- Theoretical Discussion of Both Supply Chain Management and Material Handling

- Theoretical Discussion of the TV Industry

- Design of Systems for both Supply Chain Management and Material Handling

- Photos of Some Material Handling Equipment for the TV Industry

- Reasons for Choosing the Material Handling Equipment for the TV Industry

- Graphs and Charts for Supply Chains Management

- The Raw Materials and the Manufacturing Process of LCD TV

- Photos of the LCD TV

- References

Theoretical Discussion of Both Supply Chain Management and Material Handling

The supply chain entails a network of suppliers, manufacturers, assembly plants, and distribution channels. Similarly, the supply chain conducts the procurement of materials and the conversion of such materials into transitional and finished products (Bozarth & Handfield, 2005). The final role entails the distribution of these materials to the respective customers.

From this description, it can be noted that supply chain management is crucial in various industries. Generally, supply chain management (SCM) refers to the systems of managing the transfer of information, materials, and services right from the raw materials to the final consumers. Ideally, it is observable that SCM differs from the supply management that only stresses the consumer-supplier affiliations (Mahapatra, 2010).

SCM has been reputed for productivity and competitiveness within manufacturing/service enterprises. Furthermore, it remains a fundamental application area within the electronic commerce industry. This dependency on the electronic industry has consequently led to increased attention to material handling and other related processes within such organizations (Li, 2007). There are two features within the SCM. The foremost portion is called the back-end.

This composes the physical structure blocks, supply amenities, production structures, warehouses, distributors, and retailers. The logistic facilities are also pertinent components of this system. The back end entails production, assembly, and physical transit (Frazelle, 2001). In this stage, there are fundamental decisions that are bound to be made. In this decision process, there is a supplier appointment as well as the appropriation of optimal procurement frameworks.

In the manufacturing considerations, there are major decisions helpful in choosing plant situation area, product line choice, as well as capacity planning and production arrangement. The distribution considerations involve decisions about warehouse setting, client allocation, demand speculation, and inventory management (Radhakrishnan, 2001). It is also important to consider logistics within the SCM processes.

There must be a choice on the methodology of logistics, ports selection, and supply schedules. In the global arena, critical decisions consider the desired products, processes involved, planning for uncertainties, and real-time monitoring and management of the SCM (Mahapatra, 2010). Additionally, integrated scheduling constitutes a critical component of this decision-making stage. It is vital to consider various models and theoretical concepts about SCM.

Some of the notable models include the stochastic models. These have the Markov chains and queuing networks as their major components. Also, there are the optimization models that include the LP, MILP as well as heuristics. Simulation theories also offer a critical basis for these decisions. The second phase, normally termed as the front-end, involves the IT and ITEC (Li, 2007). There are processing and application of facts in the facilitation as well as optimization of back-end activities. In this stage, there is the considerable application of vital technologies including those for the transmission of messages across dissimilar actors within the chain of supply. There are those technologies for choosing the suppliers or distributors and demand forecasting.

Material handling entails the unloading of the exhibit material within the warehouse or at the various show sites. Additionally, it also involves the transit of the merchandise to an organization’s designated exhibit points, storage as well as the return of the particular containers. The process is long and may also entail the reloading of the organization’s exhibit material to the selected outbound carrier (Radhakrishnan, 2001).

Material handling refers to an effective short-distance transfer of merchandise that normally occurs within a specific building. The building might be of diverse applications like the plant or warehouse. The process of material handling might alternatively occur or transpire between a particular building or a specific transit company. Generally, it is notable that SCM is a process usually accompanied by material handling initiatives (Mahapatra, 2010). The material handling process is seen to transpire in many different stages and dimensions. Some of these include the identification of the movement, time as well as quantity. Additionally, space is an important dimension within material handling processes.

Since the process of material handling involves the interaction of man and his machines, the occupational safety and health considerations have become pertinent considerations within the process. Safety measures remain grossly observed during the processes to enhance material and human safety (Frazelle, 2001). This is basically in terms of minimizing severe breakages that might lead to losses and reducing workers’ or handlers’ exposure to occupational health risks.

