Introduction

New product development is pivotal to bring added value in the market. In most cases the new product entering the market would shake up similar existing products in terms of price and quality. Development of new product takes into account several factors that must align together to enable effective implementation of the entire process.

One of these involves definition of roles played by each partner who is taking place in the development process (Clancy, Krieg & Wolf 2006). Efficient development would mostly depend on the person handling the food product at the end of the process before its formal release into the market. This would involve assessment of food quality in terms of flavour, colour, texture, and taste (Christine 2011).

This development process takes place in the laboratory, where the laboratory technologist plays a significant role to ensure food manufacturing process adheres to quality outcome. In this case, the major role played by the technologist would ensure the salmon pastries developed meets the market demand, customer preferences, and standardized criterion to avoid failure upon its introduction in the volatile market.

This lays the ground in which effective design of a practicable plan and its implementation helps the process of food development (Key Note 2002a). Tasks like processing and manufacturing, sorting, blending, grading, and packaging are paramount in ensuring the food produced attains its competitiveness in the market segment.

Therefore, technologist has to ensure the product meets these specifications by taking an active role in the entire developments and processing stage at the laboratory level. Use of certain equipments and technology would also add value to attaining this standard.

Market survey shows that the process must take into consideration the customers’ cultural values, ethical issues, social lifestyles, and some specified responsibilities, such as, codes of standardization, nutrition content, and health claims (Clancy, Krieg & Wolf 2006). This will help the technologist design an appropriate procedure for processing the food free of any risk or hazards.

Opportunities are immense if the product comes with an added value from what the market has to offer. Competitiveness of the product will therefore, depend largely on its features, and the response of the customers on the same (Grebitus 2008).

General input

The input would involve taking an active role in ensuring the proposed food product underdevelopment meets the laid criteria for safety, quality, and hygiene. This happens by making sure the entire laboratory process in which food processing takes place has good microbiological protocols to maintain precision and standardized hygiene during manufacturing process.

Application of hygienic work practice would help provide a safer environment. In most cases the food may be free of pathogens but if the environment of preparation is full of normal flora, the possibility of gross contamination of food may take place and this is the basis for ensuring the environment if free of microorganisms to produce hygienic food.

Analysis of food properties would enable sorting and blending after the process of processing is complete. These functional properties are physical, chemical, and sensory aspects of the product. They help in safe selection, preparation, and processing of the product underdevelopment (Clancy, Krieg & Wolf 2006).

At the laboratory, these processes will require expertise and knowledge in the varieties of food underdevelopment, this must also tally with the cultural and social aspects of the consumers who would either accept or reject the product. Market survey plays a major role to help incorporate these factors in this crucial process of the product development.

The input in the project would involve ensuring the product meets the market threshold in terms of quality outcome, social, and cultural values, safety, hygiene, and some specific properties dictated by the market demands. Ensuring these issues come into accomplishment would take active participation in every step of development from sorting to packaging of the product.

This must be in line with the designed planning process agreed upon by the members taking active role in the product development to ensure its viability (Christine 2011).

Importance of new product development

Economic importance is the primary factor for this step. Market surveys indicate that the majority of current population prefers fast foods in which they do not need to take an active role in their preparation. A majority of people are aging up, they take most of their time in work places, or far from their homes and whenever they arrive home they cannot prepare their food.

These people have alternative of buying readymade foods, which is their preference in most urban centres. The behavior is of late cutting across ages, even the young fresh employed graduates experiences the same.

This provides a ready market for the Salmon Pastries, the product underdevelopment (Reed et al. 2003). The rationale for choosing this product is the fondness it has among several age groups. The market is thus readily available (Mintel 2003).

The other driving force is the desire to bring a new look of the product to the customers. Although there is volatile competition in the marketplace, uniqueness of the product underdevelopment will help drive the process into higher levels (Burrow 2002). The expectation is that the product will stand above other competitors because of the well choreographed procedure in the entire development process (Key Note 2002a).

Introduction of features in the process of manufacture, advertising will help in making the process a fruitful one. Embracing technology for this development and advanced utilization of knowledge base also plays a significant role and this is because most processes of product development keeps changing with time yet this still remains an illusion in the industrial segment.

This will help in effective utilization and application of sessions learned in classes as well, although this is not a primary role.

