Abstract

For any building project, an electrical layout for building (ELB) is required to give the construction engineers the map of the house. However, the approvals make the construction project to delay as they take extensive time to implement. The main problem is majority of organization consultants have defected ELBs, that do not match the authority prerequisites. The research aims at improving the Consultant’s Electrical Drawing for the building by implementing Lean Six Sigma (DMAIC) for the Authority in UAE to reduce the approval time. The acquisition of approvals ensures honest contractors, who ensure the utilization of safe and standard methods, including electrical layouts. The methods used in the research include interviews and field observations together with literature reviews from journals, conference papers, and databases, including SCOPUS, EBSCO, Proquest, and Google Scholar. The key research objectives include identifying the root causes of the electrical layout for building (ELB) drawings defects, identifying the root causes of the electrical layout drawings defects and to investigate the application of DMAIC methodology in improving the technical drawing process. The expected outcome includes reducing the ELB errors, thus enhancing the immediate construction process.

KEYWORDS: Consultants, electrical drawing, approval process; Construction projects delay, DMAIC, Lean Six Sigma

Introduction

All the structural buildings require to be accomplished in a specified time and schedule. However, there are many people involved in such project works including authorities, contractors, designers, clients, and suppliers, who share the same goal of reducing costs and delivery time. The construction project delay has many consequences such as cost and overrun, stress among the contractors, disputes for all involved parties, and poor-quality work due to rush. In order to eliminate the ramifications and derive the benefits, there is need to minimize the construction project delays (Rachid et al., 2019). Many building clients frequently become frustrated with the electrical outlet’s locations or anticipate changing the switch position in the building. To a greater extent, that is why electrical structural engineers develop an electrical plan (electrical drawing), which is the rough layout of what a building’s electrical system resembles before installation to avoid construction delays. The electrical drawing is not only essential to the electrical engineer but also the customer (Adelakun et al., 2020). Not acquiring the electrical layout for building (ELB) causes project delay, which negatively affects the success of the entire project.

Significantly, a technical drawing refers to a visual representation of where all the building’s electrical points need to be situated. Therefore, it describes the number of switches, sockets, circuits, and outlet locations. Despite that, it showcases entire electrical appliances and lighting fixtures. Different symbols become utilized during the electrical plan to highlight which materials need to be utilized at a given point, these symbols arrangement in the buildings massively determines the electrical drawing. A study by (Adelakun et al., 2020) shows electrical drawing is essential as it ensures building safety because it enables the electrical system to run smoothly and safely. Having an electrical diagram enables all the crucial electrical preparation processes to complete before moving to another step of constructing the building.

However, most of the ELB that is done by the consultants contain massive errors and defects, both in the design itself and the electrical calculations, which can cause building electrical unsafety to the occupants of the buildings. The consultants are responsible for designing the building hole electricity, which is to be submitted to the authority. In that process, the electrical engineer conducts an electrical drawing audit to ensure that the layout meets the authority requirements for approval. Otherwise, the electrical engineer who’s working in the authority gives feedback regarding the electrical design and calculation for the electrical drawing consultants, for example, calculating the proper breaker (CB) and type of CB, among other calculations, including capacitor bank. Such errors give the electrical engineer much time to revise the design, deterring their approvals and may result in financial losses before sending the consultant to fix the technical drawings (Kamal et al., 2020). The delays in getting approvals also lead to setbacks, including construction process delays. The defects in electrical drawings can be attributed to inexperienced consultant engineers, who have higher job ratings and have not familiarized themselves with large building projects.

The building construction companies are currently operating in an increasingly competitive marketplace. Regardless of their size and experience, they are forced daily to offer the highest quality electrical diagrams with no defects. Companies failing to enhance productivity, quality, and client satisfaction encounter a bleak future whereby business rivals overtake their market share, resulting in huge financial losses. The business contracting consultants need to offer them the best guidelines and measures to compete effectively in this construction-changing environment. In our case, for the consultants to fix the errors in their electrical drawings, they require to execute a fixed methodology, such as Lean Six Sigma (DMAIC), to attain vast improvements in productivity, quality, and client satisfaction (Sreedharan et al., 2018). One of the biggest concerns with the consultants working in Construction company is to eliminate defects, like electrical drawing calculation and design errors, which delay the project approvals. In that case, the firm consultants waste their resources and time reworking the ELB process and lose the client’s trust and satisfaction due to the delayed construction process (National Academies of Sciences, Engineering, and Medicine, 2017). The companies and consultants need to improve the quality of their technical drawings processes to create a strong business strategic advantage and introduce themselves as an international firm for further prospects. This study examines electrical drawings quality issues and offers a solution to minimize the most critical errors. In order to attain this, the study proposal advocates for the use of the most effective quality management and improvement methodology, that is, Lean Six Sigma, in particular DMAIC (Define, Measure, Analyze, Improve, Control) as a problem-solving and improvement model.

