Abstract

The establishment of a degree program requires a feasibility study to determine its sustainability. The main components of the feasibility study encompass actual and expected market demands, availability of skills, and a survey on the perception of potential beneficiaries of the program. To carry out a study with the unquestionable confidence level, the actual sector performance of related courses should be overviewed at the backdrop of structured establishment, monitoring, and expansion module. This report aims to explore the feasibility of starting a Master’s level academic program on Safety Engineering/Management at King Fahd University of Petroleum and Minerals (KFUPM) in Dhahran, Kingdom Saudi Arabia (KSA). The motivation for exploring the feasibility study for such a program is rooted in the growing importance given to safety in the workplace.

In introducing the master’s program, the aim is to advance the knowledge and practice of management of safety in engineering as a discipline. Safety management is a fundamental arm of engineering discipline that seeks to increase manpower productivity through the reduction or elimination of accidents and various fortuities that may occur in the field of engineering. The concept is also very significant in the elimination of errors in engineering designs and systems, especially in the software engineering subset. The inception of the program shall go a long way to introduce specific and major areas of concern in engineering safety and designs. With the expansion of engineering programs in the university, a new facet of the engineering arm is indeed very important in managing safety in the sector.

Introduction

This report aims to explore the feasibility of starting a Master’s level academic program on Safety Engineering/Management at King Fahd University of Petroleum and Minerals (KFUPM) in Dhahran, Kingdom Saudi Arabia (KSA). The motivation for exploring the feasibility of such a program is rooted in the growing importance given to safety in the workplace. More specifically, as safety in workplaces is a complex issue, there is a growing need for personnel with specific skills set who can function as safety managers/engineers. There is a two-pronged approach required to ensure the safety of individuals in a workplace: An active approach and a reactive approach, and both are important. The reactive approach is the presence of a policy structure that enables people who are injured at work to gain access to appropriate help and support.

In conjunction with the well-developed medical sector in KSA, starting from 2011 a law makes it mandatory to cover all private-sector employees with health insurance. According to the Council of Co-operative Health Insurance (CCHI), “The very promising health insurance sector represents one of the most important and influential factors affecting… health care services presented for Saudis working in the private sector and ex-pats” (Chaturvedi 2006). So along with government sector employees, this new law ensures a support system for private-sector employees. It is important and works well as a reactive approach to workplace safety complications. On the other hand, it should be accompanied by an active approach. This would be to develop safety systems and skilled personnel who would operate to actively thwart workplace-related injuries and hazards in KSA.

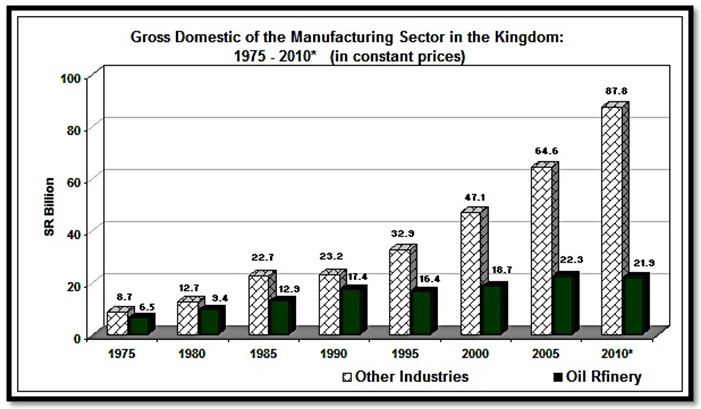

Out of a population of around 27 million, over 8 million are comprised of the workforce in KSA, of which 12% are engaged in agriculture, 63% in services, and 25% in industry and manufacturing (Chaturvedi 2006). Although safety should be mandatory in agricultural and service sectors as well, in the industry and manufacturing sector it is a crucial requirement. However, this report focuses on this last sector to gauge the importance of creating skills in personnel, which can enable them to function as safety managers/engineers. According to a study by the Saudi Industrial Development Fund (SIDF), the number of industrial and manufacturing sectors has grown significantly (Karmis 2001). Figure 1.1 below indicates how the country’s economy is dependent on this sector to a great extent:

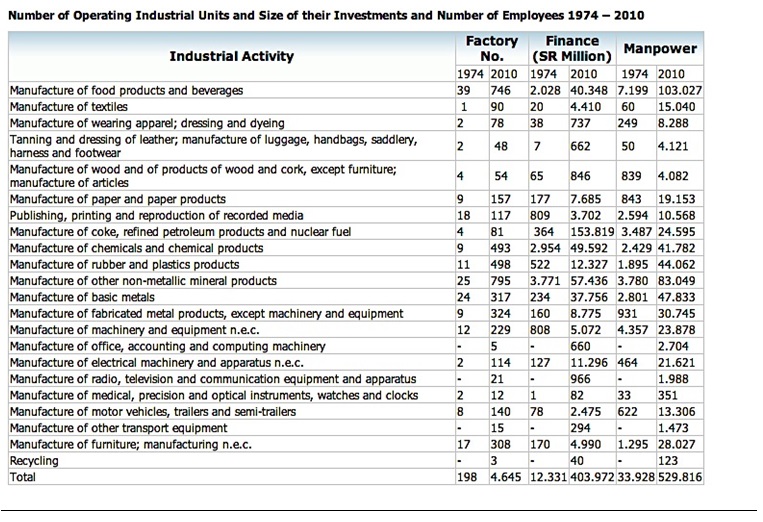

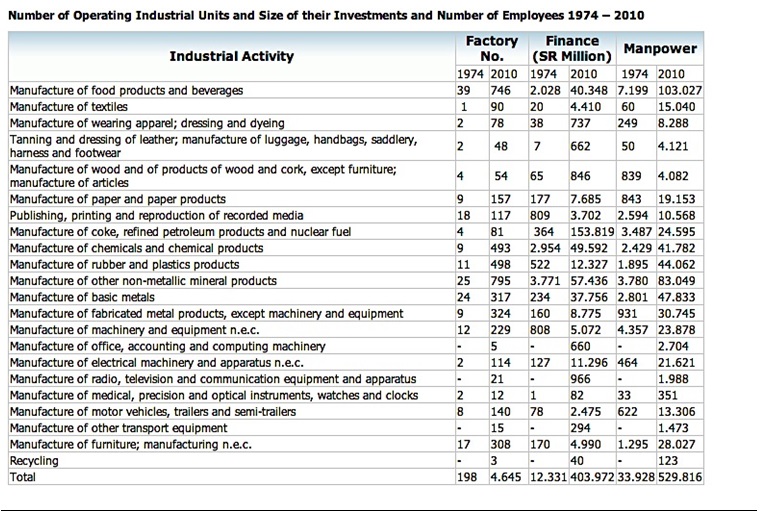

Reflectively, lack of adequate safety measures and systems in place -and more importantly personnel who can operate them- translates directly into exposing employees, production lines, and the country’s economic security to potential harm (Karmis 2001). Table 1.1 below highlights the specific types of factories that have grown in KSA.

In trying to explore the feasibility of an academic course in “safety”, the broad potential hazards in all the above types of industries were particularly considered. Finally, Table 1.2 below shows how this growth has spread across, and consequently, how the demand for safety managers/engineers can be speculated in various parts of the country.

It is clear to a large extent that these industrial and manufacturing cities would require much personnel to perform the function of safety managers/engineers within various units/factories/plants. Against the backdrop of such a rampant and growing sector, it is a systemic shortcoming that only one university in KSA recently offers a “safety” orientated academic program.

The main features of the proposed program will seek to offer individuals know-how on how to prevent and deal with almost all the broad hazards that may occur within workplaces. More specifically it would seek to cover all major KSA industries and manufacturing discussed above. It will also be influenced by the results of the survey conducted within various KSA organizations to gain an insight into the various sources of hazards within these organizations.

