Introduction

Environmental pollution is a severe issue in the modern world because urbanization and constantly increasing production rates lead to higher CO2 emissions. This and many other gases contaminate the atmosphere, creating a greenhouse effect. According to Packham (2021, para. 2), Australia is “one of the world’s largest carbon emitters on a per capita basis.” This information demonstrates that the country should draw adequate attention to reduce its impact on the environment. That is why appropriate ecological forums and conferences are widespread in the nation, while its government wants to invest millions of dollars in new technologies that promise to improve the given state of affairs (Packham, 2021, para. 1). However, the data of the past two decades demonstrates that Australia has shown a decline in green production compared to other G7 nations (Andres and Mealy, 2021, p. 1). This information denotes that Australia seeks new technologies that reduce carbon emissions, and green steel production is among them.

Thus, the given report attempts to present the assessment of the green steel production technology. A few separate aims will contribute to achieving this overall goal. Firstly, it is necessary to deliver background information about the selected technology to identify how it works and why it deserves attention. Secondly, the report will overview the potential social and environmental impacts of green steel production. Thirdly, the identified impacts will become more evident when compared to the use of existing or alternate technologies to produce steel. Fourthly, it will be necessary to analyze and interpret the found information on the topic to see what outcomes the selected technology offers. Finally, the report will present conclusions that will summarize the data and provide recommendations as to whether green steel production is efficient technology. It is worth admitting that separate sections will introduce each aim, while the report will rely on case studies and official data to assess the chosen technology.

Background

Green steel production is a new technology that offers to revolutionize the process of steel manufacturing. Traditionally, this material is produced by burning coal, which results in almost two tons of CO2 emissions for every ton of steel (Allen and Honeyands, 2021, para. 2). This information results in the fact that the steel industry is significantly responsible for the greenhouse effect. Thus, the technology under consideration attempts to make the process above more environmentally friendly. Wood, Dundas, and Ha (2020, p. 19) explain that green steel production implies the use of hydrogen instead of coal, which only creates water as a byproduct. This information demonstrates that the proposed technology promises to emit fewer pollutants into the atmosphere.

When it comes to steel-making, one should highlight that there exist three ways of manufacturing it. The blast furnace is the most widespread approach that relies on burning coal. However, it is possible to use hydrogen instead of some portion of coal to strip oxygen from iron ore and create water (Allen and Honeyands, 2021, para. 11). At this point, it is necessary to stipulate that more hydrogen cannot replace coal “at a ratio of 1:1,” meaning that renewable electricity is needed (Allen and Honeyands, 2021, para. 12). This condition is present in Australia because much evidence proves that the country has plentiful alternative sources of energy (Wood, Dundas and Ha, 2020, p. 14). Recycling is the second possible approach that involves burning fossil fuels to remanufacture the material. The use of hydrogen could also make this process more environmentally friendly. Finally, direct reduced iron technology is the third way of producing steel, and it uses methane gas (Allen and Honeyands, 2021, para. 18). Even though this method has minor emissions, the green hydrogen technology can lead to more advantages.

Analysis of Impacts

Green steel technology deserves attention since it leads to a few advantages for numerous stakeholders. Firstly, it is evident that the principal goal of implementing this innovation is to protect the environment. Yong (2018, p. 51) admits that this technology can lead to significant improvement because it avoids polluting the atmosphere with large amounts of carbon dioxide. Muslemani et al. (2021, p. 128127) support the claim above and highlight that this positive effect is achieved because a significant portion of coal is excluded from the steel manufacturing process. In addition to that, the proposed technology leads to a better future because of avoided natural resources depletion and reduced global warming (Tiwari, Ahmad and Alam, 2017, p. 668). This information demonstrates that the discussed green steel technology can help Australia make a valuable contribution to fighting against the greenhouse effect.

