Abstract

Starruca Viaduct is a monumental bridge in Pennsylvania, which is a pioneer work in the field of engineering using concrete. This paper gives an overview of how the viaduct was constructed. It starts with an introduction followed with an overview of when, where, and the size of the bridge. The paper then gives the civilization and prevalent culture in which the viaduct was constructed.

The body of the paper highlights how the bridge was built, including the materials, methods, tools/equipment, the labor force, and the cost of the viaduct. It also gives an analysis of how the bridge would be built in contemporary times before giving a conclusion.

Introduction

Starruca Viaduct is a monumental bridge in Pennsylvania, which is perhaps one of the most important concrete engineering works of the 19th Century. Before the construction of the bridge, the journey from New York to Lake Erie was a long and arduous one as people had to travel to New Jersey, then climb the Gulf Summit in Pennsylvania, and ultimately get to New York via Binghamton. Fortunately, surveyors discovered what would later become a ‘logistical redeemer’ to people transiting from New York to Lake Erie and beyond.

The discovery was Starruca Creek, who joined the two locations. However, the eminent problem was how to come up with a structure to connect the two locations via the newly found creek. Julius W. Adams, a respected civil engineer, was tasked with the duty of figuring out how people would cross the valley. Adams had several options with the most straightforward one being to fill the valley by removing tons and tons of raw earth and gravel, which conventionally would be a laborious and costly exercise.

The second option was to construct a wooden supporting tower, which came out as the most feasible and inexpensive exercise. However, the wooden trestle would require regular maintenance and a couple with its vulnerability to disasters like fires; this option could not qualify as a long-term solution to the problem at hand.

The last option was to venture into a monumental concrete bridge, which had not happened anywhere else across the world at the time. Nevertheless, Adam decided to take the road less traveled, and he chose the last option, which led to the birth of the Starruca Viaduct as it stands today.

The structure was a pioneer bridge in many aspects. First, the bridge was the first concrete structure of its kind. In addition, it was completed in record time, and it was the longest structure of its kind at the time. This paper is a report highlighting the different issues surrounding the construction of the Starruca Viaduct including when and where it was constructed, and the prevalent culture in the era of its construction, and the civilization that built it.

Other elements include how it was built, the materials and methods employed, the tools and equipment used, and the labor force used at the time. The report concludes by speculating how the structure would have been built if it were constructed in contemporary times.

