Introduction

The well-established systems like thermal, hydroelectric, and nuclear power generation plants play a major role in meeting the electricity demands of over 600crore population. However, they can no longer meet the dramatically growing requirements for electricity. Moreover, the depletion of fossil fuels and the rise of environmental concerns have made scientists look for more alternative techniques that use renewable energy sources with less damage to the environment. This motive has resulted in focusing on wind and solar energy. Apart from these, innovative techniques have been proposed to trap the energy from water in various methods to generate electricity. They include the use of wave and tidal energies, and ocean temperature gradient (ESO 2007: 1). Researchers are even trying to use saline water for solar ponds and growing algae.

‘Ocean Thermal Energy Conversion (OTEC)’ technique converts the solar energy absorbed in ocean water to electric power. A French physicist, Jacques Arsene d’Arsonval, put forth the concept in 1881. The main requirement for this, as will be evident in later sections, is that the temperature difference between warm surface water and cold deep seawater no more than 1000metres below should be at least 20oC (36oF) (OTEC 2007: 1). Though the technique has not received large-scale commercial application till today owing to various hindering factors, its potential benefits in today’s world are making many nations consider feasibility. This paper explains various types of OTEC, analyses its advantages and disadvantages, and focuses on the scope of this technique.

Methodology

Basic Technique

The warm seawater is carried into a chamber and is used to produce vapor that, in turn, is used to rotate a turbine. Electricity is generated with these rotations. The vapor is then passed through a condenser whether the cold seawater converts it to a liquid state.

The main components of the plant include carrier systems for seawater, heat exchangers, evaporators, turbines, condensers, and other facilities as per the intended utilization of the secondary products.

Types

OTEC systems can be of the closed cycle, open cycle, or hybrid varieties with minor variations in the procedure.

Closed-Cycle System

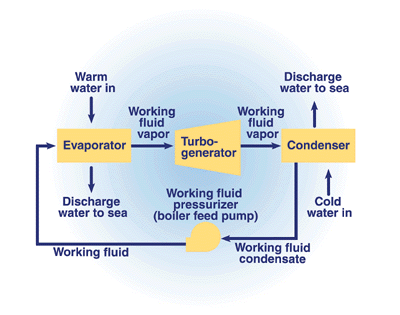

The plant pumps in the warm seawater to boil an intermediate fluid with a low boiling point, like ammonia or propane. This vapor is now pushed over a turbine to generate electricity. The cold seawater then cools down the vapor.

Figure 1: Closed-Cycle System (OTEC 2007: 7a)

Open-Cycle System

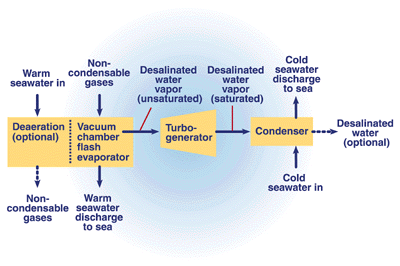

It is similar to the closed cycle except that it does not need an intermediate fluid. The warm seawater is converted to low-pressure vapor under a partly vacuumed environment and is then passed on to rotate the turbine. The cold water condenses the vapor into desalinated water.

Figure 2: Open-Cycle System (OTEC 2007: 7b)

Hybrid-Cycle System

It is a theoretical model to maximize productivity. It uses the closed cycle first to create a necessary low-pressure environment for the open cycle (OTEC 2007: 7). Another method is to use two open cycles to enhance the production of desalinated water.

Placement Variations

Depending on the need and availability of resources, an OTEC plant can be placed as a land-based or floating system (SER 2007: 22a). Both have their own advantages and disadvantages. Floating plants mounted on an altered cargo vessel do not need long pipes to carry the cold water. However, the generated electricity needs to be transferred to the land. Also, several problems like the mooring, sustainability from ocean currents and storms, potential damage to cable materials in deep water need to be considered. On the other hand, land-based plants need longer pipes to carry warm and cold seawater to the production site. During the transfer, there lies the risk increase in the temperature of cold water. However, it is easy to transfer and/or utilize the generated electricity and other by-products with a land-based system.

Advantages

Apart from generating electricity, OTEC plants offer various benefits that make this system a multipurpose facility.

- The plant produces fuels like ammonia, hydrogen, and methanol as sideway products. This is particularly important, as these fuels can be produced from a renewable resource and transferred without much difficulty (OTEC 2007: 5).