The rest of this document contains the literature review, where existing international programs are discussed and literature on “safety” is reviewed. Besides, the methodology is ‘operationalized’ by discussing the designs, results, and scoring from questionnaires sent to various organizations. Finally, this is followed by data analysis and results, where the program needs are analyzed based on evidence of national and international demand for an academic course on safety. Besides, a comparison is made with specific national/international programs that are similar to the one proposed. Besides, the program objectives along with the intended learning outcomes are discussed.

Literature Review

Major Academic Programs on “Safety” at a Master’s Level

This chapter discusses the boundaries of this research, presenting current peer-reviewed and credible information on safety and management efficacy. The approach and methodology proposed for this research are argued with support from current literature. The literature presented is grounded in the conceptual frameworks outlined in Chapter One. The number of academic institutions programs related to “safety” is significant, yet inadequate when compared to the scale of the expanding industrial and manufacturing sector globally. During an initial search for various programs, I found 65 recognized/accredited academic institutions in the USA (45) and UK (20) that offer “safety” related programs at different levels, ranging from Bachelor’s to Master’s, to Ph.D., and a mix of these offered Online. All these, with relevant details, can be found in Appendix A.

My focus here is on academic programs related to “safety” at a Master’s level. For a detailed preview of theses courses, the modules they offer relevant to “safety”, and (where available) their program description/objectives/expected outcomes, see Appendix B. Out of the above 65, I found 35 institutions (21 in USA and 14 in the UK) that offered a “safety” related program at a Master’s level. Of these 35 institutions, 3 offered more than one program related to “safety”, that is, University of Connecticut, Edinburgh, and Ulster (Stellman 1998). Therefore the total number of programs offered comes to 38 and their breakdown is as follows:

- Fire Protection Engineering (University of Maryland, USA)

- Safety Sciences (Indiana University of Pennsylvania, USA)

- Safety Technology (Marshall University, USA)

- Occupational Safety and Health (Murray State University, USA)

- Environmental Health and Safety (EHS) Management (Rochester Institute of Technology, USA)

- Occupational Safety Management (University of Central Missouri, USA)

- Environmental Sciences Safety (University of Houston Clear Lake, USA)

- Safety Management (West Virginia University)

- Occupational Safety (East Carolina University, USA)

- Safety and Occupational Health Applied Sciences (Keene State College, USA)

- Engineering Technology, Occupational Health and Safety Concentration (Middle Tennessee State University, USA)

- Occupational Health and Safety (Southeastern Oklahoma State University, USA)

- Environment Safety and Health Management (University of Findlay, USA)

- Safety (University of Wisconsin Whitewater, USA)

- Occupational Safety and Health Engineering (New Jersey Institute of Technology, USA)

- Environmental Safety and Health (Oregon State University, USA)

- Environmental Protection and Safety Management (Saint Joseph University, USA)

- Environmental Health and Science (University of Minnesota, Duluth, USA)

- Public Health with a Concentration on Environmental Safety (University of South Florida, USA)

- Fire Protection Engineering (Worcester Polytechnic Institute, USA)

- Fire Science (University of New Haven, Connecticut, USA) and

- Emergency Management (University of New Haven, Connecticut, USA)

- Occupational Health, Safety and Wellbeing (Cardiff Metropolitan University, UK)

- Occupational Health and Safety Management (Loughborough University, UK)

- Occupational Safety and Environment (University of Birmingham, UK)

- Occupational Health and Safety (University of Salford, UK)

- Environmental Health and Safety (University of Sunderland, UK)

- Health, Safety and Risk Management (Robert Gordon University, UK)

- Safety, Health, and Environment (University of Greenwich, UK)

- Safety, Health and Environmental Management (University of Glamorgan, UK)

- Fire Engineering (University of Central Lancashire, UK)

- Structure and Fire Safety Engineering (MSc) (University of Edinburgh, UK) and

- Structure and Fire Safety Engineering (MEng) (University of Edinburgh, UK)

- Hydrogen Safety Engineering (University of Ulster, UK) and

- Fire Safety Engineering: (University of Ulster, UK)

- Critical Safety Engineering (Bangor University, UK)

- Safety Engineering (Lancaster University, UK)

- Fire Explosion Engineering (University of Leeds, UK)

An analysis of the above table indicates the following ‘focus’ which overlaps the different Master’s level courses.

- Number of courses with a focus on “Fire”: 8

- Number of courses with a focus on “Health”:16

- Number of courses with a focus on “Occupational Safety”:11

- Number of courses with a focus on work “Environment”: 11

- Number of courses with a focus on “Safety and Management”: 9

- Number of courses with a focus on “Safety and Engineering”: 12

- Number of courses with the term “Safety” in the title: 31

It is important to note that many of these universities offer modules that cover most of the above ‘focuses’ (see Appendix B). Here I have attempted to deduce their primary focus predicated on the “title” of their Master’s program.

Needs for a masters program in safety

It is a fact that a humongous industrial revolution of unprecedented nature is occurring right now at an advanced level. Several industries of different nature are being set up on an almost daily basis. This, therefore, has greatly increased the demand for safety management in engineering. The program should explore avenues on enhancing safety in all engineering setups.

An exclusive study of the undergraduate programs that are currently offered in different universities, reveals that the course units on safety are very general, they cover a very narrow facet on engineering safety management and focus a lot on the engineering designs course units. A specific program that focuses on safety, therefore, must be sought. This, to say the least, shifts focus on the management of the environment where the work is done and the worker himself. (Suurmond, 2008)

With the advent of new machines and engineering technologies, the management of safety in engineering has invariantly posed major challenges. The inception of newer technology brings forth unique safety issues that should be researched and mitigated. (Grimaldi and Simmons, 1975) Other than the study of the safety of the workers and the environment of work at large, the technocrats in this field must be vastly knowledgeable in the equipment. (Hammer, 1976) This provides an insight into all the threats that the equipment exposes the workers and the environment.

As earlier noted, the industrial growth witnessed in Saudi Arabia is a factor that has created enormous demands for the personnel trained in the field of engineering safety management. (CoVan, 1995) Industrial growth in any country exerts pressure on the market demands for professionals, however, these professionals must be well trained to accommodate both knowledge in the engineering field and the safety field at large. The inception of a program that instills occupational safety and management in engineering is therefore inevitable.

With a specific example of environmental safety, it is very factual to reason that the field is very wide. Environmental safety, as a discipline, covers a very huge area of study since the environment is significantly very large; this essentially calls for a narrow area of study that would focus on specific areas of environmental safety. (Rosner, 1987) The inception of the engineering safety and management program would therefore fill this void. The specificity of the program in a given area not only offers the engineering fraternity a more specific discipline of study but also an exclusive knowledge in an area. (Roth and Teltscher, 1975)

While exploring the vast field of ergonomics, an important breakthrough has been established that tries to highlight the interaction between human factors and machines that have been designed and developed. (Roland and Moriarty, 1990) The ergonomics field, however, remains largely unexploited especially in the developing world, initiating a masters program thus ensures that proper machine-human interaction levels are established. The ergonomic analysis enables the human interface to understand machine design and probable error genesis. (Guarascio, 2007). An in-depth exploration of this field needs is required through extensive research, this is achievable through an elaborate master’s program. (Bauman, 2012) It is therefore in such interests, that the university should explore this program to develop knowledge that suits the demands of the market. (Kavinian and Wentz, 1990)

Need and Importance of “Safety”

There are some ways that the need for “safety” may be assessed within the industrial and manufacturing sectors. For instance, just like the prevalence of this sector in KSA was discussed above, the same can be done at a global level (Stellman 1998). Relying on the above function, Figure 1.2 and Figure 1.3 below show the amount of global capital.

