SCADA is an automated system used in industries with complex processes to manage and monitor the control of the automated processes. The system components include computers, controllers, interfaces, networks, instruments, sensors and actuators that analyze the industrial processes through data collection (Indra et al. 44). SCADA collects data and information; transfer it to the central site, execute the necessary analysis, control and displays report information on operator screens.

The Importance of SCADA

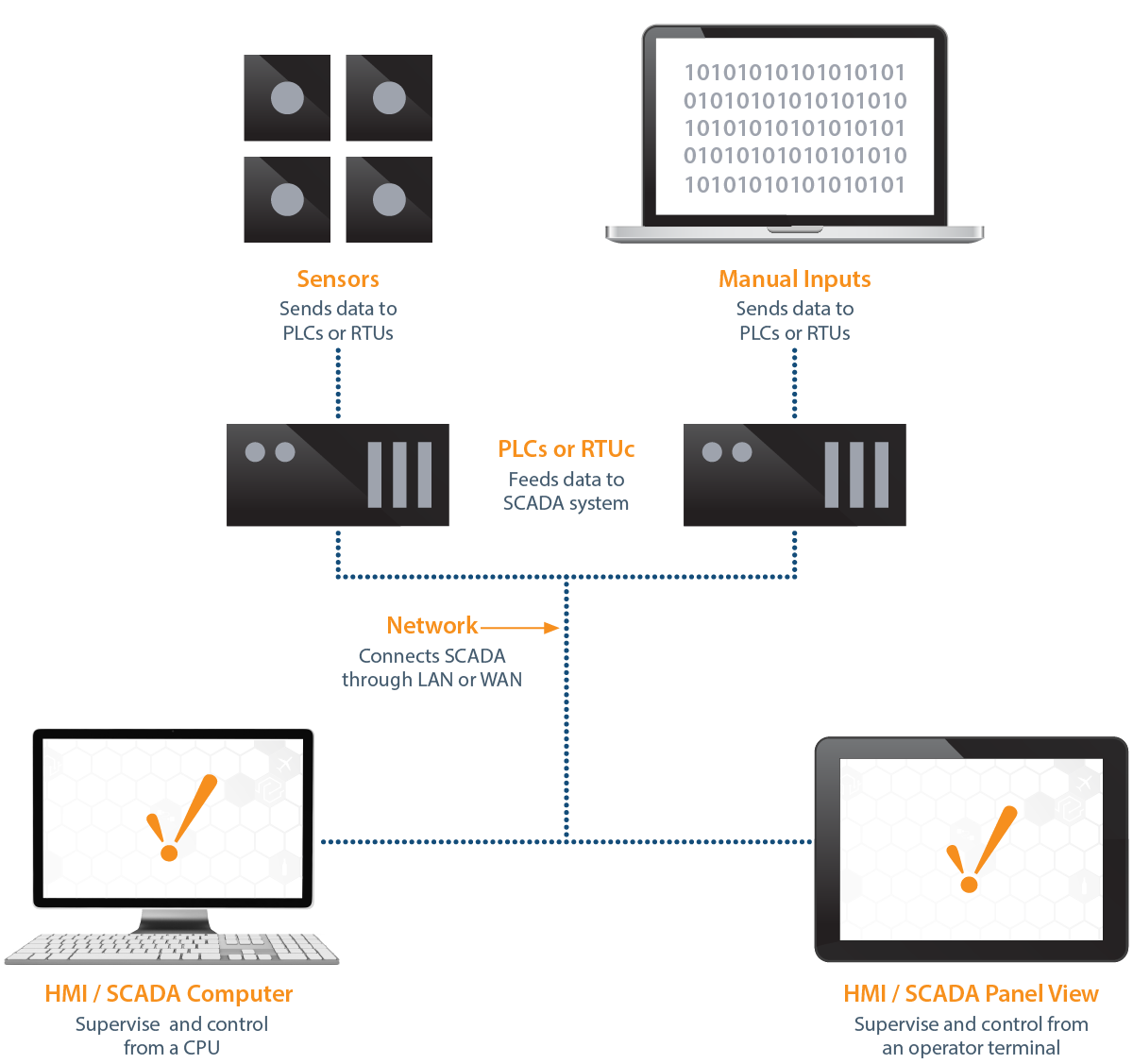

SCADA system core functions include the acquisition of data, network communication, data presentation and control. System components execute these functions by application the sensors and control relays that provide an interface with the system management. Sensors and control relays transmit data to RTUs and PLCs deployed in specific locations of the managed system, and this is where data acquisition occurs. RTUs and PLCs send the acquired data to the master terminal units (MTU) of the SCADA system. The SCADA master unit has a human interface, and it controls, regulates and manages the system automatically. The automatic control is based on the information from the sensor. There is a communication network that provides a pathway connecting SCADA master unit to the RTUs and PLCs (Indra et al. 46). SCADA system is important for the complex industrial processes monitoring and the real-time control. It provokes the increase in efficiency and profitability and helps to reduce costs.

Advantages and Disadvantages of SCADA Systems

The SCADA systems are pervasive, and, therefore, they have a wide connective area. The system has a diverse functionality with the extensive facilities for development (Bolzoni, Hadziosmanovic and Hartel 235). The efforts required by the end-users and the tasks performance are significantly reduced, and it makes SCADA suitable for the complex industrial processes. SCADA system has a greater robustness and reliability. SCADA is used to regulate and control the critical industrial processes. The systems vendors have a flexible support and maintenance. SCADA systems integrate the automated technologies and monitoring networks. Other advantages include standardization, parallel polling, routable, large addressing range, reduced downtime and minimal frequency of accidents (Bolzoni, Hadziosmanovic and Hartel 246).

