Internal combustion engine

Internal combustion engines operate on valves by pushing on the stems with cams and cam followers. This motion is coupled to the crankshaft generating the motion of the vehicle or machine parts. In earlier designs of engines, the valves were made parallel to the cylinders in a design that was referred to as the L-head engine due to the cylinder’s shape. Despite this design being cheap to construct, it has two main disadvantages which are; limited airflow limitation of the maximum speed. The design evolved to F-head, which has an intake valve in the block while its exhaust valve lies in the head; later on, both these valves were pushed to the head (Basshuysen and Schaefer 10).

Applications of Lubricants in an internal combustion engine:

Cold starts or lack of lubricants are the main cause of wear out in engines. In these internal combustion engines, there are numerous ways of oil circulation within them. Here the key point is to make sure that the efficiency of the crankshaft motion within the walls of the cylinder is enhanced. This offers protection to the piston and its cylinder walls from friction between the two of them, which normally cause wear out hence damaging the engine in the long term. This dramatically prolongs the overall life expectancy of the entire engine and enhances its performance.

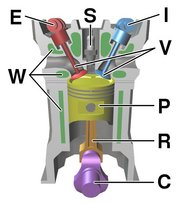

Internal combustion engines have and will always need lubrication which is meant to keep the part together and working with minimal noise and reduced wear and tear. In so doing, the life of the engine is highly prolonged. Lubrication can therefore be termed as being inevitable in running the machinery of any form for as long as they have movable parts. It is really important to have every movable part of machinery lubricated. Below is a representation in diagram form of an engine showing the movable parts (“Poppet Valve” 1).

The components above are typical of a four-stroke cycle DOHC piston engine where; (E) is the Exhaust camshaft, (I) the Intake camshaft, (S) the Spark plug, (V) the Valves, (P) the Piston, (R) the Connecting rod, (C) the Crankshaft and (W) the Water jacket for coolant flow.

Lubricants

Lubrication is an old affair dating back to the year 1650 B.C. In those days, olive oil, as well as animal fat, was used for lubrication as opposed to oil and grease in modern-day science. The use of oil came into existence when oil was first drilled in the year 1859 by scientists of that time. Immediately petroleum-based lubricants took center stage in the protection of movable parts, it was discovered that viscosity was one of the most important considerations to make when considering a lubricant (Mang and Dresel). With all this important in the functioning of any machinery, most lubricants face great setbacks in their operation in the respective machinery like the engines. This is due to the fact that the conditions always change with every new place of operation. These conditions should be analyzed and the eventual analysis be performed to check if there are any improvements that can be made on them. For the eventual good of the operation of the various machines that make use of such lubricants, this project seeks to find out a number of important facts pertaining to engine oils and analyze them in relation to the various environmental conditions. One such important consideration is the viscosity which is immensely affected by temperature variations (Neale 86).

In this conditions of high temperatures and high shear conditions, it is possible that engine oil loses its lubricating capability much faster and thus may need replacement at least once in an operating year. Rheology is generally termed as the scientific study of deformation together with the flow of various materials. Lubricants rheology will identify the factors which affect the viscosity of the lubricant in order to help maintain stable viscosity regardless of the outside factors.

Engine Oil Grades

There is a significant growth in variety of cars and their manufactures, there is an increasing demand for having many types of oils that could be used for the various forms of engines and that perfectly suit each one of them in their operating conditions. In an attempt to reduce the range within which viscosity varies, there has been the development of viscosity stabilizers to ensure that the range is minimized. Additives are made up of long chained polymers basically polymethacrylates, polyolefins, or polystyrenes. They however have the problem of compromising other properties of the respective lubricant which include; stability, oxidation, and resistance shear breakdown. In other words, oil additives may end up reducing the life time of the lubricant.

Since oil may operate in cold or hot conditions, it subjected to grading to obtain the best forms for each condition in order to keep the viscosity and enhance protection of the engine parts. Viscosity index in modern day oils is clearly stated on its packaging to ensure that the buyer gets the correct type. Some grading is clearly labeled for cold weather conditions and suits the user mainly in winter. The viscosity of normal multi-grade lubricating oil is divided into two parts; these are for the normal conditions and the extreme cold conditions. There is normally a letter ‘W’ which is there represent winter in the event of starting in cold places to allow for quick flow in such conditions. Along with this letter comes what is referred to as the viscosity rating of the given oil (a number). It generally offers information on the thickness of the oil. Thick oils may face challenges circulating in the engines. In other words, that number is simply the measurement of viscosity, that is, the measurement of the oil’s restriction to flow. An example is oil labeled 5W/40 where 5 is the oil’s viscosity at a temperature of 20 degrees while 40 is its viscosity at a temperature of 60 degrees.

