Abstract

It is already past a century since the Los Angeles Department of Water & Power (LADWP) constructed the Los Angeles Aqueduct to reroute the water in Owens River so that it can meet the demands of the rising population. The construction of the LA Aqueduct occurred when people in the region had a utilitarian approach towards the usage of water.

The crucial resource had to be tapped such that it benefited the greatest number of residents. The subsequent sections of this paper will give an in-depth explanation on the location of the First Owens River Los Angeles Aqueduct, the existing culture at the time of its construction, method of construction, and/or how it would be designed if the construction were to be done in the contemporary age.

Introduction

Water has always been a matter that cast doubts among residents of California. The conflict has developed to a norm. The resource has become evidently fickle to the extent that courts are being compelled to deal with several water disputes from anglers, farmers, and cities. Imbalanced climate that is occasioned by torrential rain paves a way for shriveling droughts that heighten tension among people who thirst for water.

As a result, Californians constructed one the greatest hydraulic systems in the globe, namely Owens River, LA Aqueduct, to cater for the needs of the region. This paper is based on this aqueduct. It shows its location, construction, and/or how culture was reflected in the construction process. Besides, the paper reveals how the situation would have been if the construction were to be done today.

Location of the First Owens River, LA Aqueduct

Although the building of the LA aqueduct commenced in 1908, a year after the resident of LA endorsed US$ 23 million bond to be invested in the project, the work is still perceived as a great product of engineering in the contemporary age. This impressive work of engineering begins from Owens River, Inyo County. It runs to the Granada Hills of LA.

It covers a distance of 375 kilometers with a capacity of 13.7 m3. The LA Department of Water and Power was in charge of the building and management of the aqueduct under the leadership of Chief Engineer William Mulholland. Mulholland was assisted with other engineers such as John R. Freeman, Joseph D. Schuyler, J.B. Lippincott, and Fred P. Stearns. The project hired about 4,000 workers who applied advanced technologies such as Caterpillar tractors.

The aqueduct rerouted Owens Rivers through canals and tunnels across the rough topography Mojave Desert as well as the Antelope Valley to San Fernando where it eventually surfaced in November 5 1913. Addressing a crowd of over 40,000 residents, he loudly stated, “There it is; take it!”

This phrase has become popular with reference to the aqueduct. The First Owens River LA Aqueduct could now supplement the scarce water resource from the LA River on which the growing city was depending. At the time of its completion, it was the only major water construction in California. The impressive product of engineering could only be compared to Panama Canal as noted by American Society of Civil Engineers (3).

Culture and Society

The growing demography of LA was exhausting the scarce resource. In the absence of the engineering phenomenon of the section of water and power, the residents’ thirst for water would have killed them. The green topography of Southern Californian would mislead one to forget that it was indeed a semi-desert.

The climate of South California includes a wet period that runs from November to March. The remaining months are characterized by dry seasons. Rain is meager. Summers are dry. During this period, inhabitants are compelled to acclimatize to the dry and harsh weather from June to September.

When Spanish occupied the region earlier in 1769, the city was suffering from a prolonged drought. The famine made life strenuous for the inhabitants whose main income came from agriculture. The tough climate led to a reduction of livestock and poor harvest, which made life unbearable.

The alternative supply of water, LA River was also anecdotal. Beginning from the Woodland Hills, it received supply from several streams along the way until it reached the Glendale Narrows. As it moved towards the ocean, the river developed a loose path close to an open basin. It was susceptible to floods. Subsequently, the Spanish people resided along the banks of the river during the dry season. They used the water to feed the livestock and/or irrigate their farms.

Nonetheless, during the rainy season, they moved to secure zones away from the river to flee from heavy floods. In one particular instance during the winter, torrential rains damaged the banks of the river, thus causing it to flow through the Long Beach unlike its initial spot, Santa Monica.

Despite the harsh climate, the inhabitants had adjusted to their agricultural needs to the available resource. LA River was a sufficient alternative for farmers and ranchers with reference to their crops and cattle respectively. However, the growing population and the urge for economic growth and development in the city triggered a need for a better alternative water resource other than LA River (Mulholland 18).

According to the American Society of Civil Engineers, the population growth was rapid. It had already gone past 175,000 by 1903 (7). It was guaranteed among the city authorities that unpredictable supply of water from LA River could sustain the residents. The only matter that people could doubt was when such a ‘miracle’ was to happen. A year later, it was a reality. LA Water Company was unable to sustain citizens’ demands of water.

Under the leadership of Engineer William Mulholland, the department was forced to begin looking for an alternative water supply option. Earlier, Fred Eaton and the Mayor of Los Angeles had conducted a surveyed the Owens Valley. Mulholland sought assistance concerning how he could devise a means of bringing the water to the dry areas of LA. In his previous expeditions, Eaton had observed that snow dropped into the valley down to the Owens Lake, which was essentially a dead fraction of the Owens River.