The Starruca Viaduct

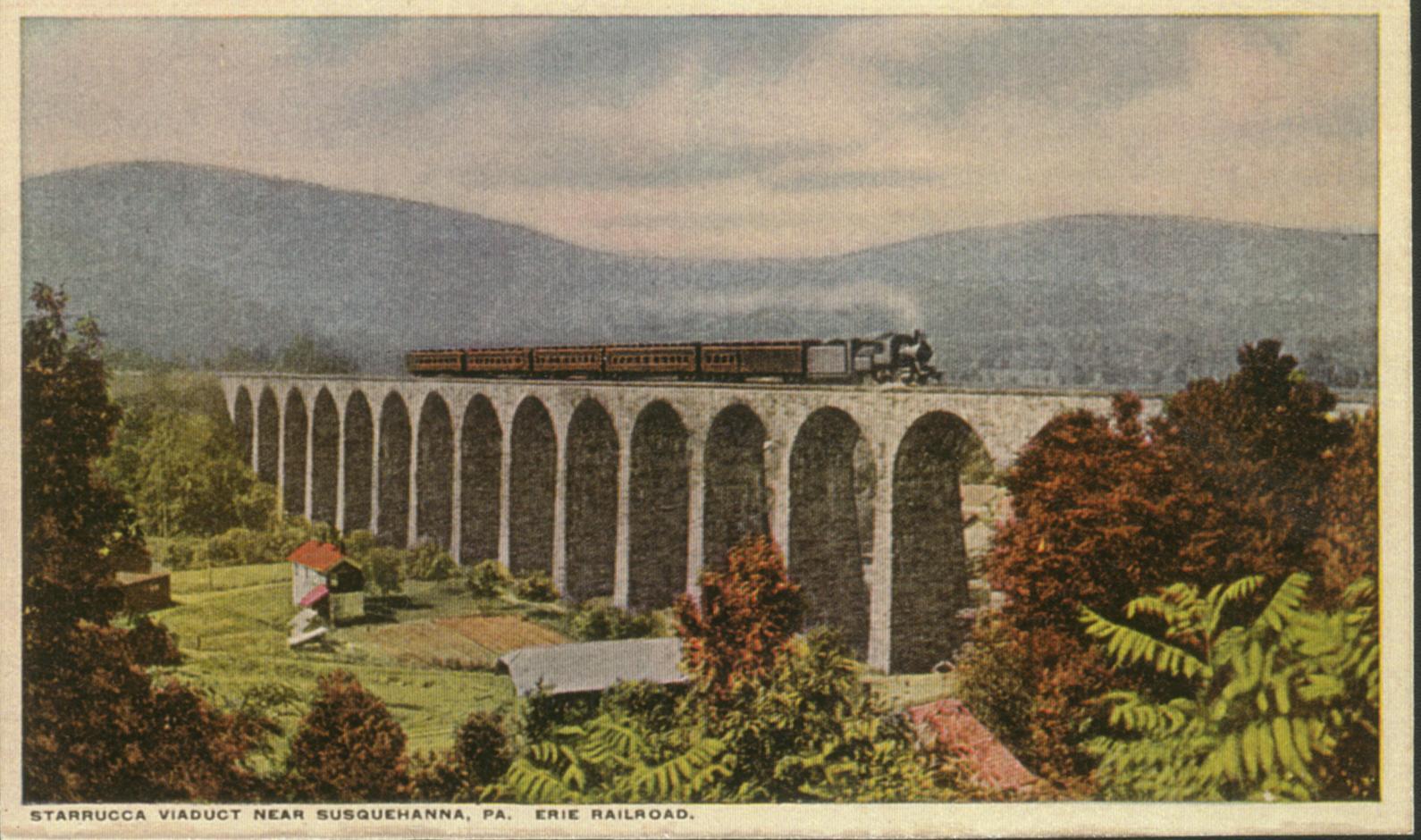

The groundbreaking work of this historic bridge occurred in the spring of 1847, and it took one year to complete the project in 1848, and as aforementioned, the viaduct is located in Pennsylvania. As noted before, this bridge was the largest of its kind at the time of its construction. Mott affirms, “At 1040 feet in length, 25 feet wide at the deck level, and 90 to 100 feet high, the Starruca Viaduct was the largest and most expensive stone arch bridge built in the United States at the time” (76).

The bridge was built in the 19th century American civilization. During this time, the United States was undergoing a transformation, which was marked by unparalleled optimism and growth. Unfortunately, life in the country was extremely obtuse, and the most available labor opportunities were menial jobs in the dispersed industries across the country. The transport sector was not different as most people depended on mules or horses dragging wagons for miles to reach one’s destination or deliver goods at the appropriate areas.

However, in Pennsylvania, the Erie Canal was a reprieve as it offered a better option of transport mechanisms to the benefit of the areas that are connected. Nevertheless, this canal alone was not adequate to serve the ever-growing population. Most importantly, there was a need to connect New York and Erie for business purposes for as aforementioned, the journey between the two places was time and resources consuming as one had to pass through New Jersey.

The prevalent culture at the time was highly dictated by politics, just like the contemporary United States. Slave trade was still prevalent at the time, and so menial workers were readily available. However, the sociopolitical environment was charged as anti-slavery groups had started voicing their demands for liberation.

In New York, the famous Seneca Falls Convention took place at the time. At the same time in Pennsylvania, the black minority population was experiencing mob attacks from white supremacist groups, and thus the prevalent culture was in transition. In the business arena, wealthy British capitalists were still commanding a sizable portion of the economy, which is one of the factors that contributed to the construction of the Starruca Viaduct.

The New York and Erie had to connect somehow, and different surveyors were tasked with the duty of finding a solution to the problem at hand. Initially, New York and Erie authorities had embarked on a project to connect the two areas via a railroad in the 1840s. Unfortunately, the project had taken almost a Century, and with revised charters, the authorities had agreed to complete the project in 1949.

Unfortunately, time was fast approaching, and the initially proposed route had to be altered as, by the time the construction started, the involved authorities had less than 18 months to complete the structure of losing the charter. Adams enlisted the services of an equally respected civil engineer, James Kirkwood, in a bid to beat the set deadline. Kirkwood went on the records for telling Adams, “…I can build that viaduct in time, provided you do not care how much it cost” (Mott 101).

