Introduction

One of the most outstanding innovations in the contemporary corporate management is supply chain management.

Innovation, unlike the prior management techniques embraces the management of all players in the supply chain right from the supplier of the raw materials to the distributor.

This change in management techniques has proved worthwhile in helping organizations to produce goods and services at a cost efficient mechanism and ensuring satisfaction of the consumer by availing the product and services when and where they are wanted.

This paper pays a review of the various techniques in supply chain management with case studies of organizations that have successfully implemented the technique.

Background: The Airbus case

An official commitment of Airbus to develop and launch the A380, a 555-seat superjumbo plane, at a cost of $11.9 billion, which represented more than 70% of Airbus’ total revenues in 2000, represented a high risk investment.

Following this commitment, Boeing, a competitor in the industry, cancelled, for the second and last time the project to develop and laugh a similar product, the stretch jumbo (Cole 23).

This came regardless of the fact that Boeing was in a better financial problem to finance the project compared to the Airbus.

As per the forecasts, the project proved to be success. With such success, the case ushers the manager into a new dimension in rethinking strategic planning. What lessons can the contemporary manager learn from this case?

The MTO model

The primary note in this case is the fact that though manufactured in different places across the Europe, the final assembly of these parts took place in two locations. From this information, it is evident that the managements’ choice of supply chain model was make to order.

Now the question is, why this choice. First, MTO offers the organization much lower cost options especially concerning opportunity cost, Depreciation, staffing and warehouse costs (David 403).

Furthermore, the model works well for customers products and in this case, since each of Airbus’ planes requires customization according to specific customer requirements, the model presents the perfect opportunity for the management.

Further, considering that the production of the planes is not on mass basis, which would give the company a chance to explore other models, MTO the better model choice for the company.

Leave alone the low demand, the other explanation for the choice of this model is the risks to which the investment exposed the company (David 405). Such high-risk investment, just like Airbus’, would best adopt the MTO model to secure the company and shield it from this exposure.

Besides all this, the industry in which the company operates, the aviation industry, experience many technological changes within short periods and thus, the company stands a chance that these technology changes may rule the project obsolete before completion.

For this reason, the MTO model passes as the best choice given that it offers the company an opportunity to follow technological changes and thus securing the product front obsolesce.

The EOQ model

Another very important consideration that every manager has to make is the consideration of how to place orders of raw materials. The planning of raw materials inventory is a quite daunting task for the manager.

One of the considerations is whether to place bulk orders or to order small batches repeatedly. Though many might consider the consideration discretional, in practice, the process gives the management an opportunity to create value (Weiss and Gershon 136).

In almost all cases, ordering big batches and maintain and inventory is far much economical as compared to small purchases.

For a better understanding of this very important decision, a closer study of SILOG shades more light on the subject. The company places most of its orders in bulk by road transport and small batches by air in case of emergencies.

This bulk ordering is associated with high warehousing costs. However, the longer lead-time for SILOG has helped it combat this challenge. By the time of new arrivals, the company has converted most of the raw material inventory to finished goods and therefore there is enough space.

Besides this, the large inventory secures the company from running out of stock in case of emergencies like for example during the time of the volcano. The other consideration that is of interest when making this decision is the cost factor.

It is more expensive to transport smaller quantities many times than transporting large quantities for less time (Weiss and Gershon 136). This is because the cost of transport is rather a function of the distance and means of transport than quantity.

Therefore, transporting bulk by road or sea is more cost efficient than transporting small batches by air.

Safety Stock Level

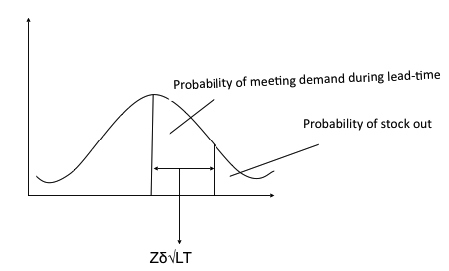

Maintaining a safety stock level is an important consideration if the management has to avoid stock outs in case of non-constant demand (Krupp 26). Supposing a company faces a non-constant demand characterized by a normal distribution with a mean value of D units per month.

Using this value, the manager can calculate the order size Q in the EOQ model and calculate the probability of experiencing stock out if a safety stock level is not in place (Krupp 26).

Where, Z: Number of Standard deviations corresponding to Service level probability

δ: Standard Deviation of Demand during lead-time.

In case there is no safety stock, the value of Z is zero.

Therefore, the reorder point R = LT X D.

Hence, the service level equals the probability of having no stock outs. The implication is that there is a 50% probability of incurring stock outs if there is no safety stock.

Measuring performance

The first reason why individual performance in the Beer Game does not constitute the final grade is the interdependencies across all the activities in the supply chain.

Thus, the decision in one stage cannot fix or break the chain and therefore, it is crucial to view and evaluate the process as a whole as opposed to the individual activities (Lee et al. 96).

The butterfly effect, in the chaos theory, is a term that explains this. The theory proposes that, in any dynamic system, small initial differences may, over time, lead to large unforeseen consequences.