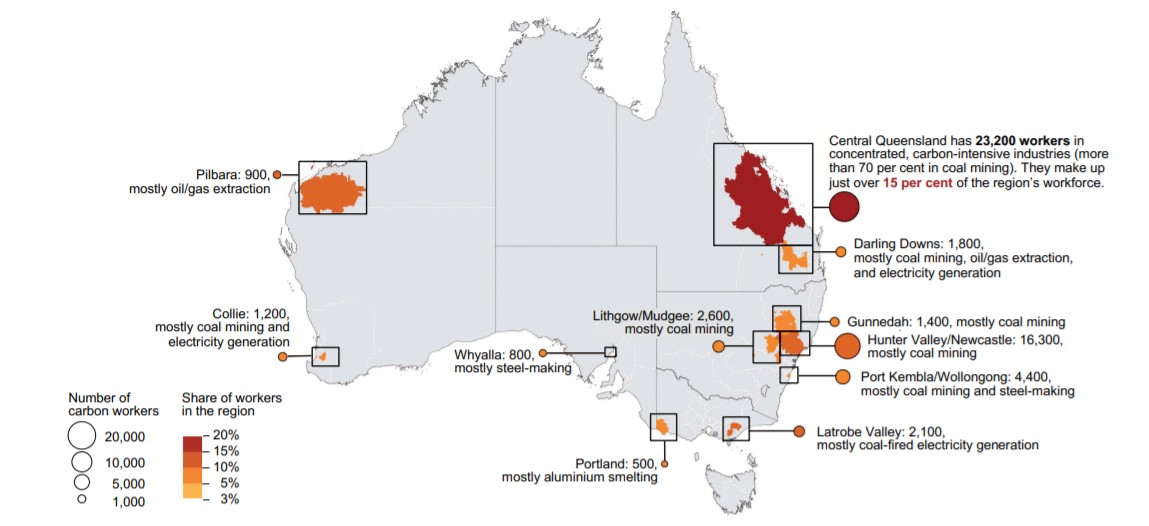

Secondly, the selected technology has the potential to bring positive socio-economic outcomes. Mathews (2020, p. 929) stipulates that green steel is almost all about cost reduction. Even though this statement is generalized, it represents an overall trend of using the technology, and further details will support the thought. On the one hand, the technology will provide individuals with some benefits. The rationale behind this statement is that Australia has approximately 100,000 carbon workers who are members of industries that produce many CO2 emissions (Wood, Dundas and Ha, 2020, p. 9). Figure 1 by Wood, Dundas, and Ha (2020, p. 10) below demonstrates how these workers are scattered across the nation. The future employment of these individuals is threatened because a global threat is to reduce the amount of CO2 emissions, which traditionally implies the reduction of the manufacturing process and, consequently, loss of jobs. However, the new technology addresses the problem and offers a way to preserve the manufacturing rates and create “tens of thousands of jobs” (Wood, Dundas and Ha, 2020, p. 29). This fact will contribute to improved socio-economic conditions in Australia.

On the other hand, the selected technology can also result in positive economic outcomes for the whole nation. This statement refers to the fact that green steel is associated with a cheap production process. Many analytical bodies forecast hydrogen production and shipment costs of less than US$2 per kg in the near future (Wood, Dundas and Ha, 2020, p. 22; Sharma, Gallagher and Sultoon, 2021, p. 466). This data demonstrates that Australia will need fewer financial resources to produce steel using the technology under consideration.

In addition to that, the green steel technology can help Australia maximize its potential. This statement implies that the country produces 38% of the world’s iron ore and only 0.3% of the world’s steel because shipping the raw material is cheaper for Australia than to use it in manufacturing (Wood, Dundas and Ha, 2020, p. 22). Thus, the implementation of the new technology will help the nation obtain more financial benefits from producing steel because it is one of the leading internationally traded commodities (Pooler, 2021, para. 1; Evans, 2021, para. 3). That is why there is a clear connection between the technology under analysis and economic benefits for Australia.

Thirdly, green steel production will present positive cultural and political impacts for Australia. Since many developed countries admit the necessity to address the climate problem, Australia should make sufficient efforts to meet the imposed trade requirements on carbon-intensive imports (Tucker and Meyer, 2021, p. 3). This information will contribute to the fact that Australia will have a positive image in the world, which will promote its cooperation with many international partners.

It is also necessary to admit that the proposed technology can imply some negative impacts. The transition from traditional to hydrogen manufacturing will mean technical difficulties and particular financial investment (Wood, Dundas and Ha, 2020, p. 24). Furthermore, some problems can arise if the government fails to implement the required policies to drive the demand for green steel, and price incentives can be a suitable option (Muller, Saddler and Melville-Rea, 2021, p. 10). Finally, Burdon et al. (2019, p. 10) admit that Australia’s failure to cooperate with international partners to develop and implement the technology can result in adverse outcomes for the nation. This information demonstrates that both advantages and disadvantages should be considered when assessing the technology.

Alternate Technologies

It is worth admitting that green steel is not the only technology that can be used to reduce CO2 emissions. Carbon capture and storage (CSS) is the first option that can be used instead of the technological solution under consideration. According to Arens, Ahman, and Vogl (2021, p. 110938), CSS implies capturing, cleaning, compressing, and transporting CO2, “which increases the overall energy consumption of steel-making.” This information demonstrates that this alternate technology requires more resources to be implemented. Furthermore, this approach does not imply the reduced extraction of coal and other fossil fuels, which will keep harming the environment.

