Introduction

Electronic home appliances have become a vital aspect of human life in contemporary world. They range from mobile phones, television sets, computers, radios, and cookers. It is noted that such gadgets are intended to make life more enjoyable. However, the intention notwithstanding, there is an emerging trend where the same machines pose a danger to the environment (Vallero & Brasier 2008, p. 217).

Consequently, stakeholders and policy makers have developed a number of frameworks to monitor and minimise the negative effects that electronic appliances have on the environment. One such concept is the Life Cycle Analysis (herein referred to as LCA). According to Crawford (2008, p. 496), LCA is regarded as a technique that is essential in understanding the environmental impacts of a given product.

The current essay is written against this background. In the paper, the author examines the environmental impacts of a toaster. The report seeks to develop a concept to redesign a sandwich toaster. The aim is to ensure that the appliance is environmentally friendly.

The paper begins by addressing the weaknesses of the gadget. The analysis is based on the knowledge acquired by the author with regards to LCA (Zamagni 2012, p. 375). Thereafter, a critical review of the implications of these weaknesses is provided. At the end of the paper, a new design for the toaster is proposed. The envisaged design has two major benefits. First, it is expected to improve the performance of this appliance. Secondly, the new model will alter the components of the toaster, reducing its negative effects on the environment.

Weaknesses of the Sandwich Toaster

Trusty (2010, para. 3) is of the opinion that the energy consumption associated with various home appliances should be reviewed from an environmental perspective. A domestic electronic gadget, such as a toaster, is essential in the production of sandwiches. It is very convenient as it eases the whole process of food preparation.

However, the materials used in manufacturing and designing the machine have varying effects on the environment. The United States Environmental Protection Agency (2012, para. 3) has tried to address this issue. The organisation advocates for the utilisation of eco-friendly appliances at home and in the office. The need to reduce negative ecological impacts necessitates the redesign of appliances. Such remodelling improves the performance and ‘eco-friendliness’ of the said machine.

Today, there are diverse culinary techniques that require similarly diverse appliances to execute. Pastry lovers will agree that toasted bread is a delicacy that saves a lot of time and eliminates the need to rush to the coffee shop. When prepared at home, such snacks tend to bring the family together and reduce expenditure on unnecessary inputs. As a result of this, a toaster is one of the appliances whose role is realised when there is a need to prepare bread and other types of food.

Lowell (2009, para. 3) affirms that most modern kitchens contain this vital appliance. In terms of power consumption, Lowell (2009, para. 4) points out that a typical toaster requires an average of 900 watts. At this level of consumption, such machines are usually used to toast two slices of bread at once.

The only way to understand and redesign a given machine is by analysing its various components (Horne, Grant & Verghese 2009, p. 43). The structure of a simple appliance, such as a mobile phone, is characterised by dozens of parts. Each of these parts is designed to play a specific role. The various roles are synchronised to achieve the overall functionality of the machine.

Murielle (2011) provides an illustration of the materials used in the packaging of an average toaster. A review of the structure of this machine reveals that most of the components used are manufactured through industrial processes that are harmful to the environment. As a result of this, the finished product is associated with a number of shortcomings as far as its use is concerned. The varying weaknesses have serious ramifications to the surroundings.

It is important to understand the uses of a given appliance. Such an understanding enables one to determine the inefficiencies, if any, that are linked to the machine (Hendrickson, Lester & Scott 2006, p. 39). Murielle (2011, para. 4) indicates that most heating appliances used around the home are made of steel.

As a result, they consume a lot of electricity. In light of this, it appears that the first weakness associated with a toaster, as a domestic appliance, has to do with its energy consumption. According to Guo (2012, p. 47), most heating appliances consume approximately 5% of the total power in a home setting. Since a toaster falls under this category of gadgets, it follows that its kilowatt-hour consumption is quite high.

Vogtlander (2011, p. 76) points out that many appliances that are used domestically are made from synthetic materials. Owing to the complexity of their applications, machines like toasters require artificial materials that are inexpensive to produce (Vogtlander 2009, p. 104). An example of a commonly used component in manufacturing these machines is phenol formaldehyde. An average toaster is made up of several parts that are designed using this material. Bakerlite is another common substance used in producing heating components.