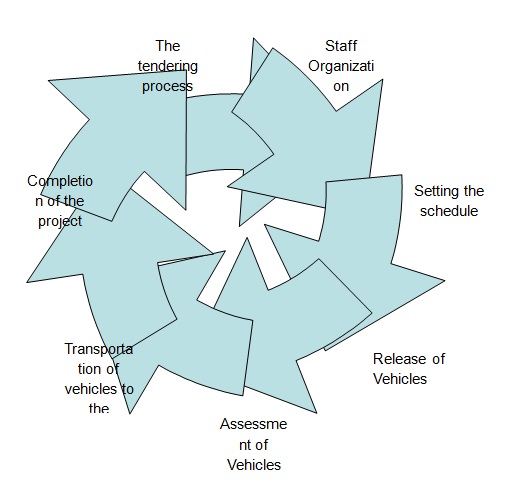

Although it is easy to assess the worth of the industrial and manufacturing sector at a global level, by mentioning the above, I intend to give a ‘live’ indication of the growth of this sector. It indicates an imminent and forthcoming need for personnel who can function as “safety” managers/engineers within the industrial and manufacturing sector at a global level shortly (Stellman 1998). However, how and where then does “safety” actually play come into the operations of these manufacturing and industrial plants? The following Figure, though not in English, is easy enough to understand the broad basic operations of many plants in this sector:

From the above figure, one can deduce various general “safety” measures that may be put in place at each stage to safeguard production lines, personnel, and plant. Drawing from the various Master’s level programs discussed above, the focus of many of these programs is on ‘fire’; ‘health’; ‘occupational safety’; safety in the work ‘environment’; ‘safety management’, and ‘safety engineering’(Karmis 2001). There are various hazards that these different focuses on entail. The major ones that are mentioned in the survey originate from: machinery; chemical; heat; welding; electrical; noise; radiation; fire, and others.

The specific type of “safety” under scrutiny here is that in the workplace. Occupational safety is a multi-disciple issue and concentrates on the welfare of those who are engaged in employment or work. Karmis (2001) defines health as “the absence of ‘disease and infirmity’, and are directly related to, ‘safety and hygiene at work” (Karmis 2001, p.98). According to, Barnett-Schuster (2008), safety can be understood as the ‘absence of danger’ and the ‘absence of safety’ in danger. Thus, Bernett-Schuster argues that these organizations believe that major hazards fall in four primary categories: ‘Physical, chemical, biological and carcinogenic’ (Barnett-Schuster, 2008, p.1). The classical definition of a hazard is the potential for an accident. However more formally, “hazard has been defined under Occupational Health and Safety Management System (OHSAS-18001) as source or situation with a potential for harm in terms of injury, ill health, property damage, damage to the workplace environment or combination of these” (Chaturvedi, 2006, p.163). How people view “safety” often depends on how it is projected and what importance is given to it, “workers’ motivation and behaviors regarding safety at work are influenced by the perceptions they have of the priority given to occupational safety by their superiors and top managers’ (Stellman, 1998, p. 595). This in turn means that “effective health and safety management must include acknowledging the importance of occupational health hazards and the proportionate application of resources to address those issues” (Karmis, 2001: 22).

The Canadian Center for Occupational Health and Safety has a wealth of information and indicators, which underscore various aspects of “safety” in the workplace. The main areas they cover, and which could be treated as one of the sources when devising an academic program on “safety”, are, ‘accident investigation’; ‘basic Organizational Health and Safety Program Elements’; ‘confined spaces introduction’ and ‘program’; ‘effective workplace inspections’; ‘emergency management checklist’; ‘emergency planning’; employees assistance programs’ (EAP); ‘employee orientation checklist’; ‘ergonomic safe patient handling program’; ‘first aid-general’; ‘guide to writing an Organizational health and safety policy statement’; ‘handling suspicious mail’; ‘hazard control’; ‘hazard reporting by employees’; ‘hazard and risk’; ‘health and safety committees’; ‘inspections checklist’; ‘job design’; ‘job safety analysis’; ‘risk assessment’; ‘sanitation’, among others (Karmis 2001).

The importance given to occupational safety is not new in KSA and gives us an insight into the predecessors of “safety engineers”, the “labor inspectors”. For example the ILO’s Record of Proceedings from 1991, as the then Minister of Labor and Social Affairs of KSA, Al-Fayez notes that:

I have the honor, on this occasion, of outlining for you some of the importance which Saudi Arabia accords to the environment as regards occupational safety and health. To meet the required standards, the Labor Code provides for labor inspectors to monitor the occupational environment to ensure the safety and health of workers (Organization 1991, p. 114).

Today initiatives like SFPE-SAC (Society of Fire Protection Engineers) Saudi Arabian Chapter are conducting its 4th Fire Technology Conference & Exhibition under the slogan “Join us to Prevent, Manage and Control Industrial Fires”. The conference will include twenty (20) carefully selected papers covering a wide range of topics such as safety programs in educational, community, and industrial facilities, fire service organization and manpower, fire hazards identification and risk assessment methodologies, and fire equipment and system acceptance testing requirements. Also, IFSEC (International Fire & Security Exhibition and Conference) with a focus on OSH (Occupational Safety and Health) speak of its, ‘9-12 December 2012| Riyadh: OSH Expo Arabia is an annual exhibition for the occupational health and safety community in Saudi Arabia…this new event offers health and safety professionals and business operators from across a broad range of industries the opportunity to source new products and services, hear keynote seminars and take part in exclusive networking events’ (Organization 1991)Various annual surveys have been conducted in Europe and USA on OSH. Similarly, studies have also been conducted in KSA, which unequivocally point to the main problem in the context of occupational safety in the country: lack of qualified personnel. For example, Sebiany Ahmed, & Ballal (2002) indicate that:

The Kingdom of Saudi Arabia is rapidly industrializing, and the economy is now less dependent on oil. The future of industrial growth is very bright. Two industrial complexes (at the Arabian Gulf and the Red Sea coasts) of eight provide the basis for the Kingdom s programs to develop hydrocarbon-based and energy-intensive industries. Expatriates from the driving workforce in the industry. Today, more Saudis are being recruited and trained to man the factories. Occupation-related disorders in the industry vary from minor irritations to injuries and cancers. However, the risk of massive releases of toxic chemicals is not great. The national Occupational Health Service Directorate is based at the Ministry of Health. Together with the Ministry of Labor, it assumes the overall supervision of industrial health and safety. However, there are constraints the most important of which is the lack of enough qualified Saudis in this field (p. 475).

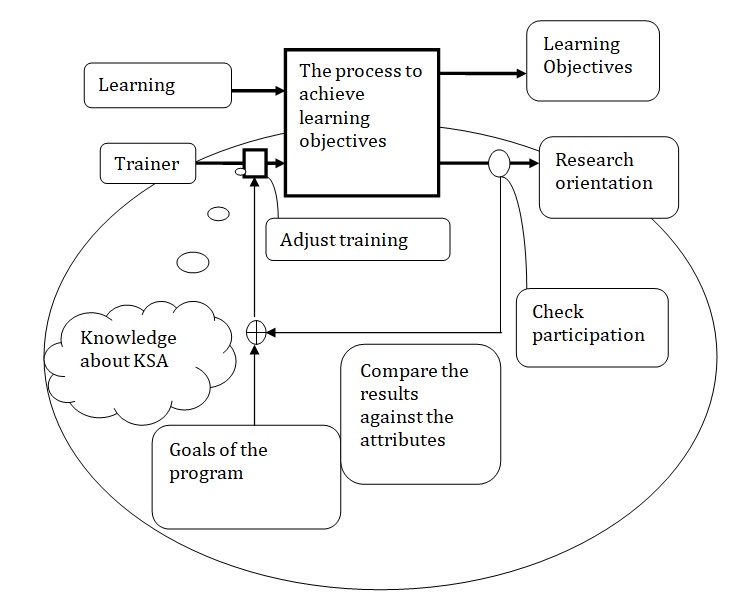

Reflectively, this indicates the importance and demand for personnel who can function as “safety managers/engineers” in KSA it also underscores the relevance of this report. A comparison is then done between the ratings and the expected results as agreed upon at the beginning of the year and also with expected skills profiles for these areas. Such appraisals are important as they help education providers to establish their performance about the expectations from the labor market and expected outcomes as agreed during program planning (Karmis 2001). Further, the appraisals reveal gaps that may be inherent when executing duties. At the end of the appraisal procedure, the line program implementation committee formulates a plan for further development for the next period.

