Introduction

Transport system is a very significant component in supply chain. Before the final product reaches the consumer, there are transportation costs involved. These costs involve the transportation of raw materials to the plant and then the ready products to the market. They affect an organization’s profitability directly thus companies have employed transportation as a strategy of gaining competitive advantage.

The more the transportation is demanded by the market, the more the costs involved. While some firms opt to establish storage points near the consumers, others have taken their production to the market by establishing production sites near the market. These decisions are influenced by the transportation costs as well as the profitability experienced in the long run.

Movement of products requires that a company maximizes the tools in use to ensure that minimal costs are experienced. In shipping, firms have now discovered the concept of coordinating inbound and outbound movement of ships to ensure that the return trip is also transportation of either goods or raw material.

Depending on the operation that a firm runs, transportation from a supply chain view can work to add value to the goods supplied hence more profits. In the modern market, customers want to obtain goods conveniently within the shortest duration possible. The less the time taken to obtain a given product, the more the value that they attach to the product (Coyle, 2011).

Organizations have used transportation as the link that binds a firm’s individual outlets and operations to function as one system. It addresses the issue of time and place utility of delivering goods to the right destination at the right time as required by the customers. It serves two main functions; movement and storage of products. Therefore, it should be utilized to ensure that a firm employs this strategy only when it adds value to the product.

It is not only a logistic function, but also an element for supply chain, which is employed to place a firm ahead of the competitors (Mentzer, 2001). This paper will analyze the transportation system for the Toyota Company; it will describe its current flows and the expected flows in future.

It will focus on its products and services, market and the supply chain strategies employed. From this analysis, a transportation improvement plan for the supply chain of this company will be developed. This plan will provide ways of minimizing costs while obtaining maximum profits and growth for the company. A reliable transportation plan is essential in supply chain; it adds value to products and services.

Background information

Toyota Motor Corporation is an auto mobile company that is engages in designing, manufacturing and selling of cars. It was founded by Kiichiro Toyoda in 1937 and has since grown to become a giant auto maker. It also incorporates this business with the financial services which mainly focus on the sale of its products including leasing of the cars and other equipment. This company is based in Japan but has established itself in many countries across the globe.

The first operation outside Japan was established in Brazil in 1959. Today, the company has expanded its research, design and development plants in Japan, North America and the European markets. It has been placed third in the automobile manufacturing industry.

Its products are well known in the Market making the company a market leader in the global market. It is through this company that the automobile industry has been placed at its best over the recent decades. Toyota established a production system in 1959 and the system concentrated on reducing inventories and defects in its plant and suppliers. This system worked remarkably well, and the company extended its operations in many locations across the globe.

A big percentage of Toyota’s production is exported to other countries all over the world. Orders are given a time frame of one month before the vehicles can be shipped due to the large distance between plants and dealers located outside Japan.

The company has established itself in twenty five countries and regions in the world selling its brands in more than 160 countries. The brands include the Lexus, Daihatsu, Hino and Toyota. It manufactures small cars; luxury vehicles like the Sedan pick ups, trucks and even crossover vehicles (Toyota Motor, 2009).

North America has grown to be the most significant market for Toyota outdoing its domestic markets in Japan. In 2002, it registered the most growth in profits and production. The company’s philosophy is to achieve continuous growth and development that benefits the society, the global environment and contribute to growth in the world’s economy. It aims at setting the pace for revolution in the auto mobile industry.

In terms of transportation costs, the company has adopted the Ex-work transportation system in which those purchasing can collect vehicles from the factories. This is applied in cases where companies have subsidiaries and factories in the countries that are importing. The company has subsidiaries and affiliate companies in overseas; it helps in saving transportation costs and is not affected by fluctuating exchange rates (Toyota Motor, 2009).

