FMEA for SCOD-19 Project

Failure Modes and Effects Analysis for SCOD-19 project

Phases of Six Sigma

Define Phase

Resulting from the DMAIC approach, the initial steps in the Six Sigma are to form a program management team and develop a project charter. The main purpose of the SCOD-19 project is to ensure efficient detention of COVID-19 in its early stages. In the definition stage, the SCOD-19 project utilizes tools such as the Project Charter and the voice of the customer. The Project Charter, an unofficial contract, is created at the start of the project to summarize the arrangement of the work project (Oliveira et al., 2018). It also helps to manage any information that develops during the progress of the project.

The SCOD-19 project solves the problem of inefficient detention of the COVID-19. The virus is widely tested in medical facilities by the use of long procedures that involve taking samples from the respiratory system of an individual (Bhat et al., 2022). The samples take a long time to be tested and the results are provided to the individual. This poses the challenge of high spread of the virus while infected individuals await the results. To overcome these issues, this smart device will detect the virus early by using the various features installed on it to ascertain that the individual has contracted the COVID-19 virus.

The SCOD-19 has main features that make it more efficient compared to the other testing procedures on the market. The body temperature feature has been widely used to make individuals subjectable to COVID-19 testing. However, temperature measurement is not precise in defining fever in COVID-19 because it varies throughout the body by anatomic site. As per Salleh and Nohuddin (2019), 19% of the publications reported that the minimum temperature to describe a fever ranged between 37.3 °C and 38.1 °C. This smart device combines several such features as body immunization level, the type of virus variation, and the user’s historical data so as to fully determine the health status of an individual in relation to COVID-19. The voice of the customer tool is used to determine the specific requirements that the market demands from this smart device (Amit and Cholli, 2022). Historical data from the customer’s registry will be used to determine any special requirements that most of the markets are requesting. The target clients for this product will be medical facilities; therefore, there is a great need to ensure the efficiency of the product to eliminate any errors.

Measure Stage

The measurement stage entails using the requirements from the clients to create product specifications. The SCOD-19 is capable of performing autonomous computing while connected to other devices for the purpose of sharing data. This stage will use the affinity diagram tool, which is used to organize and analyze ideas and opinions and categorize them based on how they are related. The client’s past information and feedback will be collected and analyzed to create an affinity diagram for the development of the SCOD-19 smart device. A metric system has been developed to measure the quality of the device to ensure it meets all the customer’s needs (Banawi et al., 2020). This metric system will consist of parameters that show how the device works in relation to the features fitted to it. The body temperature parameter will be gauged based on its ability to detect the individual’s temperature from a distance of two meters. This means the client does not need to be physically close to the subject so as to measure their temperatures. Its ability to trace the user’s historical data will be determined by how fast the device can retrieve the individual’s past health information. Fast retrieval saves time, and it is possible to serve a large number of individuals at a given time.

Historical information about a patient is vital as it helps to show a pattern in the patient’s health status. The clinicians to come up with the best treatment plan for the patient then use this pattern. The body immunization level indicates the current status of the individual’s immunity. If the individual has been vaccinated, the device will detect it and show the level of immunity in relation to the COVID-19 vaccines. This helps to establish whether the vaccine was effective or if the vaccine is wearing out, which means the individual might need an additional vaccine.

This smart device should accurately show the immunity level to prevent excessive vaccination of an individual, which could be fatal. There have been different variants of COVID-19 that have emerged ever since the pandemic began (Patel et al., 2019). This smart device will detect the type of variant the individual is infected with. The effectiveness of this parameter will be gauged based on the ability to detect different types of virus variants. It should indicate the specific variant the individual has been infected with for easy administration of treatment. Treatment of COVID-19 varies based on the type of variant and the infection level. SCOD-19 therefore detects the virus and indicates the level of infection as either critical or mild.

