, which is optimized to serve as a refrigerant in the refrigeration cycle.

- Ejector specially designed and optimized to operate with such a binary fluid.

May-Ruben system use water as the refrigerant fluid, and an environmentally friendly fluid such as hydroflouroether as the driver fluid.

Benefits

- Refrigeration system that can efficiently use a renewable energy source.

- Can be used for freezing goods, cooling buildings, heating buildings, purifying fluids, desalinization of salt water, and generation of water out of the atmosphere.

Energy Saving

- Through the use of solar refrigeration and air conditioning in U.S.

- Solar refrigeration system additionally serve as a heat pump, space heating with solar energy could represent an additional energy savings of 10%.

- Reduction of residential energy usage by about 65% of total current residential electrical demand in U.S.

- Can be expanded to a global level to provide a global opportunity for energy saving.

- Generation of energy occurs at the point of use.

- Switching both commercial and residential air conditioning to solar in the U.S. could result in a 25 – 35% reduction in total peak grid demand.

Global Warming

- Reducing the carbon footprint of energy production.

- Reducing the Impact of Fugitive Refrigerants.

Water shortages

- Reclaiming Tailings Ponds:

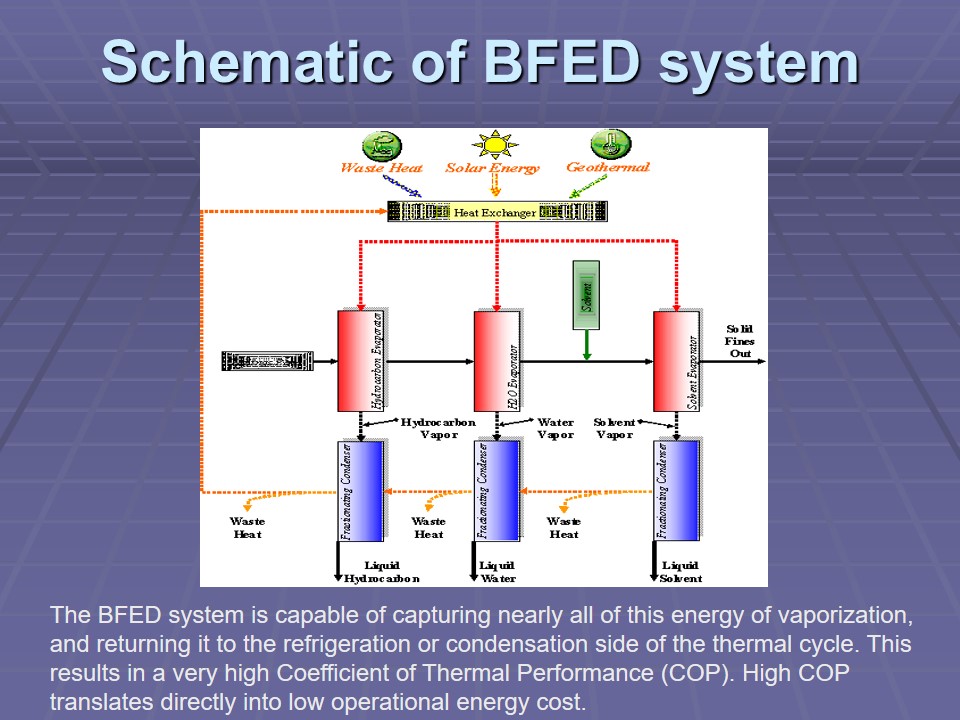

- MRT system design is capable of capturing nearly all of this energy of vaporization, and returning it to the refrigeration or condensation side of the thermal cycle.

- MRT uses an innovative Binary Fluid Ejector Distillation technology (BFED) to accomplish the distillation of water and certain hydrocarbons from oil sand tailings.

- Purifying water from chemically polluted sources:

- A high volume BFE distillation system.

- Desalination:

- BFE distillation system can be used as a desalination unit to provide fresh water from seawater in arid islands and coastal communities.

- Capturing water out of the atmosphere:

- BFE system can be configured and optimized to drive an atmospheric condenser in arid regions.

Third World Disease

- Food Preservation through Ecological refrigeration,

- Interdiction of Malaria through environmentally safe air conditioning,

- Clean Water : BFE system can be configured and optimized to drive an atmospheric condenser.

