Executive Summary

Driving value through procurement and supply is the aim of every firm that has mastered the market forces. Such firms know that quality of the products they deliver to their customers and the price they shall charge all depend on their procurement strategies. As such, it is important to develop techniques that can be used in acquiring raw materials to improve the benefit, especially when the implementation is to be done in the future. According to this paper, negotiation is one of the very critical aspects of procurement. The procurement department must be able to negotiate high value for the firm using a win-win strategy. The aim should always be to get the best value when sourcing raw materials. As shown in this paper, having a strong relationship with suppliers is as important as getting great value from them. The management should know the inclusions that should be made in the contract and measures that should be taken to ensure that changes in the market forces do not affect the agreements made in the contract. Effective management of the supply chain can help reduce the cost of production and in increasing value for the customers.

Introduction

In the current competitive business environment, the success of a firm is partly determined by the strategies it uses in managing procurement and supply chains. One of the ways of ensuring that a firm gets the best value in its procurement and supply chain is to use effective negotiation strategies. O’Brien defines negotiation as “a process in which two or more people with differing views, reach agreement by the use of different methods of persuasion” (67). A negotiation process can only be considered a success if the two parties reach an agreement. Not all negotiations often end up in an agreement. However, if the parties can agree on the contentious issues involved, then the process is considered completed. According to Turner, acquiring raw materials from suppliers is a process that requires negotiation (41). While the supplier may try to get as much profit from the supplies as possible, the buyer would want to purchase the products at the least possible price. These conflicting views must be addressed to make the two parties sign a contract acceptable to both of them. The management must ensure that the firm gets the needed materials within the right time and in the right quantity. In this paper, the researcher seeks to create a sourcing plan for future requirements for a mid-sized firm, which in this study will be referred to as ABC Company.

Roles of Procurement and Supply in Managing This Area of Expenditure

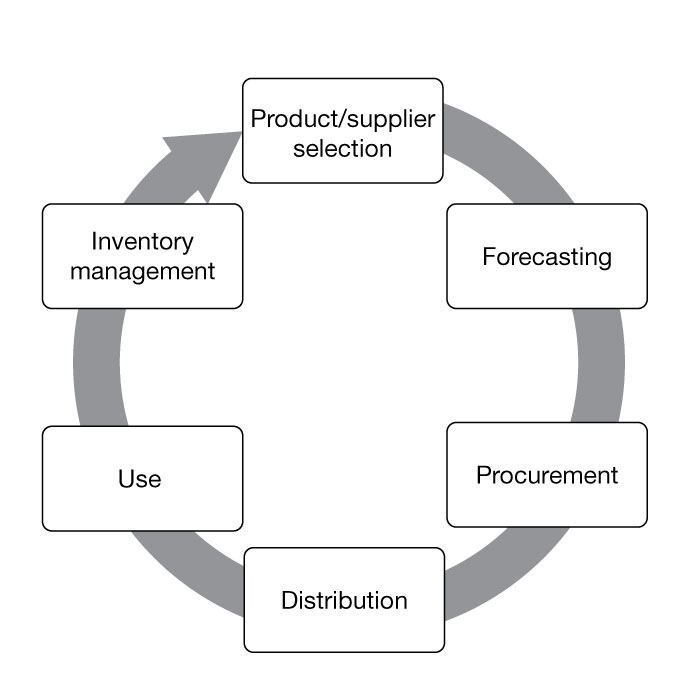

Acquiring raw materials is one of the most important stages in value chain management. According to Guth, the approach used in acquiring the raw materials often defines the cost and quality of the final product (38). Managing expenditures when acquiring these materials is, therefore, of great importance. It is for this reason that it is necessary to evaluate the roles of procurement and supply in managing this area of expenditure. O’Brien defines procurement and supply as “an area of management that involves buying of goods and services to enable a firm to operate” (81). It entails sourcing raw materials from various parts of the world and making them available for production. The following figure shows the stages that should be taken into consideration by the management of ABC Company when sourcing raw materials.