- The procedure yields desalinated water that can be used for drinking and irrigation.

- Nutrient-rich deep seawater becomes available for mariculture, aquaculture, and also for pharmaceutical purposes.

- Coldwater after treatment can be used for air-conditioning and moderate refrigeration facilities.

- Electricity is produced in an apparently environmentally friendly system. It also minimizes the greenhouse effect, which is the main concern with fossil fuel combustion.

- Considering the potential business opportunities, it can help in enhancing international trade.

- Floating-type plants can provide a base for deep marine research, marine adventure tourism, and the implementation of emergency rescue systems (OEST 2007: 1).

- It helps in combining atmospheric carbon dioxide with nutrients and other minerals of deep water through photosynthesis, which in turn reduces the carbon content of the environment (Richard Crews 1997: 2).

Disadvantages

- In spite of its possible multiple benefits, OTEC has not gained proper attention due to its high initial investment compared to conventional systems.

- Lack of any experimental project to demonstrate the full-scale advantage of the OTEC plant.

- Plant can be placed only in tropical areas where ocean water temperature gradient is equal to more than 20oC.

- Difficulty in transferring products to areas of utilization.

- Need for protective measures for survival of the plant from harsh and varying environments of the sea.

- General reluctance of governments and private investors to accept a relatively new technique, no matter how beneficial it can be.

Analysis

The prospects of OTEC technology can be derived with proper feasibility analysis along with a comparison of expenditure and profits.

Feasibility Analysis

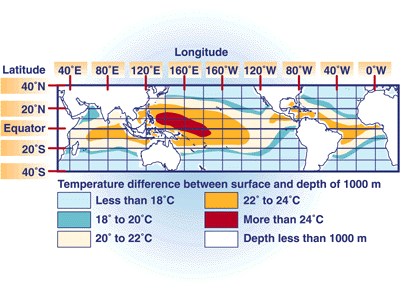

The required temperature gradient of ocean water is the main deciding factor in establishing an OTEC plant. Though nearly 70 percent of the earth is covered with water, tropical areas that lie between 20oN and 20oS latitudes are the most favorable positions. Here, the temperature gradient between surface water and deep water is equal to or more than 20oC. This area covers nearly 29 territories and 66 developing nations apart from America and Australia (OTEC 2007: 4).

Figure 3: Favorable Geographical Area (OTEC 2007: 1)In the above picture, the temperature gradient varies from more than 24oC to less than 18oC. Still, the temperature differences between surface warm water and deep seawater lie at favorable levels within the territorial limits of many countries. Though it seems like showing a vast area suitable for OTEC plants, many other factors need to be considered. As the plant requires highly engineered materials, design and maintenance, initial expenditure naturally remains high. So the intended amount of population who will be benefited from the plant becomes important for cost and benefit analysis. Also, the country’s economy and infrastructure are crucial, as the plant needs supporting facilities

to get the full benefit from various products of the OTEC. Island nations that largely depend on imported oils for energy requirements can consider OTEC as an effective alternative, because of the decreasing fuel resources and rising prices.

Competency

World Energy Council has produced data comparing the efficacy of a 10MW closed-cycle OTEC plant in regard to its expenditure and output (SER 2007: 22d). After following stringent constraints and including contingencies at various levels, it has been found that the efficacy is 25-35% when compared to the efficiency of diesel fuel power plants and nearly 35% in relation to a modern fossil fuel power station. The estimated costs for the production have been found relatively favorable.

However, the result can be more positive in a practical approach. Firstly, the comparison is an experimental one with the only aim of finding the plant’s productivity in a relatively expensive environment. Also, large-scale establishments with full productivity can reduce production and maintenance costs and result in substantial net power. Secondly, the estimation has excluded the added value of OTEC plants in producing many by-products, including drinking water. Moreover, it aids in aquaculture with potential benefits. If the proposed ‘carbon tax’ on fossil fuel plants is also included, the OTEC plant will have fair chances of gaining international attention (SER 2007: 22c).

Economic and Environmental Perspective

Resources necessary for conventional power plants are non-renewable and are depleting rapidly. Energy demands are increasing uncontrollably and much beyond current production capabilities. The need for alternatives is at its peak, making to search for every possible option for power generation. Many developing countries are being forced to spend huge amounts on domestic energy demands. Moreover, dramatic industrial growth in recent decades has resulted in alarming pollution levels, which is becoming worsened with fossil fuel combustion. Moreover, island nations with a paucity of freshwater resources have an added burden of water costs.