Smil (2013, p. 88) argues that most ecological problems arise from synthetic materials that fail to decompose when their life span expires. The hypothesis is based on the fact that all appliances have a certain duration within which they are expected to last (Vogtlander, Maestre, Rosan, Arno & Reene, 2013, p. 66). A skeletal observation of a toaster indicates that it is manufactured using most of these synthetic items. For example, its plug contains bakerlite, whereas its handle cover is coated with phenol formaldehyde.

The explanation illustrated above indicates that appliances made from synthetic materials have a negative effect on the environment. Guo (2012, p. 93) is of the opinion that this is one of the weaknesses of these products. As already indicated, most of the components found in a toaster are made using the aforementioned man-made materials.

The observation highlights the second shortcoming as far as a toaster is concerned. The life cycle analysis suggests that appliances should be made from bio-degradable materials. The objective of such a preference is to ensure that a given machine can be safely and effectively recycled upon the expiry of its life cycle.

Another element associated with the life cycle of an appliance, such as a toaster, involves its packaging. Vogtlander et al. (2013, p. 103) argue that any product should be packaged in a manner that conforms to the stipulated safety standards. The standards are formulated to ensure that the pack can be recycled. An example of such a scenario involves packing the product in a biodegradable material like cardboard. Such items decompose easily and are eco-friendly.

Pablo (2009, p. 172) points out that most electrical appliances are packed together with several accompaniments. To this end, it is common to find such elements as manuals and other wrappings in the container used to pack a machine like a toaster. The appliances may be wrapped in multiple layers of plastic material.

Such a presentation adds to the gadget’s shortcomings with regards to disposal. Plastic, as aforementioned, is a synthetic material. As a result, a toaster with such kind of packaging is an ecological hazard in itself. The wrappers add to its weaknesses. Figure 1 below illustrates a typical toaster:

From figure 1 above, it appears that the most conspicuous aspect of the appliance is the extended heating material. The curved copper element arcs across the inner surface of the plates. One places their sandwich on the rectangular part (Murielle (2011, para. 4). Evidently, a lot of heat is lost during the toasting process.

The heat dissipates into the regions that are not in contact with the bread. In addition, the toaster has a phenol formaldehyde casing that acts as an insulator. The same is indicated by the darkened regions on the diagram. The material used to make the handles should be biodegradable to make the recycling process easier

Implications of the Weaknesses

Klopfer and Grahl (2014, p. 83) are of the opinion that the performance and durability of an appliance are directly linked to the machine’s shortcomings. The said weaknesses have several implications on the functionality of this gadget. Such weaknesses should be addressed to improve the overall quality of the item. In life cycle analysis, such a product as a toaster is expected to complete its cycle.

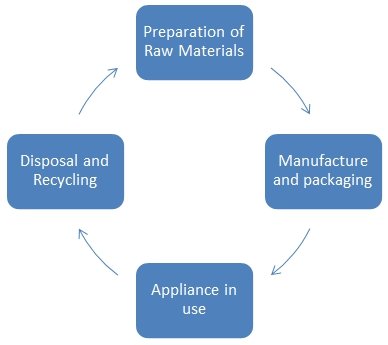

The phases run from the time it was manufactured to the recycling point. The inability to complete the span implies that the performance of that appliance is compromised (see Figure 2 below).

From Figure 2, it is evident that an appliance undergoes several stages that make up its ‘life’. The phases are evident in spite of the fact that the machine is inanimate in nature. Roughly, there are four phases in the life of an appliance. As indicated in the figure above, the stages start with the preparation of raw materials and end with the recycling of the product (Alastair 2009, p. 151). In some cases, shortcomings may inhibit the flow of the cycle. Under such circumstances, overall performance is affected (Esty & Simmons 2011, p. 188).

The discourse provided in the previous section reveals that the major weaknesses of a sandwich toaster are related to its energy consumption, packaging, and difficulty in disposal. Curran (2012, p. 93) argues that it is possible to regulate the rate at which an appliance consumes power. The major components of the sandwich toaster, as illustrated in figure 1 above, comprise of steel and copper heating materials. The abundant use of these elements is responsible for the high consumption of electricity.