The study undertakes a literature review of DMAIC, indicating the positive impact and benefits of the theory on the electrical drawing on eliminating defects for its quick approval. Therefore, the study aims at enhancing the electrical technical drawings undertaken by the consultants. By integrating and executing lean Sigma (DMAIC) to the ELBs, the study outcomes will have reduced ELB auditing for the electrical engineers in the authority, which will improve the construction process due to approving it in a shorter time.

The research report for the study will involve the literature review, which will discuss the major accomplishments in the ELBs in buildings, the use of DMAIC tool, causes of project delays, research gap, and provide critical discussion. The report will have research methods, the study aims and objectives, and provide a feasible case study directed towards improving the electrical drawing for the buildings to reduce the approval time and minimize construction project delays.

Literature Review

Major Accomplishments in Electrical Layout for Buildings

According to (Sreedharan et al., 2018) over the several years, the electrical drawings have improved from manual designing and calculations to specialized software, which aids in minimizing the layout errors. The availability of the maps has made the electricians and other construction workers have full detail on how to install and repair the electrical systems. Over the years, several building approval agencies have been developed to ensure that the building adheres to the standards to ensure the safety of the occupants. In that case, most companies have highly invested in having highly trained and qualified engineer consultants to develop the best electrical layout for building (ELBs) (Saldarriaga et al., 2019). The literature pinpointed the role of approval authorities in designing the best ELBS, but it did not showcase how the approvals assist in reducing layout errors.

A study done by (Zarei et al., 2018) shows that with internal and external consultations, the errors and defects associated with electrical drawings are effectively tackled to enable approval for beginning the building construction process. The availability of computers and computation software has increasingly led to effective technical drawings. In that case, the technical diagrams contain extensive database regarding the site plan, including external wiring, floor plans, and structural location. A study by (Sreedharan et al., 2018) shows that wiring diagrams have a blueprint of electrical circuits and their physical connection. The literature identified defects for ELBs for buildings, but it did not offer recommendations to improve or eliminate the errors.

According to the statistical reports, the entire ELBs must embed comprehensive details, including light fixtures, power transformers, the main and fused switches, and the tiebreakers. Other information necessary to integrate in the technical drawings includes the interconnection and switching of the electrical system parts, such as electrical wires and calculating size and voltage of equipment, like generators, batteries, and solar panels (Madsen & Madsen, 2016). Such measures have been implemented to eliminate design errors associated with electrical drawings (Saldarriaga et al., 2019). The literature identified the primary components of ELBs, but it did show how their absence causes delay in construction projects.

Different researches have been done on how to improve electrical drawings. However, the available literature does not indicate how much electrical drawing errors cause delays in approval leading to increased construction process wait-time (Sreedharan et al., 2018). All the components of wiring diagrams should be designed error-free to ensure the quickest approval of the projects (Madsen & Madsen, 2016). Multiple research advocates for interscapular knowledge exchange, whereby the qualified engineers of the client company and the consultants work together to attain non-defective technical drawings during the design. The study does not provide data on how technical diagram errors cause construction project delays, but it advocates for interdisciplinary fields working together.

The Lean Six Sigma (DMAIC) Tool Use in Construction Field

Literature has advocated using the DMAIC tool and technique to improve the wiring diagrams, which deploys other quality and improved performance models, including control plan, measurement system analysis, Pareto chart, fishbone diagram, and capability analysis. The DMAIC approach usage helps analyze a process before implementation, which enables the fixation of a wrong issue that can impact the whole project (Wogan et al., 2017). The use of DMAIC process during the ELB approval by authorities can minimize construction project delays leading to their success. The phenomenon results in general performance improvement and ultimately filtering such through to happier clients. Through rectifying the electrical drawing defects, the literature suggested methods, including DMAIC, ensure improvement of the process, minimizing the approval delays and recurrent reworking (Newbery et al., 2021). The literature gives statistics on importance of using DMAIC tool.

Despite improving the design quality, the Lean Six Sigma (DMAIC) acts as a management strategy and philosophy applied to each process, like electrical drawing, to abolish the error root causes. To a greater extent, several authors argue that the primary advantages to the building electrical design development companies from applying the Six Sigma. They include defects elimination, cycle time improvements, cost reduction, rise in profits, and improved customer experience (Wogan et al., 2017). The literature suggests that the DMAIC methodology becomes utilized in design process enhancement. It can be expanded to improve other business elements, including legal and purchasing, attached with electrical drawings. Incorporating DMAIC with other techniques helps in encouraging employee participation in the project, increases the process knowledge of the less qualified and inexperienced building specialists, and engendering problem-solving by using statistical thinking concepts (Bhawika et al., 2019). The literature does not give the names of other techniques to be incorporated with DMAIC to improve construction delays despite identifying the root causes of ELB failure.

