Summary

It is evident that simulation facilitates modeling of the production processes, which allows quantitative analysis of the system performances. In this paper, the Simul8 simulation model presented examines the possible benefits of adjusting the current processes at Parsley Pallets (LLC.). The Simul8 model facilitates decision-making by allowing prior assessment of the production processes. In particular, three solutions presented: (1) SMED implementation; (2) Kanban cards; and (3) line balancing.

It is clear that simulations using Simul8 give a clear picture of the situation in a company’s production processes. Graphical representations give an understanding of the existing business processes, which facilitates optimization to improve efficiency and output. Using Parsley Pallets (LLC.) as the case study, the research demonstrates that Simul8 modeling is a cheap and convenient method for investigating different scenarios in its three stations, optimizing production and finding solutions to its production problems.

Introduction

In the current global economy, proper supply chain management is central to organizational success. Supply chain forms a vital component of flow of materials in any organization. A majority of organizations has developed policies aimed at promoting supply chain management.

These policies work differently in different industries. According to Chang and Makatsoris (2001), the term ‘supply chain management’ was coined in the early 90s and it entails the process where manufacturers, suppliers, warehouses, and retailers are integrated with the aim of enhancing efficiency and reducing operational costs. When trying to put up systems to be utilized in organizations, some challenges may be encountered, which may affect the operation of the final product, hence the need for a simulation.

The conventional definition of simulation is that simulation is a model of the actual system, which can be experimented with the aim of predicting the efficiency of the real system (Banks 1998). Supply chain management can be simulated to establish the likely outcomes as the various parts are reconfigured or interfered with to achieve a particular result. Simulation can currently be achieved using special software that generates the actual program, process, or product.

One of the software used for this purpose is the Simul8, which will be utilized in this model. An example of a company that will be utilized in this simulation project is Paisley Pallets (LLC.), which is a family owned business entity that has produced pallets since the beginning of the year 1965.

The company operates in more than 50 countries and it produces pallets that are vital in the logistics industry. It has continued to be the leader in the market with more than 100,000 people visiting its different outlets in a single year and more than 12,000 people working under the organization.

The company has a clear supply chain management policy and thus, a simulation of its manufacturing process and supply chain management is possible. The following part is a literature review on simulation and supply chain management with a focus on the areas that simulation is applied and some of its advantages and disadvantages.

Simulation and areas of application

As aforementioned, simulation is used to create a model of a part of the real world, with the aim of using this substitute to experiment or predict changes when alterations are made (Hollocks 1995).

Simulation can be applied in a number of fields to predict changes when variations are made to the normal or known operational characteristics of any system. However, according to Hollocks (1995), the most common field where simulation is applied is in the manufacturing industry. Other sectors where simulation is applied include finance, health, service, and retail sectors (Hollocks 1995).

Simulation allows firms to mitigate industrial crises and enhances the efficiency of supply chains. In the present day, global trade is a characteristic of any industry and supply chains of present day organizations run through continents and thus, simulations find wide applications in many areas.

Therefore, supply chain management has evolved to be an important component of any organizational management. The simulation of supply chains is one of the methods that are currently being utilized by organizations to improve on their efficiency and output. As Ebrahimy, AbouRizk, Fernando, and Mohamed (2011) state, there are a number of toolkits that may be utilized in the simulation of a supply chain in organizations. However, in their research, the researchers focused on construction simulation tools.

Carson (2005) describes a simulation model as a “descriptive model of a process or system that includes parameters that allow it to be configurable; that is, to represent a number of somewhat different systems or process configurations” (p. 17). Through the different configurations that are available, one can alter this model to achieve the desired results.

Khorramabady (2006) posits that a good supply chain model should have a detailed model of the project as well as a detailed upstream supply chain model, with the two constituting the two main important components. Supply chain management is reported to have improved over the last few decades and one of the contributing factors is the presence of simulation as a tool. On their part, Zee and Vorst (2005) state that simulation has become an important tool in decision-making in matters to do with supply chain management.

The construction industry is one of the industries with complex supply chains. Thus, supply chain management is vital for firms operating in this industry. Moreover, demand variability can adversely affect logistics management in this industry. Thus, its complexity can be addressed through a stochastic simulation modeling approach (Vadalakis, Tookey & Sommervile 2011).