In the program development plan, the coordinators set objectives based on the feedback from their performance appraisal and all education providers must have such a plan. The whole interactive appraisal process is beneficial as it aids education program developers in developing a focused objective learning model. New information and communication technology has greatly changed the perspective of educational practice (Karmis 2001). The implementation of these new information and communication technologies in the education system is considered one of the most challenging and important issues in the 21st Century. The first suggestion was the introduction of computers into the education system which when aligned in the safety master degree program, will make its implementation sustainable.

Research Background

The Saudi Arabian Kingdom has developed rapidly in the last two decades due to improvements in infrastructure, better education, and gainful employment opportunities. In the face of growing demands for personnel in the Safety engineering industry, there has been a need to incorporate new market-oriented training within its many universities. Thus, this report explores the feasibility of starting a Master’s level academic program on Safety Engineering/Management at King Fahd University of Petroleum and Minerals (KFUPM) in Dhahran, Kingdom Saudi Arabia (KSA) in line with the high demand for trained personnel in safety management. The motivation for exploring the feasibility of such a program is rooted in the growing importance given to safety in the workplace. More specifically, as safety in workplaces is a complex issue, there is a growing need for personnel with specific skills set who can function as safety managers/engineers.

Aim and Objectives

This research aims to examine the feasibility of starting a Master’s level academic program on Safety Engineering/Management at King Fahd University of Petroleum and Minerals (KFUPM) in Dhahran, Kingdom Saudi Arabia (KSA) in line with the high demand for trained personnel in safety management.

The objectives of this study are as follows:

- To understand the social institutions in place to cater safety engineering course at King Fahd University of Petroleum and Minerals (KFUPM) in Dhahran

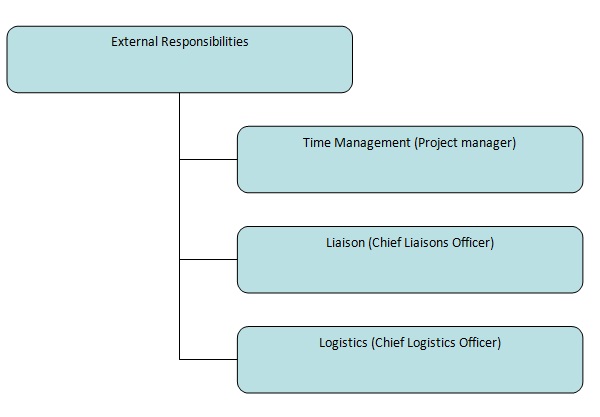

- To examine the internal and external transition models within the education system that will facilitate the establishment of a masters degree in safety engineering at King Fahd University of Petroleum and Minerals (KFUPM) in Dhahran

- To determine the existence of transition objectives and their effectiveness as part of market demand for safety engineers within KSA to determine the feasibility of establishing a masters degree program in safety engineering at King Fahd University of Petroleum and Minerals (KFUPM) in Dhahran

- To examine some policy proposals to manage the transition process and major challenges that might face the implementation of a new masters degree program in safety engineering at King Fahd University of Petroleum and Minerals (KFUPM) in Dhahran

Methodology

Summary of Methodology

This is a systematic but comprehensive method of data collection, grouping, and analysis to scientifically apply reasoning from the analyzed data. The result of this process combines the outcome, the purpose of the research, and actuality. Reflectively, a blueprint is transformed into a research design through a series of operational studies aimed at drawing a factual outcome comprising of evidence-backed claims. This research is developed across the research tactics which are decided by several types of data and different analysis ways to be used. On the front occasion, the researcher used to use mixed research ways to combine two different sets of variables that had the same data referred to as quantitative and qualitative data. After the analysis of data details, symbolic qualitative and high technological ways were employed to arrive at conclusions. The content analysis was used due to its ability to review a wide range of non-construction data. The actual scenario was then analyzed through mathematical, statistical, and computational modus operandi to derive quantifiable results. The process relied heavily on respondent information from the twenty-four participating organizations. Open-ended online questionnaires were the main data collection tools since the process relied on voluntary responses.

Operationalizing the Aim through Questionnaires

This study aims to explore the feasibility of starting a Master’s level course on “safety” at KFUPM. The basis is exploring the demand for ‘safety managers/engineers’ in KSA. To operationalize this goal, a survey was created and sent out to various organizations in KSA and other GCC countries asking, among other things, their need for personal in the coming years, which can function as ‘safety managers/engineers’. As a methodology that is most suited to the aim of this report, “technological improvements in survey method techniques, such as probability sampling and standardized measurement, allow researchers to feel confident that the population sample is not biased… another benefit… is that it is, in a sense, flexible- many questions can be asked on a topic” (Cargan, 2007, p. 90).

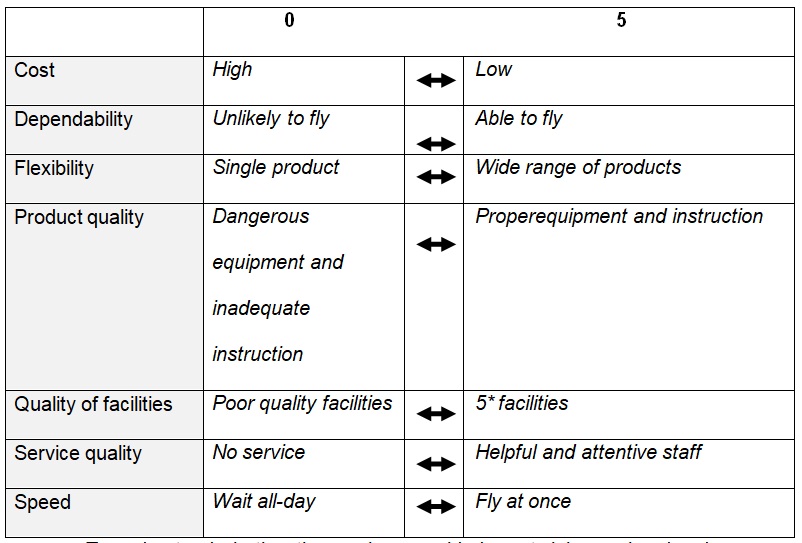

Design of the Questionnaires

The survey constitutes of 13 questions, which are designed to gain an insight into various aspects of “safety” within target organizations. The result was then collected and analyzed. This section throws light on the questionnaires’ design, statistical sampling, scoring, and the flowchart, which explains the methodology of the survey.

Name of Organization

Several employees within the organization

- Under 500

- 500-1,000

- 1,000-5,000

- More than 5,000

Field of the business conducted at the organization

These first three questions are geared towards finding out about the organization’s size and nature of business. Apart from how they define their needs in the rest of the questionnaire, it grants the researcher an insight into the potential number of “safety” managers and type of safety management.

Please select the source of hazards in your organization

- Machinery

- Chemical

- Heat

- Welding

- Electrical

- Noise

- Radiation

- Fire

- Other (Please Specify)

From the point of view of seeking to device an academic program on safety, this is one of the most important questions. It establishes, to an extent, what the emphasis of training safety managers should be in the context of the potential hazards.

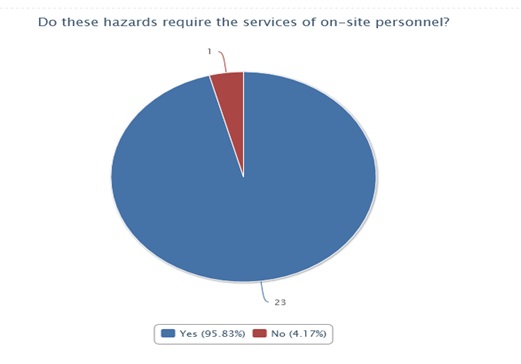

Do these hazards require the services of on-site personnel?

- Yes

- No

Is the need for safety personnel fulfilled with on-site safety officers?

- Yes

- No

These two questions are designed to gauge how these organizations perceive/prioritize occupational safety.

