Executive Summary

The waste assessment was conducted to identify the waste generating processes and how to minimize waste at Nowra Chemical Manufacturers. The assessment indicates that wastes are mainly generated during the production of various chemicals. Specifically, wastewater is produced in the process of cleaning the manufacturing facilities. The wastewater is collected in a single waste tank where the chemicals in it mix to form solid waste (sludge).

Thus, the main waste minimization opportunity is to eliminate the formation of sludge. This can be achieved by installing at least three different waste tanks to collect wastewater. Wastewater that contains a specific chemical will be collected in a particular tank to prevent sludge formation. This strategy will enable the company to reduce the cost of waste management significantly.

Description of the Facility

Nowra Chemical Manufacturers (NCM) is a medium sized producer of various chemical products in Australia. The company has employed 45 people who are specialized in various disciplines such as chemical engineering. The company produces “over 200 specialty chemicals, which include various detergents, cleaning products, and disinfectants” (NCM 2014). These products are manufactured in the company’s production facility that covers 5 acres of land.

The company’s production site is located in Nowra, New South Wales. The site has three sections, which include the administration block, the storage area, and the factory. The factory area has 24 reactor tanks that are used for various chemical processes (NCM 2014). It also has 38 mixing vessels that are used to blend various chemicals and raw materials. The capacities of the vessels vary from 200 to 20,000 liters. The factory has 20 tanks that are used for bulk storage of raw materials and finished products that are in liquid form.

Currently, the company’s waste management practices focus on reducing discharge of effluent into the ambient environment. In this regard, the company has built bund walls to prevent spillage of wastewater and chemicals. The company also recycles wastes and steam to reduce pollution. Moreover, it strives to reduce the wash down water that it uses to dispose wastes from 50KL to 30 KL per week. These practices cost the company $60,000 annually (NCM 2014).

Rationale for Waste Assessment

The reasons for conducting the waste assessment include the following. First, it will help the company to comply with the regulations in its industry. The government of Australia requires all manufacturers to submit annual reports on the amount of wastes that they discharge into the environment (Chauhan 2008, p. 57).

Manufacturers are also required to report on the actions that they have taken to reduce pollution. Second, the assessment will enable the company to achieve its desire to reduce wastes. The assessment has identified the areas that require improvement in terms of reduction in waste production. It has also recommended strategies for reducing the wastes. Third, implementation of the recommended waste reduction measures will enable the company to reduce its operating costs.

Methodology

Waste Assessment and Data Collection

Site visits were conducted in order to collect the data that was required for the assessment. The first visit focused on collection of firsthand information concerning the operations at the manufacturing site.

Specifically, the aim of the visit was to identify the sources of the wastes, the disposal routes, waste generation rates, and the composition of the wastes. Subsequent visits were conducted in order to review the company’s waste management system. The main objective of the subsequent visits was to identify opportunities for waste minimization and safe disposal of wastes.

The data used for the assessment was collected through the following strategies. First, interviews were conducted during the site visits to collect information concerning the waste generation processes. The interviewees included the company’s technical manager, production engineer, and the general manager. Second, observations were made during the site visits to identify the waste disposal routes and the composition of the wastes generated by the company.

Finally, data was collected by reviewing relevant documents such as the company’s environmental sustainability reports, financial statements, and strategic plans for waste management. These documents provided important information such as the amount of waste generated per year, the cost of disposing the wastes, and the strategies being used by the company to minimize waste.

Waste Generating Processes

The company’s wastes mainly consist of solid and liquid materials. Sludge is the main solid waste produced by the company. The liquid waste mainly consists of used water and toxic liquid chemicals. The liquid waste is often treated before being discharged into the ambient environment. This helps in reducing the environmental effects of various toxicants in the liquid wastes (Kumar 2007, p. 78).

NCM produces a large number of chemicals on a regular basis to meet the needs of its customers. As a result, it uses a wash down approach to clean vital facilities such as reactors and mixing vessels after every operation. This process generates large volumes of wastewater that is contaminated with various chemicals (NCM 2014).

The wastewater and toxic liquid chemicals are collected in a waste tank where they are treated before being discharged into the environment. However, mixing the liquid wastes in the tank leads to formation of large quantities of solid wastes in the form of sludge. Overall, the company produces 25 tons of solid waste (sludge) and 2,400 KL of wastewater annually (NCM 2014).

The disposal route begins at the waste tank where the liquid wastes are collected. The sludge produced in this tank is transferred to another tank where it is diluted and discharged into the company’s sewer. The sludge that remains in the tank is shoveled into filter bags to separate water from any solid wastes (NCM 2014). The sludge is then disposed in landfills that have been hired by the company.

The cost of disposing the wastes is very high due to the inefficiencies in the company’s waste management system (Australian Government 2008). In particular, the waste management system is labor intensive since most of the processes such as shoveling sludge is done manual. Additionally, the solid wastes have to be transported by trucks to landfills where they are disposed. Overall, the company spends approximately $60,000 annually to dispose its wastes.

Results from the Waste Assessment

Solid Wastes Analysis

Sludge formation in the company’s waste stream is mainly caused by 41 chemical products that are regularly produced (NCM 2014). The 41 chemicals are categorized into three groups namely, anions, nonions, and others (disinfectants, emulsions, and oils). These chemicals react differently when mixed in wastewater as shown in table 1.

Table 1

The production rate of each of the three categories of chemicals that produce sludge is summarized in table 2.

