Introduction

Today, there is massive competition in the corporate world. Companies continually seek ways to stay in business and to outdo their rivals. Consequently, many institutions have embraced advertising to stay in business. There are many ways to advertise especially by use of media. In this century, use of internet and audio-visual media is gaining popularity as the medium for advertisements.

In spite of their popularity, these forms of advertisements are yet to outdo print media. For centuries, print media has dominated the advertisement industry. The most essential material for print media is the paper. Over the years, the paper has continuously changed form from scrolls to thick sheets, and then to the current thin sheet we have today.

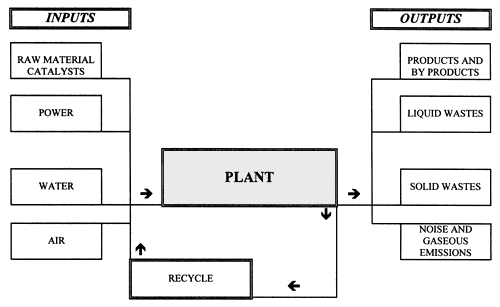

Newspaper advertisements are among the popular mediums of presentation used today. For a newspaper to reach the intended party successfully, it goes through a series of complex processes. The production processes consume raw materials and energy from the environment. Consequently, at the end of the processes, the factory release emissions and wastes to the environment.

To appreciate this process, it is necessary to understand the life cycle of the production processes. Life cycle assessment methods help in calculating the raw materials and energy consumed by this processes. Further, the methods used establish implication of emissions released to the environment by this processes (Carnegie Mellon University 1).

This article focuses on steps involved in production of papers, which are the main raw material used in making newspapers. This article highlights steps followed in factories to produce paper. These steps include acquisition, manufacturing, transportation, and distribution of raw materials.

Additionally, it focuses on recovery and management of wastes and emissions released. Further, this article reports on the findings of the investigation conducted. It highlights the assumptions made and failures in the course of the research.

History of the paper

Some researchers trace the origins of the paper to Egypt, in River Nile while others link the origin of the paper to china. People started using papers about 5,000 years ago. Just like today, people in the past used various materials such as cotton, linen, wood, grass, and papyrus to make papers. For years, many communities have used the as a measure of quality of life (Roekel 1).

Acquisition of raw materials

Paper manufacturing plants use renewable resources for production of papers. The main raw materials used are pulp, water, and energy. Pulp comes from plants such as trees, elephant grass, papyrus, and switch grass. In addition, some factories use vegetable matter, recycled papers, and recycled linen to produce papers.

Workers harvest the trees manually or using machines. Lorries or tractors then transport the materials to the respective factories. Pipes and pumps supply water to the factories. The factories get chemical components such as dyes, inks, bleaches, and filler materials from the respective suppliers. Factories get energy form of electricity, firewood, and gas.

Processing and manufacturing of the raw materials

This involves converting fibers from the respective sources into flat thin sheets of paper. Factories use chemical or mechanical processes to convert wood into pulp. In the mechanical process, workers use large drums to debark the logs. The workers then put the logs inside grinders fitted with rotating slabs, which squeeze and crush the logs to remove water. After this, the workers filter the resulting solution to remove dirt.

In the chemical process, the workers remove the barks from the wood and chop the logs into small pieces. The next step involves placing the logs in digesters and boiling them in chemical solutions at high pressure. The workers bleach the pulp to give it a rich white color. The workers then add filler materials to the pulp to make the sheets opaque.

In addition, they add sizings such as rosin and gum, which influence the reaction of the sheets to different inks (Lecta Group 12). The workers then feed the pulp into automated machines that squeeze the pulp through several rollers. This rollers help to remove water in the pulp and convert the pulp into flat sheets of paper. A dandy machine then moves across the thin sheets in order to design them.

The sheets then pass over a series of steam-heated cylinders to get rid of the remaining water. The workers then smooth the papers by passing the sheets through machines called calendars. Further, the workers coat, shape, brush, and size the sheets accordingly. Finally, they count, pack, and pile the papers in a safe place using automated machines.

Table 1: Paper Manufacturing Process

Transportation and distribution of the papers

After the workers complete the manufacturing process, they pack the papers according to size, color, texture, and design. They then distribute the papers to different companies based on the orders. Finally, the workers transport the papers to their respective destinations. Factories use road, rail, or air to transport the papers depending on the quality and quantity.

Figure 1: Transportation of paper manufacturing materials and products

Use, re-use, and maintenance of papers

Papers have diversified uses. Research shows that almost all corporate institutions and households use papers in their day-to-day activities. People from diverse lifestyles have embraced the use of papers. Examples include students, teachers, parents, employers, and employees among other people.

The widespread use of the paper shows its importance. People mainly use papers to communicate. However, papers have advanced uses such as making decorations and bags. Used papers are also useful. People recycle them to make more tissue papers, cartons, and decorations among other uses.

It is essential for individuals to use papers efficiently. This is because the resources used come from the environment, which is susceptible to degradation and pollution that results from the paper making processes.

People should maintain papers by using them for the right purposes. In addition, individuals should put used papers to proper use. This way the papermaking life cycle will be less harmful to the environment (European Commission 1).

Waste management

Evidently, papers are essential to a large population in running their everyday duties. This makes industries related to paper and pulp industry important as they play an integral role in the social and economic developments.