As a result, a lot of health audits are always conducted as part of the material flow process. There are numerous basic merits of the application of material handling in the distribution or manufacturing processes within organizations. Foremost, material handling enhances efficiency. This occurs through enabling the logistics to rapidly respond and sufficiently make up for consumer needs.

The process remains vital for a continuous and successful movement of merchandise in the stores. It also involves identifying the stock, filling the orders, and preparing the orders for transportation to various consumers (Mahapatra, 2010). Therefore, it is critical to note that organizations need to incorporate the handling requirements effectively. This is not particularly to fit the firm’s departmental requirements, but also cater to the demands of the general clientele.

There have been critical observations that the process of material handling applies the right procedure. It also offers the right quantity of the appropriate material or good during the right period, time, and at the needed location (Bozarth & Handfield, 2005). This process follows the appropriate sequence, right position, condition, as well as cost. Moreover, it entails the handling, storage as well as material control.

When conducted appropriately, the process helps to add value to the material, good, or product based on time and place utility. The process may also impact the space needs, revenues, quality as well as safety or productivity considerations. It is observable that the application of material handling within various organizations differs. For instance, according to the

Arnold Electric, Inc., material handling refers to the loading, unloading as well as the movement of products or merchandise (Li, 2007). The movement may involve the transit of raw materials to various processers of products. Alternatively, it might also entail the transit of products to various distributors or shipping agencies. It entails all the procedures of the conveyor systems as well as the storage processes.

Theoretical Discussion of the TV Industry

The globalization effects together with the increasingly recorded technological advances have led to significant influences within the entire entertainment and social sector. The TV Industry remains one of the notably affected sectors by these present trends (McDowell, 2006). Generally, it is observable that the TV industry continues to undergo significant revolutions. Although originally the solitary networks domain, the arrival of cables to act as the delivery systems enhanced the rapid development of the smaller channels (Tinic, 2005). These finally have challenged the former rivals.

The influences of the internet on the TV industry cannot be underscored. For example, the internet started a transformation in television viewing. This shift was actually from the main gadget developed for its medium to the application of computer screens. Additionally, iPods and phones have become some of the transformers within the TV industry. Therefore, whilst in the past decades, this sector is comprised of only three networks and the mere TV, televisions within this 21st century have a variety of entertainment options as well as several ways of viewing (McDowell, 2006). Confronted with the transforming trends, the TV industry presently remains challenged to rethink previous business plans. Moreover, there are growing concerns about the shrinking audience size as well as the ever-transforming approaches of distribution.

Most organizations or television manufacturing companies have realized the fluctuation and transformation in the uses of television and have established critical strategies to adapt to the changes (Cook, 2006). The discovery and invasion of the new rich markets is an initiative by most multinationals involved in the manufacture of televisions. It is observable that Africa has provided a rich niche for the distribution of televisions that have modern technological applications including the 3-dimension as well as the decoder TV sets.

Generally, the internet has transformed the rate of adoption and the hours spent on TV watching. This is basically because people presently consume most of their time in internet browsing as compared to TV viewing. Additionally, watching TV on the internet is also a common practice currently. Most sites such as Netflix have become increasingly visited for purposes of online TV viewing (McDowell, 2006).

The impacts of digital infiltration on the television mainstream have caused significant influences on the trends of consumer demands on the televisions. In sequence, the trend has also affected the supply trends and manufacturing capacities of most television industries (Cook, 2006). There is a great demand for innovation and novelty for potential manufacturers to remain focus and competitive in the present television manufacturing industry.

The increased time spent on home entertainment by most people has also potentially influenced the trends in television manufacturing. Due to increased time spent in home entertainment by most persons, TV manufactures have been forced to venture into a novel, internet-enabled TV models (Tinic, 2005). Therefore, it is apparent that even as traditional TV is getting challenged through the emergence of internet-video showcasing, it is vital to note that the manufacturers continue to embrace novel consumer behaviors.

To realize considerable sales turnover and capture a wider audience, TV manufacturers have to integrate robust technological applications in their production systems. Additionally, there is a need for strategic management as well as marketing approaches within the novel markets by these organizations. The entry of Sony’s search-centric “Google TV” into the market perhaps demonstrates the level of technological ambition that most television manufacturers have adopted in the recent past (McDowell, 2006).

