Background of the Company

Established in 1903 by Henry Ford, the Ford Motor Company has expanded its operations into different global locations and consumer markets making it one of the best known brands in the world. Unfortunately, within the U.S., Ford Motors has been experiencing an influx of competition from local and international brands that focus on affordability and gas mileage as their means of competing against ford (Brown, 2006). Evidence of this can be seen in the growing demand in local markets for foreign made cars that are cheaper than locally made cars.

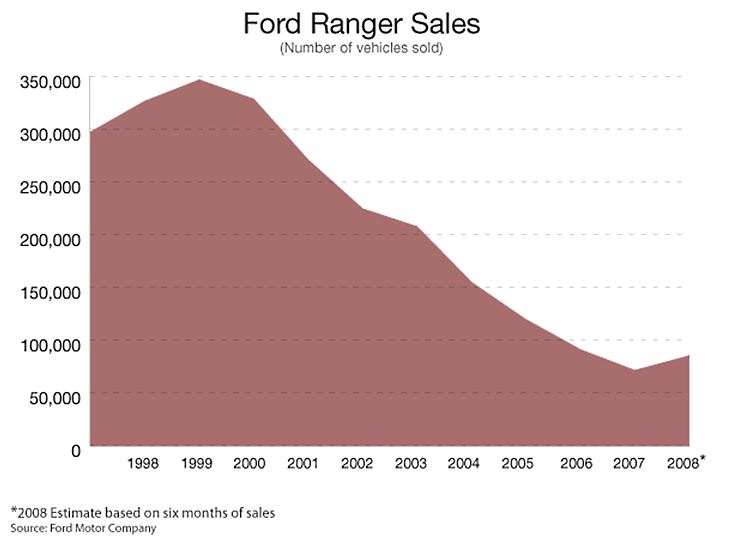

As it can be seen from the graph, Ford Motors has been experiencing a steep decline in the amount of vehicles sold under its ranger brand which is unfortunately endemic in its other brands as well (Hartley, 2008). While car models from Ford always rank the highest in terms of horsepower and appearance; they unfortunately rank the lowest in terms of affordability. It is based on this that the company is currently evaluating its operational infrastructure in order to develop a means of more affordable production while at the same time meeting the stringent quality standards that it holds itself too (Hartley, 2008).

Ford Benefitting from Kelly Services

When examining the case of Ford Motors, it becomes immediately apparent that what the company needs is a considerable degree of operational flexibility in order to meet the shifting demands of present day consumers while at the same time maintain the viability of its operations from a financial standpoint. Basically, the company would need to shift operations “at the drop of a hat” so to speak when it comes to satisfying consumer demand or reducing operations due to ill timed shifts in the market as a direct result of economic instability as seen during the 2008 financial crisis which adversely affected the sales of the company. One possible solution to this apparent need was presented by Tan, Denton, Rae & Chung (2013) who stated that in order for a company to achieve extreme levels of flexibility in its operations, it would need to have a human resources approach that allows it to increase or reduce employees at will depending on what the company needs at an given production quarter. The approach suggested would be to shift its current permanent workforce into one that is on a contractual basis.

The effectiveness of this approach was seen in SM Supermalls which was featured recently on several prominent websites due to errors in the type of message that was being broadcast by one of their products which cast the company in a negative light. Further examination of the company’s operations reveals that it utilizes workers on a 3 to 6 month contractual basis and increases or reduces them as needed. This enables the company to respond to the increased influx of customers during the holiday season by hiring more workers while at the same time allows the company to reduce the amount of employees by not renewing the contracts once the holiday season is over (Weick, 2014).

A similar strategy can also be utilized by Ford Motors in order to increase or reduce its workforce depending on current trends within consumer markets. However, the main issue that they would encounter would be to find the necessary contractual agency that would assist in providing the necessary labour force that the company would need. This is where Kelly Services enters into the picture as the aforementioned contractual agency. As one of the largest temporary staffing agencies within the U.S., Kelly Services can provide the temporary workers that the company would need in order to meet market demand. Not only that, given the nature of Kelly Services, it can also act as a recruiter of sufficiently capable blue collared workers that could stay with the company for extended contracts of a year or more depending on the need of Ford Motors. Lastly, while Kelly Services does not specialize in the training of assembly line workers, some form of training can be implemented which would enable workers to adapt to the working environment that they would be placed into.

Given the level of automation inherent in the production processes of Ford Motors, the combined training of both Kelly Services and Ford Motors within a span of one to two weeks can be considered as sufficient enough to bring an ordinary blue collar worker up to speed as to how a particular machine and process works. Overall, when examining the needs of Ford Motors and the capacity of Kelly Services, it can be stated that the latter would be the best solution to the problems of the former given the present need for flexibility yet affordability in the present day hypercompetitive market of car sales.

Reference List

Brown, S. (2006, July). Down, but not out regional focus. Automotive Manufacturing Solutions, 67-73.

Hartley, T. (2008). More auto industry buyouts will shrink WNY workforce. Business First Of Buffalo, 24(20), 4.

Tan, K., Denton, P., Rae, R., & Chung, L. (2013). Managing lean capabilities through flexible workforce development: a process and framework. ProductionPlanning & Control, 24(12), 1066-1076.

Weick, R. (2014). Businesses and workforce planning learn to be flexible. Grand Rapids Business Journal, 32(19), 13.