Other researchers who recognize simulation as being important in supply chain management are Vankateswaran and Son (2004), who, based on experimental results, underscore the importance of simulation. They also state that more research is needed to test experiments in different conditions of supply chains to prove that the use of simulation is efficient in multiple settings (Vankateswaran & Son 2004).

Scheduling models are some of the products of simulation in supply chain management that are applied in manufacturing, which improve the supply chain performance in the manufacturing industry (Selvarajah & Zhang 2013). Simulation of interaction between clients and organizations has also led to improvement in the workshop environment, which is attributable to facilitated modeling (Robinson et al. 2014).

Organizations do not exist in a vacuum and thus, companies should engage with like-minded partners to improve on their performance in the industry. As such, partnerships have been developed in the supply chain systems especially for multinational logistics networks. However, for large companies, local simulation paradigms are used in supply chains within the organization to verify policies (Terzi & Cavalieri 2004).

Agriculture is another important industry where simulation is used in supply chain management. According to Cacho and Power (2014), simulation can be used to develop a bio-economic model to estimate a stochastic risk frontier, which “is a novel approach to investigate the effects of management on the tradeoff between farm business profit and risk” (p. 31).

Longo (2011) also states that the use of simulation in supply chain management can be important in reducing crises especially after the economic crisis that followed the major disasters in history. Long, Lin, and Sun (2011) suggest the use of simulation as a replacement for the traditional analytical model, which is unable to cope with the current supply chains that exist.

According to Yang, Koziel, and Leifsson (2013), some of the important trends in simulation and supply chain management include “nature-inspired meta-heuristic algorithms, Surrogate-based model and optimization, Green computing and grid computing” (p. 859).

Various software tools are used in simulation in supply chain management and some of these tools include the Simul8 software. This computer package allows users to generate events and objects, which are defined in various characteristics to allow the simulation of the desired results.

The software also comes with a number of plug-ins that maximizes on its efficiency and ensures that the user is in a position to create the model as it appears in reality. Updates have also been made available, which help users to add a number of advanced features. Gonzales (2013) also presents software that may be used in simulation of multiple models. However, further research is needed in some areas such as supply chains with more than two stages as they exist in some industries (Albino, Carbonara & Giannoccaro 2007).

Advantages

A number of advantages are associated with the use of simulation in supply chain management. One of the major advantages of using simulation in supply chain management is the reduction in operating time and costs (Hollocks 1995). Simulation allows the actual management of the supply chain to be efficient, and one of the ways in which the program achieves this goal is through a faster implementation of changes and reduction of the capital costs (Hollocks 1995).

Simulation has also allowed organizations to reduce the time taken to design a product and avail it to the market. Courtesy of this development, organizations can now ensure that products are always available in the market and at the right time. This move has ensured increased performance and profitability for companies that have adopted these policies. Some of the other benefits of using simulation as opposed to trying things in the real world include the reduction of risks (Vadalakis, Tookey & Sommervile 2011).

Organizations are in a position to simulate the supply chain and make alterations where potential risks arise, which has aided in risk reduction. Through simulation, managers and the other parties involved in the supply chain can now have an understanding of how the process works, which leads to increased output and efficiency (Hollocks 1995).

The program is also known to improve communication in organizations as well as create better working teams and skills (Hollocks 1995). Carson (2005) also states that simulation allows the identification of problems before a system is built or modified and at the same time allows for studies in dynamic systems.

Disadvantages

Whereas simulation in the supply chain has a number of advantages, a number of shortcomings are associated with this program. One of the demerits is that the creation of a simulation is time-consuming (Carson 2005). The time taken to develop the appropriate systems is important for the organization as a whole and could be utilized in other activities. However, the advantages that come with simulation outweigh this disadvantage.

Obtaining the data required in the construction of simulations is also costly and in some instances, the data may not be available to organizations (Carson 2005). Simulations aid decision-making in organizations regarding the appropriate supply chain policies. For effective decisions to be made, time should be invested. However, in the use of simulation, the time available before the decision-making process is often insufficient (Carson 2005). These are some of the disadvantages of the use of simulation in supply chain management.

