Introduction

The first question requires the removal of a valve for four weeks. There are additional chemical hazards and pressurized nitrogen to consider, in addition to the usual hazards of the actual process of removal and the prevention of any mistakes while the valve is missing. The risk must be assessed and the steps identified for the prevention of accidents before a permit to work can be issued. Then this must be documented and all labels placed properly and the documentation must be properly located in the central area designated. The work order must include the steps required for safety during the removal procedure and the steps required to prevent accidents while the valve is missing.

To increase the safety of the workplace and decrease injuries and fatalities on the job, a system for safety has been developed which, when follows, will ensure that the workplace is as safe as anything involving human beings can be. The parts to this system involve assessing the risk, identifying the steps needed to limit the risk, using a permit to work system which will require the assessment and implementation of the steps it identifies to mitigate danger, assigning responsibilities, and documenting with date and time all of these in designated central areas to be certain they are available where and when needed.

Most accidents are caused by one or more of three critical factors:

- Failure to properly assess all workplace hazards and identify the steps required to mitigate or eliminate them.

- Failure to follow the steps provided in the sell done assessment.

- Failure to reassess and make changes when circumstances change.

A properly done risk assessment will include all the steps of a job concisely but completely described, all the possible hazards and the steps and tools required to compensate plus a detailed plan with a map of hazardous areas and the locations for all permits. If all of these are followed carefully, there should be no added risk for the removal of the valve.

The procedure which should be followed in the case of this task (valve removal) a TRA (Total Risk Assessment) must be done since this is what is known as a one-off job, not something often done. The assembled team for this job must include an expert on attachment and removal of this valve, someone (preferably supervisor level) who will be present on this job in the areas where the valve is located, an expert on pressurized nitrogen, and an expert on the hazards of disulfide oil. An independent documentation specialist would be included who is, ideally, not connected to any of the departments of the other members of the assessment team and is very familiar with the process.

Hazards Identification

Graph A-Material and Procedural Risks

Job Safety Analysis

A JSA (Job Safety Analysis) must be done to identify all the steps required in the task and any hazards inherent or created by this process. It provides the criteria for the process of removing the valve by listing the procedural actions in proper order that will accomplish the task while ensuring the safety of the workers (Yli-Petäys, 2010, para. 2). In this case, the following are required:

- A work description detailing all of the steps required to accomplish the task safely.

- A list of required tools and safety equipment.

- The permits required to begin the task.

- A list of response patterns in case of problems or accidents.

- There should also be a safety shower and stations for eye washing around the work areas for people engaged in disulfide oil handling (Nettis, 2002, p. 102).