The supply chain management of this company involves a number of plants based in different regions. For North American production, vehicles produced in this plant are shipped to the North American dealers. This process involves a marshaling yard in which the vehicles are prepared before shipping. At this stage, all the finals in terms of accessories and the quality assurance checks finalized. The shipping process employs either trains or tracks.

When trains are used, they also require the use of tracks at the railhead that is near the dealership. Tracks deliver the vehicles directly to the dealers, and this process can take between two days to two weeks depending on the distance involved. It is at the dealership that prep is performed just before the vehicle is delivered to the customer.

Alternatively, vehicles are produced in Japan and then transported to North American ports by shipping them via large vessels. This also requires that they are further transported to the dealers through trucks. This process takes a similar duration of time as that of shipping within North America because this shipment is conveniently done to reach the port that is geographically nearest to the dealers (Iyer & Vasher, 2009).

In Europe, the distribution procedure is different because the dealers are located in the urban centers where there is no adequate room to stock a lot of vehicles. When the vehicles leave the plant, they are moved to the marshaling yard where they are staged before shipping them to the dealers. Once shipped, these vehicles are moved to a hub in which they are stored until the dealers sign contracts with customers.

The dealers collect them from a hub which may be shared by dealers from different countries depending on the size of the countries. Bigger countries may have several hubs. Shipping a vehicle from a hub to the dealer takes an average of one week. Therefore, in Europe, vehicles are stored in the hub and not by the dealers as in North America.

In japan, distribution is like that of Europe since the dealer outlets are also small. However, in Japan they have consolidation centers where dealers can sell the vehicles without necessarily having to ship them to their outlets (Iyer & Vasher, 2009).

Hubs and consolidation centers are the most common forms of storage because they allow the dealers to enter into contracts with the customers before the car is shipped. In other cases, the dealers can sell the vehicles from the consolidation centers and do not incur shipment costs. It is evident that the duration taken to ship vehicles to the dealers and that to customers are influenced by the procedure taken.

The physical distance is not the determinant but the processes involved. The procedures used in shipping also influence the shipment costs involved. This determines the profitability achieved in each of the regions and can be modified to ensure that the least possible costs are incurred (Iyer & Vasher, 2009).

Physical flow of Toyota’s Supply Chain

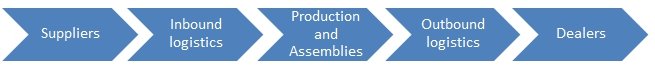

The physical flow of vehicles involves the outbound and inbound logistics. It is a step by step process in which the vehicle is prepared until it reaches the customer as one piece. The transport process begins from the assembly plant; the first stop is at the body shop then the paint shop after which assembling follows and finishes at the inspection. This is the inbound logistics which must be performed first before the vehicles can be released to the dealers.

The outbound logistics involve the transportation of vehicles to the dealers. This process is complex due to the bulky nature of vehicles. They are not only bulky but also involve assembling thousands of pieces which come from different suppliers. These combinations are also differentiated by the model that is being prepared. These processes make assembling and transportation complicated and requires a lot of concentration and care to ensure that the complete piece does not exhibit any faulty features (Iyer & Vasher, 2009).

Inbound logistics

This form of transportation is mostly concerned with the supply of raw materials in an organization. The inventory levels, the cost of warehousing and handling of materials are the main areas of focus in inbound logistics. Rail service is known to be the cheapest form of transportation; however, it also has an effect on the costs of inventory and warehousing. The three concepts work together and should be considered while establishing the bets form of transporting raw materials (Coyle, 2011).

At Toyota, suppliers also influence the transportation system of the company because their supplies must first be received before the production process can begin. The company receives these components via inbound logistics, which also originate from a network of other suppliers. The first suppliers receive from their suppliers who also have their supplier making a network of supplies. This makes the supply chain for this automobile industry extraordinarily complex.

Since this network, of suppliers is located at different geographical regions, the components supplied arrive at varying times; this variation may lead to a lot of time consumption and cause delays. The Toyota Motor Corporation has come up with operational and planning procedures that are dedicated towards simplifying this process to ensure that vehicles are distributed efficiently (Iyer & Vasher, 2009).