According to diverse research undertaken, using DMAIC in this research project will enable all the individuals involved in the electrical diagram to enhance their skills and knowledge, thus effectively solving problems through gained statistical expertise (Hsu et al., 2017). Therefore, all the consultant engineers receiving high stars despite having decreased ratings will have improved experience in improving the electrical drawings, making them error-free. The study will benefit from the five interlinked phases: define, measure, analyze, improve, and control. The literature identifies DMAIC stages, but it does not show how they will reduce the project construction delays.

Regarding the definition stage, this phase entails determining the project team’s responsibilities, customer requirements, and expectations, elaborating the project scope and limits and establishing the project’s identified goals using the project charter (Wogan et al., 2017). The other step involves mapping the electrical drawing process to help comprehend the defects in the implemented design. The ‘measure’ DMAIC stage involves choosing the measurement factors to be enhanced, offering a structure to assess pre-existing performance, and evaluating, contrasting, and monitoring subsequent improvements and capability. The frequent revision of electricity drawings shows that the operations failure costs exceed the target of escalated design defects over time due to denied approvals (Newbery et al., 2021).

The study done by (Riva et al., 2019) indicates that it is essential to prioritize the causes of frequent electricity design process failures. This can be achieved by integrating the Pareto chart to showcase the highest triggers of the wiring diagram errors, which the design quality inspector might not detect. The ‘analyze’ phase focuses on determining the problem’s root causes, comprehending why defects have occurred, and comparing and prioritizing chances for better advancement. The study encourages the incorporation of a fish-borne (cause-effect) diagram to pinpoint the root causes of the electrical drawing failure. Improper design maintenance and poor process release procedure can attribute to such defects. The ‘improve’ stage concentrates on deploying. statistical techniques to create future improvements to minimize the number of quality issues Last is the control phase, which focuses on sustainability enhancements and monitoring the ongoing performance. The stage enables institutionalization and documentation of ELB improvements through training wiring operators on the newly used tools and the current modified processes and updating the control plan, which is essential for this project. The literature gives a vivid description of each DMAIC process phase and the attached advantages in minimizing the construction delays of the ELB for building.

Technical Drawing Problem Improvement by other Sources

Several study sources have developed ways to improve the problem of quality electricity diagrams, which have resulted in quicker approvals. Literature suggests using Deming’s continuous learning and process enhancement model plan-do-check-act (PDCA). Despite PDCA being a learning model intended for executing advancement activities, it also envisions data collection and analysis directed towards finding the problem associated with electricity layout (Realyvásquez et al., 2018). The literature fails to compare PDCA with DMAIC to showcase which is more effective in reducing construction delays despite giving its benefits to improve ELB.

According to literature, such a phenomenon enables project team members to take decisions and courses of action grounded on actual and scientific statistics instead of relying on personal knowledge and experience, as with many consultation wiring companies. The literature does not highlight the effective decisions to be undertaken by the project team despite advocating for the same.

Causes of Construction Project Delays

According to (Ren et al., 2021), There are many causes of construction project delays. The first one is budget inaccuracies. A building project’s budget might suffer greatly if an incorrect estimate is provided. Several positions are temporarily or permanently axed. In order to avoid overspending, estimates must be accurate. Software streamlining bids, estimates, and financial project planning makes the process less risky. As a result, contractors need a simple method to enter the job into their construction management platform and start to work. Real-time access to data is essential after the work is started to assess how progress is compared to expenses. The literature provides the causes of project delay but fails to show how they should be effectively implemented to realize results.

The study done by (Madsen & Madsen, 2016), shows that the data reporting between the field and the office is typically delayed due to outdated spreadsheets or on-premise software solutions. People responsible for monitoring project productivity sometimes work with days, weeks, or even months old data. Automating procedures and giving sophisticated data and analysis tools in real-time is the answer provided by a cloud-based, integrated construction management system

According to (Umar, 2018), Labor is a major cause of building delays in the modern-day. While many skilled individuals laid off during the crisis could find employment in other areas, the downturn impacted this business. Construction jobs have seen a decline in popularity among newer employees entering the market. That dynamic is shifting due to the use of technology to streamline human resources and labor management processes in construction companies. Building a construction schedule may be made or broken by correctly assigning a team.

Approvals also cause construction delays. The government authorities require buildings, particularly commercial, industrial, and residential buildings, to have permits. Lack of compliance with the requirements may cause approval denial; thus, construction increases wait time (Ren et al., 2021). The project obstruction is frequently caused by overreliance of experts in each stage due to many paperwork involved and their reluctance in executing their duties and responsibilities (Bhawika et al., 2019). When owners are in charge of a project, they have to make choices that keep it going forward. Keeping construction projects on schedule and within budget may be achieved by swiftly coordinating and approving tasks. The literature indicates how approvals causes project delay and their benefits but fails to highlight the attached consequences if not acquired.

A study done by (Wogan et al., 2017), indicate that every following task on the construction site might be delayed if a subcontractor is overworked or uninformed of the timeframe for the bigger project. There is an increased possibility of legal challenges or disputes if a contractor is not in compliance with their bonding, license, or other contractual requirements. In order to ensure that initiatives go off without a hitch, open communication is crucial. The literature indicates how a subcontractor causes project delay but fails to highlight the attached consequences.