Development process of Salmon pastries

The process of development will keenly follow the design agreed upon by the members tasked with the process completion. This part of processing will ensure the procured ingredients and raw materials undergo a safer processing procedure from preparation to packaging. The raw material will undergo testing process to ensure they are free from poisonous substances, risks, and hazards (Reed et al. 2003).

This is the initial process of instituting standardization and quality assessment of the product. The environment of development in this case food laboratory must also satisfy the basic requirement.

This must have appropriate equipments in which the development process can easily take place without causing or triggering contamination of the product (Moskowitz et al. 2005). These equipments must have standard calibrations, well maintained, clean, and used appropriately by the personnel tasked with handling them (Clancy, Krieg & Wolf 2006).

This process will also ensure the product accommodates all the population irrespective of their health status. Including a diverse option will accommodate vegetarians and those responding severely to some elements (allergic individuals). Developing different lines of production that ensure consideration of these factors will help attain the goal.

Although the process may be initially expensive because of the inclusion of different production line, it will help establish relationship with people from all walks of life. These will go hand-in-hand with cultural and social effects; the other important issue that would form basic recipe in this process is the product pricing (Burrow 2002).

Determination of this will depend on many aspects that come with specific type of product produced and its content or the target individuals. The presence of different lines of production will dictate the value of the product.

Every step of the laboratory technologists will adhere to good laboratory practice procedure. This ensures identification of any anomalies in case there is a problem for easy troubleshooting. Stepwise manufacture also takes into account the system of Hazard analysis and critical control point (HACCP) (Christine 2011). This system enables checking of product right from the firm to the fork.

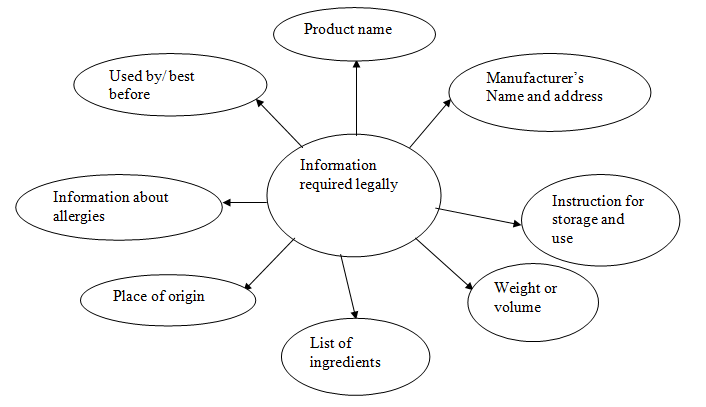

It makes it possible to underpin the stage in which possible contamination or introduction of harmful substances took place by either adulteration or accidental. The technologist would take attention and note to some of the legally required information once the product goes to the market as shown in the diagram below.

Schematic representation of legally required information of the product

(Christine 2011)

Food consumption in the United Kingdom market

This is the main factor that dictates the choice of food product underdevelopment. The market trend and consumer demand plays a significant role in determining the ingredients and other additives for inclusion in the product development.

As the technologist this information is crucial to help come up with the right product in terms of choice, taste, and preference to make sure the product does not hit a hard rock during its introduction in the market (Burrow 2002; Young 2000). Market survey shows that most people prefer readymade foods, this cut across all age groups. The market is, however, very unpredictable and volatile in most case.

This is because the competition from a variety of fast foods is gaining momentum each day. Major cities have the highest saturation of this trend, which makes it hard for new entries (Burrow 2002).

There is, however, likelihood of gaining substantial group based on the uniqueness and preference the product. If the product turns out to be what most have been looking for in terms of taste, texture, content, and value it will appeal to most consumers (Grebitus 2008).

The diverse cultural orientation in the UK makes it possible to predict a possible success upon introduction of the product. The eating habit has also been changing with time because many people prefer to shift from a new product with some added features (Young 2000). This sets the marketplace a level playing ground for any new players introducing something new to have a fair share of the clients.

Packaging process

This is the most vital process within the laboratory setting because it gives the final look of the product to potential customers. The final appearance of the product will add value to enable its acceptance in the marketplace. Packaging involves several processes in which protection of the product from pathogenic bacteria and dirt is the basis.

