There has been an increase in demand for energy globally because of industrialization and an increase in population. The rise in energy demand has necessitated countries to seek alternatives to the traditional sources of energy. The petroleum and natural gas sources are only found in a small fraction of countries, mainly in the Middle East.

A bio-refinery is a plant that converts biomass to produce fuels and chemicals. A bio-refinery utilizes sources of renewable energy that are more reliable than non-renewable sources. One of the bio-refineries is green bio-refinery. The green bio-refinery uses green grass or immature cereals to yield energy (Demirbas, 2009, pp. 2782-2801). For efficient production of energy from immature cereals, crops are harvested before flowering. This ensures proteins and carbohydrates are harvested when they are being synthesized, i.e before translocation. It has been found that green crops yield more energy per area of land than mature crops or mature cereals. In addition, alfalfa and clover are also used in green bio-refineries. A green bio-refinery utilizes both mechanical and chemical processes to yield energy (Demirbas, 2009, pp. 2782-2801).

The first process involves compressing raw materials in a press unit. The products from the press unit are passed through a press juice unit to extract water-soluble components through biochemical and physical processes. Solid products from the first press unit are passed through a press-cake unit to undergo hydrothermical and enzymatic processes so that they are converted into cellulose. The cellulose (from the press cake) and proteins and soluble sugars (from the pressed juice) are combined in the last step to yield fuels, chemicals, feeds, and waste products.

Green bio-refinery is quite economical and it can be applied, in small-scale or large-scale, to yield energy and feeds. The raw materials are readily available either from cultivation or permanent grassland. The energy produced from green bio-refinery is used in homes or industries, while feeds produced are used by animals (Demirbas, 2009, pp. 2782-2801).

Algae bio-refinery is the second system that is used to produce energy and chemicals. It involves the use of microalgae. Microalgae are plants that are too tiny to be seen with naked eyes. There are several types of algae in marine systems, and they are necessary for ecosystems. Microalgae grow faster than higher plants and can be harvested all year round. Just like higher plants, they require sunlight, carbon dioxide and nutrients to grow. However, they do not compete for resources with higher plants when they are grown in arable farms. Algae are excellent sources of proteins, carbohydrates, lipids, and other compounds like pigments and vitamins. A typical algal bio-refinery has a section for microalgae cultivation. When the algae are mature, they are harvested in the form of algae biomass. The biomass is concentrated to form wet biomass. The wet biomass is then extracted to obtain carbohydrates, proteins, lipids, pigments, vitamins and antioxidants. The extraction process also yields residual biomass, which undergoes biogas technology, to produce methane. Methane is used to produce electricity for domestic and industrial applications (Cherubini, 2010, pp.1412-1421).

Woody bio-refinery is an excellent source of fuels and electricity. The raw material in this bio-refinery is wood biomass. The wood biomass is converted into chips and hemicelluloses. The chips are passed through pulp mills which convert them into a pulp and black liquor. The black liquor is combined with hemicelluloses to form lignin. The lignin undergoes chemical processes to be converted into fuels and electricity, and other products like phenols and adhesives. The fuels and electricity produced in the woody bio-refinery are used for domestic and industrial applications.

Lignocelluloses bio-refinery is a technology that utilizes chemical processes and biotechnology to yield biofuels for domestic and industrial applications. A lignocellulosic bio-refinery can also produce chemicals, food and feed components. The major chemicals found in the feeds are cellulose, lignin and hemicelluloses. A lignocelluloses bio-refinery has many mechanical, chemical and enzymatic processes that result in different products. The products are utilized in many applications domestically and industrially. Lignocelluloses bio-refinery is based either on cereals or forests to produce lignin. In a cereal-based lignocellulosic bio-refinery cereals are used as raw materials. They are converted into grains and lignocellulosic biomass. The lignocellulosic biomass undergoes enzymatic and chemical hydrolysis to form cellulose which is then converted into pulp. The lignocellulosic biomass is converted into lignin residues. The residues are combusted to yield heat and electricity. The grains formed from the cereals undergo extraction to form starch. The starch is hydrolyzed to yield sugars which are fermented to produce ethanol that is used as a transportation fuel.