Simulating the Case Study

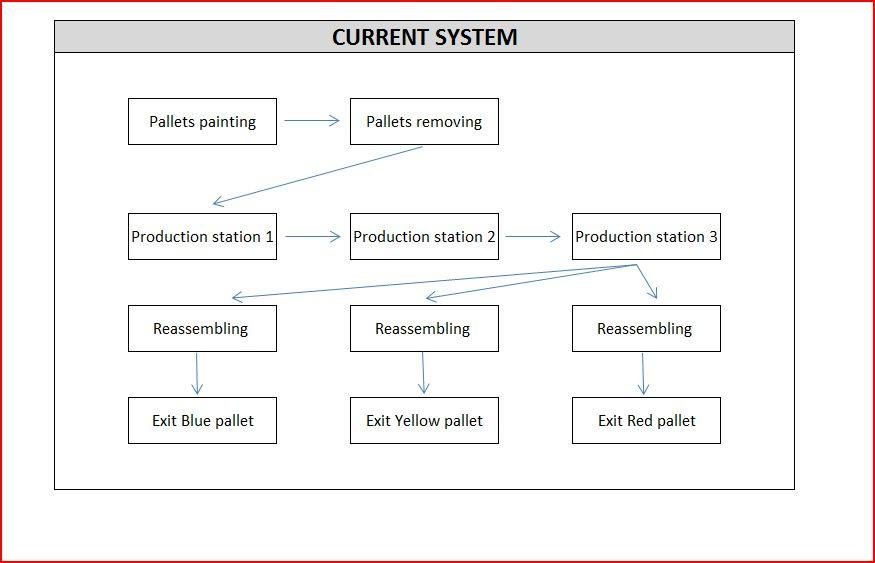

The second part of this coursework describes the case study and three solutions. First of all the current system is illustrated in a flow chart. This helps the reader to understand the process much better.

Figure 1: A flow chart of the current system

The company’s general process consists of three phases. The first step is the painting of the pallets after they have been removed by a remover machine. Subsequently, individual parts go through three different production stations. The process ends with reassembling. See figure 1 (flow chart) shown below.

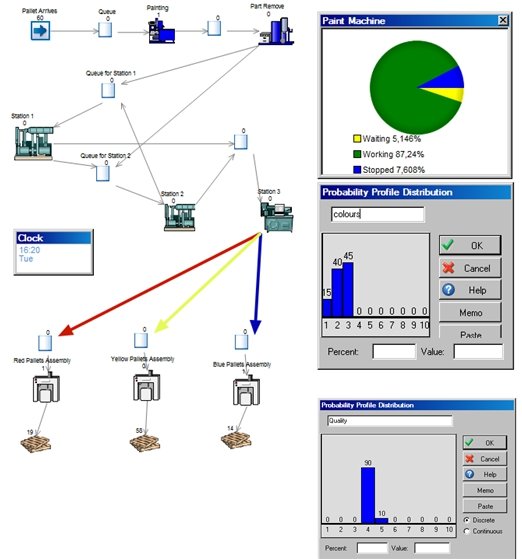

The model is created based on the instructions in the case study. Figure 2 shows a print screen of the model. At the end of simulation run the results are as follows;

- 19 red pallets

- 14 blue pallets

- 58 yellow pallets

- The utilization of the paint machine is 87.24 %

Figure 2: The current model in Simul8

The modern manufacturing industry market is highly competitive (Terzi & Cavalieri 2004). Three solutions are suggested that will enable Parsley Pallets (LLC.) to gain a competitive edge over its rivals.

Solution 1: Implementing SMED for cleaning painting machine

Parsley should implement SMED (Single Minute Exchange of Dies) for cleaning painting machine. This will ensure quick changeover within the facility. Visual management using simulations can help reduce wastage during changeovers. Since changeover is necessary in cleaning operations, SMED would make the process instantaneous and efficient by reducing the loss of capacity.