The process starts with need identification. In this case, it is understood that the need will arise in the future, but there is a need to make plans on how these future needs will be met. As such, the whole process should begin with a selection process. When making the plans for future requirements, the management of ABC Company must understand that it is important to select an organization that is most qualified in delivering the best value in the market. Several factors should be taken into consideration in this selection process. The first factor is how well a supplier can provide the needed product. It means that a firm will have to conduct a review of the current suppliers to ensure that they can deliver the raw materials of the highest quality.

As Guth notes, the procurement officers may need to go beyond the brand when evaluating the suppliers (74). Decisions should be made based on the quality offered, not the popularity of the brand. The second factor is the sustainability of the operations of the supplier. As stated, the planning at this stage is for the future, not current needs. As such, the firm to be selected must be in existence in the future when its services shall be needed. It is not possible to be completely certain about the future existence of the suppliers. However, their past and present records can help determine chances that they may still be available in the future to offer the needed products. Issues such as the ability of the supplier to provide the needed quantity should also be taken into consideration when selecting the supplier. At this stage, procurement and supply will help the firm to identify the most qualified supplier that will offer the best value at the least possible cost.

The next stage involves forecasting. According to Weele, when making sourcing plans for future requirements, various stakeholders should help in forecasting to ensure that a correct decision is made in the entire procurement and supply cycle (29). The market forces keep on changing and prices of the products and supplies keep on fluctuating based on these forces. It is always in the interest of a firm to ensure that its prices on the products offered to the customers remain as stable as possible. The stability of products’ prices helps in eliminating negative reactions among clients and helps fight the perception that they are being exploited. Various stakeholders will be responsible for the forecasting process. The marketing manager and the entire team in the marketing department at ABC Company will need to help predict the future relevance of a product and possible reduction or increase in its price. The product may be irrelevant soon based on the changing tastes and preferences. If that is the case, it may not be necessary to set huge resources for the product when making the plan because it has no future.

Information is critical in the decision-making process in the procurement and supply cycle. The procurement manager and his or her entire team at ABC Company will also have to be involved in the forecasting process. This team will help in determining the future availability of the needed raw materials. They will help determine if the material will be available in the future or not so that a decision can be made early enough to avoid shortages and cut down costs of procurement. The team can also help in determining whether the price of the raw materials may go up or not. When it is established that the price of these materials may drastically increase in the future, then it may be in the interest of the firm to purchase the items early enough as long as they can last long enough to be used when the time comes. The finance officer, the insurance manager, and other senior managers are other important stakeholders who should also be involved in the forecasting process to ensure that the decision made is acceptable to all the stakeholders.

When the forecasting has been made, the next step is procurement. As stated in the stage above of forecasting, the most important decision that the top managers at ABC Company will make is either to purchase the item today and keep it for future use or wait and make the purchase in the future. If the decision is made that the purchase will be made in the future, then planning shall end at that stage. However, if it is considered that it is necessary to proceed with the process, then the team may need to proceed and acquire the needed raw materials. In most cases, such a decision is made when it is determined that the items needed may be more expensive or scarce in the future in a way that their demand will outweigh the supply. The team will need to ensure that they get the best products from the suppliers at the best price possible.

After acquiring the products, the team will need to distribute and store them for future use. O’Brien says that it is always in the interest of a firm to ensure that raw materials spend the least possible time in the warehouse (110). This is so because the longer they spend in the warehouses, the more they become costly to manage. Breakage and pilferage are some of the factors that inflate the cost of these materials when they are in the warehouse. Some products may become stale when kept for a long time in the warehouses. The decision to make early purchases can only be made if it becomes apparent that the overall cost of warehousing the products is less than if the products were to be purchased in the future.

The used inventory management is the final stage in this cycle. At this stage of planning, the team can only make suggestions on how the process should be conducted, but as Weele observes, futuristic changes may require changes in the plan in line with the prevailing environmental forces (45). The most appropriate action at this stage will be to let the team involved to decide when the time comes, whether it will be necessary to change the current pattern of inventory management or not based on the realities that they will be facing in the future. It is, therefore, very clear that procurement and supply will provide the team with a clear pattern on how to behave to ensure that the best outcome is achieved when creating a sourcing plan for future requirements.