Table 2

Waste Management Costs

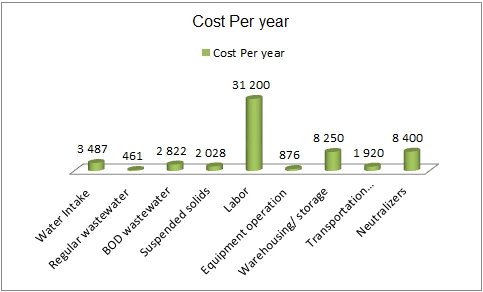

Table 3 presents a detailed analysis of the cost of managing the company’s solid and liquid wastes.

Figure 1: comparison of waste management cost items

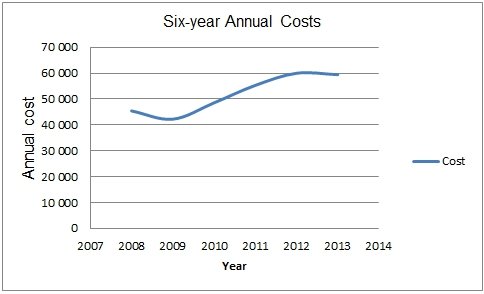

Figure 2: Six-year waste management costs

Analyses of Results

Waste Generation

Table 1 indicates that solid waste (sludge) is generated when wastewater that contains different categories of chemicals mix. In addition, sludge is produced when wastewater that contains disinfectants, emulsions, and oils mix.

Table 2 shows that anions form the largest share (40.94%) of the chemicals that cause sludge formation. Thus, much of the sludge formation can be attributed to wastewater that contains anions. The data presented in table 1 and 2 means that generation of solid waste can be reduced if the company avoids mixing wastewater that contains different chemicals.

Table 3 and figure 1 indicate that labor is the major cost item in the company’s waste management budget. This is attributed to the fact that the waste management system is labor intensive. Figure 2, shows that the waste management costs have been increasing in the last six years. Thus, the company has to minimize its wastes in order to reduce its operating costs.

Waste Minimization Opportunities

The alternatives that the company can adopt to minimize waste include reduction of wastewater and solid wastes. Reduction of wastewater is likely to reduce the costs associated with treating wastes and discharging them into the ambient environment (Anand 2010, p. 89).

However, achieving significant wastewater reduction will be difficult since future increase in production will lead to increased water intake. However, the company can achieve significant reduction in solid waste generation if it integrates clean production principles in its operations (Berkel 2000).

In particular, the formation of sludge can be eliminated if the wastewater is discharged according to the chemicals that it contains. This means that the wastewater that contains each chemical will be discharged in a separate tank, thereby eliminating the formation of sludge (solid waste).

Cost Benefit Analysis

The costs associated with implementing clean production principles in order to reduce solid wastes include the following. First, the company will incur the costs associated with modifying its waste disposal system in order to prevent wastewater with different chemicals from mixing. Second, the company will incur the costs associated with conducting chemical mixing trails in order to identify more chemicals that are likely to form sludge when mixed.

Finally, the company will have to train its employees on how to implement the new waste disposal system. In this case, the company will have to pay for the training if it is outsourced.

The benefits of implementing the new waste disposal system include the following. First, the volume of solid waste (sludge) will reduce considerably. As a result, the cost of disposing wastes will reduce significantly. Second, the company will not be required to change its production system by eliminating some products or using alternative raw materials (Australian Government 2008).

Thus, the company will improve its competitiveness by reducing its waste management costs without changing its product range. Third, reducing sludge formation will reduce labor costs significantly. Labor costs will reduce because disposal of sludge is labor intensive. Finally, the storage space that is currently being used to store large filter bags that are used in the solid waste disposal system will be available for storing other items.

Savings Analysis

The new waste management system will enable the company to realize cost reductions as shown in table 4. Cost reduction will be achieved in water intake, labor, warehousing, and transportation.

Table 4

Recommendations for Waste Minimization

Objectives

The aims of future waste minimization include the following. The first objective is to reduce the volume of solid waste (sludge) by 60% in the next two years. The second objective is to reduce the volume of wastewater from 2,400KL to 1,200 KL (50%) in the next two years. The final objective is to train all the five employees who are working in the technical department on the new waste management system.

The waste minimization strategy is to prevent sludge formation at the disposal point. In this regard, the waste disposal system will be modified by installing different waste tanks to collect wastewater that contains each of the major chemicals that produce sludge. The reduction in sludge formation will lead to reduction of wastewater since little water will be required to dilute solid wastes at the treatment plant (Berkel 2000).

Implementing the Recommendations

The first stage should focus on conducting chemical mixing trials to identify all the chemicals that are likely to form sludge when mixed. This will enable the company to determine the number of waste tanks that it should install to dispose wastewater that contains various types of chemicals.

The second stage should focus on training the employees on the new waste management system. The training should focus on improving environmental conservation awareness among the employees, cleaning procedures, installing waste disposal facilities, and effluent management.

In the last stage, the company should modify the effluent stream by installing at least three waste tanks to collect wastewater that contains each of the three types of chemicals that have already been identified as major causes of sludge formation. Each tank should have a unique color to prevent confusion during disposal of wastewater.

Timeframe for the Implementation

References

Anand, S 2010, Solid Waste Management, McGraw-Hill, New York.

Australian Government 2008, Cleaner Production Demonstration Project at Nowra Chemical Manufacturers,. Web.

Berkel, R 2000, Cleaner Production for Process Industries. Web.

Chauhan, B 2008, Environmental Studies, McGraw-Hill, New York.

Kumar, A 2007, Environmental Studies, John Wiley and Sons, New Delhi.

NCM 2014, About Us: Sustainability. Web.