Engineering Managers and Organizations

The success of any organization is heavily dependent on its management. The style deployed by managers has a direct effect on the employees. Managers decide the direction of the organization, as they are the decision makers.

Engineering management can be defined as a specific form of administration relevant to engineering due to its distinctive characters and technological nature or way of engineering.

Programmes categorized under engineering management include namely; environmental management, economics, operations research, industrial psychology, finance, quality control, mathematical optimization and modeling, health and safety matters, human resources management among other disciplines.

Managers would be regarded effective if they can only steer their organizations to high performance but also be people oriented. Nevertheless, this does not mean managers or heads of engineering departments should be satisfied with mediocre or typical performance since the resulting company output is what holds the exist and future prosperity of the organization.

Decision Making

Project Managers are frequently required to make decisions regarding project work. These decisions range from choosing among options a path that is likely to result into optimum production. In the case of a large organization, the decision process will be more formal. Wrong decisions in this case would result into far reaching impacts and therefore the need for consultation prior to making a decision.

Problem solving also requires decision making, which involves choosing the best course of action in relation to the perceived challenges. Decisions made are highly dependent on the available information (Buckingham and Coffman 44).

In some cases, the available information may be unrelated to the actual ‘problem. Some information may not be adequate or biased. To make knowledgeable choices one needs the adequate correct information, at the appropriate time.

Dr. Laurence Weed, a professor in the School of Medicine at the University of Vermont came up with “SOAP,” which stands for Subjective information, Objective information, Analysis of the information, and Plan of action. He recommended this principle to all healthcare professionals as a standard decision making process (Ireland 2).

First, Break All the Rules

This is a new approach that relates to how managers select volunteers, train and later evaluate them. It demonstrates the important characteristics of successful managers in their work places. This way of selecting condemns the conventional “H Extension educators and other Extension educators and calls for managers to rethink on how to manage their volunteers” (Ireland 2).

First, break all the rules, as a principle emerged from a study completed by Gallup Organization, which involved an interview of company managers and employees.

The approach provides principles that are easily adaptable to various systems especially in the private sector where performance is fundamental. For instance, the methodology can help improve delivery of services in extension and the evaluation of volunteers in extension

Training, it is believed improves workers’ performance. More often than not, people strive to improve on their performance by putting in long hours of training and eventually they reap the benefits.

Skill and Talent

According to Coffman and Buckingham, successful managers differentiate between talent and skills or experience. Studies show that the most successful business managers have disputed this notion of skill and talent. They define talent as “a recurring pattern of thought, feeling, or behavior that can be productively applied” (Ireland 3).

The Gallup study found out that some administrators or managers think that human beings will never surmount weak spots in talents. For instance, if they do not have the talent for accounting, example, they will never be great accountants.

This is attributed to the fact that every human being is exceptional in each individual’s way and he/she will always be true or right to themselves and their inimitable surroundings.

The authors continue to assert that “People don’t change that much. So do not fool around attempting to install what not put there initially and instead, seek to utilize what the person may still be having, that is hard enough” (Buckingham and Coffman 45).

The authors also conclude that, great managers are not explicitly concerned with a potential employee’s skills. As an alternative, managers when screening or interviewing a prospective member of staff would direct the discussion in favor of the abilities and skills essential for the prospective employee to be victorious in the position they will hold if successful.

A great manager should be able to tell the kind of talent required for a given job. For that reason, it emerges that the interview or interrogation ought to be designed or structured in a such a manner that it draws out the sort of answers upon which the interviewing panel would be in a position establish whether the potential staff’s skills or talents are in accordance with job profile they will assume or not prior to making decision.

The Goal

Every organization has well defined goals that act as a guideline to its operations. The success of the company will be determined by the level at which the goals are achieved. For instance, a company’s goal may be a process of manufacturing a product.

Goal achievement is accompanied by ongoing improvement. This includes the engineering and production process, marketing, sales, and interaction with corporate and regional headquarters.

Business model advanced by Goldratt is based on two principles. The first principle describes three ways, which can be used to assess whether or not company is achieving the goal of making profits. The degree of achieving a goal may be evaluated at three levels.

First, throughput, or “the rate at which the company generates income through sales” (Goldratt and Cox 61),inventory-this refers the sum total of the money that system has invested in purchasing assets which it intends to sell, and “operational cost-all the money the company spends in order to transform inventory into throughput” (Ireland 4; Goldratt and Cox 62).

The three levels help in determining if the manager’s decisions actually help the company to achieve their goals. The goal of a company, such as manufacturing plant is to make. This is demonstrated by increasing throughput and decreasing inventory and operational costs.

“Goldratt’s model’s second principle shows a correlation of dependent events and statistical fluctuations to the manufacturing process” (Goldratt and Cox 66).

Dependent events refer to events that must be undertaken before other ones can get underway a car assembly is a good example of this. A frame has to be finished before the engine is put into the car. Additional, a navigation column must be installed in the right place prior to installing navigation wheel.

Statistical fluctuations exist where one cannot accurately predict to precisely predict events or quantities (Goldratt and Cox 66).Goldratt argues that managers should refrain from offering incentives for good performance, economic order quantities (EOQ) should discarded, and that the costs of productivity and product cost are often not what they seem (Buckingham and Coffman 47).