After the invention of measuring tools for viscosity, the Society of Automotive Engineers (SAE) came up with various classes in use even today. These classes can be listed as; SAE 5W, SAE 0W, SAE 15W, SAE 10W, SAE 25W, SAE 20W, SAE 30, SAE 20, SAE 50, SAE 40, and SAE 60. Those with ‘W’ as earlier stated were formulated for cold temperature while those without it were suited for high temperature surrounding operations as lubricants. In lower temperature countries, it is better to make use of oil with a low cold viscosity rate and hence with much ease of circulating in the engine. The engine therefore has a chance of starting better due to less friction. In some other condition, additives are applied to the lubricant in question. Today’s engine oils have additives with the sole purpose of enhancing the viscosity verses temperature behavior of the oil. Eventually, it makes the viscosity of the oil stable changing much more gradually than in the event of it being plain.

Mineral oil which also goes by the name of liquid petroleum comes as a by-product whenever crude oil goes through distillation to obtain gasoline. It is a transparent kind of oil made up of alkanes together with cyclic paraffins. Mineral oil is produced at a lower cost making it much cheaper and available in large quantities. This oil has two grades, that is, the light and the heavy grades. Synthetic oil on the hand is used mainly to do the tasks of a lubricant. It is much more preferable since it can be assigned specific needs within the engine. Though they are a bit costlier to produce and thus more expensive, it offers significant performance advantages due to their stability especially at high temperatures (“Synthetic Oil” 1). This makes them preferable in solving our challenge here.

As every aspect of technology slowly but steadily transforms, so does the engine oil technology. To address these changing conditions there has been a constant growth eventually this project comes in. It seeks to test six different engine oil types using the rheometer (Anton paar rheometer) in relation to shear rate of viscosity and the operation temperature.

Rheology

Rheology can be said to be the study of how mater flows. This is done primarily in liquids but sometimes also in soft solids. In solids however, the flow is plastic rather than deformation responding to the force applied (Alexander and Isayev 50). Due to the increase of harsh /extreme environment which machines are required to operate in, there has been an increase in the number of complex rheological lubricants. There are many factors that can affect the performance of the lubricant inside an engine ranging from the shear rate to the outside temperature. In general terms, rheology has been called the study involving deformation together with the flow of materials (Tanner 50). Lubricants rheology will identify the factors which affect the viscosity of the lubricant, in order to help maintain stable viscosity regardless of the outside factors. The flow of the various liquid is heavily dependent on the viscosity of the given material. The viscosity of the various fluids in turn depends on a number of factors some of them being external to themselves like temperature and the shear stress. All these factors looked at together amount to rheology. Fluids are generally categorized into two main categories; non-Newtonian as well as Newtonian fluids. The idea of viscosity having been founded and greatly associated to Sir Isaac Newton, the study of variation in this particular viscosity has often been called non-Newton fluid mechanics.

Newtonian Fluids

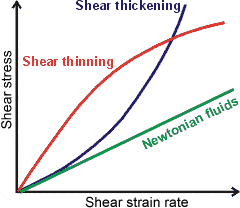

A Newtonian fluid is a fluid which regardless to the forces applied to it will have the same viscosity as long as the ambient conditions are the unaltered. Therefore, the curve of shear stress against shear rate of any fluid in this category is linear and goes through the origin; this is illustrated in Figure 2. A basic example of a Newtonian substance is the water we encounter on daily basis since its viscosity is constant.

Non-Newtonian Fluids

Non-Newtonian fluids viscosities changes by the kind of forces that act on the fluid regardless to whether or not the ambient conditions are constant. In addition to this, they are also influenced also by the environmental temperature where operate and the time of the operation (Schowalter 23). There are two categories of non-Newtonian fluids namely:

- Shear thickening non-Newtonian fluids

- Shear thinning non-Newtonian fluids

- Shear thickening of Non-Newtonian fluids:

When shear force is imposed to a shear thickening liquid, the atoms reorder themselves so as to have the fluid acting like a solid. Thus, with the increase of shear the viscosity of the fluid increases. An example of shear thickening fluid is when cornstarch is added to water, when applying high shear with a hammer it will act as a solid, but when a relatively small amount of shear is applied it will act as a normal fluid.

Shear thinning of Non-Newtonian fluids

Most shear thinning fluids have a relatively high viscosity, and when shear is applied it becomes thinner thus, viscosity of the material decreases (Owens and Phillips 120). Example of a fluid that brings out shear thinning is the toothpaste we use, should stress be applied, the toothpaste thinners thus reducing viscosity.