In a forest-based lignocellulosic bio-refinery wood, pulp and forest residues are used as raw materials. The raw materials undergo mechanical and chemical processes to form black liquor. The liquor is burnt to yield heat and electricity. The liquor is also fermented to yield ethanol which is another source of energy for domestic and industrial applications. The black liquor may also undergo a gasification process to produce syngas which is passed through Fischer Tropsch Synthesis to yield transportation fuel and chemicals. The transportation fuel yielded is used in the automobiles industry.

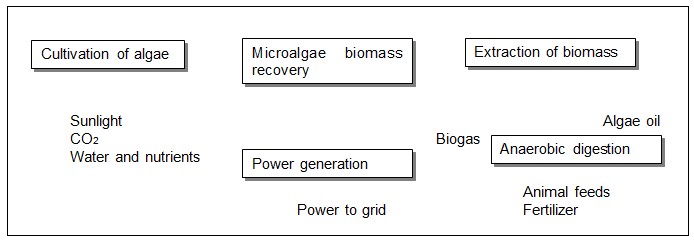

Algae bio-refinery flow sheet and description

The above figure shows the significant processes involved in producing energy in algal bio-refinery plant. The first step involves cultivation of algae in the presence of nutrients, sunlight, water and carbon dioxide. These are the same requirements that higher plants need to grow. However, microalgae take a shorter time to grow and mature than higher plants. After microalgae are mature, they are recovered (harvested) and are ready to be extracted. The microalgae biomass is passed through an extraction process that yields pure microalgae biomass and algae oil which can be converted into biodiesel and diesel. The biomass obtained undergoes enzymatic breakdown (digestion) in the absence of oxygen to yield biogas and other products (Cherubini, 2010, pp.1412-1421). The other products include fertilizer used in farms and animal feeds for feeding animals. The biogas produced is used to generate power which is fed to a power grid and used for lighting, cooking and other applications.

The power generated from algal bio-refinery has applications in both domestic and industrial environments. The amount of power produced depends on the size of plant and level of technology used in algal bio-refinery. If the size of bio-refinery is small, then little amount of power will be yielded because it also implies that not much algae was cultivated. Likewise, if the technology used does not fully utilize the algae biomass harvested, then there will be leakages resulting in low power output (Cherubini, 2010, pp.1412-1421).

Sustainability of the algal bio-refinery

In the current times when sources of non-renewable sources of energy are being depleted, it is prudent to find alternative sources of energy that are sustainable. Algal bio-refinery is a sustainable process of generating energy for domestic and industrial uses which utilizes breakdown of algae biomass. The biogas yielded is friendly to the environment, unlike petroleum-based fuels (Subhadra, 2011, pp.2-13). The cultivation of microalgae requires water, carbon dioxide, sunlight and nutrients like phosphorous and nitrogen. The micro-plants mature faster than higher plants. In addition, micro-algae do not compete for growth resources with higher plants. This fact makes it possible to cultivate micro-algae and higher plants in the same arable land without worry that they would interfere with the progress of the higher plants. It has been estimated that micro-algae can produce 30-50 tonnes of biofuels per acre per year and 800-5000 gallons of oil per acre per year. Surprisingly, it has also been suggested that sustainable algal bio-refineries can supply 48% of U.S fuel imports.

Algal bio-refineries do not need vast landscapes to grow. Moreover, micro-algae are excellent micro-plants for fixing carbon dioxide and changing energy trapped from the sun into chemical energy and nutrients required by crops. In fact, it has been confirmed that micro-algae fixes carbon dioxide better than terrestrial plants (Subhadra, 2011, pp.2-13). Generation of power from algae bio-refineries is sustainable provided that proper biotechnology is used. The biotechnology ensures efficient biochemical conversion processes in a bio-refinery. In addition, proper planning and estimation of power output is essential to ensure that an algal bio-refinery will be sustainable in the long run.

Reference list

Cherubini, F., 2010. The Biorefinery Concept: Using Biomass Instead of Oil for Producing Energy and Chemicals. Energy Conversion and Management, 51(7), pp.1412-1421.

Demirbas, A., 2009. Biorefineries: Current Activities and Future Developments. Energy Conversion and Management, 50(11), pp.2782-2801.

Subhadra, B., 2011. Algal Biorefinery‐based Industry: An Approach to Address Fuel and Food Insecurity for a Carbon‐smart World. Journal of the Science of Food and Agriculture, 91(1), pp.2-13.