The main objective of such initiatives is to respond to the ever-transforming client demands and tastes. It can be noted that these flexibilities are attributed to the high degree of technological development and advancement within the present globalized world. Most firms have noted the importance of integrating television applications with those of the internet in creating unique brands with significant customer loyalty. It is also important to note the effect of the movie industry on the rate of television consumerism (McDowell, 2006).

There seems to be a transforming trend towards the adoption of the 3D television systems especially in the watching of movies amongst the consumers. However, there is growing evidence that the 3D screens and technologies are most preferred just within the movie theaters but not within the viewer’s homes or residential places. However, some of this resistance might also be due to the glasses factor (Cook, 2006). This is because most people may find these glasses uncomfortable and inconvenient.

Sony remains the biggest acknowledged brand within the TV industry. However, this trend is observed to be increasingly transforming with the invasion of other brands in the market. For instance, Samsung’s LG has caused a great stir and threat to the Sony brand within the market place presently (Tinic, 2005). The size of the TV screen is also seen to hold great influence in the rate of its adoption. For instance, there have been observations that most clients prefer the larger TV sizes and would purchase them relative to the smaller TV screen sizes.

Design of Systems for both Supply Chain Management and Material Handling

The objective of any SCM and material handling processes within the TV industry should be to increase the total value generated. This forms the disparity between what the ultimate merchandise can cost the client and the inputs any supply chains invest in meeting customer demands (Frazelle, 2001). The SCM within the TV industry must be measured or examined in terms of its general profitability.

The establishment of the SCM must follow a coherent set of principles to enhance the efficiency of the distribution system and increase the safety, value as well as credibility of the TV brand. Setting up international or overseas SCM systems is vital for multinationals to reach wider novel markets especially within Africa as had been already noted earlier. It is also important to note that the efficiency of the systems of distribution largely depends on the capabilities or competencies of the specialized workforce involved in the distribution systems (Li, 2007).

The utilization of casual labor is vital, particularly within material handling procedures. In this regard, the effective utilization of occupational safety and health policies within the material handling sections is important (Bozarth & Handfield, 2005). This is basically to reduce or minimize the instances of occupational hazards that may confront the material handlers and other machine operators within the systems. Additionally, the policies are established to minimize the cases of TV breakages as well as accidents to significantly reduce losses during the material handling process (Shapiro, 2007).

The SCM to be applied for the TV industry will include the flow management of the critical phases within the supply chain. This would immensely assist in the maximization of the general supply chain’s effectiveness (Radhakrishnan, 2001). There are also critical decision phases that must be carefully executed for the SCM to operate effectively. There are decisions to be made on the structuring of the supply chain for the coming duration. Chain configuration is considered a critical factor.

There exist critical resolutions to be made regarding the location and the extents of production. Such resolutions also influence the location and operation of the warehousing amenities. There should be an analysis of the goods that ought to be manufactured and warehoused within diverse locations (Mahapatra, 2010). The type of transit to be availed of is also a vital consideration. It is important to note that for the TV SCM, an appropriate and up to date information system must be applied within the supply chain planning (An & Fromm, 2005).

There are critical planning decisions that must be conducted to enhance the profitability of TV SCM. These include resolutions on targeted markets, the outsourcing of additional inputs from relevant firms to aid in the SCM and material handling. Additionally, it may also relate to the applicable inventory policies.

Marketing promotions and brand building initiatives are also critical for enhancing the suitability of the SCM (Radhakrishnan, 2001). Generally, there must be a given set of working guidelines that control short-term activities. The TV SCM may specifically follow four critical pathways towards customer reach and satisfaction. Ideally, these should comprise the client order cycle, the replenishment phase, manufacturing stage as well as the procurement cycle. These will be very critical during the consideration of vital operational decisions.

Photos of Some Material Handling Equipment for the TV Industry

Reasons for Choosing the Material Handling Equipment for the TV Industry

As noted earlier, material handling refers to the movement of materials to different required or preferred sections within and outside the manufacturing area. It is critical to note that all businesses and industrial operations entail a certain level of material handling processes. The management of such enterprises must choose the right available and cost effective material handling equipment to be applied in their operations (Cherunilam, 2004).