The use of energy is further compounded by the quality of steel used to assemble the product. Poor quality steel translates to high energy consumption (Chapman 2005, p. 187). The case is the same for copper with impurities. Appliances that utilise a lot of energy lead to increased demand for electricity, which has a ripple effect on the environment.

Today, fossil fuels and a host of other non-renewable energy sources account for most of the electrical power produced in the world (Klopfer & Grahl 2014, p. 97; Thwaites 2011, p. 109). Alastair (2009, p. 106) is emphatic that fossil fuels contribute to environmental degradation. As such, appliances whose electrical consumption is high lead to increased massive ecological deprivation. The exploitation emanates from the fact that a lot of fossil fuels will be required to produce electricity.

On a more positive note, high demand for energy gives rise to the formulation of innovative measures. Curran (2012, p. 100) suggests that the need for environmental protection has triggered the development of alternative sources of energy.

The existence of appliances whose power consumption is high means that the demand for energy in the market will persist. Innovation is needed to come up with appliances with low power consumption. The objective of these interventions is to minimise environmental degradation by reducing reliance on fossil fuels.

The other major weakness discussed in the previous section is the difficulty of recycling a toaster. According to Chapman (2005, p. 129), life cycle analysis has specific guidelines that should be followed in disposing an item.

The analysis requires the appliance to be re-used to prevent the generation of more synthetic materials. As already indicated in this report, the need to recycle is governed by the element of environmental conservation. To this effect, an appliance that is assembled using materials that pose a challenge during the recycling process will increase environmental degradation.

Proposed Redesign of the Toaster

According to Energy.gov (2013, para. 2), the rising demand for electrical appliances leads to a proportionate increase in demand for energy. The aspect of environmental protection comes in when the energy is produced in a manner that is not eco-friendly.

Kibert (2012, p. 163) insists that it is important to manufacture appliances that consume less power. The interaction between such gadgets and the environment is not harmful. The scenario illustrates the need to dismantle the typical toaster and come up with a new design that addresses the aforementioned weaknesses.

To enhance the performance of an electrical appliance, the preferred redesign should be based on the incremental improvement of the constituent components. Horne et al. (2009, p. 96) hold the opinion that such re-engineering is achieved by substituting the unnecessary material. However, the replacement should be done in a way that does not interrupt the functions of the device. On the contrary, the functions should be improved (Horne et al. 2009, p. 96).

With regards to the toaster addressed in this report, it is important to make several changes as far as packaging is concerned. Pablo (2009, p. 61) argues that most clients misplace the instruction manuals that come with an appliance. The few who retain the papers end up disposing them at some point.

To address this issue, manufacturers of a simple machine like toaster should consider printing the instructions on a section of the actual device. For example, the instructions may be embossed at the bottom of the machine. Such a modification will help to reduce the adverse effects that papers and plastics have on the environment. The same will also ease the recycling process, meeting the specifications laid down by LCA.

The power cable is another aspect of the toaster that requires redesigning. According to Murielle (2011, para. 5), the plastic cords can be redesigned to improve functionality. Plastics are non-biodegradable, something that complicates the recycling process. It is advisable to replace the long cables with a shorter version, which further insulates the toaster. Still on the subject of insulation, the phenol formaldehyde used to coat the handles should be replaced with a bio-degradable material like bamboo (Crawford 2008, p. 500).

The most important aspect of a toaster is its heating capabilities. Murielle (2011, para. 5) holds that the only way to improve the performance of a toaster is to enhance its heating qualities. Such an improvement calls for increased insulation by covering the exposed parts. In addition, manufactures can make use of components with little electrical resistance. One such material is copper with very few impurities.

The new design should avoid having the copper arc across the cross-section of the plates. Instead, the sandwich toaster should have the heating material concentrated on the sections where the bread is placed. The same helps to distribute the heat evenly. Murielle (2011, para. 4) posits that an even distribution of heat helps to hasten the heating process, which reduces the amount of electricity spent.

The major objective of the proposed modifications is to enhance the performance of the machine and improve its efficiency (Alastair 2009, p. 73). Redesigning a toaster is meant to enhance the quality of the toasted bread and eliminate components that have a negative effect impact on the environment.