He perceived that water was an unutilized resource. He figured out that if the city authorities altered the path of the river, it would be of great benefit to the inhabitants of the dry parts of LA. Furthermore, there was great lava that had tampered with the flow of the river. However, he insisted that an impressive aqueduct could be constructed if the blockade could be removed (Mulholland 22).

The city was redeemed. The water company began designing an aqueduct under the supervision of Mulholland. The design comprised canals, tunnels, and reservoirs. A number of mountains that formed part of the society’s topography had blocked the water. Hence, the aqueduct channels had to be passed through the mountains. Seeking assistance from J.B. Lippincott who was working for the Reclamation Service, the company developed mechanisms on how it could extract water from the Owens Valley.

Since Lippincott had conducted an initial survey of the land, his opinions were of great significance. The company bought huge tracts of land that surrounded the area in which it intended to construct the aqueduct. The society suffered displacement to pave way for the water channel.

In essence, the company bought 98 percent of all individually owned tracts of land along the Eastern Sierra Valley. Financing the project was at the core of its success. LA Department of Water and Power sought the assistance of society to fund the project. The society received this move with both negative and positive reception.

Some farmers and tradesmen opposed the idea. Besides, political dilemmas arose with respect to the construction of the LA Aqueduct. Prominent hydraulic engineers were hired to assess the credibility and feasibility of the plan. Their report was affirmative. Journalists and city authorities conducted public education to inform the citizens of the benefit of the project. It paid. Ultimately, it received a unanimous support from the constituents who agreed to fund the project with US$ 23 million.

The project was successfully completed in five years. However, the aftermath of its completion was both positive and negative. Residents of Owens Valley were adamant to hamper its use through all the available means. Several lawsuits were filed against the city authorities to prevent its usage. When all lawsuits were dismissed, the inhabitants of Owens Valley resorted to other illegitimate means, thus causing the California Water Wars.

Dynamites were thrown into the aqueduct in an effort to damage it. In one particular occasion, dynamite exploded in a siphon to the extent of crushing the surrounding pipes and causing great damage. In another instance, the Owens Valley residents took over the Alabama control gates for more than two days, thus obstructing the performance of the aqueduct. The hostile reactions by these inhabitants continued for a while.

However, the society eventually yielded to the thought that LA needed to grow and develop and that waters from Owens River were of great necessity for the society’s success. Since the attack ceased, LA witnessed no other brutal response to the present age. The aqueduct is now over 100 years old. Los Angeles has grown to become one of the most popular cities in the world with a population of about 10 million constituents.

Construction of the Aqueduct

An aqueduct can be defined as a cross drainage construction that is built to transport water past an obstacle, which may comprise valleys and mountains. Aqueducts have been used for decades to transport public water from distant places. Initially, they only comprised open channels. However, with the advancement in science and technology, they now comprise siphons, tunnels, and reservoirs. The construction of the Los Angeles commenced in 1908 after the funding.

People were informed of the high demand for laborers to do the construction. Many people from disparate nationalities such as Mexico, Serbia, and Bulgaria came with their beddings to the work camps to be recruited for the project.

Nonetheless, the fact that workers were from different nationalities affected the rate of construction. For instance, when war erupted in Balkans countries, due to their loyalty to their state, some of the laborers went back to the homelands to defend their nations, which had a direct negative impact on Mulholland’s project.

The work in the construction site was quite involving since it was done under a harsh weather condition. However, workers demonstrated persistence in the course of the project. The welfare of the workers was at the core of the project leaders who offered them food, haven, and health care.

The Bureau of LA Aqueduct established a health care plan whereby laborers who were in the rank of $40 received $1 plan whilst those who had less salary were awarded 50 cents in addition to their salary.

The plan catered for their surgical, medical, and hospital requirements, although it excluded venereal ailments, injuries that could arise from conflict with other workers, and/or chronic ailments that might have developed prior to joining the working stations.

The head of the medical plan noted that Owens Valley had an extreme weather condition in both summer and winter that affected the laborers’ performance. About 43 workers died out of serious injuries whilst about 1,200 mild injuries were reported (Brown 40).

Hydroelectric power plants were constructed along the aqueduct to supply energy for the machines that were being used for the construction. This power construction was done under the supervision of Ezra F. Scattergood. 14 power plants were erected along the construction site. From the onset of the construction, Caterpillar traction trailers were used in the construction, as they were perceived to be cost-effective, despite their loud noise.

Nevertheless, the cruel weather conditions coupled with dry environment and rough terrain tampered with the performance of the machines. There was a frequent need to repair the machines because of unfavorable environment. This situation turned out to be an expensive affair.