The use of biomass with coal is another technology that can be used instead of green steel production. Allen and Honeyands (2021, para. 13) explain that biomass stands for “a fuel developed from living organisms.” This approach is said to produce fewer carbon emissions, but some drawbacks are still present. On the one hand, this technology does not eliminate fossil-fuel-derived emissions because some portions of coil are still implied. On the other hand, this approach can produce the most environmentally friendly results if these emissions are captured and stored (Allen and Honeyands, 2021, para. 14). However, such an approach is costly, which outweighs all the possible advantages of using this technology.

Discussion

The information above demonstrates that green steel production has both advantages and potential challenges, and it is reasonable to compare them. This activity indicates that positive aspects significantly outweigh adverse ones. The rationale behind this statement is that the disadvantages refer to difficulties associated with implementing the selected technology. However, the potential advantages essentially affect the whole nation and separate individuals. It has been found that green steel production can result in the fact that Australia will deal with a cheaper manufacturing process, which will lead to some economic benefits. The nation will also benefit because steel is a requested commodity internationally. Furthermore, this technology will be beneficial for multiple individual workers because it will ensure that they will keep working in the industry. It is also worth admitting that relying on the green steel technology will create a positive image of Australia, which will enhance the country’s international relationships.

The technology assessment also reveals that using hydrogen is better compared to other technological possibilities. Scientific evidence has demonstrated that CSS and the use of biomass with coal cannot be considered efficient alternatives to green steel production. The rationale behind this statement is that the first technique does not lead to reduced extraction of coal and other fossil fuels, while the latter one does not exclude fossil-fuel-derived emissions. Consequently, the comparison of the alternate technologies supports the suggestion that green steel production is an appropriate and practical approach to reduce carbon emissions and result in positive outcomes for Australia.

Conclusion

Reduction of CO2 emissions is a top priority for many nations, and Australia is among them. Green steel technology is gaining popularity in the country because it promises to bring a few positive outcomes. The potential impacts will be beneficial for the environment in a broad sense of the word. The Australian economic, cultural, and political spheres will face some improvement if the technology under analysis is implemented. Even though the proposed solution implies potential drawbacks, they are not as essential as positive outcomes. Furthermore, the comparison of alternate technologies has revealed that green steel production using hydrogen instead of coal is an optimal decision for Australia to manufacture steel and avoid harming the environment. That is why the technology assessment reveals that the Australian government should keep investing efforts and resources in introducing green steel production.

Reference List

Allen, J. and Honeyands, T. (2021) ‘Green steel’ is hailed as the next big thing in Australian industry. Here’s what the hype is all about. Web.

Andres, P. and Mealy, P. (2021) Navigating the green transition: insights for the G7. Web.

Arens, M., Ahman, M. and Vogl, V. (2021) ‘Which countries are prepared to green their coal-based steel industry with electricity? – Reviewing climate and energy policy as well as the implementation of renewable electricity’, Renewable and Sustainable Energy Reviews, 143, 110938.

Burdon, R. et al. (2019) Innovation and export opportunities of the energy transition: insights from the Australian-German energy transition hub. Web.

Evans, S. (2021) Could green steel become one of Australia’s most strategic minerals? Web.

Mathews, J. A. (2020) ‘Schumpeterian economic dynamics of greening: propagation of green eco-platforms’, Journal of Evolutionary Economics, 30, pp. 929-948.

Muller, F., Saddler, H. and Melville-Rea, H. (2021) Carbon border adjustments: what are they and how will they impact Australia? Web.

Muslimani, H. et al. (2021) ‘Opportunities and challenges for decarbonizing steel production by creating markets for ˈgreen steelˈ products’, Journal of Cleaner Production, 315, 128127.

Packham, C. (2021) Australia promises $437 mln for low emission technology. Web.

Pooler, M. (2021) ‘Green steel’: the race to clean up one of the world’s dirtiest industries. Web.

Sharma, P., Gallagher, B. and Sultoon, J. (2021) ‘Green pivot: can Australia master the hydrogen trade?’, The APPEA Journal, 61(2), pp. 466-470.

Tiwari, M., Ahmad, S. and Alam, S. (2017) ‘Production of green steel through green manufacturing using most innovative green and cleaner technology’, International Journal of Engineering Sciences & Research Technology, 6(4), pp. 668-676.

Tucker, T. N. and Meyer, T. (2021) A green steel deal: toward pro-jobs, pro-climate transatlantic cooperation on carbon border measure. Web.

Wood, T., Dundas, G. and Ha, J. (2020) Start with steel. Web.

Yong, Y. (2018) ‘Challenges and responses in the Chinese steel industry’, Asian Steel Watch, 05, pp. 44-53.