The operations and planning activities integrate both suppliers and the dealers forming a link through which the final product reaches the consumer. For the suppliers, the inbound logistics involve shipping the components from the suppliers to the assembly plants. For the ones coming from overseas in Japan, they are transported through vessels after which a rail car delivers them to the plant. On reaching the plant, the containers are off-loaded and then driven through trucks to the assembly docks.

This procedure makes the processes fast and efficient as compared to when the individual suppliers initiate the process. For the parts that are produced locally, trucks are used to ship them to the plants. However, the company employs the aid of logistics partners to simplify the process and enhance reliability. This is because the company has an inventory practice dabbed “Just in time” which promotes the quality of the delivery services offered to dealers and even the final consumers.

By outsourcing these logistics partners, the company takes full responsibility in ensuring that there is adequate coordination between plants and local suppliers. Suppliers are appointed to supply to a selected plant, and this is achieved by organizing the suppliers into clusters governed by geographical locations. Suppliers located in the same region are organized so that they all supply in a central place.

This is convenient because the trucks collect supplies from multiple suppliers and deliver them to a regional dock. It is also possible for these trucks to collect from different suppliers and deliver to several plants. This saves time and speeds up the production procedures (Iyer & Vasher, 2009).

Dealing with a variety of suppliers and plants can be exceedingly complex and the company has come up with strict schedules for the trucks. The suppliers organize their delivery programs to fit in these schedules. This ensures that the trucks take extremely minimal time at each supplier’s stop.

The unloading procedure is determined by the progress of production in a given plant. The trucks wait at the yard and are admitted according to the planned schedule to ensure that there is order of receiving goods. If this schedule is followed, then components are received as expected by the plant and therefore order is established. The production process becomes continuous consequently improves efficiency in production and delivery of orders as given by the dealers.

To improve efficiency, the corresponding empty containers are reloaded in the truck, and a reverse procedure is initiated. With such arrangements, the trucks serve to transport the supplies while at the same time collecting the empties. This is a continuous cycle which simplifies the transportation process. It saves both time and cost (Iyer & Vasher, 2009).

The production process

When different parts from different suppliers are converged in one central plant, the production process begins. At Toyota Motor Corporation, separate lines are established so that the plant is subdivided into smaller outlets referred to as shops. The vehicle’s birth process begins with the body shop in which the frame is formed. Parts are assembled and wielded together and the piece is ready for panting in the paint shop.

This shop specializes on the exterior of the vehicle and prepares it for the next step which is the final assembly. In this stage, parts provided by suppliers are installed to come up with a finished product. Bar code labels are fixed, and the vehicle is fuelled and driven to the assembly line where it undergoes quality checks. After this inspection, the vehicle is ready for shipment to the dealers (Iyer, Seshadri & Vasher, 2009).

Outbound Logistics

Outbound logistics involves the transportation of finished goods from the factories to the market. Since it deals with the final product which is normally higher in value, it is relatively more expensive than the transportation of raw materials. Focus should be put on the issue of physical distribution management to ensure that the mode of transportation and warehousing chosen maintains the quality of products at a low cost.

This process is initiated by the information shared between the dealers and the corporate division. The orders and deliveries are organized to ensure that timing is correct and that the process is one way to minimize on costs (Coyle, 2011). At Toyota, this process involves moving the finished vehicle from the factory to the dealer. The vehicles are first staged in large yards before shipment. Depending on the mode of transport to be used, the vehicle is either placed at a rail car or truck staging area.

This is also divided into sections determined by the destination that the vehicle is headed. Trucks and rail cars are assigned these vehicles depending on the route plan scheduled for each. The company provides the truck and rail companies with a forecast daily to ensure that they their capacity to ship the vehicles is adequate (Iyer & Vasher, 2009). This helps the company in avoiding cases of delays because the stations prepare for the expected shipments a day before.