Techniques That Can Be Applied to Improve Added Value

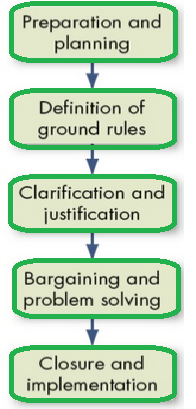

Driving value through procurement and supply is the primary aim of this plan. The aim is to ensure that this firm can meet its future needs in the best way possible and use the least resources. For this to happen, the team involved must have proper negotiation skills that will give it an advantage and ensure that it signs a contract that is beneficial to it. The team should start by first understanding the stages involved in the negotiation process. The figure below shows the fundamental stages of negotiation.

As shown in the above figure, it all starts with preparation and planning. In this context, the firm will need to plan how it will negotiate with the suppliers that will offer it the needed materials. The team responsible for procurement should clearly understand the power of suppliers. The next step is to define the ground rules. At this stage, the two teams come together and set the rules and regulations that shall govern the negotiation process. Fairness is very important at this stage. Both teams must uphold integrity to ensure that they can develop trust with each other. Neither the supplier nor this firm should feel that the rules are set to purpose outmuscle them.

After setting the rules, the next stage will be clarification and justification. Each of the parties involved in the procurement process will be offered the opportunity to present the arguments and the terms they feel are fair. Value creation for this firm starts at this point. As Weele suggests, the team assigned this role should give a passionate and articulate definition of the need to sign the contract at given terms and conditions (87). The justification should not be seen to be self-centered because that may bring an intense argument. The team must be very convincing and the other party should feel that its interest has been taken into consideration. The next stage of bargaining and problem solving is very critical. The two parties will be making counterarguments to ensure that the final decision is as favorable to them as possible. The procurement officers at ABC Company should be keen on ensuring that through such negotiations, this company gets the best value in terms of price, quality, and quantity of the raw materials. Sometimes the negotiation may ground to a halt if the parties do not employ proper strategies that will be acceptable. Using Kilmann’s conflict-handling styles, the team responsible for the negotiation for this firm can choose any of the five options. The chosen option should be that which offers improved added value. The figure below shows the model.

Based on the importance of the relationship between the firm and the supplier, and the significance of the outcome, the team can choose any of the five options shown in the model above. The best option is often the collaboration approach. This is a deliberate attempt by the two parties to ensure that they both come out winners in the negotiation process. The firm can convince the supplier to collaborate with it and benefit from its success in the market. Sometimes one or both parties may consider collaboration as an impossible option given the prevailing circumstances. If that is the case, then the next best option would be compromising. Each of the two parties will appreciate the need to make some concessions to reach a common ground. Although the parties will not get what they exactly expected, they will come out with something valuable from the final deal that shall be made.

Under these conditions, this firm will be accepting to lose just for the sake of making the process a success. It will be making an agreement knowing very well that the supplier has come out as the winner of the process. Although it is undesirable, this strategy may be necessary in cases where the supplier has very high negotiating power and the materials it offers are not easily available in the market. In case the firm has other suppliers that can offer the same materials at better terms, then competing may be considered an appropriate option. It means that the firm will force the supplier to stick to its terms and conditions. The supplier will be offered the option of either taking the deal offered or cancellation of the entire process. The fifth option, which is the least desirable one, occurs when the negotiation is grounded. It takes place when both teams agree that the outcome of the negotiation is very important to them, but fails to agree on the terms and conditions of the deal. The team must understand that such a situation may occur, but the problem is that it does not earn the firm the much-needed value.

