Introduction

Safety of health is the priority concern of the company in food and beverage business. The case study presents a scenario wherein Coca Cola failed to maintain the quality standards of its products. The paper aims to understand the quality standards of Coca Cola and its operations in its bottling plants. The issue related to the poisoning of schoolchildren due to bad quality drink must be handled seriously and taken as an example to maintain quality of the products. The paper will first discuss the quality measures maintained by the organizations and how these measures should be standardized throughout all its plants globally. The paper will also discuss the quality parameters of the product and its manufacturing process. In the end, the paper will provide recommendations regarding product creation and quality.

Product Quality

Maintaining product quality is a priority for beverage companies. In case of Coca Cola, there had been a breach of the safety norms that may have led to the disastrous outcome. However, beverage companies must ensure that carbonated bottled drinks are prepared such that they are safe for human consumption. In order to maintain this quality, they must follow certain procedures and meet certain standards that are carried out at various factories. In this section, we will discuss the various aspects of quality that has to be maintained by the company in order to produce quality product.

Water: Water is an essential element for production of soft drinks or bottled drinks. For beverage industry, the quality of water used for bottled drinks is of paramount importance. According to the stipulations of the Food Standard Agency, the “water used in the production of soft drinks must meet all the quality criteria of potable water as defined in the Water Supply (Water Quality) Regulations” (Beckett, 2009). But in many cases, it has been observed that even the water that meets the quality standard, it may cause problems due to higher concentration of certain constituents of the soft drink that may cause health hazards. Usually, most beverage manufacturers follow in-house standards. In case of Coca Cola, they give their water specifications to the vendors who manufacture the product at different geographic locations. The water is usually treated through a process of de-alkalization, which is an ion-exchange process, chlorination, and reverse osmosis. Reverse osmosis is a process that is more sustainable and leaves less carbon footprint and its operating cost is also low, therefore, has been adopted by most soft drink manufacturers. Further, this process provides a 99 percent removal of impurities from water as compared to other processes (Beckett, 2009). Therefore, this is a more reliable process of water purification to be used in firms. One of the problems in maintaining the water quality safety is the company’s diverse geographic locations and plants in diverse locations. Different places have different water quality and purification of these waters to meet the desired standard may differ. However, this being the most important process, the challenge of different water quality must be solved.

Raw Material: Different soft drinks have different ingredients, which may be faulty and may cause health hazard. Soft drinks usually contain water, sweeteners, and flavouring agents. The sweetener may be sugar, high fructose corn syrup or in case of diet drinks, sugar substitutes (Aurelia & Cristian, 2011). Soft drinks also contain certain percentage of caffeine, fruit juice, or both. Some soft drinks have a small amount of alcohol that is usually less than 0.5 percent of the total volume of the drink (Aurelia & Cristian, 2011). In another instance, in Paris a report presented by the National Institute of Consumption in 2012 presented a report showing content of alcohol in Coca Cola beverages (Coca-Cola, 2012). However, Coca-Cola Company provided enough data to show that there was only “0.0048 grams of alcohol per kilogram (0.00048 percent)” in each serving of the bottled drink, which did not refute any quality standard for quality. Another problem faced for ingredients is caramel colouring that is used in several of the beverage products of Coca-Cola (Coca-Cola, 2012). Some researchers, such as the Center for Science in the Public Interest poses that the caramel colouring used in Coca-Cola products poses cancer threat as it contains 4-methaylimidazole (4-MEI) (Coca-Cola, 2012). Though the company in its GRI report categorically states that it disagrees with the research and the outcome of the research, it has asked its manufacturers to maintain the secure standard presented by the external research agency.

Packaging Standards: For all beverage companies, one of the priority quality maintaining process is in its bottling process. Bottling is an essential part of the product creation of soft drinks. Coca-cola follows a BPA standard much higher than the set government standard. BPA or bisphenol A is used the lining of the aluminium cans in which the beverages are bottled. BPA is a chemical product that is used in lining almost all metal containers that are used to store food or beverages. The purpose of using this canning is to preserve the food product against contamination and helps in increasing the shelf life of the product. It is also used for “manufacture shatter-resistant bottles, medical devices, and sports safety equipment and compact disc covers” (Coca-Cola, 2012, p. 38). This is a commercially viable product and hence is used rampantly in most food and beverage packaging industry. However, BPA is supposed to have negative health effects as it has the quality to mimic the character of certain hormones that can activate estrogens receptors causing cancers. However, some studies have actually showed that BPA consumed in adult body is deoxidized and eliminated from body, therefore causing no health concern (Coca-Cola, 2012). Therefore, in most countries such as Australia, Canada, Europe, Germany, Japan, New Zealand and the United States pose that BPA levels used in food packaging is low and cause no health hazard to the human body (Coca-Cola, 2012).