The shipment process involves trucks and rail cars depending on the distance involved. For instance, in the United States both modes of shipping are employed, three quarters of the of the vehicles are transported via rail cars and are only loaded on trucks from the rail stations to the dealers. For the dealers who are located near the plants, then trucks are used. This forms a quarter of all the vehicles shipped.

Sometimes the company is forced to use ships in cases where waterways have to be crossed. The whole transportation process is progressive. The components increase with each level of transportation. The same case applies to Toyota which has limited plants supplying to dealers who provide to a big population of customers. The production plants are much less as compared to the number of dealers and the final consumers involved.

This means that the more the company grows, the more the sophistication that is involved in transportation. Despite this sophistication, the company has been ranked among the fastest in the product development. While the competitors may take two to three years in designing new trucks and cars, the company takes one year or than one year (Liker, 2004).

Dealers’ role in Toyota Motor Corporation’s Supply Chain

Dealers are highly significant in the company’s supply chain because they represent the company to the customers. They not only sell the vehicles directly to the customers but also influence the choice and satisfaction of these customers. Two factors are involved in satisfying the customer; the quality of the vehicle and the selling process. The interaction between the buyer and the seller adds value to products and care must be taken to ensure that the experience is advantageous.

If the quality of the vehicle is not supported by a wonderful buying experience, then the value attached by the customer to the vehicle may be under rated. Quality goes hand in hand with the way a product is presented to the customer. The Lexus vehicles are known to receive positive feedback from consumers because the assembling not only detailed, but the dealers also pamper the customers while selling this vehicle to them.

It is recommended that dealers should give more attention to the quality of their facilities to ensure that they are efficient. They should not just meet the customer’s expectations, but they should exceed them. Vehicles are sensitive when it comes to clearing old stocks.

The motor world is very dynamic and new models spring up at very frequent intervals. Dealers should ensure that they stock a wide variety that persuades customers to buy. If variety is less, there is a likelihood that the vehicles may become aged and gain less interest from the customers (Iyer & Vasher, 2009).

The Toyota motor corporation has provided guidelines for the dealers to promote and advertise the popular models. Displaying them and placing them in areas where customers can see is also encouraged for the purposes of attracting more customers. Once the dealer enters into a sales transaction with the customer, this is sent to the manufacturer, and the dealer is credited for the sale. This is also used to indicate the warranty date (Iyer & Vasher, 2009).

Through this, company has achieved astounding reputation that is associated with the quality of its vehicles. The secret to this is the consistency that the company has shown in its operations. The revolution of “Lean Manufacturing” focused on adding value to the vehicle in every step without faulting. The step by step processes is influenced by demand and strives to improve by every party in the organization (Liker, 2004).

The supply chain management for the Toyota Motor Corporation is a continuous process that transforms parts to final products.

Future freight Flows

Corporations and consumers have gained significantly from the advances achieved in supply chain management. These economic gains are attributed to reliable transportation systems used to move goods to the demand area. Timely and efficient transportation of raw materials, supplies and the finished goods results to great economic gains. Alternatively, disruptions may be very costly to an organization which may lead to erosion of the anticipated economic gains (Coyle, 2011).

Supply chain flows are manifested in all the processes, in the system. It affects the planning process and these two concepts are integrated together to enhance efficiency. Uniformity in procedures is encouraged to ensure that variations in individual processes are experienced. Making procedures standard enables activities to run smoothly. Moreover, cost is reduced, and the quality improved because chances of delays are minimized.

Variability in the way dealers order and get deliveries can be controlled by establishing a standard procedure which should be followed by all the dealers. It should be established in both systems so that they work as one unit. The operations may be different, but these three entities should modify their processes to fit in each other’s schedule. This is because they all work towards achieving a common goal. This will involve the suppliers, the company and the dealers.