Inclusions That Should Be Made In Contracts Formed In The Future

Developing contracts is one of the most complex processes that require a deep understanding of the law of contracts and the reasons why a firm needs to make a commitment to another firm. In most cases, a contract often has four essential components, which include an offer, acceptance, consideration, and intentions to create legal relations. If the contract is to be executed soon after an agreement is made, then both parties will look at the present market forces and make sure that they get the best deal. They will look at the offer made and if they feel the other party is not fair in their offer, they can make a counter-offer. The process may continue until such a time that the parties reach an agreement. However, there are other cases where the parties are forced to look beyond the current market forces. Engaging in contracts formed in the future is a very complex process because market forces may drastically change and what seems to be very fair today may be unreasonably unfair in the future. Cases where the cost of the raw materials increases or decreases by as much as 25% have been witnessed in the past.

Futuristic contracts must have additional clauses that clearly stipulate how both parties should address these changes that may occur. In the spirit of utmost good faith, both parties entering into a contract agree that they intend to ensure that neither of them will be subjected to unfair conditions during the period of engagement. After signing the contract, the procurement officers at ABC Company must understand that it will be legally required to abide by the set conditions irrespective of the future market forces. As such, it is very important to make some inclusions in the contract that will primarily protect both parties in cases of environmental changes. The following are very important clauses that should be included in any contract that is expected to be executed in the future.

Indemnity Clause

The indemnity clause is one of the most important inclusions that must be clearly stipulated in a contract formed in the future. As explained above, the parties may not be absolutely sure which of them may be favored by futuristic forces. Sometimes it may be the supplier and in other cases, it may be the buyer. As such, the two parties must agree that they are committed to compensating either of them in case the future forces are not favorable to them. The indemnity clause is primarily meant to ensure that the relationship between the buyer and supplier remains fair as a way of protecting the relationship. According to Guth, the inclusion of an indemnity clause eliminates cases where one party may consider violating the terms of the contract because of the inability to execute it as per the terms specified in the past (78).

Limitations of Liability Clause

The parties involved in the contract must also state the limitation of liabilities among them based on their agreement. For instance, it may be agreed that it is the supplier that will be responsible for the transportation of the raw materials to the supplier’s premises. In the transportation process, it is possible that unexpected events may occur that may cause damage to the products. Terror attacks, piracy, arson, or natural disasters are some of the events that may affect goods while on transit. The two parties must agree on the issue of liability in case such events occur. They may jointly consider paying for an insurance cover for the period that the goods will be on transit to ensure that the liability is transferred from them to the insurance company. Lack of this clause in the contract may lead to conflicts between the parties that may affect their future relationship.

Dispute Resolution Clause

It is common for the parties in a contract to have disagreements on a number of issues, especially in contracts formed in the future. Sometimes one party may realize that the agreements made are unfair in one way or the other. In other cases, one party may feel betrayed by the other party. Whatever the case may be, once a dispute arises both parties must have a mechanism of resolving it. When signing the contract, both parties must come up with a mutually agreeable way of resolving conflicts. In most cases, the two parties may choose re-negotiation, arbitration, or mediation as the basic means of resolving the conflict. It is only when these options fail that they may consider litigation as the last resort of resolving their conflict.

Warranties Clause

When purchasing the raw materials, both parties must appreciate that mistakes may occur. Sometimes the mistake may be made by the supplier in terms of providing defective raw materials. As Guth observes, mistakes often occur even in situations where maximum care is taken to eliminate them (88). As such, it becomes necessary to have a warranty clause that expressly protects the buyer from possible losses arising from the mistakes made by the supplier. In this clause, it should be clearly stated how the supplier will compensate the firm for any defective product that it delivers. The clause may also specify the timeline within which the warranty will be applicable. Specifying the timeline in the warranty protects the supplier from instances where the buyer makes claims to damages on the products that may have occurred at the firm’s premises.

Force Majeure Clause

In contracts made in the future, force majeure is one of the most important clauses that must be included to protect both parties in case unforeseen forces occur in a way that inhibits the ability to undertake the project. A good example is a natural disaster such as a major earthquake or a cyclone. These forces may affect either of the parties in a contract. It may be the buyer’s premises that are destroyed by such forces, making it impossible for it to receive the products from the supplier as per the agreed timeline. In other cases, it may be the supplier affected by the forces of nature or a direct attack by terrorists or criminals. In the contract, the force majeure clause will define how to address concerns arising from such unexpected occurrences.