Fortunately, funding was not a problem as affluent British merchants had pledged to support the project regardless of the cost. Unfortunately, there was a problem, the Starruca Creek was under the jurisdiction of Pennsylvania, and thus New York and Erie had to broker a deal with the Pennsylvanian authorities. The deal cost the financiers of the project an annual $10,000, which would go to Pennsylvania.

How it was built

Given that the structure was a pioneer project at the time, a lot had to be done. As aforementioned, engineers had never attempted such a feat before, and so good planning was a requisite element for the project. Fortunately, Julius Adam had the required skills. He had hitherto worked with the Western Railroad, where he was responsible for many success stories. In this project, Adam had to design a novel project.

Having completed the designing of the project, Adam had to look for other competent individuals and especially engineers to steer the implementation bit of the construction (Mott 94). Coincidentally, Adam had an equally competent civil engineer cum brother in law, James Kirkwood. In the process of looking for someone to steer the construction bit of the project, Mott records that Adam told the representatives of the involved authorities that he knew “no one who could do it unless it was Kirkwood” (103).

Fortunately, the representatives agreed with Adam’s suggestion, and Kirkwood was enlisted as part of the key players in the construction of the project. Different scholars differ on whether Adams delegated all the constructions responsibilities to Kirkwood or whether the two worked hand-in-hand towards the completion of the project. Nevertheless, regardless of how the duties were shared, the resultant structure was one of its kinds at the time.

Materials

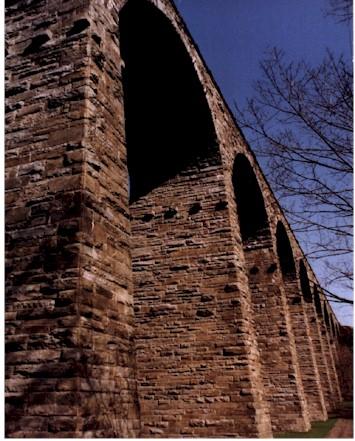

The structure called for the use of concrete. The stones used in the project were mined from two locations, just a few miles from the site. One of the quarries was Lanesboro, which supplied enough stones for the larger part of 1847 and partly in 1848. The other quarry, which supplied stones for the remaining part of the construction, was “located at Stevens Point in the Starruca Creek valley” (Plowden 82). The most used stone was the native Pennsylvania bluestone, which is a form of a sedimentary rock found mostly in the United States.

Young posits, “Wooden falsework provided the framing on which the bridge was shaped. Concrete and stone footings formed the base, upon which masons fashioned the piers, arches, and spandrel walls (the sections above the piers and between the arches) of bluestone” (78). Cement was necessary for making mortar to hold the stones together. The cement for the project came from limestone quarries, and it was known as Rosendale cement. Mostly, the quarries were found around Ulster County in New York.

In addition, bricks were of use in holding the Roman arches in place. The bricks were then readily available materials in this project as they were made locally from clay, which was abundantly available on the site of construction. Wood was also a critical material useful in making the falseworks. Initially, the designers thought that they would recycle wood used in one arch and use it on another arch until they covered the 17 arches (Young 79).

Unfortunately, this process was time-consuming, and speed was of the essence, as mentioned earlier in this paper. Therefore, Kirkwood decided to make different falseworks for every arch in the quest to beat the set deadline. Therefore, the project ended up using lots of wooden materials and timber, but such materials were readily available. The other material widely used was water, which was abundantly and locally available at the time. Wrought iron was ultimately used in the construction of the T-rails.

Methods

Advanced technology in the 19th Century was a distant dream, and thus, most of the methods applied in this project were conventional. The process started by digging the foundations of the arches. Adams had projected the foundations to be over 15 feet deep, but upon digging 9 feet, he encountered “course hard gravel, pervious to water.”

(Young 92). Due to lack of advanced machinery, Adam had to settle for 6-9 feet foundations, and even though most people were a skeptic of such shallow foundations, he went ahead to erect the arches. Fortunately, the arches have stood the test of time and criticism, and they stand strong today, which is over one and half centuries after the construction. The arches were 50 feet apart and having set the foundations; the bases were made of stones.

