In June 2016, the Occupational Safety and Health Administration (OSHA) came up with new safety standards on Silica exposure; this required most high-risk areas to be assessed if their level of Silica exposure on workers is beyond the Permissible Level. This follows a number of concerns raised previously with the people working in such an industry. OSHA wanted to validate the claims to confirm if the allegation were true. The main aim was to determine if the working condition was putting workers at health hazards that would impact their life negatively.

Iron Foundry, on the other hand, was among the suspected areas of high risk. It is a Job shop that operates on a produce-to-order basis and produces steel parts that vary diversely daily. It uses induction to melt the scrap iron and steel; at this point of melting, there are two workers who make the process run smoothly. The conditions at this stage expose the personnel to extreme temperatures, which they are using to convert the metals into a molten state.

The molten is then transported to the pouring floor, labeled Cope & Drag, using spoons operated by six more staff. This melted metal is poured into two small molds responsible for producing the end products as per the order. When the smelted metallic is added/poured into the molds, the binders and sealers in the cube decays and release some decomposition which is flammable when exposed to air. In this section, there are ladle operators who make sure the process is a success.

Due to this allegation, an Industrial Hygiene (IH) was hired to check the situation if the Iron Foundry meets the OSHA complacency safety measure of Silica exposure on workers. Data samples from the firm were collected from different points then subjected to measurement criteria. The main focus of the analyst was to confirm whether the exposure to the chemicals used during the processes is as per the standard rate or above.

Discussion

In this research, the main focus is to investigate whether the exposure rate on a worker at the Iron Foundry is above the set standard by the OSHA. After that, there will be a statistical analysis report the will determine the compliance of the industry to the OSHA requirement. During the analysis, visualized data will be presented, and an appropriate distribution model will be provided. In the end, there will be a conclusion on the findings of the analysis and recommendation to the business owner of the Iron Foundry to give an overview based on the needs of the OSHA.

Insights on Silica

Silica, also known as quartz, is a mineral found in various particles like sand, concrete, granite soil, and many other materials. The airborne silica dust can easily be breathed in, causing a significant health issue on exposed individuals/workers. In the Foundry, employees use sand particles on most occasions to facilitate their working processes. This makes them come into contact with the high level the invisible silica content.

The most severe effect of silica on exposure is Silicosis. A disease contracted if exposed for a relatively long time causes the formation of scar-like tissues in the lungs reducing oxygen entering capacity in the lungs. The condition can take relatively long to manifest, therefore making workers or the affected individuals unaware of their health status (Xie et al., 2018). When people suffer the illness, the likelihood of their survival afterward is minimal.

Results

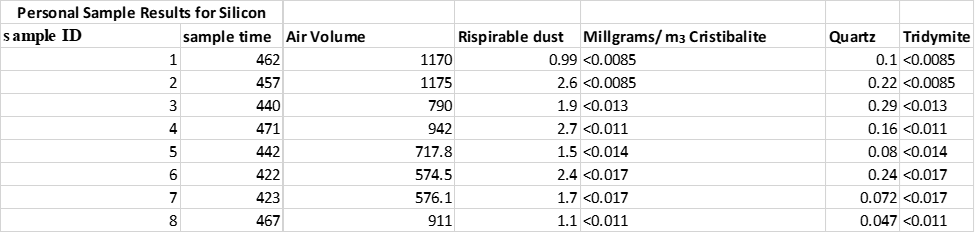

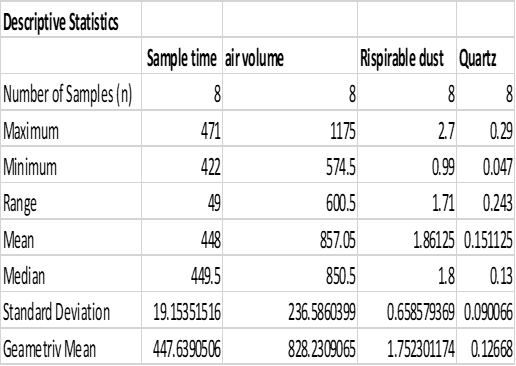

According to the analysis, the results show that the longer an individual is exposed to carrier agents of silica (quartz) say sample time greater than 471 minutes, silica inhaled is about 0.16g. The average exposure time is 7.45hrs, and the average silica is 15.11µg/m3. In relation to the OSHA compliance requirement, the finding implies that the Iron Foundry meets the set standard by OSHA, which is at 8.0hrs and 25.0 µg/m3 for exposure and silica content, respectively for individuals working in Foundry. Therefore, based on the outcomes, Iron Foundry workers are safe from Quartz exposure, as shown in Table 2 below.

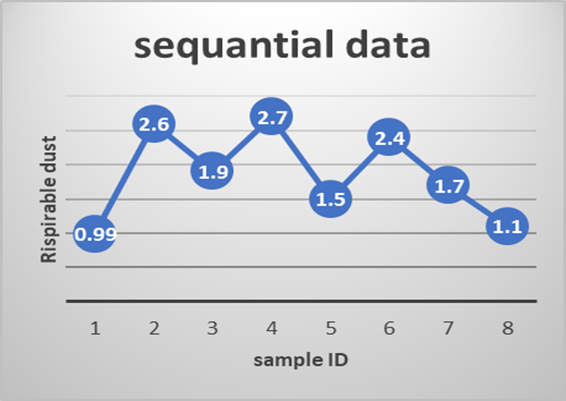

Sequential data plot using the sample results from table 2.

The 95% percentile of the sampled data is found to be 2.66 on Respirable dust. This means that 95% of the sampled data falls in the analyzed data. This percentile is best as it describes more of the sampled data. According to American Industrial Hygiene Association (AIHA), the Iron Foundry data can be modeled using the Regression model to predict the future exposure risk.

In conclusion, it is common to experience below-average results theoretically as compared to a real-life situation. The report result can be encouraging that the Iron Foundry meets the OSHA set standards, but there might be workers who are suffering from less exposure. To ensure that everyone is safe, the safety set standards of OSHA should be followed to the later, and regular check-ups for the employees should be conducted to determine the level of silica in their bodies.

Reference

Xie, J., Zhang, Z., Lu, Z., & Sun, M. (2018). Coupling effects of silica fume and steel-fiber on the compressive behaviour of recycled aggregate concrete after exposure to elevated temperature. Construction and Building Materials, 184, 752-764.