A mild level infection can be treated with home-based care, while a critical level has to be taken to a health facility for extra medical services. By determining the level of infection, it helps to prevent congestion in health facilities by making use of home-based care for mild infections. At the end of the measurement stage, process experts will be deployed to ensure that the critical process has been met in designing the SCOD-19.

To propose remedies that are likely to work, the team should initially analyze trends for faulty measurements through inspection alerts. The initial step is to get data from the SCOD-19 systems. The SCOD-19 system, in this case, is utilized to collect and store pertinent information such as temperature, final temperature and historical dates such measurements were obtained from, and defect alerts. The settings are utilized to retrieve data from the SCOD-19 system as represented the project’s constraints and limits. These settings for data gathering can then be recorded and exported to Microsoft Excel.

Analyze Stage

The analysis phase focuses on the design features of the SCOD-19. It provides details of how the design will be planned to specifically cater for the customer’s requirements. At this stage, the Prioritization Matrix tool, also known as the Quality Function Deployment tool, will be used. (Argilovski, 2020). This is a tool containing a matric of two axes. The row of the matrix is filled with the product requirements, while the columns are listed with the features of the design. This tool is used to establish how strong or weak the relationship is between the product requirements and the design features (Argilovski, 2020). The SCOD-19 contains various features which are all crucial to the overall performance of the device.

The top priority feature of this smart device is body temperature. The expected quality of this feature is converted into design features to increase the possibility of meeting the customer’s requirements. It is also critical to use the voice of customers while listing the design components of the device (Banawi et al., 2020). Medical facilities, being the target market, will provide various needed specifications, such as response time and sensitivity of the temperature sensor. The temperature sensor has to be accurate, stable, and also provide the right temperature range. However, application flexibility and sensitivity are the most crucial design features that need to be critically designed.

After the design of these features, the device should meet the need for detecting temperatures from a distance of two meters. The design features of the virus variant will include all the types of COVID-19 variants. Each variant will be allocated a unique identifier that can be easily identified by any clinician. The design features of the device’s ability to trace a user’s historical data will include a Database Management System (DBMS), which is used to record and store the individual’s information. This system will be fitted into the SCOD-19 for easy retrieval of information when it is needed.

The communication facilities of the device will be designed using the latest networking features to ensure the system is fast and efficient. Use of 5G is highly recommended due to speed; it can transfer a huge amount of data without buffering (Bloj et al., 202). The GPS system to be used in the SCOD-19 will include features such as maintenance alerts that are timely or generated when a fault is detected in the smart device. In the event of an emergency, the GPS system can send an alert to the nearest health facility to urgently attend to the affected individual. All these design features are specified to meet the customer requirements as well as meet the Control to Quality (CTQ). The metric system will also indicate how well the design features have been implemented.

The data extracted from the GPS system can be analyzed to determine if there are any potential links between the type of nonconformance notification generated and the source of emergency within an individual. The information pertinent to this project included the patient description, name of the vendor providing the thermometer for measuring temperatures, total amount of defective product associated with that device, and the description of the defect.

After which, a team extracts the data from the GPS system. The next step is to perform a series of brainstorming activities to identify potential root causes. The first tool that should be used in such a case is a pareto chart. A pareto chart is a type of bar chart that ranks data by order of predominance.

Design Phase

The design phase is the critical stage of the DMADV as it greatly determines the success of the project. The deployed Process Expert has a great role in this stage, as they are responsible for implementing most of the design phase. The tools to be used include the Design of Experiments and the Action Plan tool. The design of experiments involves testing the high and low values of each of the design features developed (Bhat et al., 2022). It allows testing of more than one factor simultaneously.

The features of the SCOD-19 can be tested at the same time using the Design of Experiments tool once the design features have been approved. The activities in the design phase involve compiling a detailed design for every feature to be included in the smart device (Patel et al., 2019). These features are then put into action by developing a device that is used to conduct pilot runs. Tests are conducted to identify issues with the product designed and test the general layout of the line production of the SCOD-19. The devices that produce mass-produced smart devices must be kept in good working order. These include the work instructions, the number of staff, and the equipment to be used. By maintaining these conditions, it is possible to combat issues as if the product were being produced in mass production.