After making the stone bases, the involved workers (who were mainly masons) made piers on each foundation. The piers were meant to connect the arches and solidify the bases. The piers were 65 feet long after which arches were erected on top in a length of 20 feet and 51 feet in breadth. Finally, the spandrel walls were then constructed mainly using cement. The stone bases and the arches were made purely of stone where the mason laid stone after stone until the specified sizes were achieved.

Surely, this was an arduous task, but it was worth the efforts. Bricks were then used to hold the arches, which ran through the hollow spandrels. At the surface, stones were laid down systematically to make a continuous deck, which ran for over 1040 feet. In a bid to demonstrate how the process was time and energy-consuming, Hungerford notes,

The stone was cut and numbered and loaded on the stone cars drawn by horses and mules over the piers and were unloaded by derricks down on the piers. They drilled two holes in the large stone, about two feet apart. They had a short chain with a ring in the center and short plugs on each end. They would stick these plugs in the holes with the derrick, hook in the ring and let them down on the piers where they were fitted to go. The stone was … marked with black paint. The masons on the piers knew where to lay [it] (90).

In the making of the T-rails, which were critical in the completion of the broad-gauge railroad, wrought iron was used. Hungerford posits, “Wrought iron T-rails for the broad-gauge railroad were manufactured at the new Lackawanna iron works 40 miles to the south, the first large order for T-rail in the country and a contract, which marked the industrial birth of the city of Scranton” (94). From the sites, the stones were transported using stone cars pulled by mules.

Tools/equipment

The most used tools in this project were hand tools. The masons had to use the brick trowel for placing the mortar between stones. Other forms of trowels used included buttering trowel and pointing trowel. Other tools included hammers, bolsters, chisels, levels, mason’s line, jointers, and mixing tools. Trucks and canoes were used to transport the required materials to the site.

The masons made creative ladders to support them as they laid brick and mortar on the topmost areas of the viaduct. The mining of the limestone mainly depended on workers who dung the material from the ground. Others included horses and mules together with carts for moving the materials.

The labor force at the time

Given the short period available to complete this project, Adams and Kirkwood enlisted the services of approximately 800 workers. Mostly, these workers were masons as the required work was mainly masonry. The only notable skilled engineers for this project were Adams and Kirkwood, who were both civil engineers. Apart from masons, other unskilled workers were required for support purposes. They had to move bricks, mortar, stones, and all other materials necessary for the project.

Most of the workers were from Scotland, and even though critics argue that 800 workers were more than enough, the excess numbers were inevitable given the short period within which the project was supposed to be completed. Despite the criticism, Adam and Kirkwood delivered results as, by the end of November 1848, the project was complete.

Funding and Cost

Approximately, the project cost $320,000. This amount qualified the project as the most expensive undertaking of the time. However, money was not an issue as affluent British investors pledged enough money to construct the viaduct as they had high business stakes in the region. The workers earned $1 every day, and given that they were about 800, a large portion of the budget went to labor expenses.

How it would be if built today

From the 19th Century to the 21st Century, a lot has changed. The technological field is ever-changing with novel ideas and machinery entering the market every other day. If Starruca Viaduct were to be constructed today, the starting point would be to come up with proposals of different technical designs. As opposed to the 18th Century, where engineers were rare, the contemporary age is advantaged with the expertise of every nature. A team of experts would be drawn from all over the world based on experience.

Perhaps Michel Virlogeux and Norman Foster would be the key candidates for the project following their successful construction of the Millau Viaduct in France (Foster 37). Structural engineers and architects would be the key technical people in designing the project. The team of international experts would then look into the different available proposal designs and select at least six of them.

Afterward, the team would look into the designs and see the best ones or probably come up with a hybrid of the different proposals. Ultimately, they would probably come up with a cable-stayed viaduct. After this point, the team would embark on a test exercise to see whether the proposed design fits the topography of the location where the viaduct is to be constructed.

The second step would entail issuing calls for tenders from international contractors. Most probably, a consortium of contractors would win the tender as opposed to a single company as the former has the capacity to handle huge projects like the 21st Century Starruca Viaduct. Most probably, the different companies within the consortium would be tasked with handling different stages of the project.