However, these industries pose challenges to the environment. In their bid to satisfy the overwhelming demand for papers, Pulp and paper industries emit large amounts of waste throughout the production processes. These wastes range from primary sludge, organic wastes, to greenhouse gases.

Factories release emissions and wastes in all stages of paper production. In the first stage, waste consist of rejected virgin pulps, sand, remains of woods, and barks, which the factory cannot use in subsequent processes. During the chemical recovery process, the factory emits wastes such as green liquor sludge, lime mud, wastewater, and chemical waste sludge.

When making paper the mills emit wastes such as fibers, wool, and impurities like metal and staples. Further, paper and pulp industries produce harmful air emissions. Components such as electricity-generating units produce gases such as sulfur oxide, nitrogen oxide, methane, and volatile organic compounds. On top of being malodorous, these emissions cause massive air pollution (Venditti 17).

Stakeholders of the paper and pulp industry have a responsibility towards management of wastes and emissions related to this industry. The government on its part should enforce firm regulations. It should also spell out the limits of this industry. The public should ensure that this industry does not compromise their safety through pollution of the environment.

These factories should recover wastes and emissions, and convert them into useful products. For example, the factories should use greenhouse gases to generate heat and energy in the manufacturing plants (Office of Air and Radiation 12). In addition, these factories should minimize the generation of wastes. They should embrace installations that save on energy. Further, they should embrace new and convenient techniques.

In case of closure, plants should leave the location in its original state or in an improved state. Further, these factories should engage in waste recovery processes such as wet oxidation and steam reformation. The factories should ensure safe and convenient disposal of their emissions and wastes.

The factories should also engage in recycling of wastes. For example, factories can use barks and rejected pulps as fuel for the furnaces. These factories can use treated wastewater in the production processes. Finally, the factories should reclaim land and engage in activities that enhance soil fertility.

Summary of research findings

When conducting research, an individual gets to learn a lot and encounters several challenges. The factory management in many firms is ready to talk of the achievements of their companies. However, it is hesitant to open up on the challenges and flaws of the firms. This investigation was a success in terms of information gained. The information gathered on the general procedure of paper manufacturing process was efficient.

Today, the paper industry is one of the big industries in the world. Many people use the paper widely in their everyday activities. This has led to the growth of this industry. There is a booming market for paper products in countries like India and the US. This has contributed to the massive production of the papers.

This industry has two main sub-sectors. The first sub-sector deals with manufacture of pulp and paper while the latter concentrates on manufacturing paper products. Manufacture of paper is the core activity of this industry. Most factories in the industry engage in the manufacture of both paper and converted paper products. This industry has witnessed a series of transformations when it started (U.S Censors Bureau 1).

Technological advancement and extensive research have propelled the industry forward and helped to improve its quality. As the investigation established, the stakeholders have put more effort in order to improve this industry.

However, this industry faces major challenges. Being a universal industry, it requires many resources for it to function. Most of these resources are renewable while several are non-renewable. Further, there are large numbers of harmful wastes and emissions that result from the production processes. The investigation carried out failed to establish permanent and lasting solutions to some of the problems faced by this industry.

No factory had a lasting solution regarding safe disposal of waste and re-use of harmful wastes. It was a challenge for the research to find out the truth regarding the actual processes involved in disposal of wastes and emissions in these factories. The research had to make assumptions for it to move forward with the investigations. Such assumptions rotated around the technicality involved in the entire production process.

For instance, the research assumed that the life expectancy of this industry would be shorter if the industry does not take precautionary measures. The research evaluated the impact of the increased use of internet instead of papers. Further, the research assessed the consequences of the environmental issues to the industry.

Conclusion

Importance of paper making industry in the newspaper advertisement process is evident. It is essential to understand the life cycle of the paper-manufacturing sub-sector. The life cycle assessment estimates the amount of materials and energy that factories consume in the process of producing papers. Further, the life cycle assessment calculates the amount of wastes and emissions released to the environment by the factories.

Overall, the life cycle assessment method aims at establishing the impact of the production processes to the environment. Researching on this process enables individuals to understand the different sub-sectors involved in production of a single product.

For instance, designing of a newspaper depends on sub-sectors such as paper, ink, electricity, and transport industries. Therefore, all these subsectors should consider the impacts of their functions on the environment and strive to maintain ecological balance for a sustainable ecosystem (Krowaski, Bresky and Pettersson11 ).

Works Cited

Carnegie Mellon University. EIO-LCA: Free, Fast, Easy Life Cycle Assessment. n.d. Web.

European Commission. Joint Research Center. 2013. Web.

Krowaski, klaus, Jan Bresky and Börje Pettersson. A Life Cycle Assesment of the Production of a daily Newspaper and Weekly Magazine. Zurich: Axel Spirnger Verlag AG , 1998. Print.

Lecta Group. About Paper Manufacturing. 2008. Web.

Office of Air and Radiation. Available and Emerging Technologies for Reducing Greenhouse Gases emission from the Pulp and Paper Manufacturing Industry. 2010. Web.

Roekel, Gertjan. Hemp Pulp and Paper Production. 1994. Web.

U.S Censors Bureau. NAICS 322: Paper Manufacturing. n.d. Web.

Venditti, Richard. Life Cycle Analysis of Paper Products. 2011. Web.