Of course, it is important to note that such decisions must comply with the existing regulatory measures regarding the material handling processes and safety requirements. These are often statutory measures outlined under the industrial operations and safety guidelines. The basic aim of choosing an appropriate material handling is, therefore, to maintain the original state of the manufactured material, protect the consumer’s interests and preferences, and to prevent occupational hazards associated with the operations. Thus, it can be observed that seeking to prevent occupational health and safety hazards remains an important focus of an effective material handling process (Frazelle, 2002).

Normally, the utilization of expert advice and design of operations from skilled health and safety officers as well as engineers is important in the decision making process regarding the type of equipment to be purchased or hired for material handling. Notably, there exist several approaches applicable to handling materials. Consequently, there is diverse equipment applied in these processes. This largely depends on the kind of merchandise or materials to be transported or handled.

The management as well as engineering departments responsible for material handling recognizes that application of efficient and effective material handling as well as storage services remains an important initiative within the TV industry operations (Cherunilam, 2004). Generally, an effective process offers a persistent material movement and minimizes the labor costs together with other inconveniences. The TV industry is very crucial within entertainment as well as the social sector.

There is an observable increasing demand for highly modernized televisions throughout the world, with major industries continuously innovating and developing more sophisticated and delicate kinds of TV. For this reason, the management as well as the engineering department concerned must apply effective mechanisms for material handling within the industry. The equipment to apply must be sufficiently modeled to minimize instances of TV breakages as well as mishandling during the conveying processes (Frazelle, 2002). This is also critical to maintaining the TV sets in their manufacturing state when conveying or transiting them over long distances such as in the overseas markets.

As seen in the equipment above, the application of wrong equipment in the material handling of TV might cause accidents, breakages, or even retard the production progress. As indicated in the photos, the applicable equipment must be sufficiently big to adequately handle the TV load to be transited (Frazelle, 2002). The equipment outlined above indicates their model attention to factors including height, weight as well as leverage. Additionally, they have the appropriate power and resiliency to handle the material in conveyance.

The conveyor belt indicated in the equipment photos is appropriate for TV material handling within considerable distances, especially within the warehouse (Cherunilam, 2004). This is because the conveyor is largely automated. This reduces great labor expenses and costs associated with manual labor hiring. Also, it minimizes the mechanical intrusion of the TV material that normally transpires through manual labor or handling.

Graphs and Charts for Supply Chains Management

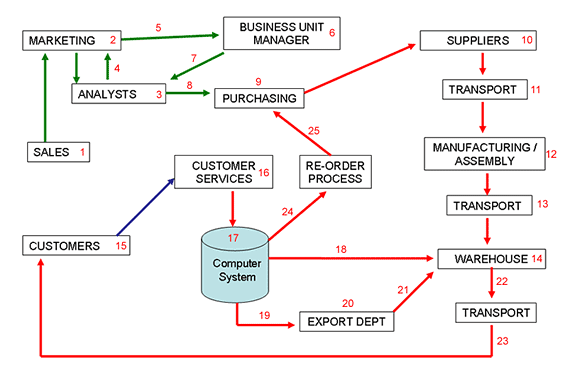

The flow chart below indicates a characteristic manufacturing supply chain operations flow to highlight the business or organizational units involved.

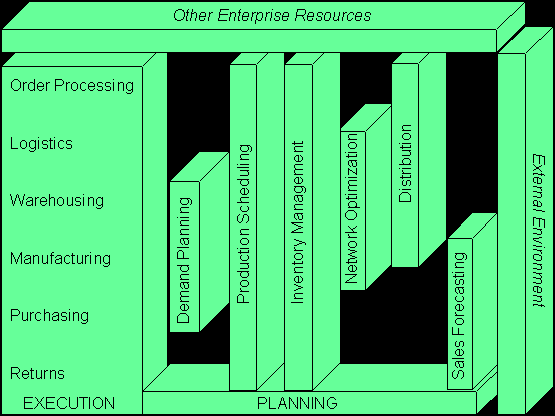

The second chart shows an SCM 3-Way Impact Chart:

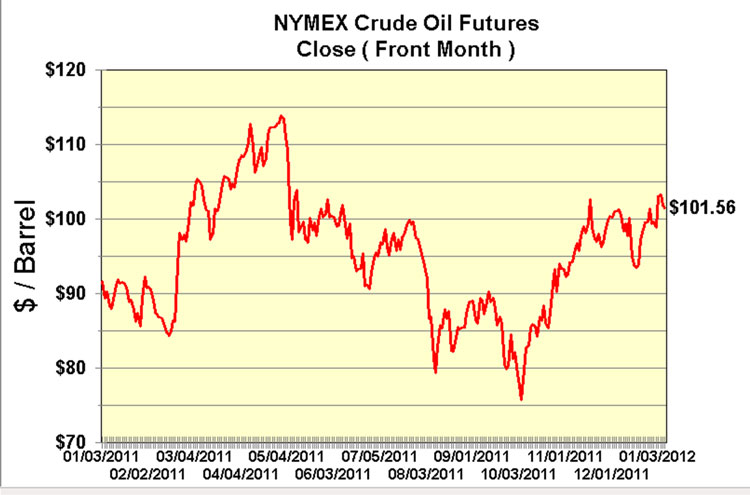

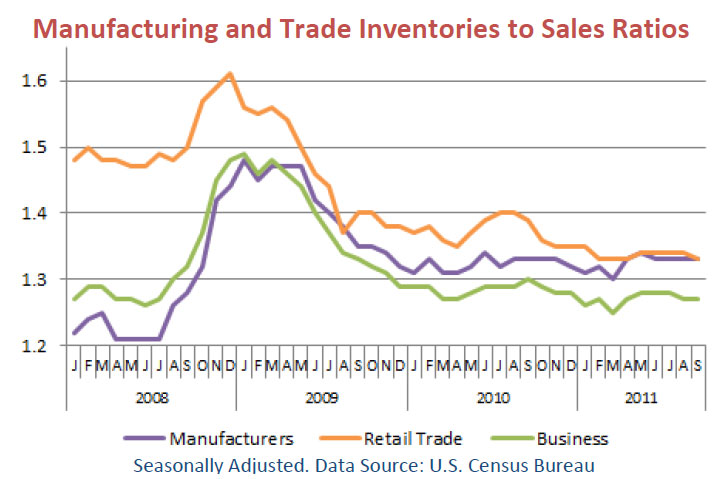

Examples of some supply chain management graphs from various US trade sectors.

The Raw Materials and the Manufacturing Process of LCD TV

The LCD TVs have recently become popular within the entertainment as well as the social sector globally. The Liquid crystal displays (LCDs) are composed of liquid crystals under the activation of electric current. This forms the display unit of the LCD TV. The application of the LCDs in TVs has recently developed recognition. The logic behind the LCD technology involves the operation of a liquid crystal (Ruland & Stribeck, 2005).

This is made of complex molecules. Generally, two kinds of LCDs are notable within the market. These include the passive matrix as well as the most recent active-matrix LCDs. The most recent active matrix LCD is brighter with more reading capability as compared to the passive matrix form. it is also notable that the manufacturing procedure in the active matrix LCDs remains more complex relative to that of the passive matrix (Sakka, 2005).

An operational LCD is composed of diverse components. These include display glass as well as drive electronics. Control electronics and the mechanical package also include some of the critical components of the system. The power supply also remains an important component since it provides room for the transfer of power into the system. A display glass provides the space for the liquid crystal. The display glass has a coating composed of the row together with the column electrode. Additionally, it is also made of contact pads that function to link the drive electronics with one row and the column electrodes. Control electronics appear as integrated circuits.

Their basic function is to decode and construe the inward signals (Sakka, 2005). A mechanical package as a component refers to the frame. Within the LCDs, a liquid crystal remains bordered by two glass portions or a transparent polymer referred to as the substrate. Whenever glass is applied, the coating is usually encrusted by silicon dioxide to enhance the liquid crystal conditions.

Application of the indium tin oxide film on the glass by the help of photolithography helps in the development of visible electrode patterns. Alternatively, this procedure occurs through the silk-screening process. The power supply helps to provide the LCD with the appropriate current. Notably, the power supply is normally purchased separately. LCD producers apply borosilicate or silicon dioxide layer to reinforce this glass. An alternative raw material for this purpose may include plastic (Ruland & Stribeck, 2005).