Economic Feasibility Vs. Technical Feasibility

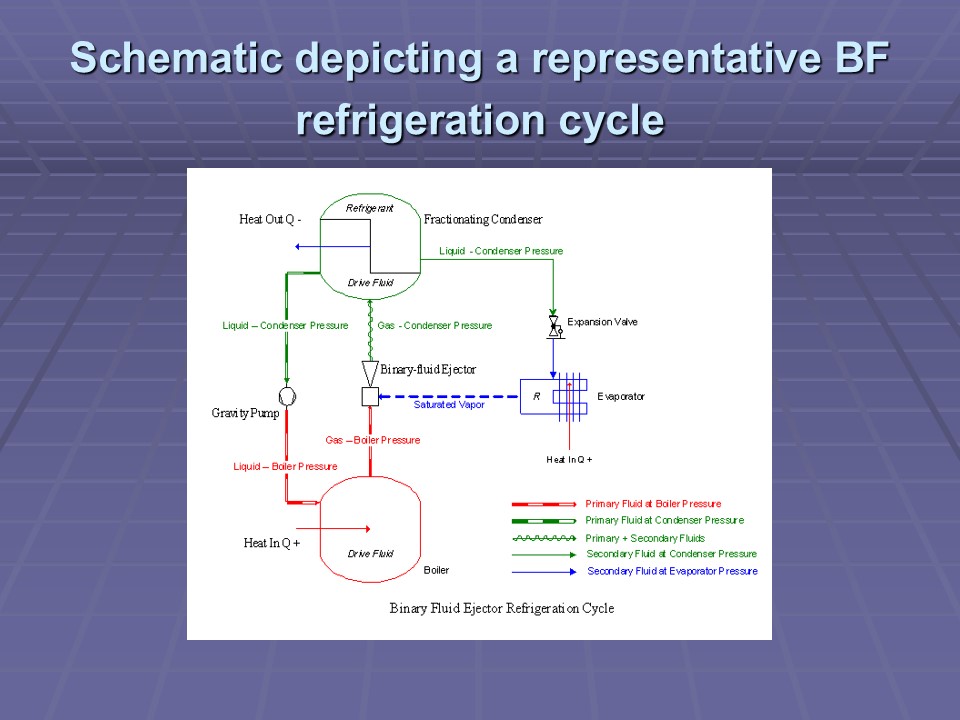

The BFE refrigeration cycle, employs a novel ejector designed to function with a complement of two fluids, as contrasted to traditional ejectors that function with a single fluid. Because of the design and mathematical analysis already performed by MRT, the company has a good degree of confidence that its proprietary BFE system will obtain a coefficient of performance (COP) in the range of 5 to 20.

The economic feasibility of this technology is solely dependent on whether MRT is correct in its assessment that its binary fluid design will generate a COP in the predicted range of 5 to 20. Consultants schooled in fluid dynamics and thermodynamics can assess the technical feasibility and probability of the MRT design achieving this target but only construction and testing of an optimized ejector will confirm the actual COP.