Please provide the number of safety professionals currently employed in your organization with the respective education

- Bachelor degree in Safety Engineering/Management

- Master degree in Safety Engineering/Management:

- Associate degree (1-2 years) in Safety Engineering/Management

Please select the type of Safety Engineering/Management programs that your organization would require for your employees (more than one can be selected)

- Short courses/workshops

- One-Two year associate degree in safety

- B.S. degree

- Master degree

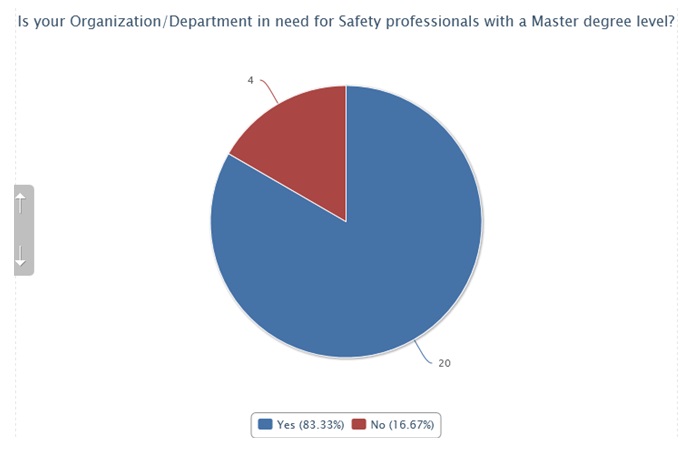

Is your Organization/Department in need of Safety professionals with a Master’s degree level?

- Yes

- No

Questions 7, 8, and 9 are designed to know the level of academic training that these organizations would require their “safety managers/engineers” to have.

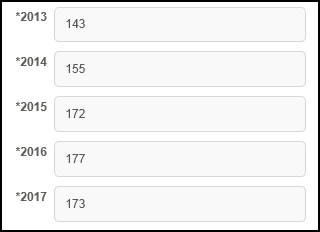

Please estimate the number of Safety professionals that will be required by your Organization/Department in the next five years

- 2013

- 2014

- 2015

- 2016

- 2017

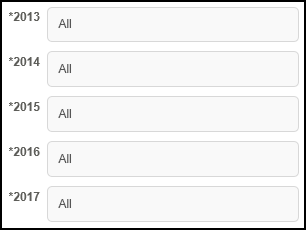

Please estimate the educational level (B.S., Master, associate, or short courses) of safety professionals that will be required by your Organization/Department in the next five years

- 2013

- 2014

- 2015

- 2016

- 2017

Please name the specialization “e.g. fire safety, environmental safety …” of Safety professionals that will be required by your Organization/Department in the next five years

- 2013

- 2014

- 2015

- 2016

- 2017

Questions 10, 11, and 12 are designed to know the hiring prospect of students trained to function as “safety managers/engineers”.

In the space below, please provide us with any further comments that would help us in providing a master level academic program on safety engineering/management.

Statistical Sampling

How an event is experienced is related to how the person who has experienced this event can give its perspective. However, in this qualitative study, the researcher will have the opportunity to get the perspective of the participants. Utilizing these experiences as a framework from which to develop the study, the work is likely to reflect the unique understanding that the personal experiences bring to the development of case studies. The interviews were conducted by the researcher because of common characteristics of culture, industry, and country. This type of relevant personal experience must be used objectively to further the work and not to color it with personal prejudices.

According to Merriam (2009), the insider perspective is quite troublesome for the qualitative researcher, as it is purely posited upon interpretation. Therefore, validity and reliability can come into question. The validity of qualitative research can come from several safeguards put into place by the researcher to balance the subjectivity of the interview format which develops the insider perspective. Developing questions from theoretical foundations can elevate the level since the questions provide a basis for further research to prove or disapprove the theory further. Obtaining feedback from the participants can also increase the validity of the research. As well, it is important to write solid descriptions of the interview experience so that readers of the research are open to their interpretations of the perspectives presented by the insiders as well as the interpretations of the researcher (Shank 2006).

To collect the data necessary for this study, several steps were taken to ensure that appropriate care was taken to protect the participants. The participants were given consent forms which outlined the topic of discussion and any relevant information that the participant might need before agreeing to be interviewed. Once consent was obtained, interviews were set up with the selected participants, in which the author of this study acted as the interlocutor with the participant, giving semi-structured individual interviews that were conducted in the Arabic language so that communication was given the depth that might not be allowed in interviews conducted in a language that was secondary to the participant.

According to Merriam (2009), to create relevant case studies, qualitative research needs participants who are purposive. These participants are not selected randomly but have characteristics that provide a foundation from which the stories of their experiences are relevant to the purpose of the study. This type of purposive sampling is done through the outlines of criteria that the participants have successfully fulfilled. Open-ended questions were designed to allow the participants to fully express their experience without being too confined within the boundaries of a question. The semi-structured interview was used as it allowed the greatest possible advantages in creating an understanding of the experiences of the participants. The structured set of questions acts as an outline allowing the participant to inject personal perspective and diverse lines of inquiry that may not have occurred to the interviewer (Hesse-Biber & Leavy 2011).

Scoring

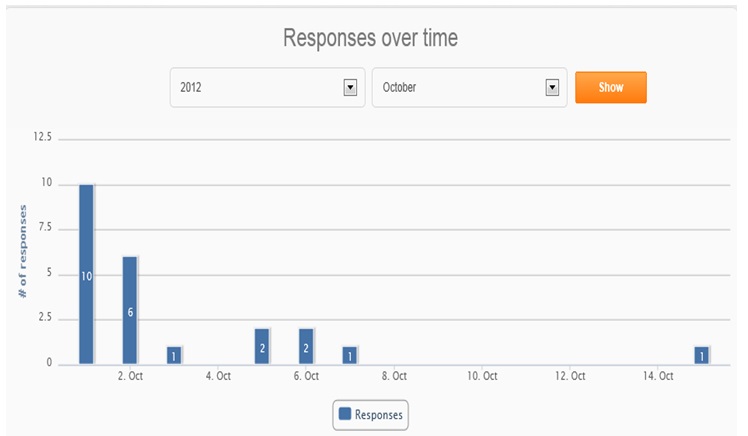

The result of this two months survey is indicated below.

Sample Size and Response Rate

The sample size consisted of twenty-one organizations with a response rate of 50%. Indicated below is the list of organizations that participated. From the 40 questionnaires sent to different companies, a sum of 21 questionnaires was submitted online which represents a 50% response rate. Notably, the positive and comprehensive responses by participating companies indicated eagerness and support towards the proposal. The target population for this survey was 40 organizations. In data collection, the researchers used a mixture of open and close-ended online questionnaires to narrow down the scope of responses that are specific to the research objective. To generate the sample size for this study population, the researcher adopted the formulae created in 1972.

Sampling Formula

n=N/ (1+N (e2))

Where:

n = sample size

N= Target population

e= Degree of freedom

n=24/ (1+24*0.052))

n= 22.6415

List of organizations which participated

- Saudi Aramco

- Kuwait Oil Co.

- FM Global

- Al Hoty Stanger Ltd. Co.

- Saline Water Convention Corporation

- Saudi Electricity Company

- Tihama power generations company

- ORYX

- Oklahoma state university

- SABIC – HADEED

- Samref

- S-Chem

- Ahmad Abdulhadi Al-Khalid EHS Senior Engineer www. advancedpetrochem.com

- Saline Water Conversion Corporation (SWCC)

- Sahara petrochemical co.

- SAMREF

- Saudi International Petrochemical Company “SIPCHEM”

- Risk and Reliability Management Section Bahrain Petroleum Company

- Worley Parsons

- Sahara Petrochemicals Company Box 11166, Jubail Industrial City Kingdom of Saudi Arabia

- Jubail Export Refinery & Petrochemical Co. Project

- Saudi Methanol Co(AR RAZI)

Field of the business conducted at these organizations

- Upstream oil industry

- Industrial and Commercial Property Insurance

- Independent testing Laboratory

- SWCC is responsible for desalinating seawater, to augment the supply of potable water to coastal and inland cities in the Kingdom

- Electricity Generation.