Secondly, the way of carrying out the Beer Game is a hurdle in that it forbids communication among the various departments in the supply chain.

This is the greatest of all challenges since communication is a very important took in making work easier and improving on quality besides making information clear (Tempelmeier 346).

Thus, in forbidding communication, the game opens a great chance for error since most decisions are on speculation.

Lastly, the beer games’ design was to imbed the Bullwhip effect. In addition to the inhibition of communication mentioned above, the beer game leads to Bullwhip effect in several other ways.

The design of the supply chain is such that it allows longer lead-time, which in turn aggregates the bullwhip effect (Lee et al. 96). The final is local optimization.

The combination of these factors provide an incentive for individual players to hold back orders and only place aggregate orders, which in turn aggravates the problem of demand forecasting because of the little information regarding actual demand which ultimately affect batch orders by unnecessarily inflating their prices.

Historical demand and R square

From the historical data of SILOG, there are five seasons explicit in the information.

This kind of seasonality has a certain implication, which is, the data points around the trend line obtained through regression analysis will be at wider span, thus giving an explanation as to why the R square in this data set are rather low (around 0.64).

However, removing the seasons explicit in the data brings the data points closer to the trend line, and hence the R square will get higher to around 0.94.

Multi-process manufacturing

While there exist not a single, and articulate reason as to why the manufacturing process may adopt various processes, there may be some arguments in support of this fact.

In general, some reasons for multi-process manufacturing may include the specialty and customization of the product itself whereby it is impossible to manufacture it in another way. Other reasons might include the order size and the repetitiveness of demand (Pettersen 134).

Another reason relates to the cost of manufacturing, whereby one option is less costly compared to the others. A review of some of the manufacturing processes, and why they are used will help shade more light into the matter.

Broadly, some of the production systems include the pull and the push systems. The push systems, majorly characterized by Just-in-time (JIT) technology, require the absence of inventory because it represents a cost burden.

Some benefits of such system include reduced WIP, reduced space and re-works, improved communications and improved defects detection (Pettersen 135). Further, it promotes shorter lead times, and is Less reliant on forecasts.

The push production systems on the other hand use the Material Requirements Planning (MRP) technology. The system encourages the availability of inventory to support the smooth running of the production process, and further allows managers to control the process.

This system therefore promotes economies of scale both in purchasing raw materials and in the production. However, this system mainly allows for the planning and completion of complex assemblies as the delivery of sub-components is only by scheduled need.

Further, considering some specific processes and the reasons and the situations in which they are preferred is important. The first process is Mass production.

This process is favored in cases where the product is highly standardized and therefore, production is on a single flow of one long process with each product identical to the other.

This process has two main advantages, which include the fact that the production process is fast and that the process uses raw materials efficiently (Pettersen 138). However, this process has it shortcoming too. The high rate of production equal relies on all machines.

The breakdown of one machine translates to a complete breakdown of the process. Secondly, the malfunctioning of any of the machines implies defects on all the units produced until find out that one of the machines is malfunctioning.

Another process is batch production. In this case, the unit g through the production process in clear groups, which can be either dozens, hundreds or otherwise as planned and each batch is operated on as a whole.

The greatest of all advantages is that it allows efficient use of equipment by moving batches around in patterns to different areas of special. In addition, the process reduces potential losses from failure of equipment since only a single batch fails (Pettersen 136).

However, the process of identifying the ideal batch size requires a lot of analysis and might take a lot of time and secondly, the process may raise the costs of management given its complexity.

Another process in this case is Job order production. In this case, the complexity of the product requires the production of a single product at a time and a combination of specific skills among the employees working on the product.

This kind of production tends to use general-purpose machine and the workforce end up developing various skills (Liker 34). The disadvantage is that set up costs are relatively higher and raw materials are varied and relatively expensive.

The last production process under scrutiny in this paper is Flow production. The process of this process aligns itself to the demand of the product.

It borrows concepts from JIT where it produces according to demand forecasts, production lines for families of products, pull material using kanbans, back flush material and costs upon completion (Gilliland 67).

The advantages of this include that it reduces inventories and guarantees efficient use of machinery leave alone reducing customer response time and easing the shop floor activities.

HP DeskJet Printer Vs LEGO Pieces

Despite the differences inherent in the above-mentioned cases, the two cases are similar in several ways.

The first similarity lies in the interdependency of the processes in the supply chain and therefore a failure in any of the processes would mean a breakdown of the whole supply chain; in LEGOs’ case, all products were faulty.

Secondly, the cooperation and communication breakdown within the supply chain lead to many problems. In the case of HP, each department had a different approach to the problem and did not reach consensus in the beginning just like LEGO.

However, the opening of communication in stage two improved cooperation and thus improved the corporate results.

Further, the forecasting system in both organizations had failed. This is highly evident in the HP case whereby some sites had stock outs and others had extra stock of the same items.

In the case of LEGO, there was no forecasting system but it heavily depended on personal opinion, more precisely the choice of color when the demand was unknown.

