Want to know more about ZARA logistics system? This ZARA transportation strategy case study analyzes the issue and contains recommendations for ZARA supply chain.

Executive Summary

ZARA has been known as the most successful retailer of fashionable clothes at moderate prices. Its unique strategies of vertically integrated system of supply chain allow to produce cheap but fashionable garment within a short period.

In contrast to other retail manufacturers, their logistics system is much more effective because it meets the changing consumer demands. In addition, the company attains much importance to the development of sophisticated IT systems ensuring effective communication and information flow throughout the chains of the network.

Despite the successful growth and increased competitive advantage, ZARA supply chain management still has a number of limitations. These drawbacks are specifically connected with vertical orientations, geographically oriented demands, and high-level transportation costs. A careful re-organization of company managerial systems can be the best solution for effective handling of logistics and data exchange, as well as for increasing the company’s sustainability.

Specifically, the creation of the second center can solve several problems on the spot – eliminate problems with transportation, improve customer demand, and reduce the risk of overproduction. Finally, the integration of the web-based supply management to the North American region can also be advantageous for the company’s profitability and performance. The transportation system, distribution lines, and modes of productions will be greatly optimized.

Introduction

Purpose of the Paper

The primary goal of the project is to provide an analysis of ZARA’s logistics process to identify the weaknesses and suggest corresponding improvements. The report, therefore, will provide information about the past and current practices of the company’s supply chain management to highlight the differences and track the existing inconsistencies.

A careful analysis of inbound and outbound logistics, as well as understanding the role of the information flow within the organization will also contribute to providing viable solutions and recommendations to the company’s strategies in the field of supply chain management.

Background Information about ZARA

ZARA is a Spanish fashion clothing and accessories chain of stores that was originally based in Arteixo, Galicia. It was organized as the joint venture of the Inditex group and as a new holding company in 1975 (About ZARA, n. p.). Since 1976, the Spanish network of stores has been expanded in a great number of cities all over the world. Its main concept consists in spreading a single fashion culture outside the national frontiers.

In addition, the venture owns such famous brands as Pull and Bear, Stradivarius, Massimo Dutti, and Bershka (About ZARA, n. p). ZARA has introduced the new trend of distributing fast fashion production to the developing countries. This unconventional strategy is also emphasized by a zero advertising policy to invest more moneys in creating new stores in different countries.

ZARA Logistics System & Practices

ZARA Supply Chain: the History

The company was founded by Ortega Gaona who has introduced an alternative outlook on the concept of clothes that should be consumed quickly rather than held in cupboard. The company has become the leading brand of the Inditex group due to its exclusive strategies and marketing concepts.

In 1975, ZARA began selling the clothes in the native city (Dutta 2). Later, the popularity of brand was spread to other cities and neighboring countries. The major marketing concept, therefore, consisted in distributing democratized fashion to masses. Because the marketing strategy was successful, the network of chains appeared in such leading cities as New York, London, Rome, and Paris.

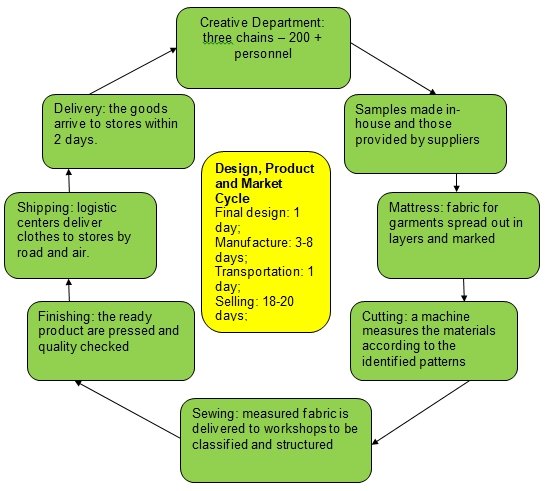

The main scope of the company’s supply chain management lies in distributing a cheap but fashionable garment within 2 weeks. In order to meet the deadlines, garment is produced in limited supplies, which also enhances the concept of exclusivity. Hence, the retail concept is based on rapid replenishment and regular creation of small amounts of new accessories and clothes.

Judging from this philosophy, the speed of manufacture is extremely high and, therefore, the effectiveness of the product distribution largely depends on the constant information exchange throughout each stage of the company’s supply chain (Ferdows et al. n. p.). ZARA’s managers realize that performance measures, office layouts, and operational procedures can be carried out properly in case the information transparency and quick data transmission is ensured.