- Energy

- Power generations

- Gas to liquids

- Education

- Safety

- Refinery

- Environmental, Health, and Safety

- Petrochemicals

- Water and power

- Petrochemical manufacturing

- Oil & Gas Refining

- Petrochemical Industries

- Integrated national oil company

- Construction

- Water and power production

- Production of petrochemicals products: 1. Polypropylene 2. Ethylene Dichloride 3. Caustic Soda

- After the completion of project construction, commissioning, and start-up. it will process Arab Heavy Crude for demotic and export products.

- Manufacturing – Methanol

- Safety and Industrial Security

Results and Findings

Distribution of percentage allocated to the preference of on-site personnel

Preference for on-site safety engineering personnel

Preference for safety engineers with Master Degree

An estimated number of Safety professionals that will be required by these Organizations/Departments in the next five years

Estimation of the educational level (B.S., Master, associate, or short courses) of safety professionals that will be required by these Organizations/Departments in the next five years

Preferred title of the specialization “e.g. fire safety, environmental safety …” of Safety professionals that will be required by these Organizations/Departments in the next five years

- Risk management

- project risk management

- safety systems

- petroleum-related safety program

- Fire Safety

- Safety Inspector & Safety Specialist & environmental safety

- Fire Safety

- general safety

- safety rules

- general safety

- Fire Safety, safety pro

- Fire safety and environmental safety

- Safety & Health

- environmental safety

- Process and occupational safety, chemical engineering, mech. engineering and fire protection/prevention

- Safety engineer, Environmental engineer, Fire Protection engineer Industrial hygiene engineer

- safety

- safety & environmental

- safety & fire

- Fire Prevention Engineering, Risk Management

- Quantitative Risk Assessment, Fire Control

- Process Safety Management, Loss Prevention

- Fire Prevention, Safety Engineering

- Safety in Major Projects, Safety Design standards

- Radiation Officers

- Industrial Hygiene Eng/ professionals

- Safety, Fire & Environmental

- Fire engineering

Recommendations and opinion on a master level academic program on safety engineering/management by these organizations

As noted in the responses, these companies suggested that Safety engineering and management can be enhanced with the support of government safety legislation which is either outdated or non-existent. Besides, Jubail Export Refinery & Petrochemical Company suggested an emphasis on fire safety and building construction safety as part of the short courses & workshops to back up the program.

Below are samples of responses on the establishment of the program

- I think cooperation (including rotation and application on-site) with international society (e.g. OSHA, NFPA, NIBOSH…etc) will make the program more likable

- I hope can see the safety program as soon as possible, the market in real need of safety. Also, I suggest including the safety course as part of the engineering program as a mandatory course. This will strengthen the graduate engineer in the end this will improve the awareness toward safety.

- Please also look at Fire related master

- We are your competitor in education, so it is meaningless for us to take this survey.

- In the summertime, I suggest working in Steel companies or Chemical companies to be more familiar with the process.

- If available employ tow

- S-Chem is willing and able to actively support-involve personnel in developing this program.

- no comments

- Safety professionals should help to develop this program.

- It is better to use the existing engineering majors and add elective courses that cover safety (process/occupational) and make it part of the curriculum. A Master’s degree can be achieved for more specialized HSE topics.

- I strongly recommend that KFUPM started very soon to establish a Diploma in industrial safety as the market needs it

- Training must be build based on international standards like OSHA and NEBOSH

- The Master’s program must ensure competency in technical aspects of fire prevention and quantitative risk management.

- I am in favor of continuous personnel development in the safety profession and support it for the Saudi Nationals as they are the future of this country. I am sure that the onsite safety training will be part of your Master’s level academic program and if not then I recommend the onsite training for all the students at Saudi Aramco plants and refineries according to the academic program for at least 6 months. During which they need to go through all the safety processes from conduction of toolbox talks, site evaluation, compiling of reports, attending meetings, Risk assessments, making and review of processes according to the recommendations, etc., and the whole process any organization wants their safety professionals to know. Another most important suggestion I want you to consider is the English language. The entire academic program should deliver in the English language and Insha Allah students trained from KFUPM will compete with the world standards.

- Please contact HR dept. to present your program

- We have a shortage of finding experienced Safety, Fire & Environment engineers in the workforce market.

- Your survey is designed to run and maintains the type of organization. I am involved with projects. That why some of these questions are difficult to relate to projects and therefore left unanswered.

- A master-level program in Safety, environmental, and Industrial Hygiene area is required for this country

- This program is offered by KFU

Data Analysis and Results

Program Needs and Analysis

The tables below represent the results of online respondents. The table indicates the percentage distribution of the workforce of the organization. Specifically, the table summarizes the preference of a safety management program based on the number of employees in each organization.

Organizations with a larger workforce in the target industry have more preference for safety engineers than those organizations with relatively fewer employees. The highest score stands at 41.67 for Tihama Power Generations Company which has more than 5,000 employees. Reflectively, the distribution of demand for safety engineers in this segmentation indicates that the market is currently short of demand. 95.83% of the respondents suggested that there is a dire need for on-site safety engineers for projects that are market demand-driven as indicated in the pie chart 1.2. Besides, the response rate for companies that are satisfied by on-site safety engineers stands at 91.67% of all the respondents as indicated in chart 1.0. Pie Chart 1.3 indicates 83.33% need for safety engineering personnel with master’s degree qualification as suggested by respondent organizations. This is summarized in table 1.8 below

In comparison with other courses, a master’s degree program accounts for 21.21% percent of popularity. A demand of 21.21% is substantial in line with the fact this industry experiences an annual growth of ten percent. Response to most of the sources of hazards is indicated in the table below.

Reflectively, it is apparent that several hazards identified above have serious impacts on the productivity and safety of the investment. Fire, chemicals, and electricity are noted as the most popular sources of hazards that these companies face with a percentage of 12.94. Among other risks identified include noise, radiation, and welding. From the data collected, it is apparent that there is an immediate need for the establishment of a master’s degree program in safety management. This is informed by the statistics which indicated that over 90% of participating companies have an immediate need for on-site safety engineers. The demand is informed by the fact hazards such as fire, chemicals, and electricity control over 12% of these companies’ risk matrix as indicated in the figure above.

Evidence of national and international demand

As in figure 1.1, table 1.1, and table 1.2 in the introduction of this proposal, it is apparent that the growth rate of industries in the industries that require safety management grow at a consistent rate of 10% annually. It is clear to a large extent that these industrial and manufacturing cities would require much personnel to perform the function of safety managers/engineers within various units/factories/plants. Against the backdrop of such a rampant and growing sector, it is a systemic shortcoming that only one university in KSA recently offers a “safety” orientated academic program.

Besides, the participating organizations were optimistic and had a specific projection of the demand for safety engineering personnel in the next five years as indicated in table 1.5. It is apparent that the projected demand for safety engineers with master’s degrees is expected to be at 143 in 2013 and grow by an average of the same in the next years are these companies expand amid growing industry and an expanding stable economy of the KSA. The demand in 2014 is expected to surpass 2013 for 9 extra personnel. This steady demand against the insufficient supply of master degree holding personnel calls for the introduction of a master degree program in safety engineering. The main features of the proposed program will seek to offer individuals know-how on how to prevent and deal with almost all the broad hazards that may occur within workplaces. More specifically it would seek to cover all major KSA industries and manufacturing discussed above.

Comparison with other similar national/international programs

As indicated in appendix A and B, universities that have established successful master’s degree program in Safety Engineering were influenced by market demand. For instance, universities such as Oklahoma, Murray, Houston, and Indiana instituted safety engineering to create skills that were in demand within the production industry of America. Based on the demands of employees and the growing economy, these universities established a structuralized safety engineering master program to service the deficit in the safety management market. Depending on a technicality, most of these universities offer full-time programs with the online option available for short backup courses such as fire safety management, hazard preparedness, and preventive hazards management.