According to (Ren et al., 2021), Projects might be delayed or even done wrong if the right and left hands aren’t communicating. It does not matter whether it’s an owner, customer, in the field, or the office; everyone should be kept up to speed on any new information that comes to light. In a disagreement, the general contractor may rely on the communication and cooperation audit trails to ensure that teams have all the information they need to address problems before they become a project problem. The literature shows how lack of communication causes building delay but it fails to show how it affects the success of the whole construction project.

Data Collection Methods

The tools and techniques for collecting and analyzing data include interviews, case studies, and observations. They will help preserve the information used in the future interpretation of the research findings (Prashar, 2020). According to a study done by (Sarstedt et al., 2019) the data collection helps in identifying the actual information regarding on what the researcher wants to examine in the study problem. The data collection methods help in spotting any errors committed during calculating and designing ELBs. The literature shows how the use of different data collection methods assists in identifying ELBs defects but it does not indicate the weaknesses of using them.

Research Gap

The research gap identified is that there are no studies on electrical drawings failure and the impact on permit approval acquisition. The topic requires future research as electricity diagram defects make the company not obtain approval, thus delaying the construction process (Tariq et al., 2020). In modern society, the acquisition of construction wiring permits is crucial to ensure the future safety of residents and enable countering electricity fire hazards adequately in case they occur.

Research Purpose and Objectives

Research Aim

The research aims to improve electrical drawings for buildings via Lean Six Sigma (DMAIC) implementation and reduce the average approval time in the construction project to avoid delay.

Research Objectives

There exist several research objectives that will guide in attaining the study aim. They include:

- Identify the main reasons for delays in the construction projects.

- Identify the root causes of the electrical layout drawings defects.

- Investigate the application of DMAIC methodology in improving the technical drawing process.

Methods

Tools and Techniques

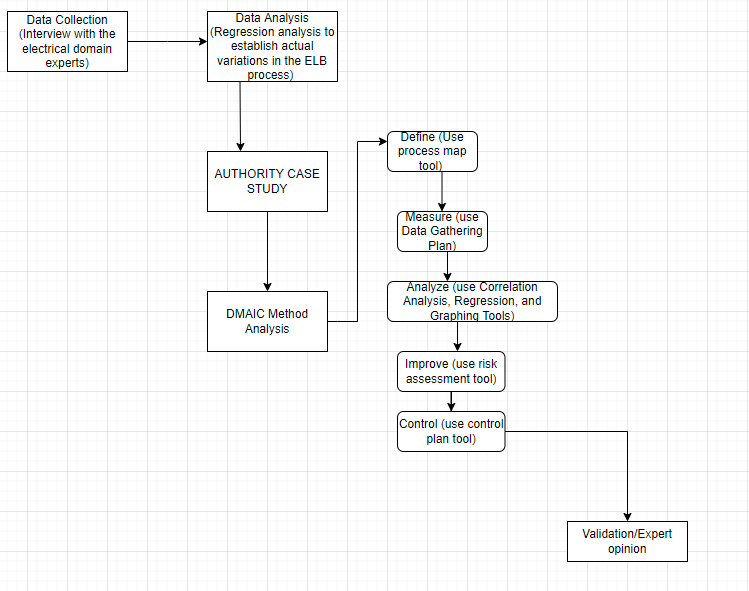

The research will be conducted by reviewing the literature and undertaking interviews. This will ensure the results obtained from the research indicate that utilization of the DMAIC is essential in improving the ELB to avoid construction project delays. The tools and techniques for collecting and analyzing data will include interviews, case studies, and observations. They will help preserve the information used in the future interpretation of the research findings (Prashar, 2020). According to a study done by (Sarstedt et al., 2019) the research methodology diagram is essential as it guides the researcher on pinpointing the links between the study topics and earlier deployed methodologies by other investigators. In becomes easy to identify the research gap by using it. The data collection carrying regression analysis helps in spotting any errors committed during calculating and designing ELBs. This is the research methodology diagram that will be follow:

The data will be gathered through both primary and secondary data collection methods. After that, regression analysis model will be used to establish the actual variations in the ELB process. In the authority case study, the DMAIC method will be used and each phase will use a different tool to ensure whether they will improve the ELB errors made by the consultants.

Primary Data Collection Method

Primary method involves data obtaining directly from the first-hand source by the researcher (Sarstedt et al., 2019). primary data collection method will include interviews and field observations. The interviews will be conducted with the electrical domain experts, including the consultant and engineers, to collect data. Moreover, discussing the most frequent errors in auditing ELBs. Secondly, through field observations of the technical drawings of ELBs, the data will be assembled regarding frequent errors. A schedule will be prepared indicating the number of consultants committing the most mistakes and the period for each case. In that case, the data will assist in enhancing the ELB auditing process and adopting them quickly.

