Introduction

It has long been argued by scholars and business administrators that effective communication is indispensible for proper functioning of supply chain. At this point, there are numerous cases which show how information technology such as Internet can benefit suppliers, manufactures, distributors and customers. This report is aimed at discussing the best practices which are adopted by modern businesses.

For this purpose, it is necessary to review scholarly works that examine the importance of information communication in supply chain management.

Furthermore, it is necessary to show this knowledge can be applied to some real life situation, in particular, to the case of Betta Struts, the enterprise which has recently introduced an e-supply chain. It is quite possible to argue that this company show how one can effectively adopt IT technologies. Some of their strategies can be emulating by other manufacturing companies.

Literature review

Quantitative and qualitative benefits

A great number of researchers have already discussed the benefits of adopting information technologies in the work place. For instance, in their study, Elizabeth Williamson, David Harrison and Mike Jordan identify several areas where Internet can be applied, namely: procurement, order processing, customer service, inventory management, workload planning, etc (2004, p 380).

They also argue that the adoption of these technologies can bring such benefits as ability to reduce labor costs, decreased expenditures, and finally ability to incorporate outside suppliers into the structure of the company (Williamson, Harrison & Jordan, 2004, p 380).

The argument advanced by the authors is that Internet accelerates the flow of information and this makes supply chain more responsive and flexible. In this context the word “responsive” means that that supply chain is able to react to the fluctuations in demand.

To some degree, this argument is echoes by other scholars. In the study, Gunasekaran and Ngai discuss hypothetical advantages of introducing IT into supply chain (2004). They lay stress on such benefits as reduced paper transactions, simplified order cycle, and ability to take the so-called Just-in-Time approach (Gunasekaran & Ngai, 2004, p 280).

Among other advantages of using IT we can single out the reduction of costs which results from knowing the exact demand generated by the efforts of sales managers (Tokar, Aloysius, Waller & Williams, n.d. p 16). The thing is that retail promotions is a very significant factor that affects the demand for a product; in many cases the manufacturer is not able to match this demand.

In part, this failure can be explained by lack of communication and coordination between retailers and wholesalers on the one hand, and manufacturing facilities, on the other (Tokar, Aloysius, Waller & Williams, n.d. p 16). The application of information technologies can greatly contribute to the solution of this problem.

When we speak about the importance of information communication, we need to mention those software solutions which are used to forecast demand and schedule production. These applications can function effectively, only if there is efficient flow of information between the company, suppliers, and distributors (Kumar, 2001, 60).

Internet technologies can play an essential role in demand forecasting. Therefore, it is quite possible to argue that effective communication of information can bring both quantitative and qualitative improvements. At this point, this approach has already benefited companies representing various areas such as car manufacturing, food and drink industry, oil-producing companies and so forth.

Finally, information communication seems to be of great importance to large companies which comprise a great number of departments, business units.

As a rule, they cooperate with numerous suppliers. Without effective utilization of information technologies these companies become more cumbersome and their organizational as well as financial performance declines. This is why this topic has become so important to business administrators and supply chain managers.

Challenges to effective communication of information

Nonetheless, one should not assume that information technologies alone can solve of the problems encountered by the company. Much attention is now being paid to strategies which are used to implement IT. One should not overlook such challenges as the necessity to train and educate employees or restructuring of business processes within the company (Gunasekaran & Ngai, 2004, p 282).

Apart from that, many enterprises often have to procure new equipment or software, and for many of them these costs are not affordable. However, there is a different and far more difficult obstacle. In their study Robert Premus and Nada Sanders (2009) point out that only 12,5 percent of manufacturers are willing to participate in collaborative planning (184).

In other words, many companies are reluctant to provide confidential information to the suppliers and without it the implementation of IT is pointless. This unwillingness to share information can be explained by security concerns which many organizations may have. There is great risk that this information can be used by the competitors, and one cannot underestimate this risk.

Furthermore, one should not assume that unwillingness to share information can be observed only between the companies; it can be also be found within organizations. For instance, sometimes the departments of a company can pursue their own objectives, while paying little attention to the needs of the whole enterprise.

A company, which intends to implement information technologies, has to remember some very important tasks. First of all, it is vital to organize a cross-functional team whose members have IT skills (Gunasekaran & Ngai, 2004, p 286).

These people examine informational needs of suppliers, manufactures, and distributors. Secondly, the management has to decide what kind of information should be accessible to business partners and to what extent.