Generally, the scope of these master’s degree programs on safety management dwells on fire safety, chemical, hazards, and efficiency to risk as part of safety precaution. These programs aim at promoting environmental, professional, and health safety at the workplace and impart critical management skills that are essential in mitigating safety tasks (Bass 1990). As recommended by the majority of respondent companies, the most appropriate name for this proposed program should accommodate the aspects of health, environment, and professional safety. This aspect is common with all the 57 universities surveyed.

Program objectives and Intended learning outcomes

Every University surveyed exhibit a distinctive and unique organizational structure that is shaped by the organizations’ goals of imparting philosophical and practical aspects of safety management. In advancing their learning objectives, the aspects of systems thinking, mental models, personal mastery, shared vision, and team learning are given a significant role in hindering as well as fostering learning and its application. For instance, Trinidad State University has evolutionary processes that occur in the organization as opposed to imposed designs on learning objectives. Culture of preventive and precautionary measures dominate the response strategies for overcoming organizational structures, work pressure, entrenched attitudes towards learning, and emphasis on meeting targets.

Thus, this master’s degree program should incorporate a supportive learning environment, concrete learning processes, and practices leadership that reinforces learning. Thus, by using the diagnostic tools, the administration can assess the areas of the learning that require urgent improvement the university closer to an ideal learning institution with a similar rating as other international campuses offering safety management programs. Safety Engineering/Management at King Fahd University of Petroleum and Minerals (KFUPM) in Dhahran, Kingdom Saudi Arabia (KSA) should thus be instituted to capture the above objective. However, these objectives should be aligned with the demands of the unique economy of Saudi Arabia.