Work plan/ removing the valve plan

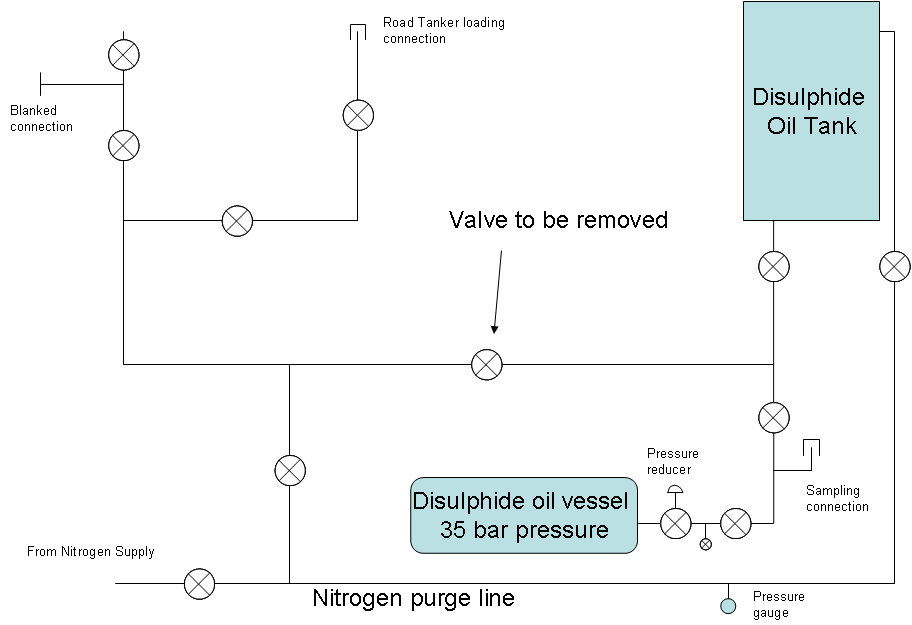

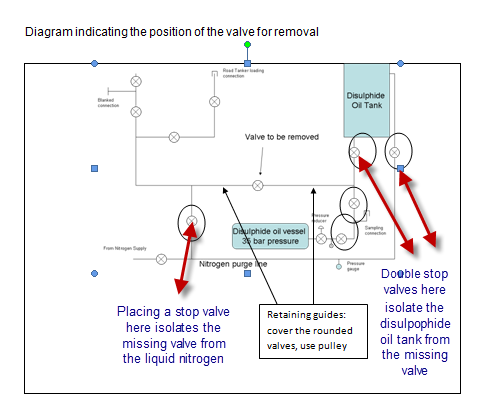

This diagram shows the location where the valve is to be removed. Using this it is possible to define where other valves can be closed in order to isolate the oil and liquid nitrogen tanks while the valve is being removed.

Examine and map the work site

Steps for Removing Valve

- Set up the valve area by removing the lead

- Engage the Clamp jacks and Check the pressure reducer and the isolation of the valve

- Reduce the pressure to a minimum level

- To confirm bubble test, remove and fix the plug and hose.

- Having fitted the valve, Remove the plug and the clamp

- Remove the valve from the channel space and attach a locking mechanism and a label for out of service.

- Check the functioning of the containment

Isolation

- The valve which is shown in the diagram below should be stopped (to isolate)

- The electricity should be stopped

- eta

Task Risk Assessment

The risks involved in this task include the material and procedural risks in Graph A above. There are hazardous materials (disulfide oil and liquid nitrogen), hazards of not carefully following the correct procedures in the correct order and the usual work hazards with tools, Safety equipment for protection of eyes and skin must be nearby in case of leaks or spills. A washing station should be set up to deal with skin or eye exposure and ventilation must be available. Because this is a deviation from the normal work, a YRA must be done for a work permit to be issued. The risk assessment for this task follows:

Routine jobs with the potential for serious incidents

The removal of a valve is a fairly routine job, but leaving the unit without a valve for four weeks, because no replacement is available is different and requires extra steps to prevent attempted use of the unit while the valve is missing.

Routine jobs with a history of the incident, including near misses

There is a history of incidents at other locations, PTW failure was a key contributing factor in the Piper Alpha disaster4.1.3 New jobs or jobs introducing new work methods

Routine jobs being carried out in unusual circumstances

This is not applicable, since the job is not routine.

TRA procedure of removing the valve from the system

(See 3.1 page 10 for list of steps)

What am I going to do?

The defective valve will be isolated from the disulfide oil and liquid nitrogen tanks and removed

What materials will I be dealing with?

The materials involved are disulfide oil and room temperature liquid nitrogen in tanks connected to the faulty valve.

What tools and equipment will I be using?

Tools employed are all hand tools: clamps, wrenches, pressure meters hoses, a pressure reducer, a plug, a locking mechanism, and labels.

When will the job be done e.g. time of day/year

The job will be carried out on graveyard shift when the plant is the least busy. It needs to be done now, so it is summer.

Where will the job be done e.g. at height, confined space?

The space is adequate for the work, although entrance and egress are complicated by pipelines. Adequate ventilation is nearby.

How might the activity affect adjacent plants/equipment/people?

The valve removal will only affect those who want to use this machinery. No other people are impacted.

How might the activity be affected by adjacent plants/equipment/people?

Nearby people or equipment will not impact the Valve removal, except that there must be some way to prevent people from turning out the lights.

What if?