Rheology has been a serious part of science since its coinage by Eugene Bingham in 1920 at Lafayette College. Since then, the characterization of materials’ rheometrical behavior has been referred to as rheometry. In actual sense it is conducted on materials that cannot be analyzed using classical mechanics or elasticity.

Rheology majorly looks at the classical parameters pertaining to elasticity together with fluid mechanics to those fluids that are hard to describe by use of classical theories and offering them a description. Such liquids as oil flow whenever they are under some form of stress. The stress in question could be either torsion stress or shear stress. To this particular stresses, the materials respond in different ways (Morrison 100). The external forces and conditions result in internal strains thus resulting in to flow in various ways.

The study of extension of material is basically termed as extensional rheology. Under normal circumstances, it is far much easier to experiment on and thus much more data is available regarding it in relation to extensional flows. Liquids are generally looked at in relation to viscosity (thick oil is actually viscous) and solids with are looked at in relation to elasticity.

Testing

In order for analysis and inferences to be made not only in reference to this project but also in the development of the current state of lubricants, there was need to develop instruments that could be used to measure the rheometric parameters of the given materials. The instruments put in use to measure the various rheometric parameters of materials are generally referred to as rheometers. They impose a given amount of stress on the material under test and observe the behavior of the material in relation to it. They have the ability to operate in extension stresses as well as in shear stresses considering either oscillatory flows or steady flows. Despite the fact that there are many types of rheometers, the most prevalent ones are; the capillary rheometers and the stress or strain rheometers.

In the actual measurement of parameters like viscosity with consideration of the shear rate in order to obtain non-Newtonian behavior, or in measurement of detailed rheological properties for example visco-elasticity or much more the environmental temperature, Malvern’s rheometers are preferred world over to help apply rheology solutions to many industries. In total, six types of engine lubricants where used to simulate how multi-grade oils behave in a car engine. In addition, the difference between mineral and part-synthetic oils will be discussed and observed.

The rheometer that was used in this test is the Anton Paarphysica MCR 301 rheometer. The temperature range of this rheometer temperature control is from -10 degrees Celsius to 200 degrees Celsius.

Two tools where used to test the lubricants which are CP50-1 and CC27. The cp50-1 is a simple cone and plate with the cone having an angle of 1 degree and the plate is flat. The CC27 is cup and bob which are specifically the design of the engine piston together with the cylinder. Both tools are manufactured from stainless steel, and were thus not handled with another stainless steel object in order not to damage the tool, only brass should be used if necessary. The tool was cleaned using acetone solution to remove any residue that may influence the next material to be tested by the rheometer.

For this project, engine oils will be looked at closer through identifying the major outside conditions that affect the viscosity of the lubricant of different grades and different types.

The car engine oil in an ideal case should be changed once every year, preventing wear to the cylinder wall and the piston. The wear occurs when the oil starts gradually degrade due to the oil be burnt out or operating in high temperatures and high shear rates. In most of today’s cars the oil is held up in the crankcase and then squirted on the cylinder walls by the oil pump. In a two stroke engine the oil is circulated around the cylinder, this can decrease the efficiency of the lubricant, because the lubricant gets burnt with the fuel.

Test types

Oscillation test is where the tool taking the cone and plate for an example, the con just oscillates back and forth whereas the plate is still. This test can be used for all materials this includes solids and liquids. Rotational test are put in practice only for testing liquids. The cone here rotates around itself with the required shear rate or shear stress, whereas the plate is still.

The rotational test has two tests under it namely; the Controlled Shear Rate test CSR and the Controlled Shear Stress CSS. CSR involves the control of the shear rate by the rheometer as it measures the associated shear stress. On the other hand, CSS involves shear stress being controlled by the rheometer as the associated shear rate is monitored and measured.

Works Cited

Alexander, Aleksander, and Avraam Isayev. Rheology: Concepts, methods and applications. Akron: Chemtech publixhing, 2006. Print.

Basshuysen, Richard, and Fred Schaefer. Internal Combustion Engine Handbook. New York: SAE International and Professional Engineering Publishing, 2004. Print.

Mang, Theo and Wilfried Dresel. Lubricants and Lubrication. New York: Wiley-VCH, 2007. Print.

Morrison, Faith A. Understanding rheology. Oxford: Oxford University press, 2001. Print.

Neale, Michael. Lubrication and reliability handbook. New York: Newnes, 2001. print.

Owens, Robert, and Timothy Phillips. Computational rheology. Oxford: Imperial College press, 2002. Print.

“Poppet Valve.” WoI, 2009. Web.

Schowalter, Choi. Mechanics of Non-Newtonian Fluids Pergamon. New York: Pergamon, 1978. Print.

“Synthetic oil.” Castrol, 2011. Web.

Tanner, Roger. Engineering rheology. Oxford : Oxford University press, 2000. Print.