Examples of Bio-Refineries

The following is a list of four different bio-refineries processes and products, which are expounded in their raw materials and products.

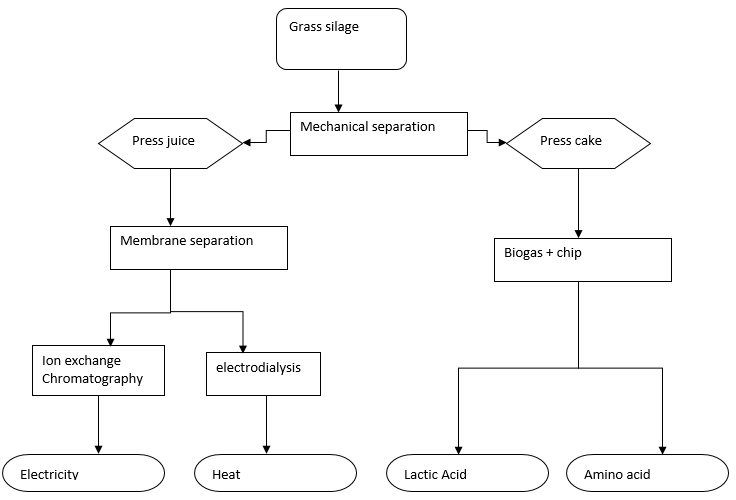

Green Bio-Refinery

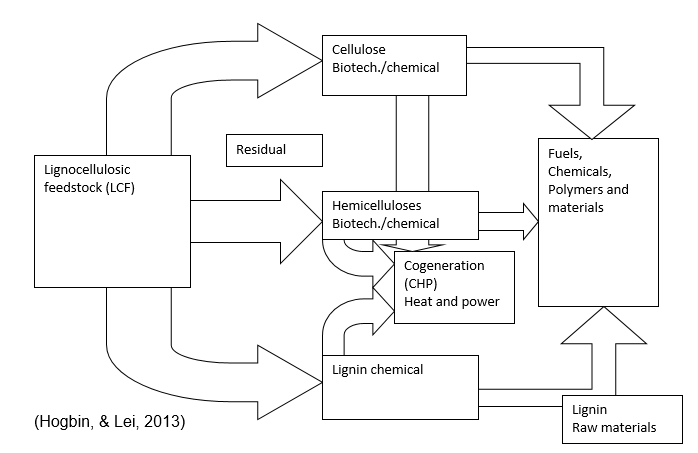

Lignocellulosic Bio-Refinery

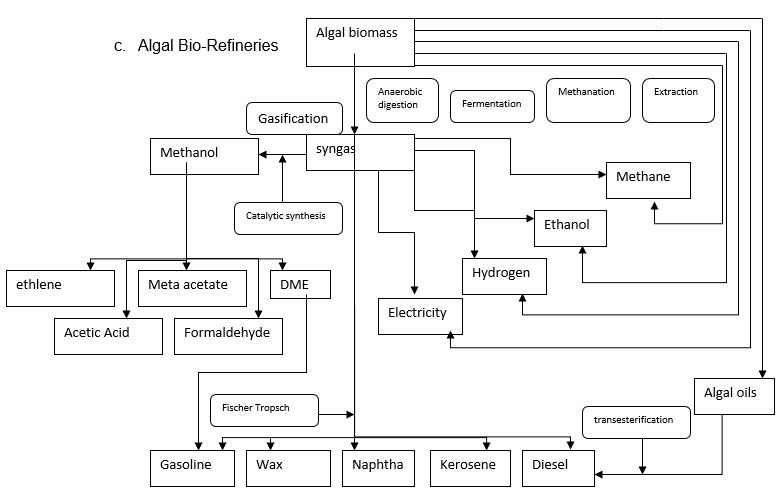

Algal Bio-Refineries

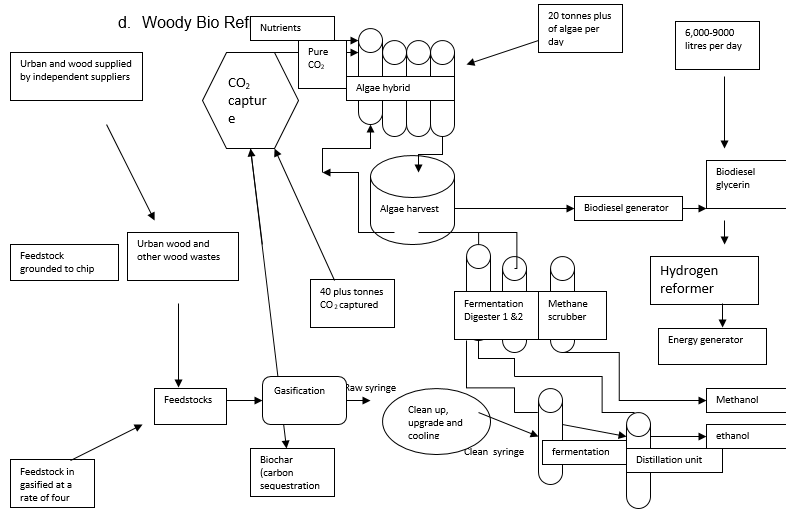

Woody Bio Refinery

Sample Biorefinery

Agave Juice Fermentation to Produce Bioethanol

Introduction

Fossil fuels are at threat of depletion. Moreover, their exploitation and processing imposes significant terrorization to the environment. On the other hand, the bioenergy, biofuels from biogas, and solid or liquid biomasses, are environmentally friendly and renewable sources of energy.

