Executive summary

Western Groceries is one of the dominant supplies in Western Australia. They have been in operations since 1920’s. Over the years, they have diversified and grown from a small to a large Grocery with branches all over the region. Their representatives requested for a survey on their premises as well as advice on availability of ACM within their old structure that was built in 1960’s.

Moreover, the company needed details on the condition and risks associated with ACM to health of its employees as well as customers. The company also requested for assessment of ACM’s potential contamination on company products and stock. Other requirements also included information on the steps that could be taken to address the situation’s industrial aspects.

Furthermore, The Company sought to know how the public would react to such findings. In addition, it required an assessment of potential risks that could be involved in future workers and commercial compensation claims.

This report therefore focuses on these areas with emphasis on legislative responsibilities of the company, products hat would be present in the building of survey, their location and methods of conducting a survey to evidence their presence.

The paper also works to assess the possible risks associated with these products as well as their prevailing conditions. Finally, the report outlines a presentation that contains commercial and insurance risks associated with talking a removal or managerial option (AIOH, 2006, p. 1).

Introduction

In the mid 20th century, many buildings in Australia utilized Asbestos-containing materials (ACM). In fact, their use went on as late as 2003. This has led to prevalence of Asbestos in most of Australian buildings. This has encompassed structures, equipment, plants, trains, motor vehicles and ships, among others. Moreover, its utilization in gaskets and friction material went on until the early 21st century.

It is therefore necessary to note that ACM were predominant in the 1950’s, 1960’s and 1970’s. Consequently, buildings made during these periods are believed to contain samples of asbestos.

In this regards, Western Groceries Ltd. requested for survey on their premises as well as advice on availability of ACM within their old structure that was built in 1960’s. Moreover, the company needed details on the condition and risks associated with ACM to the health of its employees as well as customers (AIOH 2011, p. 2).

The company also requested for assessment of ACM’s potential contamination on company products and stock. Other requirements also included information on the steps that could be taken to address the situation’s industrial aspects. Furthermore, The Company sought to know how the public would react to such findings.

In addition, it required an assessment of potential risks that could be involved in future workers and commercial compensation claims. This report therefore focuses on these areas with emphasis on legislative responsibilities of the company, products that would be present in the building of survey, their location and methods of conducting a survey to evidence their presence.

The paper also works to assess the possible risks associated with these products as well as their prevailing conditions. Finally, the report outlines a presentation that contains commercial and insurance risks associated with talking a removal or managerial option (Baker, Rogers and Conaty, 2001, p. 15).

Process description

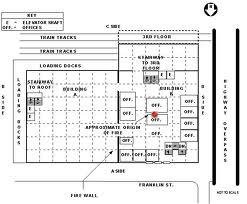

The building was built in 1960’s and has since been used as a storage facility. The grocery supplies its products throughout Western Australia with a huge advantage on the market. It was therefore very instrumental that they conduct this survey in order to ensure that their future survival is sustained. The building surveyed is known as the Storage building and lies to the south of the premises.

Western groceries storage facility is approximately 80,500 square foot. According to its representatives, it was built in 1960’s in two intervals, the first being in 1962 of about 60,500 square foot. In addition, due to demand for more products as well as storage area, another extension was made to it of approximately 20000 square foot (SAI, 2004, 5).

The building contained a basement that was laid with asbestos containing tiles. Moreover, its drainage system was cemented with asbestos containing materials. It is also important to note that its roofing was made using asbestos containing materials. In essence, the building contained numerous forms of asbestos during its development. The building contains goods that are packed in boxes and shelves.

The shelves were included to help conserve humidity of the products. These shelves were made of plastic and wood. The survey was therefore conducted in areas within the building and its surrounding. These included the washrooms, roofing, floor tiles, backup generator section and any other equipment contained in the building (MDHS, 2001, p. 7).

The grocery store was usually busy during the day due to the high rate of supply and delivery. Moreover, its inventory systems was managed electronically to promote time management. Most of electronic equipment was based in the store with a connection to the sales department.it therefore requires movement of equipment to the Sales store before conducting the survey.

In addition, the number of personnel that moved in and out of the area of survey was large. The company therefore decided to stock most of its food products in the self-service store to give way for survey in the store.

Moreover, the few personnel that were allowed to come into the store were equipped with protective clothing to avoid contact with ACM. These include overalls, facemasks to avoid inhaling gases from ACM (SWA, 2012, p. 2).

The store was in perfect condition due to the nature of good stored in it with other equipment such as fridge and blender, among others carefully carried to areas that had been renovated (MDHS, 2001, p. 7).

Methods and measurements

The survey was done in three main ways. These included limited sampling, visual inspection and analysis of materials. Samples that were suspected to contain asbestos were immediately sent to NATA accredited laboratories for analysis. This was done at J&S Consulting center using a polarized light microscope as well as the stereomicroscope.