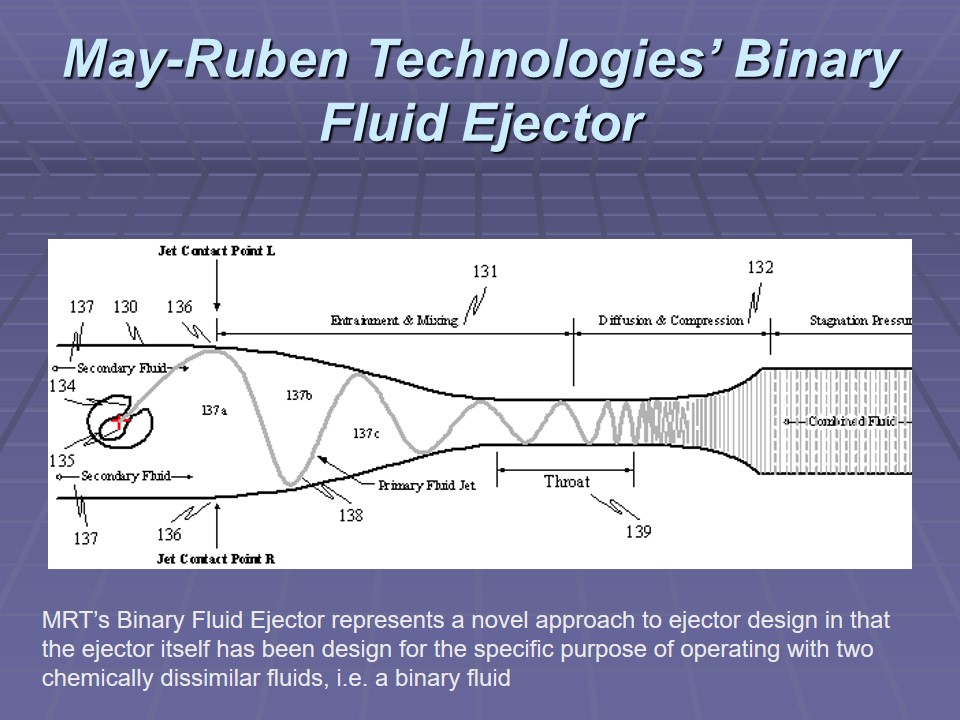

May-Ruben Technologies’ Binary Fluid Ejector

MRT’s Binary Fluid Ejector represents a novel approach to ejector design in that the ejector itself has been design for the specific purpose of operating with two chemically dissimilar fluids, i.e. a binary fluid.

Schematic of BFED system

The BFED system is capable of capturing nearly all of this energy of vaporization, and returning it to the refrigeration or condensation side of the thermal cycle. This results in a very high Coefficient of Thermal Performance (COP). High COP translates directly into low operational energy cost.

Reclamation of the Oil Sands Tailing Ponds

Binary Fluid Ejector will process the tailing ponds by distilling the liquid, capturing and separating it into pure water, oil, and residual solid precipitates. The BFED system will also be capable of capturing and condensing valuable hydrocarbon contaminates that have lower or higher vapor pressure than water.

Modular systems would be employed for the clean-up, then redeployed to other areas that require treatment of polluted water (e.g. these could be used to process the water generated in producing methane gas from coal beds).

In addition to clean-up requirements, sufficient capacity would be also be installed to process the tailings from ongoing operations, creating pure distilled water for re-use in the in-situ steam boilers (which would reduce scaling) or for use as potable water for local communities.

Development Steps for BFE Prototype

- Binary Fluid Assay and Ranking: Survey and identify the best zeotropic drive fluids, in terms of COP and environmental impact, to be paired with water serving as the refrigerant.

- Computation Fluid Dynamic Modeling Develop: a computer model of the gas phase ejector using Computational Fluid Dynamics.

- Ejector Design Computer: simulations of ejector performance can be conducted for a variety of different ejector dimensions. There are several elements of geometry and configuration of the fluid pathways that represent new art and form part of the basis of MRT’s intellectual property (patent disclosure(s) may be shared with interested parties upon request).

- Construction and Testing. Using the data from these simulations, a prototype Binary Fluid Ejector will be designed and fabricated. The prototype will be operated under various operational conditions and with the top two or three binary fluid candidates. Empirical data collected from these tests will be used to refine the analytical CFD model, as well as for making design improvements to the prototype. Fabrication, testing, and evaluation will be conducted by Wayne May of MRT in an in-house facility.

- Preliminary Engineering and Integrated System Design. Once the efficiency of the BFE is determined, it is an engineering design exercise to size and cost the various components of a system configured for a specific BFE application.

Market Development Strategy

- Mass produced appliances for air conditioning and water generation.

- Large Scale Plants:

- Desalinization Plants and Municipal Scale Water Generation Plants.

- Tailings Ponds Reclamation.

Conclusion

- BFE Refrigeration Cycle:

- The system is powered by low-grade thermal energy such as solar insolation or waste heat from internal combustion engines.

- The BFE refrigeration cycle can provide solar powered space cooling for residential, retail, and commercial single story structures. Combined with other existing technologies such as thermal storage and small photovoltaic panels for control voltage, the BFE conditioning system will operate completely off the electrical grid.

- a relatively simple but revolutionary solution to the challenge of using low grade thermal energy efficiently to drive a refrigeration cycle.

- An efficient solar refrigeration cycle to tackle problems such as global warming, energy shortages, and water shortages.

- May-Ruben Technologies has filed a patent disclosure regarding its binary fluid ejector and is currently seeking funding of approximately $2 million to develop a working prototype.