The significant security challenges, especially in wireless networks whereby non-encrypted communication can be intercepted, are the system’s disadvantage (Eusgeld, Kroger and Nan 78). The complexity of the SCADA system requires the variety of advanced operating skills.

Elements of SCADA System

SCADA has a complex structure that consists of sensors, actuators, RTUs, PLCs, communication system, master terminal units, front-end processors, servers and redundant servers, HMI computers and software.

Measurement sensors and process actuators are the components of SCADA system control loop. Process sensors transmit the measurement variables to the controller. The controller interprets the signals and generates control signals, which then are transmitted back to the process actuators (Dietz, Eusgeld and Nan 681). The actuators convert the data into the new sensor signals and transmit them back to the controller. Sensors and actuators facilitate transmission of data to RTUs and PLCs.

SCADA RTUs and PLCs execute simple logic processes without SCADA master unit necessarily controlling. The RTUs are a field device connecting the SCADA physical equipment and the sensors in the specific process locations. It converts sensor signals to digital data then transmit it to the master terminal unit. The digital data is also transmitted by RTUs to the MTU, acting like a supervisory system. PLCs are used as field devices rather than RTUs because they are more configurable, flexible, and versatile (Indra et al. 46).

The SCADA communication system provides a network communication path between the master station and the remote sites. The communication pathway can be fiber optic, wire, satellite, radio, microwave and telephone lines. Optimal and efficient transfer of data is facilitated by the specific error detection protocols (Eusgeld, Kroger and Nan 83).

MTU is the master central component of the SCADA that consists of one or more RTUs. The remote control units (RTUs) locally gather data sending them to MTU for making appropriate commands to be executed on site. Customized or standard system software is used to collate, interpret and manage the underlying data.

The device that acts as a front-end processor in SCADA is the Gemini Data Concentrator. The functions of SCADA front-end processor include capturing, monitoring, protocol conversion, and consolidation of data. This device prevents the server from overloading and reduction of communication traffic with the SCADA master.

The Ovation SCADA communication server facilitates the flow of information and data from SCADA remote terminal units to the control system and the computers of managers and supervisors. This server also facilitates automation of critical processes to the control system and the connected computers. Thus, it enhances teamwork and makes the decision-making faster (Dietz, Eusgeld and Nan 681).

Redundant control server is a backup server installed to mitigate and ensure that the processes and operations are not affected by the failure of SCADA master server. Redundant control server automatically synchronizes real-time data between the SCADA master server and the standby servers (Dietz, Eusgeld and Nan 684). In case SCADA master server fails, the automatic switch-over of real-time data flows to redundant server.

The HMI computer provides an interface between the human operators and the SCADA system. This interface has controls that allow human operators to interface with the SCADA system. This interface is a standard for monitoring multiple PLCs and RTUs (Voutchkov 399). It allows technicians and mechanical engineers to configure HMI and SCADA system easily.

The HMI software is a program package for SCADA. The operators and the SCADA system maintenance engineers can easily change representations in the interface. The representations include on-screen traffic light and other representation in industries and organizations that have installed SCADA system.

SCADA Architecture

In this SCADA architecture, the information from manual inputs or sensors is sent to PLCs or RTUs, which send it to the computer systems with SCADA software (Dietz, Eusgeld and Nan 684). The SCADA computer software processes and analyzes the information and generates reports to be used by engineers and technicians to control industrial processes and operations.

SCADA Systems in Use

The SCADA system is used to automate management and control of industrial processes that are complex in nature. SCADA is used in water and sewerage systems, manufacturing industries, traffic signals, transit and other authorities that manage the electricity regulation (McCrady 188). SCADA is also used in buildings, environment, and facilities to control devices such as entry systems, refrigeration units, lighting systems, and HVAC.

Conclusion

Installation of the SCADA systems is essential for the complex industrial processes. This system significantly reduces labor costs improving the overall performance of industries and organizations. SCADA also improves the management, because it facilitates the gathering of information to a central location saving the personnel’s time. The capability of generating reports of errors and problems makes the correction of the critical industrial processes easier. SCADA is user-friendly, and thus it has become a world-renowned system.

Works Cited

Bolzoni, Damiano, Dina Hadziosmanovic, and Pieter Hartel. “A Log Mining Approach for Process Monitoring in SCADA.” International Journal of Information Security, 11.4 (2012): 231-251. Print.

Dietz, Sven, Irene Eusgeld, and Cen Nan. “System-of-systems Approach for Interdependent Critical Infrastructures.” Reliability Engineering & System Safety, 96.6 (2011): 679-686. Print.

Eusgeld, Irene, Wolfgang Kroger, and Cen Nan. “Analyzing Vulnerabilities between SCADA System and SUC due to Interdependencies.” Reliability Engineering & System Safety, 113 (2013): 76-93. Print.

Indra, Jaganathan, R. Kirubashankar, K. Krishnamurthy, and B. Vignesh. “Design and Implementation of Web Based Remote Supervisory Control and Information System.” International Journal of Soft Computing and Engineering, 1.4. (2011): 43-51. Print.

McCrady, Stuart. Designing SCADA Application Software: A Practical Approach, London, UK: Elsevier Science, 2013. Print.

Voutchkov, Nikolay. Desalination Engineering: Planning and Design. New York, NY: McGraw-Hill, 2012. Print.