This helps to make the display lighter. Several LCDs presently apply the light source emanating from a backlight. This might be a simple fluorescent light that darkens the liquid crystal. This is particularly whenever the screen appears cloudy. The manufacturers also apply layers of polarizer substances to improve the effect (Sakka, 2005). In the manufacturing of LCD TV, the as well as rear glass is polished, cleansed, and finally coated using the silicon dioxide (SiO2). A second process involves the evaporation of a film of indium tin oxide on the glass. This is consequently etched into a preferred pattern. The next step involves the application of a film of chain polymer applied to enable liquid crystals to align appropriately.

The consequent process entails the application of a sealing resin. Consequently, the spacers get fixed into position and a glass sandwich is packed with a liquid crystal material. The foremost step is the preparation of glass substrates. In this stage, the glass substrates are cut into similar appropriate sizes, polished then cleansed. Polishing entails a procedure known as lapping. The substrates get coated with silicon dioxide following their washing. The next step is the development of an electron pattern (Sakka, 2005). The coating of both sides of the rear glass using a diminished indium oxide layer helps in the establishment of a clear electrode pattern. In this stage, manufacturers can develop a mask of any appropriate pattern. However, in this stage, there is an optional process that can be adopted.

A finer definition may be optionally attained through the application of an extremely thin film of photoresist material. This is done just on top of the indium oxide layer (Ruland & Stribeck, 2005). The next step involves the polymer application process. The polymer coating is important since it enables liquid crystals to appropriately align in accordance with the glass. In this stage, polyvinyl alcohol and polyamides might be applied. The other stage involves the application of the sealant. This is consequently followed by liquid film injection. The last step is the final assembly. After the unit is left to age, the final glass display is mounted on circuit boards with control as well as drive electronics (SONY, 2012).

Photos of the LCD TV

References

AGWEB, (2010). Material Handling Equipment. Web.

An, C. & Fromm, H. (2005). Supply chain management on demand: Strategies, technologies, applications. Berlin: Springer.

Bozarth, C. & Handfield, R. (2005). Introduction to operations and supply chain management. Upper Saddle River, NJ: Pearson Prentice Hall.

Cherunilam, F. (2004). International business: Text and cases. New Delhi: Prentice-Hall.

Cook, M. (2006). Write to TV: Out of Your Head and onto the Screen. Burlington: Elsevier.

Dbc Consulting, (nd.). Supply Chain. Web.

Dumke, D. (2011). Assessing Vulnerability of a Supply Chain. Web.

Frazelle, E. (2001). Supply chain strategy: The logistics of supply chain management. New York, NY: McGraw-Hill.

Frazelle, E. (2002). World-class warehousing and material handling. New York, NY: McGraw-Hill.

Fusion Management Consulting, FMC, (nd.). 3-Way Impact Chart. Web.

Li, L. (2007). Supply chain management: Concepts, techniques, and practices enhancing the value through collaboration. Hackensack, NJ: World Scientific.

Mahapatra, P. (2010). Operations management: A quantitative approach. New Delhi: PHI Learning.

McDowell, W. (2006). Broadcast television: A complete guide to the industry. New York: Lang.

Radhakrishnan, P. (2001). Proceedings of the 1st international conference on logistics and supply chain management. London: Allied Publishers.

Ruland, W., & Stribeck, N. (2005). Scattering methods and the properties of polymer materials: [contributions to the field of polymers and scattering, collected on the occasion of Wilhelm Ruland’s 80th anniversary in October 2005]. Berlin [u.a.: Springer.

Sakka, S. (2005). Applications of sol-gel technology. Boston [u.a.: Kluwer Acad. Publ.

Shapiro, J. (2007). Modeling the supply chain. Sydney: Thomson-Brooks/Cole.

SONY, (2012).Sony. Web.

Supply Chain Digest, SCD. (2009). Supply Chain News: The Supply Chain Year in Numbers and Graphs. Web.

Tinic, S. (2005). On location: Canada’s television industry in a global market. Toronto: University of Toronto Press.