The laboratory technologist will make sure the process is free from contamination before and after packaging process. Selection of appropriate methods of undertaking the process is must ensure the process preserves the food product as well. Studies by Key note (2002b) shows that some packaging process preserves the food product, whereas preservation extends the product’s shelf life.

A poorly preserved food product is likely to spoil faster than when properly preserved; this process therefore, takes care of possible food poisoning and spoilage that may occur during transit or storage before selling (Clancy, Krieg & Wolf 2006).

The choice of packaging material will depend on the variety of clients’ preferences and their variety of tastes. Use of color coding to signify some flavor and ingredients will make the product appealing and accommodative. The technologist will play a significant role in determining these features by putting more emphasis on the market survey prior to its introduction for consumption (Moskowitz, et al. 2005).

The final choice of packaging material should therefore, be a reflection of the anticipated response that promotes the product. Choosing material of packaging must have some properties like temper proof; it should not undergo easy damage before getting to the market (Christine 2011).

The material should also be portable, easily stored, and free from any breakage. These factors are necessary to maintain the integrity of the product from the manufacturing industry to the retail shops (Burrow 2002). The choice will also cater for diversity by settling for different modes of packaging. Materials for the process will include the plastics, metals, and the glass. This will give customers a variety of choices.

Settling for an environmental friendly packaging material will ensure the product manufacture adheres to issues of environmental awareness. This will include provision of appropriate information that guides the disposal of the packaging material. Each design of package will have a unique method for its disposal or reuse.

Other important information would include provision of legally required guidelines (Lawley, Curtis & Davis 2008). These involves indication of titbits on allergies and hypersensitivities, list of ingredients, place of origin, manufacturers address, the product name, the due date, weight or volume, and using instruction.

Inclusion of information about the content levels (if there is sugar, fat, or salt) is a basic requirement and sometimes is important legally. Serving suggestion would add value to the product users as well, its inclusion is thus essential among the legally required information (Lawley, Curtis & Davis 2008).

Product recognition comes in the packaging stage of product development. To ensure there is no confusion between the existing products in the market and the new entry, the newly developed product will have unique features in color shapes.

The main factor that governs the entire packaging process is the blending stage in which the product undergoes sensory analysis. This property of food helps evaluate texture, flavor, appearance, and aroma before their packaging process (Howard et al. 2009; Smit 2010).

The entire process will strictly adhere to good laboratory practices, which ensures the product follows HACCP guidelines and links other factors like the processing, nutritional health, and hygienic production to the product. This will make it possible to do a reverse analysis in case there is complain of food poisoning or contamination to ascertain the exact origin of the poisonous compound.

HACCP system enables effective elucidation of the origin of risks and hazards from farm to fork (Christine 2011; Reed et al. 2003). Hygienic implementation of the entire process is fruitful in validating the production process.

Scale up

Scaling up the product will require strategic planning and laying down objectives that ensures the newly produced product gains the projected vision. This will, however, require input from the marketing department. Marketing would mostly rely on the strength of the manufactured food in terms of its ingredients, flavor, color, and texture among other properties to make it stand above the rest (Burrow 2002; Grebitus 2008).

The role of technologist in scaling up the product would involve ensuring it undergoes effective manufacture within the premises of the laboratory. This must meet the UK standardization criteria for a newly produced product.

Other strategies of ensuring that the product gains anticipated levels is observation of hygienic protocols, safety procedures, and good laboratory process from preparation, processing, blending, and packaging (Mintel 2003).

Equipment

Technologist would carry out selection of laboratory equipments that suits the production process. The choice of equipment would reflect the final quality of developed product. This must also take into account contemporary environmental issues that relates to production of new food product.

The entire environment must have high standards of hygiene to prevent introduction of microorganisms during processing stage (Clancy, Krieg & Wolf 2006). The environment will also need to be safe for the other helping technologist to prevent occurrence of risks and hazards. These equipments must have standardization mark for quality purposes, their calibration should also tally with universal units of measurements.

In fact, major processes would involve use and application of technology in one way or the other before the product comes out. From the preparation process of raw materials to packaging, these procedures must be free from contamination to produce hygienically safe food.

During preparation the most important factor is the preservation of food properties like texture, value, color, and flavour (Smit 2010). The machine used for processing must therefore, ensure the product reflects the true picture of anticipated value.