Visibility of process and procedures should be established using the right metrics. Plans should only be changed once a consensus has been reached to ensure that management. This unity promotes the development because once projects are initiated positive results can be achieved (Coyle, 2011).

At Toyota, visibility of operations and processes is based on performance. 50% weight is directed towards the results while the other 50% is obtained from compliance to processes. Through this performance, metric, short term success is rewarded while ensuring that processes are followed correctly. The company has successfully managed to give immediate response to issues that arise, makes changes deliberately and maintains velocity.

This can be further improved by synchronizing variety to demand while enabling continuous learning and feedback. When process execution is influenced by the market, an organization rhymes with the market realities and excels in terms of performance and growth.

This kind of stocking is strategic because the dealers are able to provide each brand is a small quantity. This ensures that dealers are not stuck with large quantities of unmoving goods (Iyer & Vasher, 2009). In the future, the company can enhance the quantity utility by introducing more hubs in every region. This will ensure that a lesser time is taken in transporting vehicles because this will involve shorter distances.

Planning logistics requires a software program that is employed to determine the most convenient and efficient routes to be used in transportation. This software requires inputs such as locations of suppliers and dealers, the quantities of parts required, timings for pick up, the distances from the docks. This will help in establishing how this process can be carried using the minimum number or trucks and rail cars at the shortest duration.

In the future, growth in technology is likely to provide much sophisticated software. This will ensure that the focus given and the actual results experience minimum or no variations at all. This will simplify the planning process because the expected costs will be close to the estimations given while planning.

The delivery times given will obtain an assurance thus lesser time will be used in every station. The trucks will be put in an optimum use resulting to less operational costs and increased profits (Iyer & Vasher, 2009). This establishes a link between the planning process and the physical flow. These two processes depend on each other for an organization to succeed in its business development activities. Initially, the company’s response to problems resulted in the addition of waste rather than its elimination (Liker, 2004).

Factors to consider in improving Toyota’s transportation plan

Waste in the production processes is an area that drags down the performance rate in any organization. This occurs in cases where time is taken to fix a machine that has broken down. The time taken to fix this machine does not amount to sales but rather more costs on the resources and materials used.

It is better for the company to idle out a machine that is not producing parts than working on it with frequent fixing. If the time taken to fix a machine is more than possibly appropriate, then attention should be focused on maximizing on the machines that produce parts to obtain more. In the case of the transportation system, details should be given on the efficiency of the trucks in use. Real time monitoring is essential to ensure accuracy in the reports and orders given.

This is important because every order requires coordination from the retail center to the distribution center then to the corporate headquarters who finally liaise with the production factories. This requires supply chain management should allow an organization to carry out a multiple of these procedures fast and efficiently. When the information transmission factor is considered, then initiating the logistics of moving the vehicle is simplified and the trucks or rail cars can be scheduled successfully (Liker, 2004).

Transportation is used to gain a competitive advantage by adding value to their products. In terms of place utility, moving goods from the factory to the consumers gives value to products. For Toyota, this has been achieved at a great length through the establishment of plants in the major regions.

Taking the plants to the demand site is a good strategy because it reduces the importation costs that consumers are likely to experience. The fluctuations in exchange rates are also avoided by this strategy. When dealers and consumers access the vehicles locally, they are delighted, and this greatly influences their choice. Consumers would rather go for the brand that is easily available at a lower cost (Wang, Heng & Chau, 2007).

Another utility gained through transportation is the time utility. Customers not only require the products at the place they want them, but also when they want them. If the transport system is efficient, then consumers should get the products faster than they anticipated.

Toyota Company has simplified this by ensuring that dealers stock a wide variety of in terms of brands. The dealers have a variety of vehicles in small quantities. This persuades the consumers to choose from the wide variety thus increasing sales. In the future, the company is expected to promote this trend further by introducing more brands that will leave consumers spoilt for choice.