From the above section, it is clear that the health and safety concern of the product is of paramount importance to the company. However, there are certain health hazard issues that cannot be overlooked, such as the presence of BPA in cans, cancer germ carrying caramel colour, and water contamination. Therefore, effective quality control process has to be established in order to avoid any circumstantial quality breach.

Recommendations

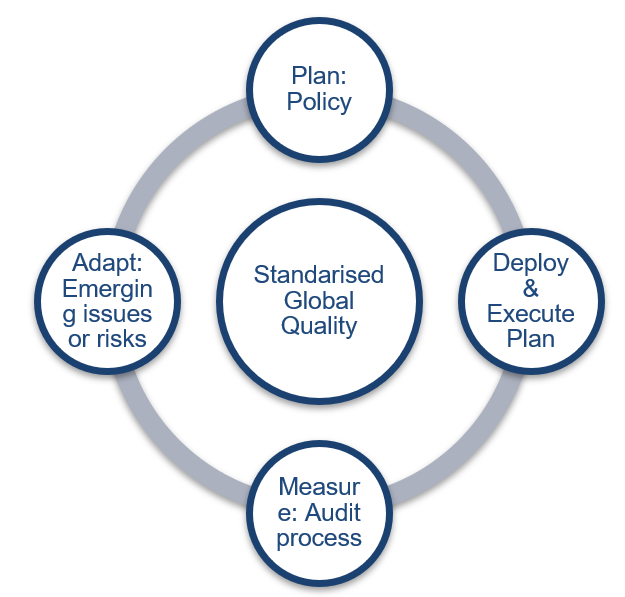

Maintaining the quality of the manufacturing process and the products for beverages is a challenge that must be adhered to in order to maintain high standard of brand, maintain international and local food standards, as well as gain customer trust on the brand. Therefore, for a beverage company like Coca-Cola it is important to follow a standardised quality practice as shown in figure 1. Four essential processes must be followed in order to maintain quality in its geographically dispersed plants. The first criteria is to establish policies regarding standards and specifications regarding ingredients, marketing equipment, and packaging process. Coca Cola must increase and diversify its product in order to cater to increasing and diversifying customer demands. Therefore, in order to meet the customer demand, highest standard must be followed in order to maintain consistent quality of its products. In order to do this, a companywide management system must be employed in order to integrate the strategic growth plan of the company and the quality management program of the company.

The second recommendation would be to deploy and execute would be adopt customer and quality oriented management system. This system would integrate both the sales and production quality end creating a seamless supply chain. One such system has been employed by Coca-Cola in 2010 i.e. Coca-Cola Operating Requirements (KORE). This process is self sufficient in maintain quality standards as and when new products are introduced or when the company enters a new market. This process has enabled the company to increase its packaging as well as quality index in 2010.

The third process to avoid such mishaps as faced in Belgium would be a continuous auditing process wherein future and emerging risks may be identified. Ensuring product compliance with all its vendors that supply raw materials or are jointly helping in production must be audited. Even the laboratory data results of raw material testing must be audited to indentify future risks. A group must be formed that would be responsible for crisis management for such incidents as well as identifying the reasons for such mishaps in order to provide guidelines to avoid such problems.

Conclusion

From the above analysis, the main learning that can be derived is to be diligent and adhere to the safety and quality norms. Make in-house regulations that surpass the standards of the local or international authorities, introduce auditing system to keep track of the production system. Create management system to indentify emerging risks and adhere to standards. And finally, to make a committee that would be responsible to mitigate risks related to product quality and handle crises.

References

Aurelia, O., & Cristian, O. (2011). Testing Of The Hygienic Quality Of The Carbonated. Retrieved from University of Oradea, Faculty of Environmental Protection. Web.

Beckett, I. (2009). Treatment technologies for soft-drinks production. Web.

Coca-Cola. (2012). Coca-Cola And Alcohol (Ethanol). Web.

Coca-Cola. (2012). GRI Report. Web.