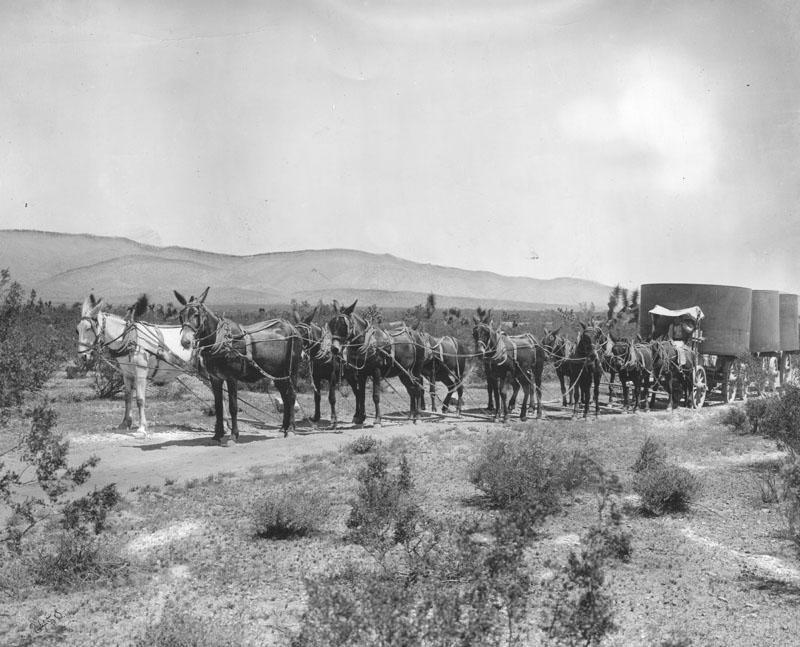

It became apparent that they had to quit using the Caterpillar Company to stick to using mules. Mules were effective even under harsh weather conditions and intolerable environment. About fifty to seventy five mules were used to transport cement from Monolith to the aqueduct construction site.

As the assisting engineer, Lippincott suggested the need to minimize costs and/or improve the pace of construction whilst striving to complete the project. A bonus system was created to motivate workers who were operating in the tunnel. Laborers were paid more if they reached the base footage, a move that triggered a sense of competition as well as morale among them.

Cement processing plant was also established close to the aqueduct construction site to supply cement and hence reduce the cost of purchasing cement from other distant plant processors. The reinforcement was made from a combination of tufa and Portland grout. The combination became stronger with age. Hence, it was the most preferable for the construction (Mulholland 25).

Tunneling was the most involving part of the project, particularly the Elizabeth tunnel. Explosives were used to drill holes through the hard rocks. An estimated five million pounds of powder that was made up of gelatin and ammonia were used during the construction with a few deaths being recorded following serious injuries from the explosives.

Dynamite explosives were never used to create tunnels as they left noxious gases that could affect the health of the tunnel crews. Nonetheless, they were used in exploding other areas outside the tunnel. A dynamite explosion in Clearwater Tunnel caused one of the scariest accidents during the construction.

The dynamite explosion damaged the roof of tunnel to the extent of causing the death of three laborers with four receiving serious injuries. Despite the exhausting and involving nature of drilling tunnels, 142 tunnels were dug to cover about 43 miles, which were accompanied by 70 miles of both channels and large conduits of about 98 miles (Fox 39).

According to Hoffman, the role of the 52-mule team was impressive during the transfer of huge steel casing down to the Jawbone Canyon siphon (32). After being transported by rail from to Jawbone, 26 tons of steel were picked by mule teams. Some of the most skilled mule drivers such as ‘Whistling Dick’ drove the mules.

He transported about 30 tons of steel to working stations across the deserts. However, there was a huge inclination towards concrete instead of steel pipe because transferring steel pipe from the site of manufacture to the job site was an expensive affair. Steel pipes were only used in situations where digging tunnels was impossible because of the rocky topography such as south of Little Lake (Brown 42).

Engineers designed a 12-mile steel siphon, which entailed placing of huge and heavy tons of steel about an inch thick. The best and the most extensive tap is located around the Antelope basin. It entailed the placing of 21,800 feet of steel. Huge and strong concrete masts were used in fortifying the stability of sag pipes because pressure from water that was flowing down the steel would have damaged the stability of the sag pipes.

Furthermore, considering the fact that transporting of the steel was done using the mules along rails, it must have slowed down the rate of construction. Efforts of workers must be put into consideration. They worked for 11 hours on a daily basis, even though temperatures of Mojave Desert increased to 110 degrees. Their hard work that saw them break records such as the construction of the 604 feet Elizabeth tunnel in a month (Fox 41).