This is supported by the dynamism that the company has shown through the introduction of superior models that leave the customers guessing. Such innovation makes the Toyota vehicles superior and increases demand, transportation sums it all by ensuring that the vehicles are available on demand by the customers (Liker, 2004).

Quantity is also another utility that is provided through transportation. When a given brand experiences a high demand, then it is important that this product is transported in the right quantities (Coyle, 2011). For Toyota, this is achieved by ensuring that materials. In the future this can be enhanced by the introduction of more plants to serve every region.

Toyota models are designed in such a way that the bigger percentage can be sold from a low level of stock. The dealer’s stock 20% of complete vehicles, which represent 80% of the totals that are realized in a given market area (Iyer & Vasher, 2009).

The time taken on transit affects the level of inventory for both the shipper and the dealer receiving the vehicles. If a longer time is taken on transit, then it is likely that the level of inventory will be high. Once the inventory level rises, the costs increase. This affects the overall supply chain and may lead to slow growth and low volume of sales.

In the future, this problem can be solved by establishing ensuring that the timings given are accurate. This is achieved by planning with objectives that match the results obtained. Studying past events and basing this information to establish the likely loopholes in the future is a strategy of saving time on transit.

Technology will also enhance the process of planning routes and come up with simplified processes that save time. Maintaining a close link between the planning processes and the physical flow will ensure that activities are carried out as planned. Accessibility is also another area of concern which is considered when establishing the routes to be followed (Coyle 2011).

Some regions may have water ways that require the use of ships while others use rail cars. Dealers who are geographically close to the manufactures may use trucks only. It is clear that the longer the distance the high costs. It is therefore, important that the company ensures that the plants are constructed at a central region which can serve a multiple of dealers with convenience and efficiency. In the future, this can be solved by taking more plants to the demand area.

This will reduce the level of inventory for both the dealer and the manufacturer. It will also have a positive impact on the level of satisfaction shown by customers. Satisfying the customer is the key area that organizations focus on so as to experience growth and profitability.

Accessibility also puts Toyota ahead of competitors because the market has become very flexible and customers want to access products with a lot of convenience. This is enhanced by taking the least time at the least cost possible to meet the customer’s needs (Iyer & Vasher, 2009).

Once the transit times are accurately allocated, the next step is to master consistency. Pick-up and delivery should go in line with the schedules laid out. At Toyota, this issue has been effectively addressed; failing in this is very costly because the invention of newer models shifts the customers’ attention and may end up registering low levels of satisfaction.

Stock outs conditions can affect demand negatively reliability is essential in maintaining demand for products. A customer can easily leave one dealer to go for the one who offers a faster delivery of goods. These impacts on the transportation demand towards a particular carrier and may lead to lost business (Iyer & Vasher, 2009).

Recommendations

For the transportation aspect of any company to run efficiently with minimum costs, it has to work closely with supply chain. Change initiatives should start from easily attainable changes to the most sophisticated ones. The initiatives should be visible to the key stakeholders and easy to implement. Such initiatives are easy to measure in terms of success and can be a basis for initiating bigger projects.

When these change initiatives involve lower costs or neutral costs, then they are sustainable in case they are not successful. For Toyota, a good change initiative could be directed towards loading. Currently the biggest mode of transportation is the three level trucks which if loaded efficiently can transport more vehicles. So loading can be maximized to ensure that one trip delivers more than anticipated, and this will help min reducing costs.

Minimizing the number of stops en route is also another initiative whose returns can be measured in a short period. When this short term success is measured and considered efficient, and then a long term change can be include in the planning process (Hillestad, Ben & Keenan, 2009).

Shipping products directly to the consumer can be very cost effective especially if the final consumer obtains goods in large quantities. It is important for a company to identify its largest customers who order goods frequently in large quantities. Those customers can be given a special treatment in which they can have their goods directly shipped to them.

