A refinery is defined as a factory where crude oil is converted into usable products that are relevant to the market requirements. These factories are set up to produce the required products in the most economical and efficient possible ways. When heated, the light hydrocarbons boil first into vapour while the heavier hydrocarbons boil off last (Beychok, 1967). The vapour is then collected and cooled back to its liquid form by use of fractionating columns. Crude oil can be thermally cracked if the temperature used to heat it exceeds the recommended 350°C (Beychok, 1967). That is why it is important to keep the temperatures used in heating crude oil closely under surveillance to avoid such incidents.

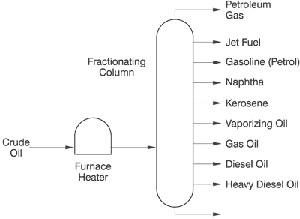

To recover more distillate products, crude oil refineries use the atmospheric distillation process commonly known as the Long Residue. This involves a further distillation process that is done in low pressure but with a very high temperature than the initial process (Beychok, 1967). While trays are used in fractionating columns to cool the vapour, in atmospheric distillation the trays are replaced with packed beds (Kraus, 2011). Packed beds are efficient in cooling the low-pressure vapour. Kraus (2011) asserts that refineries that specialize in the atmospheric distillation are said to be concerned with The Straight Run distillation procedure which is classified into either short or long run residue. However, it is important to note that the amount of products produced from the atmospheric distillation process is not always proportional to the demand of the products rather it depends on the amount of crude oil (Kraus, 2011). Below is an illustration showing a simple straight run refinery process (Beychok, 1967).

The mounting demand for other by-products of crude oil has led to an increase in the reduced utilization of crude oil. These products include lubricants, waxes, greases, and asphalt (Beychok, 1967). The demand for these products has increased globally forcing refineries to venture into the reduced utilization of crude oil in the pursuit of full maximization of production and sales. Lubricants and greases are very important in the day to day functioning of machines and nearly every other appliance. Their functions are to reduce friction between rubbing parts of metallic materials hence reducing wear and tear (Leffler, 1985). The long residue process is influenced by the rising demand in products that have the property of reducing friction in the machinery industry. This property is generally acknowledged as lubricity and is the fundamental attribute of lubricants (Leffler, 1985).

Greases and lubricants form the most important by-products in oil refining. Depending on the amount of crude oil, other by-products can also be refined. They include petroleum wax, bitumen, liquid petroleum gas, asphalt, greases, and industrial naphtha are produced (Henry, 1992). In the atmospheric distillation where lubricants are the main products, crude oil is passed through the atmospheric distillation unit after heating and desalting (Frank & Fleig, 2005). The purpose of this process is mainly to separate the hydrocarbons required which include fuel gases, kerosene, diesel, asphalt, greases LPG, and fuel oils (Frank & Fleig, 2005). Just like in the fractional distillation, the heavier residue is deposited at the bottom of the distillation unit and collected into a vacuum distillation column for further separation but at this stage, the temperature is reduced. Nonetheless, the pressure is always in a reducing trend hence achieving the lowest pressure at the bottom of the column (Beychok, 1967).

While the pressure is low at the bottom of the column, the temperature on the other hand is high (Beychok, 1967). The bottom of the column is constantly heated to maintain the temperatures at an optimum level. Temperatures at the top of the column are the lowest and here the vapour form of condensed hydrocarbons is recycled back to the column (Beychok, 1967). In this process, a pressure gradient is critical. This is achieved by the variation of pressure at the bottom and the top of the column. The heavy hydrocarbons get out of the column through the bottom channels while the lightest hydrocarbons are taken out through the overhead channels (Hargreaves, 2007).

The separation of crude oil into its various forms is done in two stages and with each stage having different boiling points. The different ranges of boiling points are called fractions or cuts. The distillation process involves changing the size and structure of the hydrocarbon molecules (Hargreaves, 2007). This process utilizes one of the four decomposing conversion processes unification, alteration, and treatment (Hargreaves, 2007). The decomposition process involves dividing the molecule through thermal and catalytic cracking while unification involves polymerization and alkylation (Beychok, 1967). The conversion process can be hampered by the presence of impurities and other non-hydrocarbons. Refineries have been using different ways of treating the crude oil to remove such impurities and this treatment can be either chemically or physically induced (Beychok, 1967).

Lubricating oils have several uses in several industries. Transformers and spindle oils are greatly used in the power industry. The motor industry is a major consumer of over 30% of the entire production of lubricants. In heavy machine industry, machine and compressor oils as well as oils for turbines and hydraulics are crucial for efficiency. Lubricants are also used in cable insulation as well as being used as heat transfer oils (Kraus, 2011). Lubricants can also be used as rust resistance agents on metallic equipment.

This research has taken an in-depth approach in discussing the background information about long residue processing in refineries. The paper has critically analyzed the processes involved in the distillation and separation of hydrocarbons in crude oil. The paper has outlined the process involved in the atmospheric distillation and has shown how the various processes take place. As noted in the paper, crude refinery factories are shifting from the fuel-based refinery process to the residue process refinery. This is caused by the rising demand for other petroleum products such as asphalt and greases in the currently industrialized world.

Other by-products of crude oil apart from fuel are very crucial in the world today. The paper has clearly defined lubricants as one of the most market viable alternative by-products of crude oil. As discussed in the paper, the uses of lubricants and other by-products are rising in demand creating the friendly market need for their production. In addition to the rise in demand for such products, refineries are finding the shift to be much cheaper and more yielding compared to other products of crude oil such as motor fuels and kerosene. The paper has offered an insightful background to show the residue processing in refineries.

References

Beychok, M., R. (1967). Aqueous Wastes from Petroleum and Petrochemical Plants. New York, NY: John Wiley & SonsKister.

Frank, W.A., & Fleig, A. (2005). Oil Empire: Visions of Prosperity in Austrian Galicia. United States, US: Harvard University Press.

Hargreaves, S. (2007).CNNMoney.com staff writer. Behind high gas prices: The refinery crunch. Web.

Henry Z. (1992). Distillation Design. New York, NY: McGraw-Hill. Web.

Kraus, R., S. (2011). Petroleum Refining Process. Web.

Leffler, W., L. (1985). Petroleum refining for the nontechnical person. New York, NY: PennWell Books.