Paradigm Shift

The shift had been made in accordance with the changed economic and political situation that required market expansion, and involvement into overseas investment activity. Therefore, the company had to change its business strategies for entering European market, and expand its financial activity by investing into European automobile industry. (Luthy and Ryan, 2007)

Techno Centric

The technological concern of the company became focused on safety of the passengers, and minimizing risks of the accidents. (Rooney, 2005) Additionally, the company is focused on creating environment friendly cars; that is why the manufacturing paradigm was changed for meeting these new requirements. VSC technology became the next step of technological advances, and this helped to increase the effectiveness of environment friendly technologies. (Savitz and Webber, 2006)

Stakeholder Concerns

These concerns are linked with the fact that Toyota is rather daring in implementing new technologies, and investing new markets. In general, the company shows a long-term stable growth, and stakeholders have little concerns. (Kotler, and Keller, 2006) However, stakeholders’ discussions are generally arranged for discussing the environmental initiatives of the company: global warming, and preserving biodiversity in particular. Therefore, these are the largest concerns of the stakeholders, and some of them claim for the necessity to develop technological basis of the company without paying so much attention to environment and ecology. (Olberding, 2008)

Functional Strategies

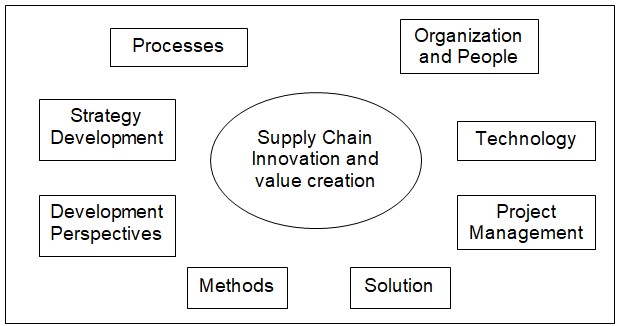

The functional strategies of Toyota company are focused on financial activity, marketing, HRM, supply chain, and information management. (Olberding 2008) In general, the involvement of these strategies into business performance is shown on figure below:

The general aspects of functional strategies are linked with the following aspects:

- Analysis of business environment

- Clear statement of vision and goals

- Business modeling (Rooney, 2005)

Public Concerns

These concerns are transformed into study of the target audience. In general, all the requirements, preferences and concerns are regarded by Toyota Company as a part of a customer care strategy. (Rooney, 2005) The main part of these concerns are linked with the environmental aspects of company’s activity, as public is interested in creating environment friendly cars, and in lowering prices. (Willard, 2002) Therefore, considering the fact that these concerns are mainly associated with effectiveness and productiveness, the company considers them in the work.

Sustainability Mapping Framework, Sweet Spot Analysis, and Triple Bottom Line Analysis

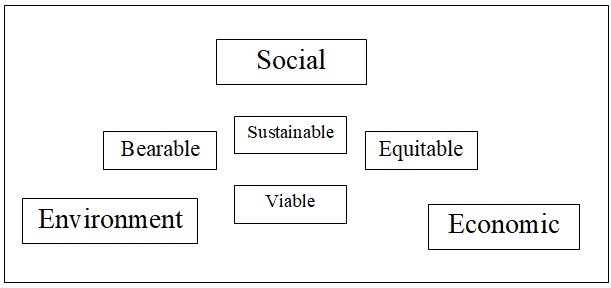

Sustainable development of the company is based on considering the environmental, social, and economic requirements towards the manufactured product. (Luthy and Ryan, 2007) In general, these requirements may be included into a sustainable development map adopted by the CEO, and applied for the general development strategy of the company.

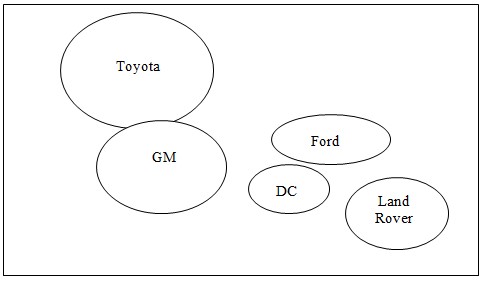

Sweet spot analysis is based on at least three business factors:

- Importance of the brand on the market

- Level of business performance of the company

- Position of the competitors on the market (Olberding, 2008)

This analysis is used as the basis for defining the progress of the company in achieving the stated goals.

Environmental, Economic, and social development in accordance with triple bottom line analysis is regarded as the key strategic priority of the company. (Willard, 2002) These three aspects of economic analysis are closely interacted, and form the basic direction for sustainable development. In fact, this approach stipulates high position of Toyota in Sweet Spot Analysis. (Savitz and Webber, 2006)

Reference List

Kotler, P., & Keller, K. L.,2006. Marketing Management. 11th ed. Prentice Hall.

Luthy, M. R., Ryan, M. H., 2007. Developing a Strategic Negotiation Plan: Toyota Highlander. Journal of the International Academy for Case Studies, 13(3), 53.

Olberding, S. R. 2008. Toyota on Competition and Quality Circles. The Journal for Quality and Participation, 21(2), 52.

Rooney, M. J. 2005. Toyota System Production Meets Large Scale Change: a Synergy for Sustainable Improvements. Organization Development Journal, 23(2), 21.

Savitz, A. Webber, K. 2006. The Triple Bottom line: How Today’s Best-run Companies are Achieving Economic, Social and Environmental success- And How You Can Too. Jossey-Bass.

Willard, B. 2002. The Sustainable Advantage: Seven Business Care Benefits of a Triple Bottom Line. New Society Publishers.