Toyota has identified the regions that register the biggest volumes of sales and taken their plants to those regions. However, the customers are still served via the dealers. It would be appropriate if those customers ordered through the agents but have their vehicles shipped directly from the plants.

This will save them time and earn them recognition. It is likely that their level of satisfaction will be high, and this is a positive sign that the company will be preferred over the competitors. Direct shipping also reduces the activities that revolve around the hubs, and also the truck loads for the products directed to the dealers. It simplifies the tasks involved thereby saves time and costs (Hillestad, Ben & Keenan, 2009).

Routing is an essential element in transportation which calls for continuous changes. This is because there are new developments in infrastructure which reduce the distances involved in the movement. If these changes occur, it is important that an organization restructures it routes to ensure that it saves more on transportation.

Toyota is a global organization with several plants across the globe. It is important that it studies the economic developments in these locations for them to take advantage of these developments. The main area of focus is the infrastructure which may provide alternatives in terms of routing. If this is done continuously, then the company is likely to improve its service efficiency and stay ahead of the competitors.

This can be improved further by instilling supply chain practices among the employees and partners involved. If this is initiated by all the participants, they can work together to come up with practices that lead to reduced use of fuel and small inventory levels. Toyota can effectively work with the dealers and suppliers to ensure that all requests on orders and supplies are placed once. It can be imposed by charging premiums on extra deliveries that ought to be part of the main order.

This will the dealers and suppliers adhere to the schedules in use. This helps to avoid unnecessary trips and promotes fast response to the consumer needs. When routing is integrated with software, loaded miles are maximized and empty miles avoided (Hillestad, Ben & Keenan, 2009).

Product packaging is also another area in which significant savings can be achieved. For Toyota, this is most applicable in the transportation of parts from warehouses to the production plants. If trucks are maximized to carry as much material as possible, then there is likely to be a significant reduction in the number of trips and fuel used.

The packaging management should work with knowledgeable expertise to help them in assessing, evaluating and planning cost reduction changes. In inbound logistics, parts are exposed to a lot of movements in the various stages of production. Toyota has the green policy in which all the containers have to be reused to ensure that nothing is thrown as waste. To optimize space in the transportation containers, parts need to be arranged carefully, it is important that parts that can be interlocked are transported together.

Containers used in transporting parts should be designed in such a way that they can be stacked together. Stacking ensures that more parts are moved and the risk of damage due to the frequent movement is minimized. For the parts that are frequently used, they can be included with less frequent lots so that their transportation is maximized.

When the frequent items are moved often, then the probability incurring extra costs in transporting the small lots is low. Packaging should be done such that it guarantees quality. No parts should be damaged due to the movement involved in shipping (Liker, 2004).

Maintenance and operations may involve simple activities, which result to unnecessary costs in the long run. For Toyota, this can be done by ensuring that equipment has alternative power units which consequently save fuel by reduction of idling costs. For trucks and trailers, maintaining proper tire inflations can also produce a lot of savings in the long run.

Customers prefer to obtain their goods from the nearest location possible. Introducing many distribution centers can be a competitive advantage for the company. Transportation costs through truck loads will also be minimized, and the inventory levels kept at their lowest.

When simple operational activities are monitored on the trucks and rail cars, then it is likely that the costs will be low. Using the right mode of transport as dictated by the distance to be covered helps in lengthening the life of trucks and rail cars. The long term costs of transportation are reduced while the profitability of the organization grows (Liker, 2004).

The adaptive capacity of a transportation system is very crucial in the profitability of an organization. For instance, if a truck catches fire and blocks the rest of the company operations, there should be mechanisms put in place to counter act any adverse effects. Toyota has several routes put in place and has alternative means of operation. This is a good strategy which can be improved by sharing information with the rest of the parties involved.

This promotes the systems to work as one unit and become more efficient. Vulnerability can also be worked on to ensure that the probability of such incidences is low. Contingency plans should be put in place to ensure that any unexpected disruption in the transportation of goods or raw materials is fixed in good time. This ensures that the successes expected in the organization’s performance are both short term and long term.