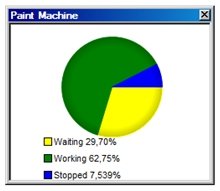

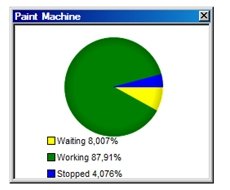

SMED can also help in setting offline fixtures. Simul8 can simulate the operations of the cleaning process for painting machine. Hastening changeovers can decrease the production batch, which reduces costs associated with inventories and save money (Chang & Makatsoris 2001). Consider that the cleaning process will decrease by 50%. As a result the utilization of the paint machine will increase from 87.24 % to 87.91%

Figure 3: Current utilization of paint machine

Figure 4: Utilization of paint machine after SMED

Solution 2: Kanban Cards for Work in Process

Simul8 will be used to simulate the three Parsley products (red, blue and yellow pallets) in the production line. A Kanban operation at station 2 will help maximize pallet productivity at a minimum work in progress (WIP). Quarterman (2008) states that, for each process, the cycle of time spent on each machine should be determined. The production at this station should take the pull approach, which means that production should commence at station 3 because Kanbans normally channels requests for raw materials to station 1 and 2.

Consequently, the request for raw materials is then sent to the acquisition stage for the station 3 to receive ample supply of the materials. In this way, the production of each station will depend on the demand on the preceding station. The Kanban cards will facilitate a backward flow of information from station 3 through station 2 and 1 to the acquisition stage.

Lean manufacturing reduces the batch size during production. Esparrago (1988) observes that WIP between different stations decreases when the batch size declines to a single unit flow. The production rate in each station depends on the arrival of products or parts from another station.

In WIP control, a withdrawal Kanban completes the request for fresh parts to preceding stations. This type of control is more efficient as it reduces lead times between stations. In station 3, the Kanban cards can be used to control batch production. The simulation shows that lean manufacturing using the Kanban approach can lower batch production to a single-unit flow, which enhances production efficiency. Moreover, a Kanban mechanism will aid in the product assembly flow using the ‘pull’ concept.

There are two Kanban systems; the withdrawal Kanban and the production Kanban (Esparrago 1988). The Kanban for WIP queue to station 2 should contain the identification number of the part (s), the storage site, the origin (supplier) and the storage container of the component.

A simulation for station 1 can be summarized as: (1) the customer places an order; (2) the system processes the order in small batches and sends a production Kanban to station 2; (3) the operator receives it and proceeds to station 3 to pick up the finished products; (4) the operator picks new raw materials, issues a withdrawal Kanban; and (4) station 1 begins production.

Solution 3: Line Balancing

Line balancing is another strategy that Parsley can use to enhance the flexibility of the different production lines. Tatsiopoulos (1988) identifies two line balancing strategies: (1) static balancing; and (2) dynamic balancing. Static balancing evaluates the capacity differences in the production units in the long-term while the dynamic balancing approach evaluates short-term production variations usually in a minute or an hour.

One way Parsley can adopt line balancing by assigning tasks that match with the employee’s skills and abilities. The application of automated technologies also enables workers to multitask while they are in one place. This will reduce wastage during changeovers and ensure a smooth running of the production unit.

To maximize the use of the equipment in the three stations (station1, 2 and 3), equipment balancing is important. However, according to Hollocks (1995), such a strategy may increase inventory and lead to equipment failure. Therefore, the utilization of equipment should be optimized to avoid shutting down the manufacturing unit. Also, preventive maintenance of the equipment in the three stations and adherence to standard operating guidelines will reduce inventory costs and prevent equipment failure. A simulation of line balancing can be summarized as: (1) labor balancing; (2) assignment/task balancing; (3) equipment balancing; and (4) line leadership balancing.

Conclusion

This paper analyzed the ways of using simulation (Simul8) to optimize production in Parsley Pallets (LLC.). It provides solutions for increasing production capacity of pallets by this company. It evaluates the current systems and procedures in order to identify weaknesses in the company’s production lines. The solutions identify the areas that need improvement in order to optimize production and suggest modifications and alternatives to the current production processes.

Through simulation, a manufacturing firm can evaluate its performance before adopting the actual system. Simulation of the supply chain has three advantages: (1) it helps firms in decision making, which enable them to improve their production processes in the future; (2) it helps in the prediction of future production capacity; and (3) it facilitates the comparison of different production units (stations) without interfering with the manufacturing process. Thus, in this case study, simulations of the production processes enhance competitiveness of Parsley Pallets (LLC.), and thus make it provide the quality goods and services.