Secondary Data Collection Method

The secondary method involves acquiring information by someone instead of actual user, thus being readily available for use (Prashar, 2020). Regarding the secondary data collection method, the literature review from journals, conference papers, and databases, including SCOPUS, EBSCO, Proquest, and Google Scholar, will be used to collect gather by reviewing twenty sources. The DEWA Circular & Regulation Book as well as, SEWA Rules and Regulation Book will be used to gather data as it gives massive information regarding the company in the study question. The checklist that include the main rules and regulation that related to electrical supplies in the building

Data Analysis

In data analysis, the statistical tool that will be used is regression. This will help establish the real causes of variations in the ELB process. In that case, the impact of one variable over the other will be measured and prove or disapprove available hypotheses on what is causing the frequent electrical drawing defects (Sarstedt et al., 2019). The solutions obtained will be formed and tested.

Case Study

In order to get a tangible, contextual, and in-depth understanding of an actual issue, a case study is the ideal research design. It gives one a chance to delve further into the case’s essential traits, meanings, and ramifications (Umar, 2018). The authority will be used as the case study. It is located in the United Arabs Emirates (UAE), and it is a government facility providing residents with water and electricity. It has over 4500 employees and over 35 branches countrywide. The authority is a state-owned enterprise type of business (Umar, 2018). The use of the DMAIC methodology will lower the approval time when reviewing and auditing ELBs from consultants to ensure they match the requirements.

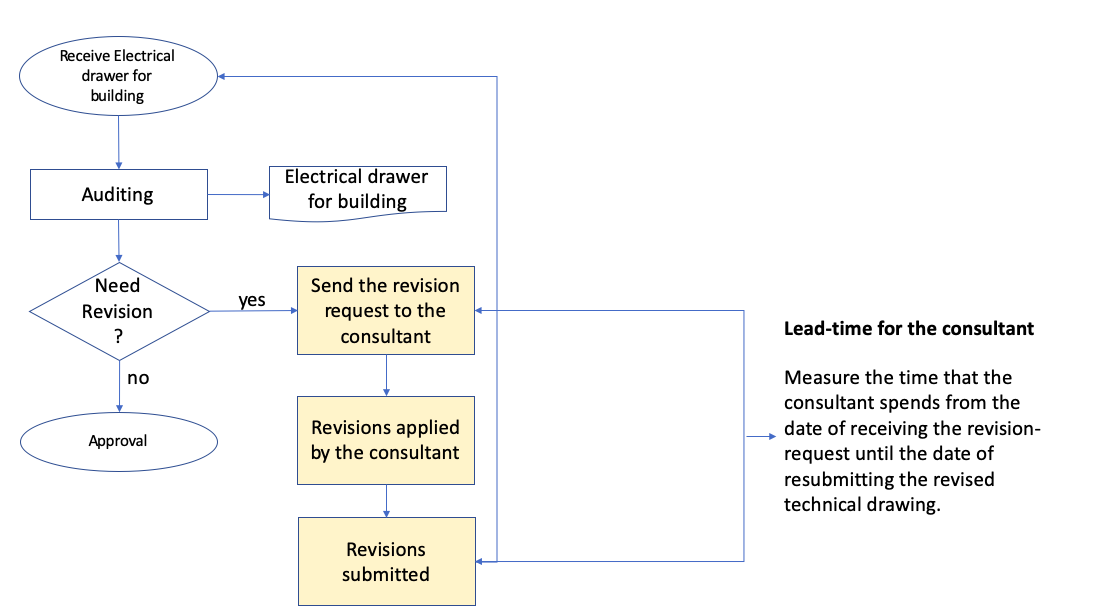

The ‘define’ phase will establish the project scope and limits and give team members duties. The process map tool will be used in this initial DMAIC stage. The second phase is ‘measure, ‘which will identify the highest triggers of the ELB defects. The data gathering plan tool will be deployed in the second process (Newbery et al., 2021). In the ‘analyze’ phase, the root causes of the ELB’s defects and failures will be established and adopting strategies for improving them. The correlation analysis and graphing tool will be used to identify cause-effect relationships (Wogan et al., 2017). The ‘improve’ stage will be geared towards minimizing the quality issues of the ELBs. The management tools, including risk assessment, will be used to create future improvements. The ‘control’ phase will concentrate on sustainability and checking the ongoing performance (Riva et al., 2019). The control plan tool will be used in this phase to ensure documentation and institutionalization of ELB enhancements via training all wiring operators.

Initial Findings

Define Phase

From the process map above, the primary problems of the case study are that there are many revisions of the ELBs approvals from the consultant to the authority and back to which causes time wastage. The case study shows that due to frequent ELB revisions, the consultants may not be developing the good electrical diagrams for the clients, which may cause fire and can access the plan in case of emergency. However, after such rectifications the customer’s receive safety enhanced building free from electrical faults. The problem can be identified by undertaking auditing of the ELBs and determining whether they require revisions. When a revision occurs, it shows that the issue is present and it requires to be corrected.