If the valve does not remove easily some benign lubricant may have to be used. If there is any leakage from either the yank of disulfide oil or liquid nitrogen the leaks must be clamped off. If the leakage cannot be contained the area must be vented, and fire prevention procedures followed until the leak can be stopped or the offending tank can be emptied and closed off. In any of these instances, a report must be made. If any contact with the materials is possible, safety gloves and goggles should be used to p[revent skin burns or irritation and eye irritation or contamination. A washing station nearby set up for the purpose should be used to clean any exposed skin or to wash the eyes.

Use checklists as prompts

The checklist which should be used for this task should include the list of tools, the list of steps for the task, a check of the work permit, a list of safety equipment, and a list of procedures for any deviation in the process and procedures after the valve is removed.

Isolation plan

Control of substances hazardous to health (COSSH) is the most important measure in the isolation process. This requires that the workers observe strict adherence to the safety precautions set for each substance used in the work (Jappinen, 2000, p. 824). After closing all the other valves and ensuring no substances flow through the channels, the workers should wipe the area before using the available equipment to effect removal of the valve. This will ensure that the surfaces will be clean and dry, preventing slippage of tools. Personal protection equipment is a mandatory protocol in the guidelines to safe

handling of the materials present during the work process. Since these are expected to remain contained, it is sufficient to have the equipment close to hand. At each step of the work process, the workers need to log each step identified for the process and include any deviation, such as the use of protective equipment in the case of leakage (Yli-Petäys, 2010, para. 1).

Part of the isolation plan includes the measures for the permit to work. Supervisors will be monitoring the work while other workers are kept away from the site, except for one worker to man the electrical cutoff and alarm system and one worker standing by ib case o emergency to help with equipment or in treatment of the injury. Another worker will not be in this section of the plant until the stop valves are installed, the pipe is cleaned, the valve is completely removed and the pipe capped and labeled, plus the report is filed and the work completion noted on the work permit and signed by the supervisors.,

Stop valve

The tank of disulfide oil should be protected from leaks and other possible risks by a stop valve. Workers on the job if removing the faulty valve in the system will then be safe from the possible exposure to disulfide poisoning (Kazan et al, 2002, 1865). Another stop valve should be installed to isolate the liquid nitrogen. This valve must be equipped with a pressure release since the build-up of pressure is dangerous, but the release of small amounts of liquid nitrogen is not. It is unlikely that dangerous pressure would build at room temperature, but extra precautions are better than taking chances.

Stop electricity supply

Because disulfide oil is very smelly, it is sufficient to have a worker standing by the circuit breaker and emergency lighting in case of a leak. However, all power to the system upon which the work will be done will be cut off and the breaker opened to prevent an accidental start.

Bleeding the line

The pipe between the oil tank and the valve must be bled to remove any remnant of oil before proceeding to remove the faulty valve to eliminate the possibility of a contact hazard or a fire. The line will be valid up to the stop valve to ensure that there is no car in the line. Then the line between the stop valve and the faulty valve to be removed must be cleaned to prevent accidental combustion.

Stop nitrogen supply

The nitrogen tank must be isolated also and a stop valve installed. As mentioned above, it should be fitted with a pressure release to prevent the build-up of pressure.

The illustration below shows the installation of the stop valves.

Permit to work system ( PTW)

A PTW (Permit to Work) System is a safety precaution that assures that any task includes all the steps required to maintain the safety of the workers. Most PTW forms have seven sections:

- General Description{ This should be short, to the point, and written in plain English.