Reference List

Albino, V, Carbonara, N, & Giannoccaro, I 2007, ‘Supply chain cooperation in industrial districts: A simulation analysis’, European Journal of Operational Research vol. 177, no. 1, pp. 261–280.

Banks, J 1998, Handbook of Simulation: Principles, Methodology, Advances, Applications, and Practice, Wiley, New York.

Cacho, O & Power, B 2014, ‘Identifying risk-efficient strategies using stochastic frontier analysis and simulation: An application to irrigated cropping in Australia’, Agricultural Systems, vol.125, no. 6, pp. 23–32.

Carson, J 2005, Introduction to Modelling and Simulation, <http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.120.8277&rep=rep1&type=pdf>

Chang, Y & Makatsoris, H 2001, ‘Supply Chain Modelling Using Simulation’, Information Journal of Simulation, vol. 2, no. 1, pp. 24-30.

Ebrahimy, Y, AbouRizk, S, Fernando, S & Mohamed, Y 2011, ‘Simulation modelling and sensitivity analysis of a tunnelling construction project’s supply chain’, Engineering, Construction and Architectural Management, vol.18, no.5, pp. 462-480.

Esparrago, R 1988, ‘Kanban’, Production and Inventory Management Journal, vol. 29, no. 1, pp. 6-10.

Gonzales, F 2013, ‘Real-Time Simulation, and Control of Large Scale Distributed Discrete Event Systems’, Procedia Computer Science, vol. 16, no. 1, pp. 177–186.

Hollocks, B 1995, ‘The Impact of Simulation in Manufacturing Decision making’, Control Engineering Practice, vol. 3, no. 1, pp. 106-112.

Khorramabady Y 2006, Symphony Supply Chain Simulator: A Toolkit for Modelling Supply Chain Coordination and Information Sharing, University of Alberta, Canada.

Long, Q, Lin, J & Sun, Z 2011, ‘Modelling and distributed simulation of supply chain with a multi-agent platform’, International Journal of Advanced Manufacturing Technology, vol. 55, no. 1, pp. 1241–1252.

Longo, F 2011, ‘Advances of modelling and simulation in supply chain and industry’, Simulation: Transactions of the Society for Modelling and Simulation International, vol.87, no.8, pp. 651–656.

Quarterman, L 2008, ‘Kanban scheduling system’, Management Services, vol. 52, no. 1, pp. 28-31.

Robinson, S, Worthington, C, Burgess, N & Radnor, Z 2014, ‘Facilitated modelling with discrete-event simulation: Reality or myth’, European Journal of Operational Research, vol. 234, no. 1, pp. 231–240.

Selvarajah, E & Zhang, R, 2013, ‘Supply Chain Scheduling at the Manufacturer to Minimise Inventory Holding and Delivery Costs’, International Journal of Production Economics, vol. 6, no. 1, pp. 117–124.

Tatsiopoulos, P 1988, ‘Some Aspects of the Input/Output Methods for Managing Work in Progress Inventories’, Engineering Costs and Production Economics, vol. 15, no. 1, pp. 235 – 239.

Terzi, S & Cavalieri, S 2004, ‘Simulation in the supply chain context: a survey’, Computers in Industry, vol. 53, no. 1, pp. 3–16.

Vadalakis, C, Tookey, J & Sommervile, J 2011, ‘Logistics simulation modelling across construction supply chains’, Construction Innovation, vol. 11, no. 2, pp. 212-228.

Vankateswaran, J & Son, Y 2004, ‘Impact of modelling approximations in supply chain analysis – an experimental study’, International Journal of Production Research, vol. 42, no.15, pp. 2971-92.

Yang, X, Koziel, S & Leifsson, L 2013, ‘Computational Optimisation, Modelling and Simulation: Recent Trends and Challenges’, Procedia Computer Science, vol.18, no.1, pp. 855 – 860.

Zee, S & Vorst, I 2005 ‘A Modelling Framework for Supply Chain Simulation: Opportunities for Improved Decision’, Decision Sciences, vol. 36, no. 1, pp. 65-95.