OTEC plants provide a possible solution to many countries, offering multiple benefits. Even small nations in the tropical zone can benefit from OTEC by forming collaborations with neighboring needy countries and also allowing venture capitals (OTEC 2007: 1e). Small-scale plants can be established where the electricity necessary for the desalination of water can be produced, thereby reducing the financial burden for governments. Huge savings can be achieved with proper maintenance and utilization of the by-products from OTEC procedures.

Landmark Developments

1881 – J. D’Arsonval proposed the idea of rotating turbines by using ocean temperature gradient.

1930 – George Claud made a small open-cycle OTEC plant in Cuba, which failed to produce net power.

1979 – National Energy Laboratory of Hawaii constructed a mini closed-cycle OTEC plant that produced 52kWe gross power and 15kWe net power.

1980 – the US Department of Energy constructed a closed-cycle OTEC plant onboard a converted Navy tanker for testing purposes. In the same year, two laws were enacted for the commercial development of OTEC technology.

1981 – Japan constructed a closed-cycle plant in the Republic of Nauru, using Freon as working fluid and titanium heat exchanger. It surpassed engineering expectations and produced 31.5kWe net power.

1984 – the US DOE achieved 97% conversion efficiency using a vertical spout evaporator for converting warm water to vapor.

British researchers have developed and tested aluminum heat exchangers that have reduced the costs of OTEC systems.

1993 – An open-cycle system in Hawaii produced 50,000 watts of net power in the experimental demonstration.

2002 – SEA Solar designed 100MW OTEC Plantship.

Scope

With technologic advancements in recent years that provide alternative materials and reduce manufacturing costs, the OTEC system is supposedly heading for a bright future. Many countries are now looking at OTEC as a better option to overcome the energy crisis, with the latest being the intention of Australia to build an OTEC system in Townsville. In 2003, there had been consultations between Saudi Arabia and Japan to utilize OTEC technology for desalination of water and electricity production, which have not been materialized yet (Country Notes 2007: 7). With the support of the United Nations Organization, the entire world is leaning towards renewable energy sources that will automatically pave the way for OTEC constructions due to potential multiple benefits.

American, Japanese, British, and French scientists are the frontrunners in exploring the possibility and scope of OTEC systems. It is estimated that there will be around one thousand OTEC plants worldwide by 2010. The energy demands for OTEC will be at 20 GW by 2020 in the Asia/Pacific region which will grow up to five times by 2050 (SER 2007: 22e).

To realize OTEC systems for practical use, research needs to be done in order to reduce production costs. Scientists need to identify cost-effective materials that are corrosion resistant and sustainable. This will reduce the costs of pipes used for transporting deep seawater. Also, major industries should come forward for OTEC experiments and constructions in view of its unparalleled benefits. Governments need to liberalize policies that facilitate the inflow of foreign investments for OTEC systems. Infrastructure needs to be improved at par with OTEC functionality to make maximum utilization of the plant’s productivity. Nevertheless, it is important to analyze the effectiveness and need of the OTEC system in relation to regional needs, as the construction of such a plant, at least at present, is very expensive and complicated.

Conclusion

All in all, Ocean Thermal Energy Conversion technology is a better alternative to meet the demands of electricity and drinking water. As ocean water is an ever-available resource, there will not be any problem for OTEC in regard to resources. Also, it must be adopted for being relatively environmentally friendly. With more research and development projects in this field, construction and maintenance costs can be reduced to manageable levels for small countries. Moreover, people will be benefited from it in various ways ranging from nutrient-rich deep seawater to cheap refrigeration facilities. As the number of projects increases, practical data becomes available that will be helpful in further development.

Works Cited

Crews, Richard. “OTEC sites.” library. greenocean. org. 1997. Web.

“Energy Sources from Oceans: An Introduction.” 2007.

“Ocean Energy for Sustainable Townsville.” 2007. Web.

“Ocean Thermal Energy Conversion.” nrel. gov. National Renewable Energy Laboratory. 2007. Web.

“2007 Survey of Energy Resources.” World Energy Council. Web.

“2007 Survey of Energy Resources: Country Notes.” World Energy Council. Web.