Termination Clause

On some rare occasions, the parties may find it necessary to terminate a contract before the actual day of the execution. There may be a number of reasons that may justify the termination of a contract. It may be a case of either the supplier or the buyer leaving the local market. Whichever reason that may be given, the parties should have a clear mechanism of how the contract should be terminated. In the termination clause, interest will be to ensure that necessary compensations are made to eliminate instances where any of the parties are subjected to unfair losses. If the payments had already been made, the clause should explain how the refund should be made and if any additional compensation is necessary for a possible breach of the initial agreement. In other cases, the termination clause may explain how the responsibility and benefits may be transferred to a third party. Turner warns that in cases where a third party is introduced, their consent must be sought and they must commit themselves to the terms in the contract in writing (90). Such commitments eliminate cases where the third party may distance itself from the contract.

Measures That Can Be Taken To Select Effective Suppliers

When looking at sourcing essentials, a firm must ensure that it takes into consideration measures that ought to be taken to select an effective supplier. The process of selecting a supplier is often characterized by numerous challenges because it may not be possible to understand their ability to deliver on their promise, especially if the contract is to be implemented in the future. This company may need to assess the possible suppliers in an effort to select the one, which is most qualified in delivering the desired value. The following are some of the factors that should be taken into consideration when selecting an appropriate supplier.

Competency

The competency of the supplier is one of the most important factors that should be taken into consideration when selecting a supplier. This can be determined by looking at the records of accomplishment of the suppliers to determine how well they executed their contracts in the past. The history of a firm may define how well it is capable of meeting its present and future needs. If the records indicate that a supplier has a tendency of failing to meet the expected quality, then that is an indication that the supplier cannot be trusted.

Capacity

The second factor that should be considered is the capacity of the firm. It may be dangerous to enter into a contract with a supplier that lacks the capacity to meet the expected obligations. There are cases where such a supplier may be forced to collaborate with other suppliers to meet the needs of the firm. It means that the supplier will sub-contract other firms to deliver the products needed. Such arrangements are often dangerous and bound to give rise to disputes. As such, it may be necessary to ensure that the supplier chosen has the capacity to deliver on its promise without having to work with other firms.

Commitment

The supplier should be committed to delivering value to the clients. Signing of contract and agreeing to deliver on the promised value is not enough to convince a firm of the supplier’s commitment to delivering on the promised value. Sometimes a firm may fail to deliver on such promises, forcing the parties to go through a litigation process. According to Lewicki et al., it is not often in the interest of any party in a contract to solve conflicts in courts (71). Courts processes are expensive and time-consuming. Even if the firm wins against the supplier, it will still have to deal with issues such as failed production, disappointed customers, loss of profits, and dented image in the market. To determine the commitment of a supplier, the management of ABCCompany may need to evaluate how it handled its past contracts.

Consistency

Consistency is another issue that needs to be looked at by ABCCompany when selecting an effective supplier. It will be in the interest of the firm to ensure that the selected supplier is consistent in delivering value as specified in the contract. If the firm has been engaged in business activities with the firm in the past, it may be easy to determine how consistent the supplier is in terms of meeting its promises. It may be necessary to evaluate the culture that a firm has embraced to determine how consistent it can be in delivering on its promise.

Cost

The final factor that a firm must look at when selecting the supplier is the cost. In the current competitive business environment, every firm is keen on ensuring that they price their products competitively because customers use pricing to make their buying decisions. Given the nature of the products of ABC Company, the cost of raw materials should not exceed 50% of the total cost of production. The cost of production can be lowered by ensuring that the raw materials are acquired at the least price possible. The supplier of choice should be the one that charges the fairest price in the market.