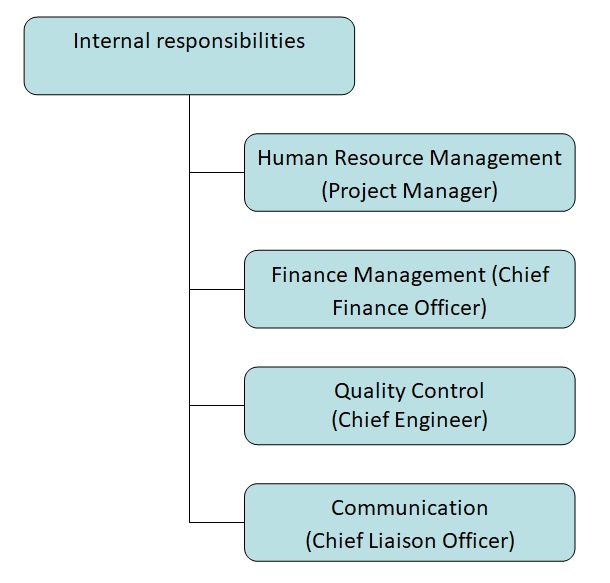

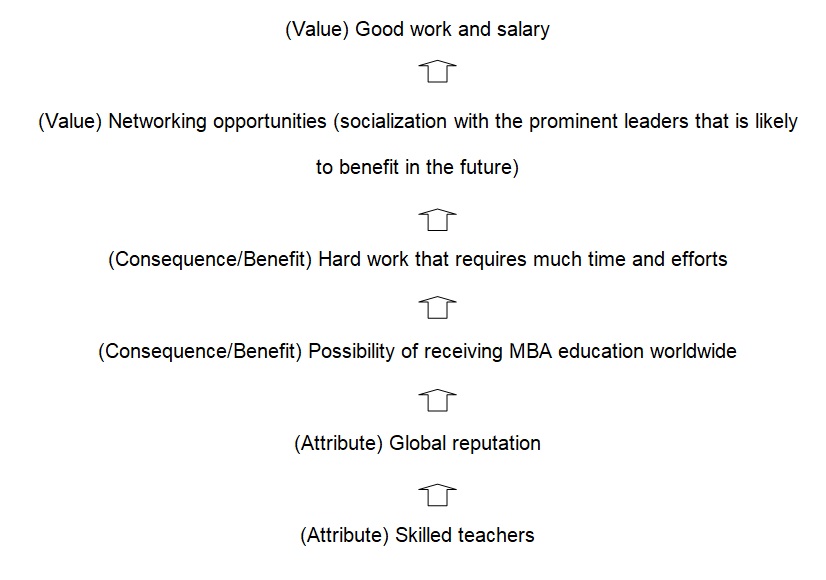

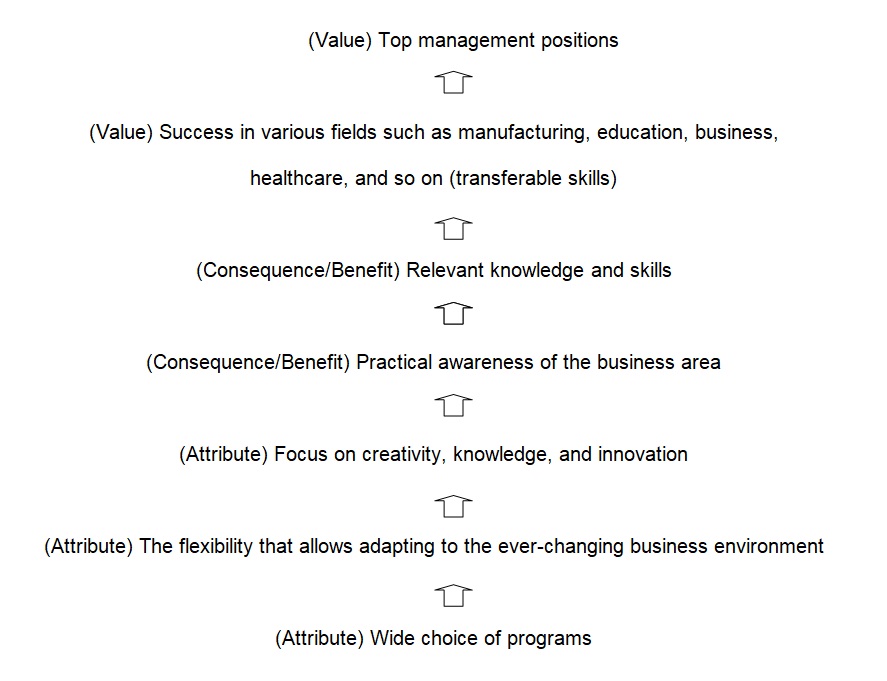

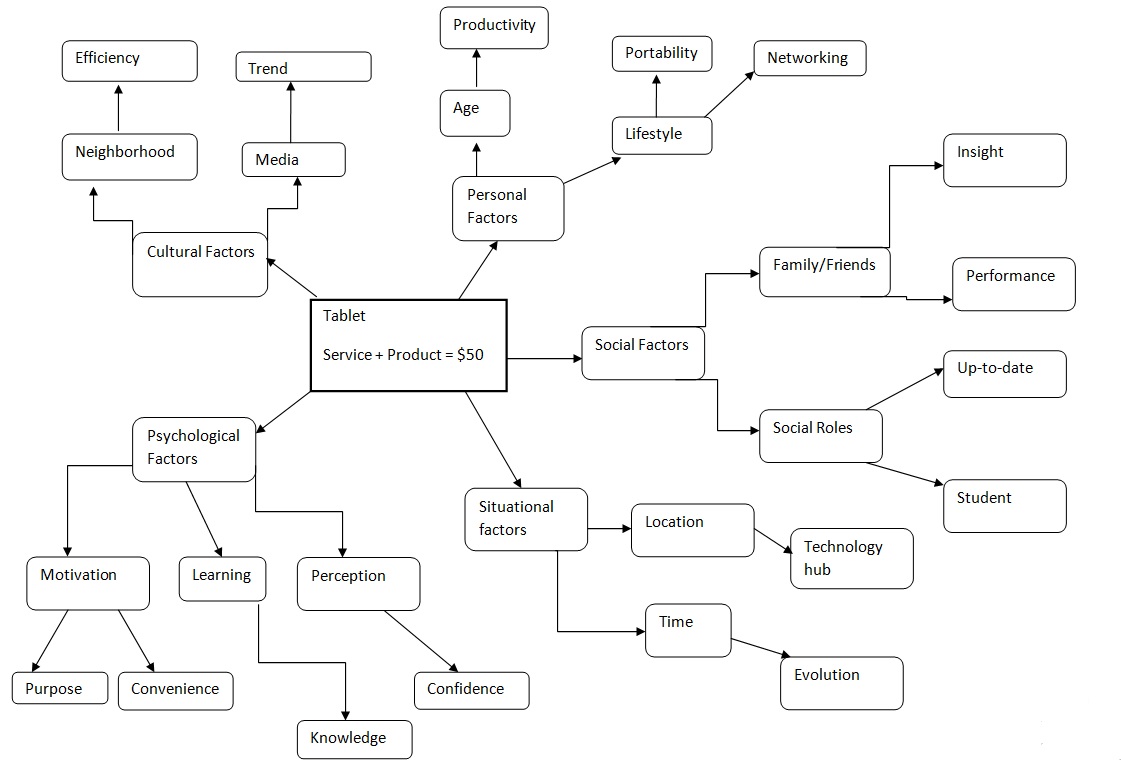

The proposed objectives of the program on Safety Engineering/Management at King Fahd University of Petroleum and Minerals (KFUPM) in Dhahran, Kingdom Saudi Arabia (KSA) can be illustrated in the diagram below.

Conclusion and Recommendations

Recommendations

The response rate from the potential market for this program is at 90% with a projected annual growth of 10%. Borrowing from other successful universities that have implemented this program, the key building block should be its philosophy, practical aspects, and proactive management. Same as was implemented in Murray University, the establishment of a master degree program in Safety Engineering /Management at King Fahd University of Petroleum and Minerals is feasible since there is a need to fill the deficit in the safety managers with a master degree program in safety engineering within KSA. However, the program should be tailored to be consistent with the culture of KSA demands of its unique economy. Education providers face some problems in designing the scope of a program. This includes data management problems, logistics, resource management problems among others. There are challenges in the education data management department that lead to other quality problems and finding their solution could lead to improvement of service delivery in the provision of this program at King Fahd University of Petroleum and Minerals.

Often, the cause of poor outcomes and expensive services is the inability of education professionals to collect and analyze comprehensive field data. This is because some universities have little information on the cost risks of varied health and safety requirements in the labor market. Also, they do not know the rates charged by different universities towards the provision of these courses. Information technology (IT) issues have made data management problem a challenge to the education sector due to the ever-expanding amount of data, applications, a database that use data, and regulations governing the sharing of data within the industry. The education sector suffers from distinctive data management setbacks. Therefore, education IT executives of this university are required to develop and operate solutions that incorporate data from a wide range of students, organizations, and back-office structure to lecturers, payers, technology, and manufacturing corporations to solve these problems. This is by Federal laws that oblige education providers to develop systems and data that are interoperable, works for electronic education records and health information exchanges.

However, in developing these mechanisms, numbers of setbacks befall education providers. The first setback is that the environments of education providers are complex due to many interrelated components. Apart from budgetary differences, there are numerous autonomous education departments. Each department manages its computer systems and data. Besides, these data are difficult to track because they abide by proprietary data formats. This problem is further complicated by university mergers, integrated education delivery services, and acquisitions. For example, in a case where affiliations of a university have different education program systems, the data collection process may be tricky. The next education management problem according is difficulty in integrating information involving multiple vendors that store semantically dissimilar statistics. Though data cleansing and editing, transforming, and loading tools are unsophisticated to develop, education providers who use them still meet challenges based on the enormity of the incorporation efforts required. Therefore, the university should establish a similar system of departmental management that is controlled from a central point.

Educational strategies are the instructional methods and the learning activities used in imparting knowledge and skills to the learners. Safety engineering is an abstract and empirical subject that requires exciting ways to drive home the concepts and facts. To achieve this, lecturers use several strategies which are not limited to gaming, problem-solving, group work, discussions, and research work. This helps develops the psychomotor and communication skills of the learners even though time-consuming. Problem-solving is a strategy in which the teacher illustrates using well-done examples to the learners to guide them in organizing their solutions. It is more efficient in giving guidance to the learners in solving their problems but the strategy lacks an in-depth analysis of the concept. It improves learner’s communication skills as well as participation. Discussion is a strategy in which the teacher simply gives guidance to the learners as they solve problems, it allows the students to have a broader view of the concept as well as develop confidence. A lot of research work is required to balance the new program with existing ones across different universities. Research work is a strategy in which learners carry out further study to ascertain a concept or fact enabling them to have full mastery of the concept as they can extensively research.

Conclusion

The establishment of a master’s degree program in Safety Engineering /Management at King Fahd University of Petroleum and Minerals (KFUPM) in Dhahran, Kingdom Saudi Arabia (KSA) is feasible and well-timed to service the deficit currently experienced in this economy that depends so much on production industry. It is clear to a large extent that these industrial and manufacturing cities would require much personnel to perform the function of safety managers/engineers within various units/factories/plants. Against the backdrop of such a rampant and growing sector, it is a systemic shortcoming that only one university in KSA recently offers a “safety” orientated academic program. At present, there is no master’s degree program at King Fahd University of Petroleum and Minerals despite its technical courses in heavy industry.

Despite technological advancements, critical information still does not reach education providers, health providers, learners, and payers. The university should review its programs to match with the ones offered at established universities such as Murray and Arizona. In this way, it is possible to offer relevant and high-quality programs that are tailored towards the labor demands of the complex KSA economy. In the changing world, teaching safety engineering at the master level needs a dynamic and flexible approach to accommodate these variances of technology and inventions. Reflectively, the university should develop a consistent evaluation model for testing the relevance of their learning objectives in line with the recommendations of the potential employers who are participating in organizations.

References

Barnett-Schuster, P. (2008). Fundamentals of International Occupational Health And Safety Law. London: Lulu.com.

Bass, B (1990). Bass & Stogdill’s handbook of leadership: Theory, research, and managerial applications, New York: Free Press.

Chaturvedi, P. (2006). Challenges of Occupational Safety and Health: Thrust : Safety in Transportation. London: Concept Publishing Company.

Hesse-Biber, S. N., & Leavy, P. (2011). The practice of qualitative research. Los Angeles: SAGE.

Karmis, M. (2001). Mine Health and Safety Management, SME.

Merriam, B. (2009). Qualitative Research: A Guide to Design and Implementation (pp. 3-5). San Francisco: Jossey-Bass, 1-304.

Organization Learning (1991). Record of Proceedings. New York: International Labor Organization.

Sebiany, A., Ahmed, H., & Ballal, S. (2002). Occupational health in Saudi Arabia. Public Med Journal, 17(3): 471-507.

Shank, G. D. (2006). Qualitative research: A personal skills approach. Upper Saddle River, NJ: Pearson Merrill Prentice Hall.

Stellman, J. M. (1998). Encyclopedia of Occupational Health and Safety, International Labor Organization.

Baumann, L. (2012). Safety engineering. Delhi: Research World. Print.

CoVan, J. (1995). Safety engineering. New York: Wiley.Print.

Grimaldi, J. V., & Simonds, R. H. (1975).Safety management (3d ed.). Homewood, Ill.: R.D. Irwin. Print.

Guarascio, M. (2007). Safety and security engineering II. Southampton: WIT Press.Print.

Hammer, W. (1976). Occupational safety management and engineering. Englewood Cliffs, N.J.: Prentice-Hall.

Kavianian,H. R., & Wentz, C. A. (1990).Occupational and environmental safety engineering and management. New York: Van Nostrand Reinhold. Print.

Roland. E., & Moriarty, B. (1990). System safety engineering and management. New York: Wiley. Print.

Rosner, D., & Markowitz, G. E. (1987). Dying for work: workers’ safety and health in twentieth-century America. Bloomington: Indiana University Press. Print.

Roth, H. H., & Teltscher, E. S. (1975). Electrical safety in health care facilities. New York: Academic Press. Print.

Suurmond, G. (2008). Enforcing fire safety in the catering industry an economic analysis. Leiden: Leiden University Press. Print.