This planning makes an organization resilient and it is less prone to break down resulting from external factors such as infrastructure. Toyota has come up with a variety of transportation modes that cater for the organization’s transport needs. If this is supported by a strong adaptive capacity, then the organization will obtain positive feed back from it consumers (Mentzer, 2001).

When a company meets its normal demand, then it is regarded as adequate in the provision of goods and services. However, when a company has the capacity to meet demand at its peak adequately, there is bound to be excess capacity in its operations. This results in underutilized and in efficiency of operations. Before such policies can be put in place, then the organization must consider the economic effects on transportation.

If peak demand can be met adequately with sustainable costs, then an organization can maintain the provisions. Alternatively, if this arrangement leads to unmanageable costs, then it should operate in the capacity that meets normal demand only. Extra resources can be outsourced during peak demand if this lowers the cost of operation. For Toyota, the transportation system is a cycle that allows trucks to deliver as they collect from the various destinations.

They have a continuous cycle which is sustainable whether demand is at its peak or not. The efficiency of this system can be analyzed to establish its sustainability. This will determine whether the transportation system can serve both normal and peak demand at a sustainable cost (Coyle 2011).

Distribution of vehicles from the production plants to the dealers is varied in Toyota. The model used in the United States is different from that used in Europe or in Japan. These can be termed as using separate parts to come up with a similar result. For a multinational company, having different modes can be a great challenge in the planning process. The company is driven by the central core values with an allowance for customization by the various divisions.

This is a good strategy which allows individual regions to maximize their performance as favored by the geographical location. The transportation system is different due to the differences in the distance and infrastructure. However, coming up with common global practices especially in transportation can form a strong system in which the various components can interact. A common system results to sharing of information and experiences and this can be useful in improving the company’s performance (Iyer & Vasher, 2009).

Conclusion

An organization can add value to its products and services by adopting a good transportation plan. Toyota Motor Corporation has focused on “flow” and this has contributed to its global success. It has changed from the traditional practices in which companies concentrated on maintaining high inventory turns and minimizing lead times. Today, what matters is being flexible and putting customer’s needs first. It is demand that drives the market.

Companies should be fast and flexible to provide customers with what they want at the time they want it while giving the best quality at an affordable price. Efficiency is no longer measured by the individual processes but the degree at which customer needs are met and exceeded. Planning logistics and transportation is very crucial in supply chain. The effects are long term and determine whether an organization achieves profitability.

If the issue of transportation is addressed and the time taken to respond to customer needs shortened, then business grows and an improvement is registered in the overall performance. Globalization has exposed this company to a long supply chain involving different nations. This consequently leads to the need for multiple transportation methods which need continuous upgrading to meet the consumer needs.

Therefore, despite sourcing for third parties who provide for logistics, it needs to work with them to ensure that there is a good flow of information and products. Therefore, the issue of transportation requires the cooperation of logistics providers and the company in responding to market needs.

References

Coyle, J. J. (2011). Transportation: A supply chain perspective. Australia: South-Western Cengage Learning.

Iyer, A. V., Seshadri, S., & Vasher, R. (2009). Toyota supply chain management: A strategic approach to the principles of Toyota’s renowned system. New York: McGraw-Hill.

Liker, J. K. (2004). The Toyota way: 14 management principles from the world’s greatest manufacturer. New York: McGraw-Hill

Mentzer, J. T. (2001). Supply chain management. Thousand Oaks, Calif. [u.a.: Sage Publ.

Toyota Motor. (2009). A History and Development of the Company. Web.

Wang, W. Y. C., Heng, M. S. H., & Chau, P. Y. K. (2007). Supply chain management: Issues in the new era of collaboration and competition. Hershey, PA: Idea Group Pub., (an imprint of Idea Group.