Measure Phase

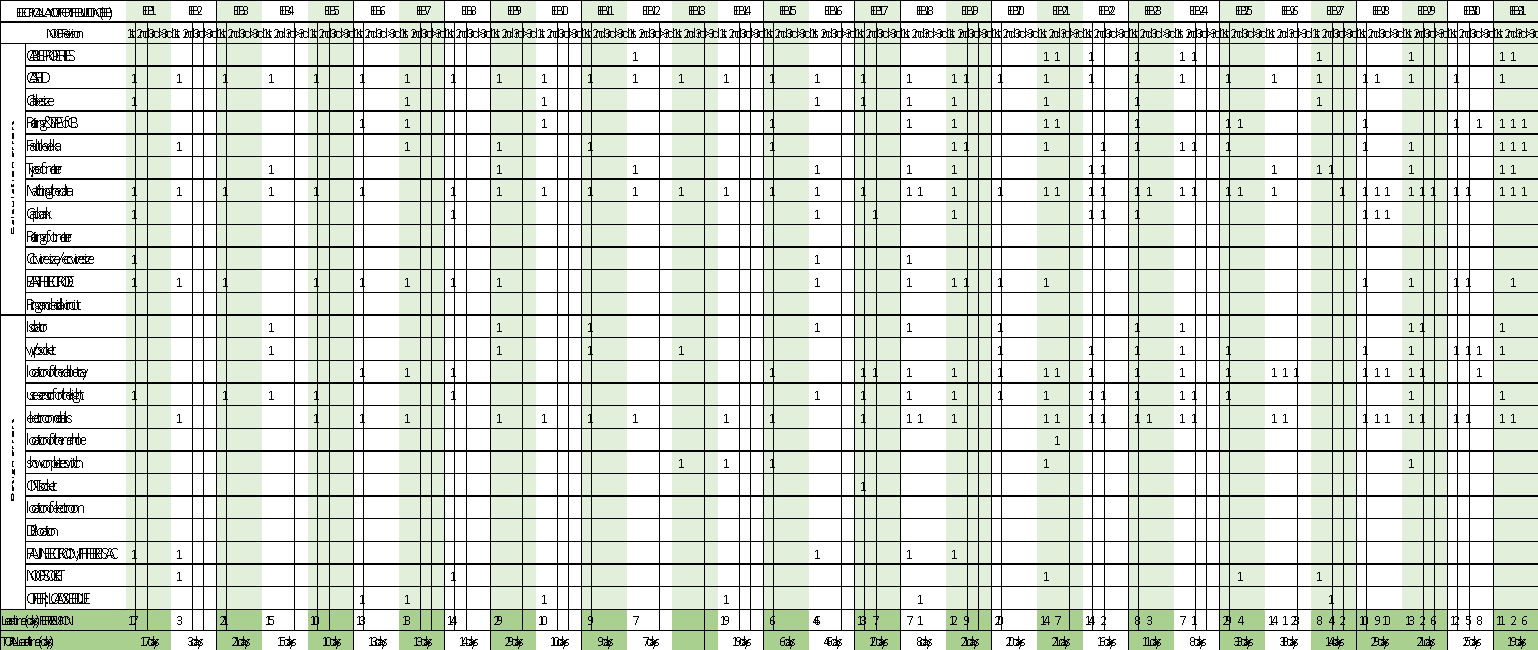

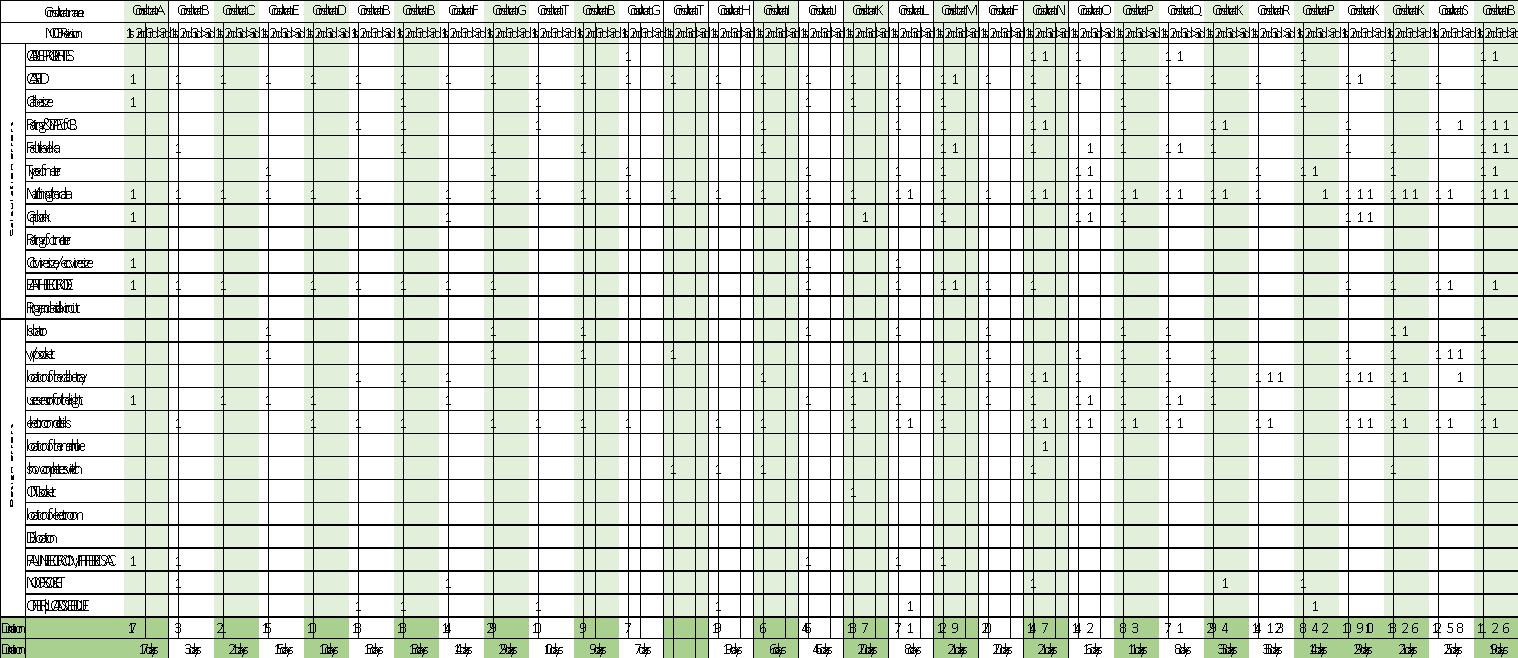

In the measure phase, the available data was collected by a worker having the direct information flow at the authority and the employee obtained SEWA book database surrounding the number of ELBs revisions undertaken. The worker was able to determine the time taken to approve the ELBs and the number of faults in each ELB committed by individual consultant in the authority. However, the interviews will be done in the next semester, whereby the data will be extracted from the ELB auditors and the consultants to determine the rationale causing ELB errors.

Analyze phase

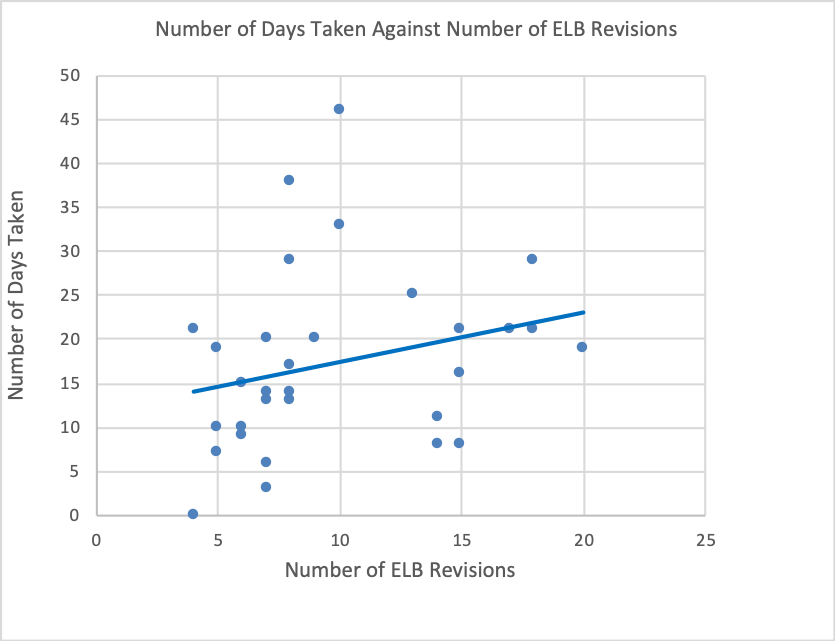

On the analyze phase, the correlation analysis of two variable involving the ELB errors and the time required to undertake the revisions will be graphed. Another correlation analysis will include the number of auditing ELB revisions by each consultant and the time used by the consultant to rectify them. In the measure phase, the current approval duration ranges between 6 days to 46 days depending on the design and calculation error revisions of each ELB.

From the graph above, it shows that the is a positive correlation between number of days taken against the number of ELB revisions. Therefore, reducing the number of the ELB revisions by the consultants can significantly lower the approval time taken as it takes lower period to rectify them.

From the graph above, it shows that the is a positive correlation between number of lead days taken by the consultants against the number of errors in each ELB. Therefore, reducing the number of the ELB errors by the consultants can significantly lower the approval time taken as it takes lower period to rectify them. The data was collected by an employee working at the authority and tells the investigator that the delay in approvals is due to many ELBs revisions in rectifying the design and calculation errors committed by the consultants.