After the completion of the pilot runs, a failure mode list is created to enable the establishment of a corrective action plan before the mass production of the device commences (Gaikwad and Sunnapwar, 2020). The majority of the advancements will require a detailed strategy to guarantee they are conducted properly and can be measured to determine their effectiveness. All these actions are purposively meant to ensure control quality meets the performance level anticipated from this smart device. In this phase, the Process Experts will also evaluate the risk assessment involved in designing the SCOD-19. These risks could include major delays, which cause increased costs, and the risk of not meeting the user’s needs. To mitigate this risk, the firm must prioritize results, which means first identifying and resolving an issue (Bloj et al., 202). This should occur well in advance of beginning to engineer solutions and design features. And the most effective method to do so is to speak with the customers.

Validate Phase

Although the verification step of the DMADV process is the final phase, it is a continuing phase. During the verification phase, the project team gathers early client input and makes necessary process improvements to satisfy the customer’s needs. The tools used in this stage include the A control chart, which is a type of intelligent line graph (Ferguson, 2018). It conducts mathematical computations on data and shows the following: as a center line, the average or median, and employing control limit lines that determine the degree of variation in data. Control charts indicate whether a process is under control or not. They illustrate the variance (or variation) in the output of a process over time. Control charts compare this variance to upper and lower bounds to see whether it falls within the range of expected, specific, predictable, and typical variation (Improta et al., 2019). Activities involved in this stage include making corrections based on the recommendations. Use of check sheets against the Control to Quality will help to ensure that the key features are implemented during the simulation.

A control plan is created to monitor any output fluctuations. It should include a list of control of quality metrics to monitor and a list of metrics that can be used to determine the quality and standard of input variables and materials (Howell, 2020). These measurements should be reviewed often during the early phase to quickly detect and correct any shortcomings (Pakdil, 2020). The project team will also meet on a regular basis to review the progress of the SCOD-19 project. Once the project is operational and has been turned over to the operations lead (the process owner), the changeover should happen without incident. The lead personnel should be informed fully about the design’s history and FAQs. This is why process manuals and work instructions should be meticulously written.

The documentation for the project will include a list of the tasks done in each phase, as well as the observations. Additionally, a full list of obstacles encountered and lessons learned throughout the project’s development will be noted down for future references.

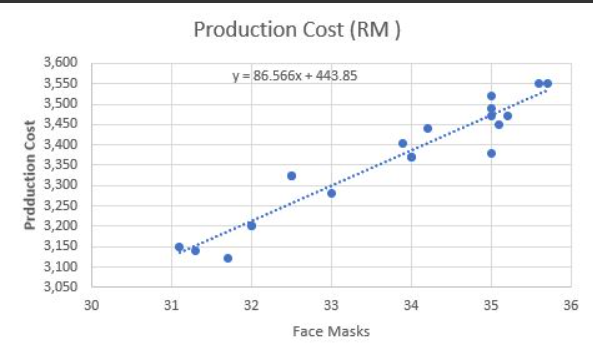

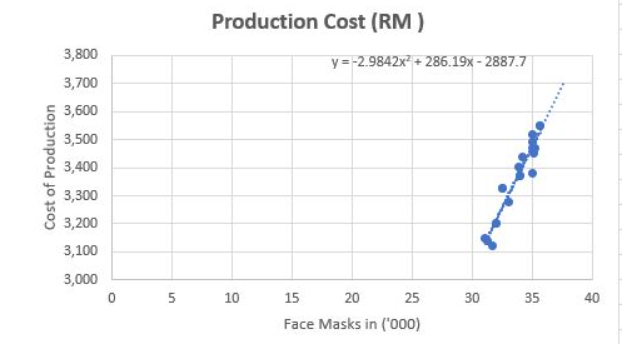

Regression Graphs

R2 and Standard deviation

R Square for linear

R² = 0.9151

Standard deviation=0.9566

R Square for quadratic

R² = 0.9165

Standard deviation=0.9573

Most suitable equation

Quadratic equation is the most suitable to represent regression because it has the biggest R square