These were conducting using the dispersion staining technique in order to identify the asbestos contained. Moreover, in order to establish confidence in availability of asbestos in the samples taken, some samples (that displayed uneven distribution) which contained fine fibres were analysis using X-ray diffraction. After this, results were recorder for further analysis (NOHSC 2005a, p. 3).

Results and discussion

After collection of samples and analysis as well as visual observation, results were used for risk assessment.

Risk Assessment

Risk assessment is done for purposes of promoting utilization of informed decision in dealing with Asbestos. It therefore works to promote control measures as designed from the survey as well as training and induction on its mitigation. It is also necessary for creating awareness on health surveillance and air monitoring which are core elements of controlling inflections through ACM.

Risk assessment method utilized for this survey considered the following aspects: Type of ACM (friability), and Location (Location of ACM within the store). Others include Extent (checks on the quantity or extent of exposure expected and whether it can cause health risks), Condition (deals with the nature of ACM material, whether damaged or intact as well as the extent of damage in case of the former).

Moreover, the other is potential for disturbance (tis lies on the usability of the store as this increases frequency of disturbance). Finally, in order to come up with a viable assessment of risk, then professional judgment is utilized with the help of risk matrices.

This brings on board the relative risk expected on human exposure to ACM. In this regard, the relative risk can be referred to as low, moderate or high, among others. It is also important to note that relative risk is mainly given to help in prioritizing ACM management.

This is utilized in line with the recommendations arrived at in this report. In this regard, it is significant to note that a rating that shows high risk may note certainly mean immediate threat to health (WADOH, 2009, p. 12). The assessment parameters utilized are:

Control measures

These are usually designated for any occurrence of Asbestos as contained in the register (See table below). This has been done in accordance with the assessment provided for ACM. However, they are not limited to Type of ACM (friability), and Location (Location of ACM within the store).

Asbestos Register

Others include Extent (checks on the quantity or extent of exposure expected and whether it can cause health risks), Condition (deals with the nature of ACM material, whether damaged or intact as well as the extent of damage in case of the former).

Moreover, the other is potential for disturbance (this depends on the usability of the store as this increases frequency of disturbance). In essence, all these factors are factored in risk assessment in order to come up with the best possible and practicable control measure (MDHS, 2001, p. 7).

Risk matrices are also essential in enabling Western groceries to manage ACM through adopting an appropriate control measure whenever required. This has been categorized into two groups as shown in the tables below.

The first contains matrix information regarding ACM, which is not sealed or is in poor condition (Matrix 1). On the other hand, the second table contains matrix information regarding ACM, which is partially/fully sealed or is in good condition (Matrix 2).

Conclusions and recommendations

Conclusion

The survey was conducted successfully with the view to providing adequate recommendation for appropriate management of ACM. From the survey, it was fond that management of ACM was appropriate since the ACM analysed were not highly damage. Moreover, exposure was limited and that accounts for the low level of health risk that had been experienced.

It is also important to allude to the fact that the hygiene condition of the storage facility was essential in ensuring minimized exposure to ACM. Air monitoring which was done also confirmed less contamination of the air with ACM fibres. However, it is essential that the management work on a plan to replace tiles and other ACM materials to ensure maximized safety in the area.

It is also necessary to note that the company was liable for any damages caused by ACM to its staff. However, this was highly reduced given that the Storage facility was highly secured and only accessible to staff members and management authorized to perform any task thereof. Moreover, evaluation conducted on the staff that had accessed the area over the time showed little or no sign of asbestos contamination.

Nonetheless, the company needs to halt any further entrance into the facility (without protective clothing) for cautionary reasons. This would assist in eliminating possibilities of being on the odds with regulation agencies. In essence, the survey was a success and its recommendations were as given below (Commonwealth of Australia, 2012, p. 1).

Recommendations

It is important to note that a number of management decisions are necessary for applying appropriate control measures on ACM and their associated risks. This involves detailed work on the area of survey to eliminate any chances of contamination. Moreover, since this is a grocery facility, the food products contained are contaminable and should be stored carefully within the shelves to avoid contact with ACM.

Control and removal of ACM is also necessary to effect good management. J&S consulting has therefore outlined the following recommendations for consideration in dealing with Asbestos and associated its risks (MDHS, 2001, p. 7).

Detailed documents should be prepared in order to address safety and health-associated issues that relate to specific site and work conditions. These should contain technical scope or works, management plans as well as risk assessments. This has the capability of ensuring cover for all work/site associated issues and hence follows the prescribed guidelines regarding the Asbestos management.

The document should always be updated annually after a regular inspection. This should also be considered earlier than the specified period in case ACM has been disturbed or in cases where there is need for re assessment of the area of survey /facility.