Aspects of the Supply That May Require Negotiation

Negotiation in procurement and supply is very critical in ensuring that a firm gets what it needs in the best quality possible. The management should try to ensure that it identifies the major areas in the procurement that may need to be negotiated. In acquiring the raw materials for ABCCompany, the following are the major aspects that will need to be negotiated to ensure that the firm gets the best deal in the market.

Price

The price is the first aspect of supply that the firm will need to negotiate in an attempt to get the best deal in the market. Different suppliers charge different prices based on a number of factors. After selecting the appropriate supplier that has the most desired qualities, the firm should try to negotiate for a lower price to ensure that it remains at 50% of the total cost of production.

Quality

According to Polish and Semanik, when purchasing raw materials from suppliers, a firm should be keen to ensure that it gets the best quality (47). As would be expected, the higher the quality of the raw materials, the higher its price is expected to be. However, sometimes a firm can successfully negotiate with the supplier to get a product of high quality without its price being increased. Negotiating for higher quality helps in improving the quality of the final product that a firm delivers to its clients without increasing their price.

Quantity

Quantity is another issue that can be successfully negotiated with the supplier. Suppliers often have terms and conditions stating the number of products they are willing to deliver at given costs. However, a firm can successfully negotiate to have additional products as a bonus without having to pay more. Such strategies help in lowering the overall cost of production.

Transportation

In most contracts, it is often specified which party will be responsible for the transportation of the purchased materials from the premises of the supplier to the premises of the buyer. Not all the suppliers are often ready to meet the cost of transport. However, a firm may convince the supplier to provide it with transport services as after-sale service. It means that the company will not have to pay for the services.

Time

Time is another aspect that may need negotiation in an attempt to have the best deal possible for ABC Company. This may be done in different ways. First, a company can negotiate with the supplier to make the payment at a future date instead of paying for the products in cash. There can be an arrangement that the payment shall be made a couple of months after the delivery is made. The firm can also negotiate with the supplier to have the raw materials purchased delivered within a shorter period than is often normal. The policy may be that the materials are delivered two days after payment is made or within 24 hours.

Conclusion and Recommendations

Conclusion

Procurement and supply chain management is very the most important strategic responsibilities of top managers. These processes help a firm in accessing the raw materials needed for production. It is normal to have situations the suppliers and the buyers have varying opinions. Each will be trying to get the best deal from the engagement. As such, the supplier will try to charge high prices and avoid any additional expenses. On the other hand, the buyer will be demanding very low prices and additional after-sale services. These differences can only be addressed through effective win-win discussions. As a firm tries to acquire materials for its operations, it is necessary to ensure that it maintains good relations with its suppliers. The suppliers should not feel exploited by this company, even in cases where this firm is dealing with small and less powerful suppliers. As discussed in the paper, each of the two parties should not start the negotiation with fixed minds. The managers at ABC Company must be open to negotiation in its procurement and supply chain strategies. Having a win-win outcome to a negotiation process should be the primary aim of both parties. Sometimes both parties may need to make compromises just to ensure that the negotiation is successful.

Recommendations

The following recommendations should be taken into consideration to ensure that this firm achieves success in its procurement and supply chain strategies.

The management of ABC Company should ensure that it has highly talented and skilled officers handling procurement activities.

The company should always be ready for a win-win type of negotiation when sourcing raw materials.

There must be clear documentation of the procurement agreements to avoid cases of litigation in the future.

References

Guth, Stephen. The Contract Negotiation Handbook: An Indispensable Guide for Contract Professionals. Lulu Press, 2008.

Lewicki, Roy, et al. Essentials of Negotiation. McGraw-Hill, 2007.

O’Brien, Jonathan. Negotiation for Purchasing Professionals. Kogan Page Limited, 2013.

Sollish, Fred, and John Semanik.The Procurement and Supply Manager’s Desk Reference. John Wiley & Sons, 2007.

Turner, Robert. Supply Management and Procurement: From the Basics to Best-in-Class. J. Ross Pub, 2011.

Weele, Josephine. Purchasing & Supply Chain Management: Analysis, Strategy, Planning and Practice. Cengage Learning, 2010.