Both companies had a form of change with HP trying to change its system to pull while LEGO mainly used both push and pull in stage one and two respectively

Finally, both company suffered customization issues.

In HP case, assigning the alignment of power supplies and specific language catalogues to the distribution centers instead of the factory helped them have faster response time to customer demand where in LEGO case changing packaging methodology and shipping the product before the beam maker and doing that in the end could also have shown better outcomes.

Lessons from 7-Eleven case

Effective management of the supply chain is an important tool for the success of any organization and this is no different for 7-Eleven, which by effectively managing the supply chain succeeded. One of the lessons includes the choice of the location for their stores.

Placing their stores close and adjacent to each other helped them drive away competition due to their heavy presence and secondly, the closeness of their store reduced the supply costs.

Secondly, the company chose to cook the food they were supplying from without the site. Cost wise, it would cost much to cook in the store since this would require huge amount of money.

More also, it would shift their main selling advantage, while guaranteeing the same tier of quality food in this case would be another hard thing to manage. Therefore, preparing food off site was the best choice given the well-organized supply chain.

Another important lesson is the role of Distribution Center Module. This reduces costs since they did not have to maintain inventory and thus reduced distribution costs a great deal.

Finally yet important is the role of a well constructed Information Technology Systems (ITS). 7-eleven has an excellent communication network such that the flow of information remains uninterrupted and unhindered.

This allows real time visibility and besides these, it promotes the decision-making capacity as concerning inventories. Further, the consideration by the company to adopt RFID technology will greatly improve their efficiency and effectiveness in supply chain related matters.

Lessons from the Beer Game experience

From Beer Game experience, it is clear that the activities in the supply chain are interrelated, and are dependent on each other therefore, the performance of a single part cannot be measured in the absence or other related activities.

Therefore, it is evident that the cause of supply chain failure is majorly internal inefficiencies rather than external factors.

Further, communication, visibility and information exchange is an important aspect that is crucial for the success of the supply chain since a failure in any of these contributes to the whip effect.

In addition to these, the game brings the desired attention to the complexity of demand forecasting in that it is more than what comes in and what goes out. Again, the game highlights the importance of a pull system rather than to make stock.

Finally, it brings the understanding that lags are a major cause of problems in the supply chain and thus it is important to have them reduced as much as possible.

Lessons from simulator SILOG

The simulator SILOG also offers many important lessons from which both students and managers can learn. One is the importance of demand forecasting. The forecasts of demand help the manager decide the level of production at every location and how much to supply for every location.

In addition, the case highlights the importance of having and maintaining safety stock to prevent stock outs in cases of emergency besides highlighting the importance of forward planning.

Considering the air transport choice in emergency cases helps us understand the priority that managers must accord to customer demands as opposed to reducing transport costs.

In addition, it highlighted the possibility of the requirement of holding more inventories in order to meet the requirements of the customer.

In this case, the management chose to expand its inventory store as opposed to renting some extra space. This therefore represents a long tern solution to the problem, which is more cost effective than renting, especially if the renting space is away from the production site.

Finally, from this case it is clear that the management can increase customer service through management of orders and supplies.

Conclusion

Throughout the discussion on this paper, the role of the supply chain is clear. Any organization that endeavors to meet its customers’ needs must appreciate the role of the supply chain in ensuring the satisfaction of the customers.

This paper further highlights the pillars of an excellent supply chain. Information is one of these pillars. At every level in the supply chain, the management must encourage and promote sharing of information.

More so, the management must understand the interdependencies within the supply chain, which means that the performance of the whole network is dependent of the performance of all the stages.

The discussion also reveals the pillar of technology in improving the communication and information sharing within the supply chain.

Lastly, the discussion brings the important understanding of the considerations that managers have to consider when choosing a particular system of production by highlighting the several advantages and disadvantages of the various systems of production.

Works Cited

Cole, Jeffrey. “Airbus Prepares to ‘Bet the Company’ as It Builds a Huge New Jet.” The Wall Street Journal 11 March 1999: 23-34. Print.

David, Frederick R. Distribution, Planning and Control: Managing in the Era of Supply Chain. Boston: Kluwer Academic Publishers, 1999. Print.

Gilliland, Michael. “Is Forecasting a Waste of Time?” Supply Chain Management Review August 2002: 56-78. Print.

Krupp, James. “Measuring Inventory Management Performance.” Production and Inventory Management Journal, Dec 1994. Print.

Pettersen, Johnson. “Defining lean production: some conceptual and practical issues.” The TQM Journal, Feb 2009: 127-142. Print.

Weiss, Howard and Mark Gershon. Production and Operations Management. Boston: Allyn and Bacon, 1989. Print.

Lee, Hau, Padmanabhan, Van den and Whang Seungjin. “The Bullwhip Effect in Supply Chains”. Sloan Management Review May 1997: 93–102. Print.

Tempelmeier, Henry. Inventory Management in Supply Networks: Problems, Models and Solutions. Norderstedt: Books on Demand, 2006. Print.

Liker, Jeffrey. The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer. London: McGraw-Hill, 2003. Print.