In addition, the proposed design will make it possible for the toaster to go through the complete ‘life cycle’ with little or no hindrances. The objective is realised through the elimination of non- biodegradable materials, which are replaced with those that are friendlier to the environment. The proposed design is illustrated in figure 3 below:

The figure above makes it obvious that the new toaster is significantly different from the old one. The surface area covered by the heating filament has increased. Each of the sections in the plates has a portion of the heating filament running on it. The thickness of the copper has also decreased to reduce energy consumption (Alastair 2009, p. 113).

The insulating material has been changed from the initial phenol formaldehyde to bamboo. The new insulator has properties that allow it to reduce heat loss into the environment. As a result, most of the heat energy is retained within the toaster. The same helps to reduce the time spent in burning the bread. The ripple effect is that a smaller amount of electricity is spent.

Conclusion

The recommendations made in this report are important in enhancing the performance of various machines used in the home and in the office. According to Chapman (2005, p. 108), the human race is heading to an era where electronic appliances will be vital components of life.

At the same time, there will be increased demand for energy. All these developments need to address the issue of sustainable source of energy. The design of new appliances should help in conserving the environment and minimising energy consumption. The recommended and remodelled toaster responds to the weaknesses of the standard machine and makes it more efficient. The efficiency of other appliances must also be enhanced. However, the new designs should not impair the normal functioning of the product.

References

Alastair, F 2009, The eco-design handbook: a complete sourcebook for the home and office, Thames & Hudson Publishers, London.

Chapman, J 2005, Emotionally durable design: objects experiences and empathy, Routlege, New York.

Crawford, R 2008, ‘Validation of a hybrid life-cycle inventory analysis method’, Journal of Environmental Management, vol. 88 no. 3, pp. 496-506.

Curran, A 2012, Life cycle assessment handbook: a guide for environmentally sustainable products, Wiley, London.

Energy.gov 2013, Estimating appliance and home electronic energy use. Web.

Esty, C & Simmons, P 2011, The green to gold business playbook: how to implement sustainability practices for bottom-line results in every business function, Wiley, London.

Guo, M 2012, Life cycle assessments (LCA) of lightweight eco-composites, Springer, New York.

Hendrickson, T, Lester, B & Scott, H 2006, Environmental life cycle assessment of goods and services: an input-output approach, Routlege, London.

Horne, R, Grant, T & Verghese, K 2009, Life cycle assessment: principles practice and prospects, Collongwood, CSIRO Publishing.

Kibert, J 2012, Sustainable construction: green building design and delivery, Wiley, London.

Klopfer, W & Grahl, B 2014, Life cycle assessment, Wiley, London.

Lowell, J 2009, Environmentally friendly toaster saves planet and breakfast. Web.

Murielle, 2011, Creating and maintaining an eco-friendly kitchen. Web.

Pablo, L 2012, Bamboo: a sustainable solution for Western Europe design cases LCAs and land-use, VSSD, Delft.

Smil, V 2013, Making the modern world: materials and dematerialization, Wiley, London.

Thwaites, T 2011, The toaster project: or a heroic attempt to build a simple electric appliance from scratch, Princeton Architectural Press, Princeton.

Trusty, W 2010, An overview of life cycle assessments: part one. Web.

United States Environmental Protection Agency 2012, Risk management sustainable technology: life cycle assessment (LCA). Web.

Vallero, D & Brasier, C 2008, Sustainable design: the science of sustainability and green engineering, John Wiley and Sons, Inc., New Jersey.

Vogtlander, G 2009, LCA-based assessment of sustainability: the eco-costs/value ratio EVR, VSSD, Delft.

Vogtlander, G 2011, A quick reference guide to LCA data and eco-based materials selection, VSSD, Delft.

Vogtlander, G, Maestre, A, Rosan, H, Arno, S, & Reene, W. 2013, Eco-efficient value creation, sustainable design and business strategies, Delft Academic Press, Delft.

Zamagni, A 2012, ‘Life cycle sustainability assessment’, The International Journal of Life Cycle Assessment, vol. 17 no. 4, pp. 373-376.