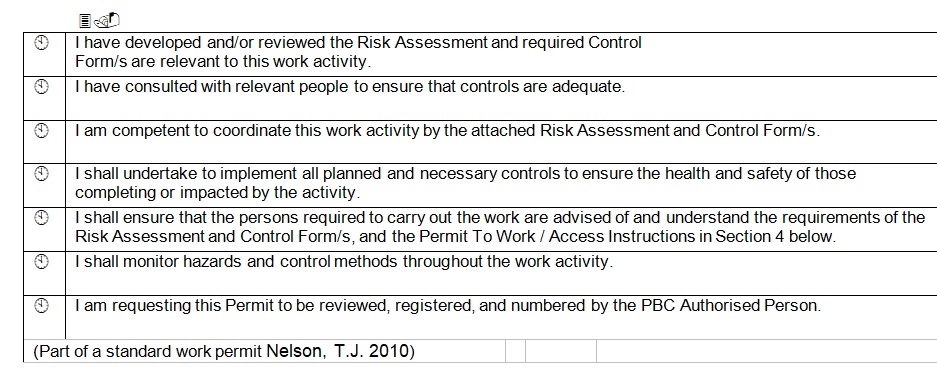

- Permit Request with Supervisors name. This contains a checklist which the supervisor checks off to indicate that he has reviewed the situation and consulted with the right people, is competent to supervise the work, has plans for proper safety controls, will inform all personnel involved of the various aspects of the work and will monitor all possible hazards.

The supervisor then signs and dates this request below the checklist.

- The third section designates which personnel must also sign off on the permit and provides that they indicate that they have reviewed the request, concur with the specifications, and have registered the PTW.

- The fourth part of the PTW provides space for persons involved in the task to enter and leave the workspace where the work is to be done if this is in a confined area, such as in a specific room. This controls personnel access and provides a way to track the work.

- Section five provides space for workers who are not entering confined spaces to sign in and out.

- The last two sections are signed off and closing of the permits by the supervisors and issuers.

Conclusions

This seems like a very complicated process in writing, but in execution, it is quite simple to follow and it covers all the steps and all possible hazards well enough to prevent most accidents, By using this system time, money, productivity, and human suffering are saved. If these steps are followed, the removal of the faulty valve should pose no hazards, either during or following the procedure.

References

“ASSE’s Middle East Chapter Seeking Papers, Presenters.” Professional Safety 54, no. 5 (2009): 16. Academic Search Elite, EBSCOhost (accessed July 30, 2010).

FANR. 2010. Nuclear Safety. Web.

Gowen, Burger, and Brent E. Gowen. “Cryo-TEM liquid nitrogen splash guard.” Journal of Microscopy 191, no. 3 (1998): 320-322. Academic Search Elite, EBSCOhost.

Hale, A.R, Heming, B.H Carthey, J & Kirwan, B. 1997. Modeling Of Safety Management Systems, Safety Science, Vol. 26, Issues 1-2, pp 121-140.

Herbert, R & Landrigan, P.J., 2000. Work-Related Death: A Continuing Epidemic, American Journal of Public Health 2000, Vol. 90, No. 4. Pp. 123-145.

Jappinen, P. 2000. Exposure To Hydrogen Sulphide And Respiratory Function, Br J Ind Med; 47: 824-828 doi:10.1136/oem.47.12.824.

Kales, S.N & Christiani, D.C. 2004. Acute Chemical Emergencies NEJM,350:800-808.

Kazan, S et al. 2002. Work-Related Inhalation Injuries Chest, 2002, 122:1865-1866.

LaGuardia, T. 2004. Occupational Safety and Health Requirements. The Decommissioning Handbook. Park Avenue, New York: ASME Press.

Nelson, T.J. 2010. Hazards of Liquid Nitrogen. Lab Safety Notes. Web.

Hurst, N.W et al., 1996. Measures of Safety Management Performance and Attitudes to Safety At Major Hazard Sites, Journal of Loss Prevention in the Process Industries, Vol. 9, Issue 2, pp 161-172

Nettis, E. 2002. Occupational Irritant And Allergic Contact Dermatitis Among Healthcare Workers, Contact Dermatitis, Vol. 46 Issue 2, pp 101 – 107.

Workplace Safety FANR. 2010. Risktec In conjunction with Liverpool John Moores University: Risk Management and Assessment for Business. Module: RSKMSM002.Consulted but not cited.

Yli-Petäys, J., 2010. Emerging Trends In Intelligent Safety-Valve Control. O & G. On-Line. Web.