One company might be dealing with the concrete construction, another one with dealing with the steelworks, while another one might be dealing with the hydraulics of the project. Another company would handle the bitumen works needed while another one would deal with the electrical aspects of the entire project. Different companies would be tasked with designing the different parts of the project like the steel deck. Ultimately, another company would be tasked with the overall management of the project.

The consortium would then come up with a timeline of the project, indicating the different stages of completing the different phases of the project. Humanity has become impatient with the need for instant results, which has become the contemporary culture, and this time would be of the essence. The viaduct would probably look like the following, which is an example of the modern-day viaduct – the Millau viaduct.

Materials

This viaduct would be constructed using three main materials, viz. concrete, steel, and pre-stressed steel. Others would include electric cables, bitumen, and other supporting materials. Plants would be established on the site to produce concrete for cost-effectiveness and reliability.

Methods

The construction would start by laying the piers’ foundations made of concrete. Each pier would have five piles with a depth of 20 meters or 60 feet. The piers would be close to 100 meters supported by temporary steel intermediates. Cranes and hydraulics would be used to make the tiers. In a bid to save time, the laying of the deck foundation would start immediately after the completion of the first three piers. The process of making the piers would be repeated until the 17 piers are made.

The steel deck would be designed and made offsite in a steel company, which would be part of the consortium. Then the different parts of the deck would be transported via road to the site. The preassembled parts of the deck would then be joined on site. The launching of the deck would be indifferent phases using the lift and push hydraulic system. For accuracy purposes, the different parts of the deck would carry a GPS receiver on the launching end in a bid to ensure that the predetermined coordinates are followed.

After placing the deck in position, pylons would then be erected. The pylons would be made offsite, transported to the site using trucks, and erected on the deck using crawlers. They would then be welded to the deck to make perfect vertical joints. This process would call for close monitoring using a special instrumentation program.

On the surface of the deck, there would be a layer of bitumen, which is flexible in a bid to cushion the surface from the adjustments of the steel structure probably due to expansion and contraction. The electrification process would then follow.

This stage would entail installing telephone sockets and temperature sensors coupled with other sensors to gather traffic, measure wind speed, and the structure’s oscillations, among others. The final step would be removing the entire temporary structures like the supporting steel intermediaries holding the piers. Then a toll plaza and a rest area would be constructed for accommodating the technical management personnel to monitor and maintain the viaduct.

Tools/Equipments

The commonly used tools in this project would be machines. The first machine is the crane for making the piers. The other major machine would be the hydraulic lifting machine for launching the deck. Others include support machines like trucks and welding tools for joining the different parts of the deck and any other wielding aspects of the project.

Labor force

Given that machines and technology have replaced the need for manual work, a workforce of 100 workers would be enough. Most of the worker’s would-be engineers.

Funding and cost

The funding of the project would come from a combination of efforts from both federal and local government. The cost of the project would be essentially numerous times of the $320,000, which was used to make the 19th Century Starruca Viaduct. The project would probably cost several billion dollars in contemporary times.

Conclusion

Starruca Viaduct is as one of the monumental bridges of the 19th Century. Made of concrete and stones, the viaduct runs for close to 350 meters in length, about 8 meters width, and close to 35 meters in height. The project was built manually under the watch of Julius Adams and James Kirkwood – the two most coveted civil engineers of the time. The project was one of its kinds as there had not been such a structure before. The main materials were concrete, Rosendale cement, and the Pennsylvania bluestone.

The stones were laid down one after the other until the project was completed. Most of the tools used were masonry tools and mules used for transporting the materials to the site. The project cost the British financiers close to $320,000.

If the project were executed today, the process would be easier courtesy of technology and innovation as explicated in this paper. The funding would most probably come from the federal and local governments, and the contract would be awarded to a consortium. The project would probably take eight months before completion.

Works Cited

Economic Development: Bridges of the Future. Web.

Foster, Norman. Millau Viaduct, New York: Prestel Publishing, 2012. Print.

Hungerford, Edward. Men of Erie, a Story of Human Effort, New York: Random House, 1946. Print.

Mott, Edward. Between the Ocean and the Lakes: The Story of Erie, Charleston: Nabu Press, 2010. Print.

Plowden, David. Bridges: The Spans of North America, New York: W. W. Norton, 2002. Print.

Young, William. Starruca: The Bridge of Stone, Susquehanna: Starruca Valley Publications, 1995. Print.