Moreover, the document should be held as an Asbestos register for regular checking and update depending of the condition of ACM. Further to this, it is very necessary that all workers at Western groceries be given a copy of the Asbestos register for conformity. This should also include all updates made to the register (WADOH, 2011, p. 2).

To comply with the guidelines and regulations as provided for by NOHSC [NOHSC: 2018(2005)], it is necessary that every action taken, as well as steps applied to control ACM and Asbestos in the grocery (place of work) be included in the asbestos register.

This will ensure conformity with NOHSC code of practice fro the management and control of Asbestos in Workplaces. Moreover, the details are to be included in the Asbestos control log (NOHSC, 2005b, p. 3).

The company is not allowed to recycle, reinstall or resell ACM. The only exception is with regards to selling the whole storage facility, in which case the new owner will apply the code of practice as provided for by NOHSC. Any such action is illegal and it shall amount to huge repercussions for the company and individuals concerned.

Western groceries should note that in the event that Asbestos materials are damaged significantly, weathered, or produce significant debris or dust that is visible then it is important that safety and health management procedures or works be implemented. This should involve the services of accredited and experienced Asbestos consultants like J&S consulting to mitigate its effects.

Before demolition and/or renovation, any equipment or part that is excluded in accordance with the limitations of survey areas should be assessed for availability of ACM or asbestos. Moreover, this should be done by authorized consultants such as J&S consulting before such demolition and or/renovation is done (MDHS, 2001, p. 7).

It is also necessary to note that removal of ACM should be prioritized during refurbishment, maintenance or renovation where possible. In essence, removal should be placed above all other methods such as sealing or encapsulation, among others (during renovations, maintenance or refurbishment). Moreover, all ACM should be removed before demolition of the storage facility (Whenever the company decides to do so).

It is important that the company refer to the legislations, regulations and guidelines as provided for safe management and/or removal of ACM or asbestos. In addition, the management should ensure that they study the general information on asbestos products as well as their removal requirements.

Regulations, Guidelines and Legislations

Q/d Workplace health and Safety Act 1995

This act has the objective of preventing death, injury or illnesses of people arising from workplace. It therefore outlines the overall requirements that must be complied with at work places in QLD. Some of the most important elements in the act include definition of persons that have obligations in Division 2 to guarantee safety and workplace health.

It also contains the frameworks that give accredited training along with management of risks. In addition, it contains information regarding establishment of consultative arrangements or committees on safety, which concerns safety and workplace health, among others. It is the responsibility of the management to go through all the information associated with this and other acts for conformity (SWA, 2011, 5).

Qld Workplace Health and Safety Regulation 2008

This regulation requires owners the grocery to retain accurate ACM as well as ensure full conformity with the asbestos management code. Again, it is the responsibility of the management to go through all the information associated with this and other regulations for conformity.

Other codes of practice include the various NOHSC codes of practice, which must also be complied with in order to safely remove, manage and control asbestos in workplaces. All these documents are important for conformity with industry standards for Asbestos and ACM management (SNSW, 2012, p. 1).

References

AIOH 2006, Guideline for Writing Occupational Hygiene Reports, Australian Institute of Occupational Hygienists Inc., Victoria.

AIOH 2011, Draft Position Paper: Synthetic Mineral Fibres (SMF) and Occupational Health Issues, Australian Institute of Occupational Hygienists Inc., Victoria.

Baker, E, Rogers, A, & Conaty, G 2001, Use of secondary Buffer Cubicle Air Filtration System in Asbestos Removal Works, Pinnacle Print, Wollongong.

Commonwealth of Australia 2012, Hazardous Substances Information System. Web.

MDHS 2001, Surveying, Sampling and Assessment of Asbestos-containing Materials, Health and Safety Executive, Adelaide.

NOHSC 2005a, Code of Practice for the Safe Removal of Asbestos 2nd Edition, Commonwealth Copyright Administration, Canberra.

NOHSC 2005b, Guidance Note on The Membrane Filter Method for Estimating Airborne Asbestos Fibres 2nd Edition, Commonwealth Copyright Administration, Canberra.

SAI 2004, Australian Standard: Method for the qualitative identification of asbestos in bulk samples, Standards Australia International Ltd., Sydney.

SNSW 2012, Injuries and claims. Web.

SWA 2011, Workplace Exposure Standards for Airborne Contaminants, Creative Commons, New South Wales.

SWA 2012, Guidance on the Interpretation of Workplace Exposure Standards for Airborne Contaminants, Creative Commons, New South Wales.

WADOH 2009, Guidelines for the Assessment, Remediation and Management of Asbestos-Contaminated Sites in Western Australia, Department of Health, Western Australia.

WADOH 2011, Guidelines for the Assessment, Remediation and Management of Asbestos-Contaminated Sites. Recommended Procedures for Laboratory Analysis of Asbestos in Soil, Department of Health, Western Australia.