Kaizen Revolution

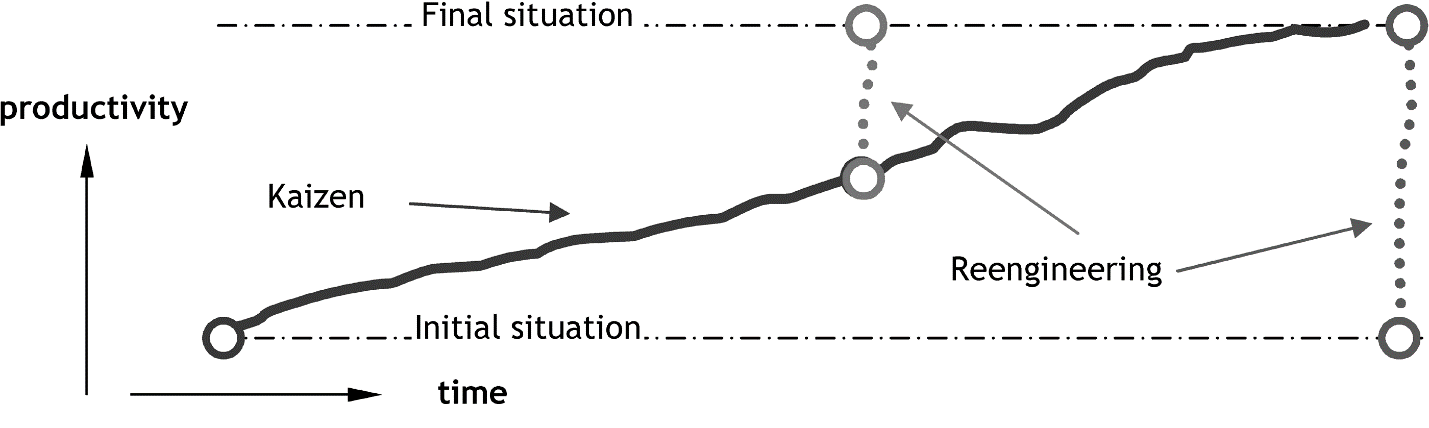

The concept refers to Continuous improvement as a management philosophy based on employees’ suggestions. In production systems, evolutionary as well as revolutionary change is enhanced through innovation of product and process innovations.

The evolution consists of continuous improvements being made in both the product and the process. In order to improve (quality, cost, and time) production activities i.e. quality, cost and time, it is essential to clearly understand the source of the company’s problem.

However, in order to find the factory’s problem, it is important to define and internalize the genesis and core of the problem. It is important to consider variability in terms of quality and productivity (Regan and Slattery 30).

In case of a deviation from the standard value of a variable such as quality and production rate is likely to result into serious problems. Understanding of the variable objective (recommended standard) is also necessary. It is also important to be aware of the present situation, which would provide a guideline in proposing a realistic objective.

Managers are said to fear three-production factors i.e. poor quality; an increase in production cost; and an increase in lead time. Such factors demonstrate poor production management. In order to correct the problem, there is need to improve processes and operations.

The figure below shows how the elements in which within the production area in which problems can appear

Evaluating Volunteers

The way of gauging execution of tasks illustrated in “First, Break All the Rules” standard can be employed in gauging task execution. Administrators who are determined to be victorious in what they are doing may have their members of staff respond the following queries:

- Am I aware of what is required of me? ( appositive response to this question would indicate that the employees understand their goal and how it is measured, while a negative answer would mean lack of understanding of objectives

- Do I have the right tools and equipment required for the job?

- Does the working environment provide me an opportunity to do what I do well always?

- How often do I receive praise or recognition for outstanding performance?

- Does my boss seem concerned about me?

- Do I receive any encouragement from people at work?

- Are my opinions taken into account?

- Does the nature of my work offer a chance to study and develop?

- Are my co-workers determined to do excellent work?

- Does my boss ever talk to me about progress?

A high score to the above questions is the goal of a great manager. A lower score would be an indication of a breakdown or a looming trouble. According to Regan and Slattery (31), this will be shown in recurrent non-attendance, higher member of staff turnover, plus poorer output.

Great managers should also ask themselves how their volunteers would answer the questions: Do they have a feeling of belonging? Do these volunteers think they are creating any noteworthy input to your company, in the quest to attain your company’s mission statement? Are their opinions or suggestions given attention, supported, or adapted?

In using performance measurement to evaluate employees, “First, Break All the Rules” has great benefits. It will present precise and dependable figures or information, which can be availed to those vested with duties of giving verdicts to sustain a suggestion for supplementary or continuous financial support to maintain a project.

Conclusion

Engineers have at most times been labeled as being disconnected with the real world, forcing difficult or impossible things to happen. An understanding of engineering management would provide a breakthrough into the difficulties of making the products engineers design.

This knowledge will enable engineers and managers to be of great value to their companies. Understanding of constraints and objectives of the entire company is critical.

Works Cited

Buckingham, Marcus and Coffman, Curt. First, break all the rules: What the world’s greatest managers do differently. New York, NY: Simon & Schuster Publishers, 1999.

Goldratt, Eliyahu, and Cox, Jeff. The goal: A process of ongoing improvement. Great Barrington, MA: North River Press, 2004.

Ireland, Lew. “Decisions, decisions, decisions: Project manager’s dilemma”. The American Society for the advancement of project management, 39 (2009):1-20.

Regan, Michael and Slattery, Mark. The kaizen revolution: How to use kaizen events to double your profits. Raleigh, NC: Holden Press, 2000.