Cost in RM

Using the quadratic equation y = -2.9842x2 + 286.19x – 2887.7

Therefore, to produce 34,500 face masks, the cost is

Cost = – 2.9842(34.5) ^2 + 286.19 (34.5)- 2887.7 = RM 3433.91

Minimum setup cost

Minimum costs

For this question, we use y = 86.566x + 443.85

Therefore, minimum costs = y = 86.566 (0) + 443.85 = 443.85

DPMO and Sigma Level

DPMO = Number of Defects/Opportunities for Effect in the sample *1,000,000 = (200/200*5000) *1000000= 200

From the table, sigma level = 5.04

References

Amit, R., & Cholli, N. G. (2021). Application of lean principles in software development processes. 2021 International Conference on Disruptive Technologies for Multi-Disciplinary Research and Applications (CENTCON) IEEE, 1(1), 38-42.

Argilovski, A. (2020). Case Study: Six Sigma project for reducing manual handling of materials in real manufacturing Company. Technical Journal, 14(4), 499-506.

Banawi, A. A., Besné, A., Fonseca, D., & Ferrandiz, J. (2020). A three methods proactive improvement model for buildings construction processes. Sustainability, 12(10), 4335.

Bhat, S., Gijo, E. V., Antony, J., & Cross, J. (2022). Strategies for successful deployment and sustainment of Lean Six Sigma in healthcare sector in India: a multi-level perspective. The TQM Journal, ahead-of-print (ahead-of-print).

Bloj, M. D., Moica, S., & Veres, C. (2020). Lean Six Sigma in the energy service sector: a case study. Procedia Manufacturing, 46(1), 352-358.

Ferguson, C. A. (2018). Using Six Sigma methods to identify root cause of moldy cheese (Publication No. 179381209) [Doctoral dissertation, University of Wisconsin-Stout]. ProQuest Dissertations Publishing.

Gaikwad, L., & Sunnapwar, V. (2020). An integrated lean, green and Six Sigma strategies: A systematic literature review and directions for future research.. The TQM Journal, 32(2), 201-225.

Howell III, C. (2020). Implementing the Six Sigma Breakthrough Management Strategy to Reduce Bowed Pipe Defects in the Oil and Gas Industry, a Black Belt’s Approach. (Publication No. 28678971) [Master’s thesis, Youngstown State University]. ProQuest Dissertations Publishing.

Improta, G., Ricciardi, C., Borrelli, A., D’alessandro, A., Verdoliva, C., & Cesarelli, M. (2019). The application of Six Sigma to reduce the pre-operative length of hospital stay at the hospital Antonio Cardarelli. International Journal of Lean Six Sigma, 11(3), 555-576.

Oliveira, G. A. Q. S. M. D., Zattar, I. C., & Seleme, R. (2018). Six Sigma tool selection to achieve goals in the short-term-a case study. International Journal of Business Performance Management, 19(4), 408-426.

Pakdil, F. (2020). Six Sigma for students: A Problem-solving methodology. Palgrave Macmillan.

Patel, S., Desai, D. A., Narkhede, B. E., Maddulety, K., & Raut, R. (2019). Lean Six Sigma: Literature review and implementation roadmap for manufacturing industries. International Journal of Business Excellence, 19(4), 447-472.

Salleh, N. M., & Nohuddin, P. N. (2019). Optimization of software requirement process: An integrated conceptual model of lean six sigma and requirement planning. International Review of Applied Sciences and Engineering, 10(2), 125-133.