Conclusion and Future Plan

To a greater extent, the ELB errors committed by the authority consultants tend to cause many revisions to obtain the approvals. The key findings established is that there is a stronger correlation between the number of ELB revisions undertaken by the consultant and the days taken. Some of the design and the calculation error committed by the consultant may take different lead times to rectify. In the measure stage, the duration required for the approval of the revised ELBs will be datamined. More data will be collected during the analyze phase to ensure the examined data reflects the actual root causes of the ELB errors. In the next semester, during the improve phase, the researcher will construct likely solutions to the research problem, select and modify the best solutions, undertake the validation testing, and document the key findings. Lastly, during the control phase, the obtained solutions will be validated and the all related changes be documented. After that, the investigator will write a comprehensive action plan, including the recommendations on what consultants need to do to avoid ELB defects for quick and direct approvals. The Gantt chart will illustrate a project timeline and progress for Project II. See Table 1.

Table 1. Gantt chart

References

Adelakun, N.O., Olanipekun, B.A. and Asogba, S.O. (2020) ‘Design of an electrical installation of a storey building’, International Journal of Engineering Technology Research & Management IJETRM, 4.

Bhawika, G.W. and Suef, M. (2019) ‘Acceleration for the administration process of project contract in power plant service company using DMAIC’, In Journal of Physics: Conference Series (Vol. 1175, No. 1, p. 012196). IOP Publishing.

Hsu, C.H., Chen, P.S. and Yang, C.M. (2017) ‘An application of six sigma for improving thee of power supply’, TELKOMNIKA Indonesian Journal of Electrical Engineering, 11(10), pp. 6087-6094.

Kamal, K.E., Hossian, A.M., Mohamed, M.A. and Ahmed, W.K. (2020) ‘Implementation of six sigma methodologies in automotive wiring harnesses manufacturing companies. “ABC” plant case study’.

Madsen, D.A. and Madsen, D.P. (2016) Engineering drawing and design. Cengage Learning.

National Academies of Sciences, Engineering, and Medicine (2017) Enhancing the resilience of the nation’s electricity system. National Academies Press.

Newbery, D., Pollitt, M.G., Ritz, R.A. and Strielkowski, W. (2018)’ Market design for a high-renewables European electricity system’, Renewable and Sustainable Energy Reviews, 91, pp. 695-707.

Pandey, P. and Pandey, M.M. (2021) Research methodology tools and techniques. Bridge Center.

Prashar, A. (2020) ‘Adopting Six Sigma DMAIC for environmental considerations in process industry environment’, The TQM Journal.

Rachid, Z., Toufik, B. and Mohammed, B. (2019) ‘Causes of schedule delays in construction projects in Algeria’, International Journal of Construction Management, 19(5), pp. 371-381.

Realyvásquez-Vargas, A., Arredondo-Soto, K.C., Carrillo-Gutiérrez, T. and Ravelo, G. (2018) ‘Applying the Plan-Do-Check-Act (PDCA) cycle to reduce the defects in the manufacturing industry. A case study’, Applied Sciences, 8(11), p. 2181.

Ren, X., Li, C., Ma, X., Chen, F., Wang, H., Sharma, A., Gaba, G.S. and Masud, M. (2021) ‘Design of multi-information fusion based intelligent electrical fire detection system for green buildings’, sustainability, 13(6), p. 3405.

Riva, F., Gardumi, F., Tognollo, A. and Colombo, E. (2019) ‘Soft-linking energy demand and optimisation models for local long-term electricity planning: an application to rural India’, Energy, 166, pp. 32-46.

Saldarriaga-Cortés, C., Salazar, H., Moreno, R. and Jiménez-Estévez, G. (2019) ‘Stochastic planning of electricity and gas networks: an asynchronous column generation approach’, Applied energy, 233, pp. 1065-1077.

Sarstedt, M. and Mooi, E. (2019) Regression analysis. In A Concise Guide to Market Research (pp. 209-256). Springer, Berlin, Heidelberg.

Sreedharan V, R., Kannan S, S. and Trehan, R. (2018) ‘Defect reduction in an electrical parts manufacturer: a case study’, The TQM Journal, 30(6), pp. 650-678.

Tariq, S.H. and Ahmed, Z.N. (2020) ‘Effect of plan layout on electricity consumption to maintain thermal comfort in apartments of Dhaka’, Energy Efficiency, 13(6), pp. 1119-1133.

Umar, T. (2018) ‘Causes of delay in construction projects in Oman’, Middle East Journal of Management, 5(2), pp. 121-136.

Wogan, D., Pradhan, S. and Albardi, S. (2017) GCC energy system overview–2017. King Abdullah Petroleum Studies and Research Center: Riyadh, Saudi Arabia.

Zarei, B., Sharifi, H. and Chaghouee, Y. (2018) ‘Delay causes analysis in complex construction projects: a semantic network analysis approach’, Production Planning & Control, 29(1), pp. 29-40.