Application of design process would help in maintaining these properties to avoid losing pivotal features that may ruin the entire process. Using a wide range of tools and equipments is therefore, essential in helping to demonstrate skilful implementation of preparation process (Howard et al. 2009). The design process will also optimize food properties during preparation process.

Involvement of personnel in the entire process is paramount in maintaining these features. Skilful use of these apparatus is thus very important.

As the technologist in charge, the main role in the entire developmental process would involve ensuring effective application of novel technology, and adhering to good laboratory practices to ensure the product is not only authentic but also nutritionally safe and hygienic for human consumption.

Manufacture assessment

Manufacturing process will take place prior to the product development, during processing, and after processing. This procedure is paramount to ensure observation of quality protocols in line with safety, hygiene, and nutritional content of the product. As the technologist, laboratory assessment during manufacture will help institute measures that would alleviate possible contamination and food spoilage or poisoning (Grebitus 2008).

During this process there is high likelihood of external introduction of normal flora, a factor that may render the entire process futile. This assessment overrides other process that ensures there is hygienic production of food, for instance, the health status of the laboratory personnel.

The assessment will take into account every step of food development to ensure attainment of standards required for any newly developed product. Manufacture assessment involve assessment of quality outcomes, flavor, colour, texture, and taste (Clancy, Krieg & Wolf 2006).

Conclusion

Development of new product would experience a number of challenges upon its introduction in the marketplace. This happens because of uncertainties and volatility in the markets. The most effective way of ensuring success is taking a decisive step to develop a design, carry out the market survey, and make recommendations in which the product development would follow to completion (Clancy, Krieg & Wolf 2006).

Definition of roles played by each partner taking place in the development process is necessary to allow smooth operations and accountability. Efficient development would mostly depend on the person handling the food product at the end of the process before its formal release into the market.

This survey should dictate the type of product for development. Decisions that guide the choice should also take into account logistics of raw material availability, customers’ preference, their diverse cultural varieties, development process.

Availability of opportunities in the market would influence the choice of product; in this respect competitiveness of the product depends largely on its new features and the response of the customers (Mintel 2003).

As the technologist, the main role is coming up with the product from its raw materials. The entire process would require application of novel technological advancement; these would conform to environmental issues to take care of both the apparatus and the personnel within the laboratory segment.

Hygienic production of the product and retaining nutritious content and flavors as well as avoiding contamination with normal flora from the environment is paramount. This happens through maximizing asepsis within the main laboratory.

Reference List

Burrow, R 2002, Early Market Review, British Potato Council, Oxford.

Christine, BA 2011, Understanding Food: Principles and Preparation, Wadsworth Cengage learning publication, Belmont CA.

Clancy, KJ, Krieg, PC & Wolf, MM 2006, Market New Products Successfully, Lexington books, Oxford UK.

Grebitus, C 2008, Food Quality from the Consumer’s Perspective: An Empirical Analysis of perceived quality, Cuvillier Verlag Gottingen, Auflage.

Howard, R, Moskowitz, HR, Beckley, HJ & Resurreccion, AV 2009, Sensory and Consumer Research in Food Product Design and Development, John Wiley & Sons publication, Iowa USA:

Key Note 2002a, Market Review 2002 the Food Industry, Key Note Ltd, Middlesex.

Key Note 2002b, Market Review 2002 the Catering Industry, Key Note Ltd, Middlesex.

Lawley, R, Curtis, L & Davis, J 2008, The Food Safety Hazard Guidebook, Royal Society of Chemistry, Oxford, UK.

Mintel 2003, Attitudes towards Buying Local Produce, Market Intelligence, Mintel International Ltd, London.

Moskowitz, HR, Porretta, S & Silcher, M 2005, Product Design and Development, Blackwell publishing, Iowa USA.

Reed, M, Traill, TJ., Barr, D, Thompson, S, Winter, M & Metcalf, R 2003, A Study of Food Production, Distribution, and Processing in Cornwall and the Isles of Scilly, University of Exeter publication, Exeter.

Smit, J 2010, Functional Food Product Development, John Wiley & Sons publication, Chichester UK.

Young, J 2000, The UK Food System A Vision of the Future, Leatherhead Food RA, Surrey.