It all started out 80 years ago in a carpenter’s workshop in Billund, Denmark. In 1932, as the global economy collapsed into depression, the Danish carpenter Ole Kirk Kristiansen started to supplement his income by selling wooden toys. He called his company “Lego”, from the phrase leg godt, which means “play well” in Danish.

Founded in 1932, the company was innovative thinking-focused and started its first innovation in 1946 by replacing wood with plastic and allowing locking connection blocks into different shapes which led to patenting the “stud-and-tube” self-locking system in 1958.

In 1970, the family business decided to hand off the management to the grandson of the founder who was able to bring to the company several innovations with a more sophisticated building system to attract the younger generation. This resulted in the great 15 years of growth of the company until 1990s when the competition level increased, slowing the growth trend along with the rise of digital play companies such as Nintendo & Sony. In addition, LEGO patent was nearly expiring and they company had to react fast to defend their position.

In the 2000s, LEGO was nearly bankrupt after several missteps until the company refocused its innovation efforts into revolutionary products that changed the nature of playing. It applied cost reduction measures to be able to defend against competition including layoffs, closing factories in Switzerland & US by moving to eastern Europe & Mexico and selling the majority of Lego land to increase liquidity.

Currently, LEGO has about 6% of global toy market share that makes it the world’s fourth largest toymaker. How was the company able to overcome its difficulties and attain such a level?

Hitting a brick wall!

LEGO started horizontally expanding into theme parks, TV programs, clothes, watches and learning labs and become over diversified, the rise in digital play experiences from companies such as Nintendo and Sony, the rise of Big Box Toys, expiration of LEGO’s brick patents, relocation of production of Mattel’s and Hasbro’s products to China, lowering the cost of their competitive toys, LEGO added more toys to its product line, but did not sell more items overall, thus inflating manufacturing and delivery costs while not increasing revenues and Manufacturing had a lack in quality and poor distribution logistics

In 2003, LEGO was out of cash and the company’s survival was in question. It made a DKr 1.6 billion ($240m) operating loss on sales of DKr 6.8 billion, having about DKr5 billion in debt.

What did LEGO do?

Simplify & Reinvent: LEGO reached a balance between growing through innovation, staying true to its core, and controlling operational complexity.

- Organized Structure: simplified management structure, more commercial culture, performance-based pay scheme and frank communication between management and employees

- Pivot: Through a 360-degree set of innovation projects, Lego reinvented itself and went back to focusing on its basic products and historical success factors.

- Open Innovation: Open Innovation, 120,000 people involved in external innovation work – DesignByMe, DreamtByMe, BuildByMe

- Efficiency: Reduced lead time from manufacturing to store (from 45 to 3 days) Implementation of a quality assurance system

- Closer to Customers: Gaining consumer insights without competing with distributors. Co-Branding with strong and selected partners e.g. Star Wars and Harry Potter

- Profitability: 80% of manufacturing moved to Flextronics/Focus on profitability and lean production with cost saving through offshoring non-core competencies

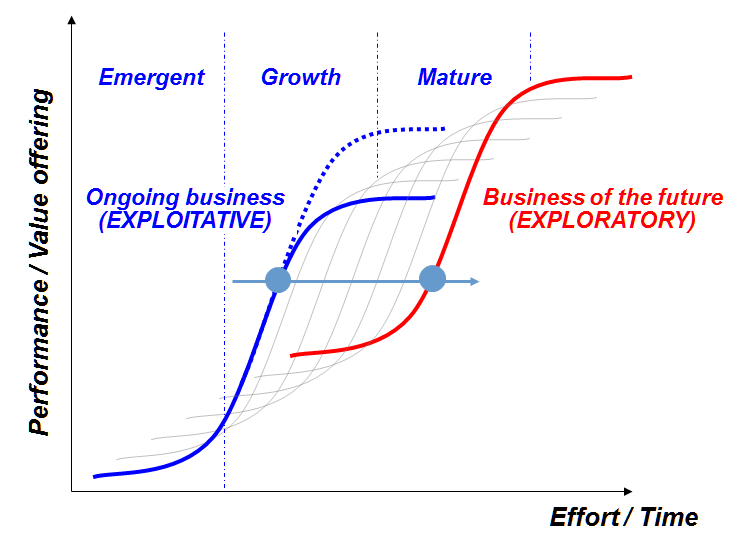

The company managed to simplify and reinvent itself, so it could shift the S-curve to a new location

Lessons Learnt

Lego diversified to the point of distraction before the 2004 management change. The new management focused on the brick Lego heritage and future in a modern and more digital marketplace, a vision described by the CEO in 2004. Lego drifted too far away from what made its customer fall in love with Lego. After heavy research, they found that the bricks are relevant. Rather than treating digitalization as a threat, they adopted it with the brick in its core to accelerate their business.

Lego’s main takeaway lessons are:

- By respecting what made them great, they understood where NOT to invest, and also the brick alone is no more sufficient. Lego needed to offer a digital experience that complements the core offerings rather than replacing them.

- Creating a culture that caters to the customer’s expectations and wants. Lego adopted a customer-centric approach to factored customers’ inputs and feedback before producing any new toy. Lego’s lesson is instead of fighting the competition, understand the customer and what they care about.

- Innovate around your core. Lego developed a family of complementary innovations that harmonized together.

- Profitability is key. Lego’s excessive diversification led Lego to lose, so the lesson learned is to keep track of the innovation R&D expenses in line with the revenue expectations, among other initiatives like consolidating the suppliers and retailers. It is evident by now that Innovation without direction and structure can put you out of business.