Besides, an important bioenergy includes bioethanol, an alcohol derived after fermenting carbohydrates, corn, sugarcane and non-food agricultural rejects, which are rich in sugar. However, the use of corn, sugarcane, and non-food agriculture rejects require some modification in the biethanol manufacturing process. This makes the bioethanol production process costly and unaffordable to poor.

In opposition, use of agave as the production raw materials in the process of producing the bioethanol is cost saving and affordable. It does not require the special processes. As a result, this paper studies the production of bioethanol using Mexican agave as the raw materials.

Process Description

The process of fermenting Mexican agave to produce bioethanol follows six steps. Firstly, there occurs the formulation of the medium for culturing the Agave tequilana at the time of developing inoculums and production of the fermenters. Secondly, supplementary equipment, Mexican Agape materials, and fermenter, are sanitized. Thirdly, one should make sufficient, dynamic, and clean ammonium sulphate for inoculating the manufacturing vessels. Fourthly, Agave tequilana is grown in the fermenter under finest product development conditions. Fifthly, the bioethanol is extracted and purified. Lastly, the waste matter is used in biogas manufacturing. This process is outlined in the below flow chart.

From the above bioethanol production process, the Mexican Agape head is fermented after harvesting. To obtain the sugar from Mexican Agape, the Mexican Agape head is steamed, milled, and pressed. The steaming procedure hydrolyze the polysaccharides into fructose. After fermenting, the alcohol is distilled, purified and concentrated.

Meanwhile, the Mexican Agape juice can ferment with or without inoculation but implementation of the Agave tequilana for fermentation ensures there are high and regulated rates of fermentation. The fermentation process of the fructose from the Mexican Agape forms products such as the ethanol, carbon (IV) oxide and wastes, which are used to produce biogas. Hence, there is a quick manufacturing of the ethanol and high-energy production at a cheap cost (Dulce, 2013).

Fermentation

Firstly, the batch fermentation process involves taking away the Mexican Agape wastes in the vessels of fermentation and the fermenting vessels are thoroughly cleaned. After cleaning the vessels, new batch fermentation process commences. There occurs loading the fermentation vessels with fresh Mexican Agape. Moreover, there is a treatment of the Mexican Agape with the Agave tequilana. This fastens and enables regulation of the fermenting process. Furthermore, in this fermentation process, there is avoidance of supplementation and separation of the Mexican Agape fermenting in the equipment. Lastly, this is the initial procedure of transforming the nutrients, products, and biomass into bioethanol.

Secondly, a fed-batch fermentation takes place. It recommends supplementation of the nutrient and this increases the rate of production. During the addition process, the fermenters concentration is monitored and the nutrients are added in recommended dosages to avoid surplus nutrients that may inhibit the Agave tequilana activities.

Lastly, continuous fermentation procedure transpires. When there is a fresh introduction of the Mexican Agape, the expected batch process will be prolonged as a lot of culture is displaced and more production occurs, the process of fermentation is continuous, and the substrate is never exhausted.

Sustainability of the Bioethanol

Sustainability is the term describing the interaction between humans, environment and economic factors. The sustainability of the bioethanol production is an initial step of determining how the energy can meet the increasing needs of alternative source of fuel by minimizing the dependence on the fossil fuels; contribute to the development of sustainable rural energy, which are carbon-neutral (Templer, Wang, & Murphy, 2012).

In order to analyze the sustainability of the bioethanol, a meter employed include analyzing the net energy and the emission of the green grass. Another aspect considered is the energy production cost, energy utilization, and energy prices. Besides, food and energy crisis can never be overlooked; the land used for food production is needed to produce the feedstock for the bioethanol production. Lastly, government policies may play a role in determining the sustainability of the energy.

Bioethanol for transport have both superior and dreadful sustainability. The good properties derivable outweigh the dark ones especially when the modern technology is employed. Bioethanol energy effectiveness (net energy balance) and the green gases emitted have a definite balance. The net energy balance occurs through the savings derived by using the bioethanol instead of the fossil fuels and other useful by-products derived from the process of bioethanol generation.

The bioethanol process diminishes the greenhouse gases productions by 50% when compared to similar amount of fossil fuel. Moreover, the bioethanol doubles the level of energy available (when compared to a conventional fossil fuel) for consumption since it leads highly concentrated product and by-products, which is the raw material to a biogas digester to produce more energy (Woods, 2013). Moreover, the Mexican Agape grows in different climates and this lowers the competition with other food crops.

As a result, the energy is sustainable and it promotes energy and environment security, saves foreign exchange, and the social wellbeing of the rural dwellers.

References

Algen (2012). Algae to energy: Technology overview. Web.

Dulce M. D. (2013). Continuous Agave Juice Fermentation for Producing Bioethanol, Biomass Now – Sustainable Growth and Use. Web.

Hoeltinger, S., Schmidt, J., Schoenhart, M. & Schmid, E. (n.d.). Optimal Supply Chain Design of Green Biorefineries in Austria – Assessment of Current and Potential Policy Support Schemes. Web.

Hogbin, C. & Lei, W. (Eds). (2013). Lignocelluloses feedstock biorefinery as petrorefinery substitute, biomass now-sustainable growth and use. Web.

Pires, J. C. M., Alvim-Ferraz, M. C. M., Martins, F. G., & Simoes, M. (2012). Carbion dioxide capture from flue gases using microalgae: Engineering aspects and biorefinery products. Renewable and Sustainable Energy Review, 16(5), 3043-3053. Web.

Templer, R., Wang, L., & Murphy, R (2012). Environmental sustainability of bioethanol production from waste paper: sensitivity to the system boundary. Energy Environ. Sci.,2, 8282-8293.

Woods, J. (2013). Sustainable bioethanol for the future. Web.