In 1913, in San Fernando Valley, Los Angeles’ residents finally came to witness and applaud the impressive work of Mulholland and his team. With Mulholland stating his popular phrase “there it is; take it!”, people witnessed as the water gates were opened. The water raced down to the San Fernando Reservoir.

The impressive engineering stirred the growth of LA. More than 100 years now, it still plays a central role in the supply of water to LA citizens. Adjustments and repairs have been done to the project several times. However, credit has to be given to initial workers who applied technology and/or invested their mental and physical energy in the construction sites (American Society of Civil Engineers 5).

If it was Constructed Today

The First Owens River Los Angeles Aqueduct was indeed an engineering phenomenon to reckon. However, if it were constructed in the contemporary age, many improvements would be witnessed in the drafting of the design and actual construction. Advancement in technology would play the central role in adjusting the initial construction technique such as using modern drilling machines. The construction of aqueducts can be traced back to the Roman Empire that existed as early as 144 BC.

Aqueducts that were constructed during the antiquity generally had open channels passing through flat slopes to increase the impact of gravity. The flow of water was controlled with small gates that prevented the flow of water into the channels. With the advancement in technology and human knowledge, contemporary aqueducts are constructed with not only open conduits, tunnels, siphons, and reservoirs.

They carry clean water over long distances. Besides, they also store water in reservoirs while others take water to treatment plants where it is examined before being supplied to the public. Construction of aqueducts normally involves excavation, which entails drilling holes and blasting them to make wide tunnels (Fox 45).

During the construction of the First Owens River Los Angeles Aqueduct, drilling was not used. However, with advancement in technology, machines such as tunnel boring machine have come in handy. The equipment has tough cutter heads that are steered by high-class gadgets.

Hence, they can drill through tough rocks such as those that are found in the Elizabeth Tunnel. Unlike the case of LA aqueduct, the extraction of tunnel is not done by laborers but by small railroad vehicles that transport materials to the shaft where they can eventually be transported to the surface to be dumped. Boring machines work at a speed of up to 400 feet. It is important that during the excavation, the stability of the tunnels is kept constant by using tools such as rock bolts and steel ribs among others.

Most passageways are positioned using cast-in-place coating to level the exterior and/or avoid permeation. In place of mules, modern means of transports such as tractors and railroads can be used to transport materials to the construction site. Modern transport systems will be faster than mules.

Besides, they cannot be affected by harsh weather conditions. Thus, they can improve the work rate. Furthermore, unlike the case of the First Owens River Los Angeles Aqueduct where laborers were semi-skilled or unskilled, skilled and experienced workforce must be a major requirement prior to being considered a worker for the project (Mulholland 28).

The construction of the Second Aqueduct is a good example of the difference of constructing and aqueduct during in 1908 and in modern age. Development in science and technology minimized the cost of constructing the tunnels and pipes of the second aqueduct. The cost of using pipes was cheaper than the combined cost of building siphons and tunnels.

Indeed, if the First Owens River Los Angeles Aqueduct were to be constructed today, there would be no need to purchase steel and/or construction huge siphons in places where the terrain is rough (American Society of Civil Engineers 5).

Unlike Eaton who conducted a survey in the area around Owens River by actual visiting of the site, the method would be different today. Prior to the construction of the second aqueduct, aerial topographic mapping survey technique would be used. Surveyors would have ample knowledge of the terrain within a short time. Furthermore, the project design was divided among many workers whilst another group was securing rights for using the land in question for the purposes of constructing the aqueduct.

As technology continues to develop, new methods of constructing aqueducts will arise. Nonetheless, even the modern aqueducts have no huge differences when compared to earlier aqueducts such as those in Rome or First Owens River Los Angeles Aqueduct in terms of the nature of their structure. However, different machines have been modified with time (Brown 43). Hence, the time that would be utilized in constructing the aqueduct today would be significantly shorter.

Works Cited

American Society of Civil Engineers. American Society of Civil Engineers – Los Angeles Section: 100 Years of Civil Engineering Excellence 1913- 2013. Indiana, IN: AuthorHouse, 2014. Print.

Brown, Jeff. “Water from a Distance: The First Owens River–Los Angeles Aqueduct.” Civil Engineering 8.34(2013): 40-43. Print.

Fox, William. “Camera Obscura: A photographic history of the LA Aqueduct.” Boom: A Journal of California 3.3(2013): 38-49. Print.

Hoffman, Abraham. “Federal Support of the Los Angeles Aqueduct, 1904-1941.” Journal of the West 51.1(2012): 30-35. Print.

Mulholland, Catherine. Mulholland and the Rise of Los Angeles. England: University of California Press, 2002. Print.