Flow and Cycle Diagram Identifying the Flow of Materials, Money, and Product

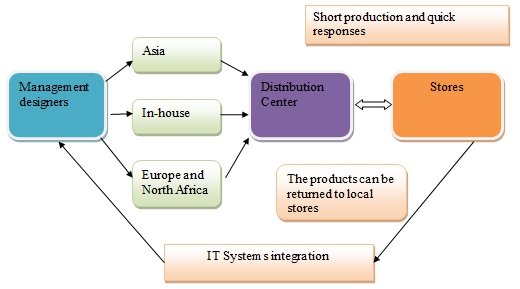

The network’s supply management concept is closely connected with time-based competition allowing to source products at the international level. These factors contribute greatly to trades off that have been introduced in order to develop strong relationships with supply chain managers all over the world. In this respect, Zara also supports this concept, as presented in the flow diagram below:

Regarding the diagram, the process of supply starts with cross-functional teams cooperating with the company’s design department located in La Coruna. The team’s perception of the leading fashion trends is further directed by regular inflows of EPOS information from ZARA’s stores from all over the world (Dutta 3). Further, the marketing specialists proceed to consult the supplies concerning the prices, costs, and margins (Dutta 3).

In order to define the volume of the production and establish deadlines, a global sourcing policy provides a wide variety of fabric supplied from different countries. Such an approach significantly reduces the risk of delays because if one supplier is unavailable, there are many other fabric producers to rely on.

Hence, about 40 % of garments are imported whereas the rest is produced in Spain (Dutta 5). Further, the finished products are price-tagged and labeled in La Coruna, the company’s distribution center. The entire production cycle lasts two weeks to gain a time-based competitive advantage and surpass its North American and European rivals.

ZARA Transportation Strategy: Past Key Decisions

Location

For the purpose of controlling the marketing costs, Zara prefers creating prime retail locations to spending money on advertising and attracting the buyers to their stores. As a result, the company spends about 0.3 % only for advertising campaigns instead of 3.5 % spent by its competitors (Dutta 6). Importantly, the company prioritizes the importance of choosing highly notable locations, which makes advertising unimportant.

Production

Unlike other leading retailers located in North America and Europe, Zara’s managers do not outsource their production completely. On the contrary, they locate about 80 % of production in Europe, near the headquarters in Spain to take closer control of the facilities (Dutta 4). Such an approach provides a greater extent of flexibility and minimizes the risk of failure. In addition, the production of limited quantities also enhances the effectiveness of risk management, as well as speed up the supply chain process.

Inventory

The inventory management is sufficiently ensured by effective IT solutions. At this point, the information and communication networks that the company uses produce cost advantages to operations and allow to follow the fundamental principle of reacting quickly to the shifts in demand.

In addition, success and flexibility allows the company’s managers to define quickly the deadlines of production due to short lead-time, variety of fashion trends, and limited supplies (Ferdows et al. n. p.). In whole, ZARA’s inventory model is based on three main pillars: inventory in store, warehouse inventory, and demand forecast that is closely controlled by the creative departments.

Transportation

Because ZARA is more inclined to use high technologies for transporting and distributing products, the matter of transportation is indispensible for carrying out two-week shipments to stores (Stewart 10). The fabrics and other materials are also quickly distributed because the supplying centers are located near the headquarters.

ZARA Supply Chain: Problems & Weaknesses

Despite the incredible results that ZARA retailer has achieved, it can face a number of challenges that can create serious problems. These limitations can be connected with just-in-time management, transportation system, excess emphasis on technologies, and inappropriate management of human resources (Gallagher 4).

In addition, the transportation process and shipment of materials within the regions can also undergo unforeseen complications in the form of natural disasters, whether, terrorism, political disturbances, or labor strife (Gallagher 6). The disconnection between the center and creative department can significantly halt the information exchange within the network throughout the globe.

Aside from the operation vulnerabilities, the challenges can also be connected with financial problems. In particular, due to the fact that the low-cost regions are supported either by dollar or by Euro, the currency fluctuations can negatively influence the cost management at ZARA.

Such a situation can lead to increase in profit margins and transportation costs. It should be stressed that a twice-weekly model of delivery is directly associated with the transportation costs and, therefore, the circumstance can become the key to ZARA’s failure to control costs (Gallagher 7).

Because the time is one of the core advantages of the company, it should take possible challenges into deeper consideration. The evaluation of rivals’ strategies is also crucial for predicting their further steps because more and more companies have been emulating the vertically integrated supply chain system introduced by ZARA.

Finally, apart from strict monitoring of consumer demands, the company’s managers should also take a closer look at the economic conditions (Dutta 3). Specific, the recession periods can make consumer buy less and shift a share of wallet to lower-cost offerings (Gallagher 6). In order to eliminate the emerged threats, the firm should conduct an in-depth analysis of future marketing opportunities.

ZARA Supply Chain: Evaluation of Web-Based Processes

Existing web-based supply chain systems and processes related to electronic data interchange

As it has been presented above, ZARA has successfully implemented a quick response program ensuring effective production and distribution of products. Hence, excess inventory and overproduction have been incorporated into the idea of customized retailing through a vertically integrated channel (Cheng and Choi 13).

In order to monitor all stages of supply, effective informational technologies and web-based supply chains should be introduced (See Appendix 1). In order to ensure quick information flow, Electronic Data Interchange (EDI) is crucial for Quick Response program being a fundament technology for processing the received data between the distributors and manufactures (Leeman 142). More importantly, the technology has been the core factor enabling technology for replenishment and efficient coordination of a supply chain process.

Provided by ERP system, this mechanism is indispensable to handling distribution and logistics processes. In addition, the information flow process is significantly enhanced through the introduction of intranet communication. The company’s intranet is necessary for a holistic evaluation of the incoming suggestions concerning the product design and price (Leeman 143). As a result, the firm designs about 10 thousand items annually.

Assistance of Web-Based Technologies in Integration and Collaboration Processes

Effective information exchange is the main condition for implementing collaborative and integrative practices. In contrast to the traditional ordering process, ZARA retailers provide the producers with all necessary information that is impossible to handle manually (Schneider 240). Second, using intranet networks enables constant flow of information and allows ZARA to eliminate the threat of overproduction.

Importantly, the integration between business activities contributes to developing information distribution leading to a tangible increase in performance and productivity. Due to the fact that the primary goal of an ERP system consists in integrating information and activities from diverse functional departments of a company, the introduction of workflow information systems can improve the data exchange and provide transparency and accuracy of communication (Dutta 7).

At this point, vertically integrated types of supply chain management require technologies that can embrace information from operational applications. In order to meet the challenges of remote data processing, the company can introduce technological systems combining the analysis of both external and internal data.

ZARA Logistics: Recommendations & Implementation Plan

Strategies for Four Key Decision Areas of Supply Chain

Location

The introduction of another distribution center can eliminate possible risks that a vertical integration system of supply presents. In order to sustain a competitive advantage and growth, ZARA should seek alternative opportunities for the global expansion in the apparel market.

In this respect, the company should develop another distribution center in the United States to diminish the logistics level and deliver fashionable clothes in a timely manner. At this point, it is possible to develop smaller distribution centers located in Brazil, Argentina, or Mexico, which enhances the possibility of meeting the demands of the American customers.

Production

The production process can be significantly fostered through investment in Internet retailing directed toward the American market. Online marketing strategy can advance the expansion process to the U. S. market. In addition, the company should also introduce specialize products with regard to various geographic locations.

Inventory

Inventory system can be improved in case Electronic Data Exchange systems are introduced as powerful tools for integrating and collaborating the internal and external data obtained from stores, designers, and marketing specialists.

Transportation

The existence of several retail centers can decrease the transportation costs because air shipments are much more expensive due to the rise of prices on fuel.

Functional Decisions Based on the Established Strategies

The presented strategies do not provide tangible shifts to the vertically integrated systems of the company’s supply chain. ZARA’s managers, therefore, only need to develop the second retailing center with similar structure. The existence of additional retailing department can deprive the headquarters of certain responsibilities and provide greater control of other regions.

The integration of IT systems will eliminate the problems of coordination between the two newly introduced centers. In addition, the re-organization process will touch on the design sphere because the American department will be specifically oriented on web-based supply chain process. Hence, part of responsibilities will be imposed on this department and, as result, there will be designers oriented on different geographical regions.

Rationale for the Identified Strategies

The development of the second retail center in the American region can enable the international company to foster the policy of global expansion. What is more important, the company can create a solid platform for controlling the financial and economic conditions in the world.

As per the production process strategies, U. S. consumers are most likely to buy goods without going outside because they feel more comfortable while having more time to select a product. Further, culturally and socially oriented policy of manufacturing can have a potent impact on the increase in consumer demand. Finally, the transportation and inventory can also be improved with the integration of effective ERP systems enhanced by Electronic Data Exchange systems.

Recommendations for ZARA Supply Chain

Excessive emphasis on vertical integration system can create a threat to the effectiveness of global expansion of the world-known retailer. In this respect, ZARA should develop several other creative departments that would control certain regions.

The re-organization, therefore, can greatly increase the customer demands because the department will be specifically oriented on a particular cultural group. Hence, the centers can be coordinated by means of EDI mechanisms integrated by ERP systems that provide greater control and increase the production volumes all over the world. In whole, such a strategy enhances ZARA’s competitive advantage.

Works Cited

“About ZARA”. ZARA. 2011. Web.

Cheng, T. C. Edwin, and Tsan-Ming Choi. Innovative Quick Response Programs in Logistics and Supply Management. UK: Springer, 2010. Print.

Dutta, Devangsgu. Retail: The Speed of Fashion. 2002. Web.

Ferdows, Kasra, Michael A. Levis, and Jose A. D. Machura. “Zara’s Secret for Fast Fashion”. HBS Working Knowledge. 2002. Web.

Gallagher, John. “ZARA Case: Fast Fashion from Savvy Systems”. Gallaugher.com. 2008. Web.

Leeman, Joris. Supply Chain Management. US: Books on Demand, 2010. Print.

Schneider, Gary. Electronic Commerce. New York. Cengage Learning, 2010, Print.

Stewart, Thomas A. “Bound To Fail, Or Set Up To Succeed?.” Harvard Business Review Nov. 2004: 10.

Appendix 1: Vertical Supply Chain