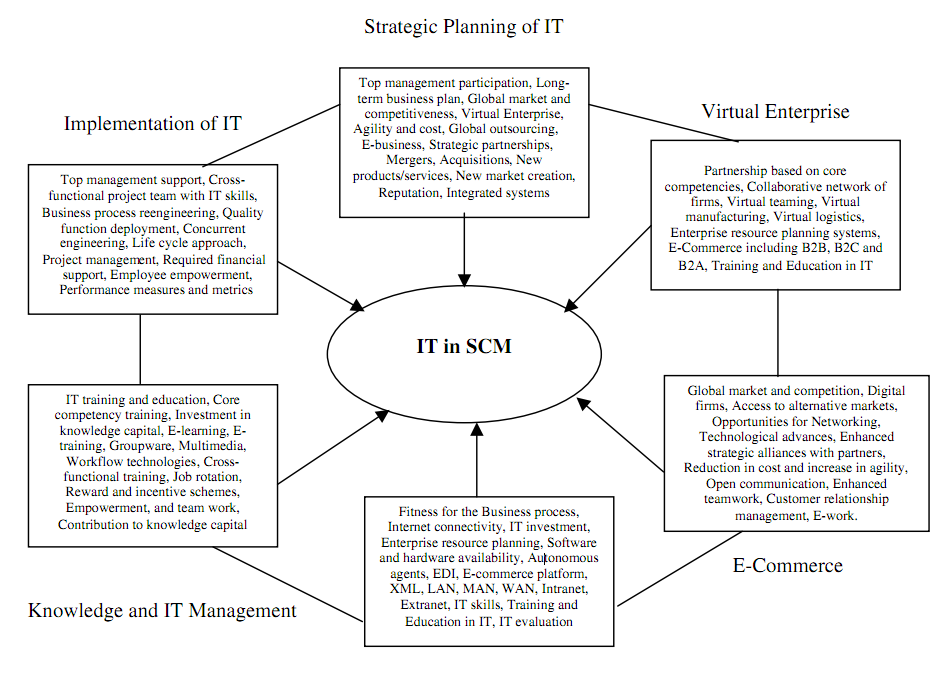

Additionally, the scholars urge managers to pay special attention to the selection of software and platform; it might be LAN (Local Area Network), MAN (Metropolitan Area Network), Extranet etc (Gunasekaran & Ngai, 2004, p 286). This framework (see figure below) may be used for the implementation of IT.

Of course, this framework should not be regarded as some universal strategies since much will depend on the previous experience of a company, its size and structure.

Thus, this literature review has identified the significance of effective information communication for effective work of supply chain. Its quantitative and qualitative benefits are quite evident. At this stage, we need to apply these theoretical concepts to a real company.

This analysis will help us better understand the advantages of using IT to manage supply chain. Moreover, this analysis will highlight the pitfalls that should be avoided by the management.

Practical implication

Important lessons of Betta Struts Case

The example of Betta Struts illustrates the point that adoption of information technologies and especially Enterprise Resource Planning (ERP) system can maximize the performance of supply chain in a company. This management understood that this company managed to retain its customers mostly due to the quality of their products.

However, organizational performance of this enterprise left much to be desired (Sadler, 2007, p 154). We can single out several important lessons that entrepreneurs can derive from the experience of Betta Struts. First, a company which is extremely departmentalized, is less likely to perform to its full capacity.

In the case it has been identified that every division of Betta Struts had its internal goals and information sharing was not encouraged by the management. The case illustrates that cross-functional teams are more efficient than separate departments like “Operations”, “Purchasing” or “Marketing” (Sadler, 2007, p 154).

This recommendation should be taken into consideration by private companies who attempt to optimize the functioning of supply chain. Another important lesson is that implementation of ERP system or other information technologies cannot be successful unless members of the staff are actively involved in this process.

In many cases, IT fails to produce expected results because the management imposes a change on the employees without asking them for their opinion or recommendations. The management of this company succeeded in avoiding these pitfalls by providing training to each member of the staff.

Additionally, the managers spent a substantial amount of time explaining the responsibilities to every employee (Sadler, 2007). The thing is that every organizational change is accompanied by employee’s resistance.

In this particular case, the management was able to minimize this resistance. Despite the fact that this measures seem to be self-evident, many business administrators do not do it, and this prevents them from achieving the results that they anticipated.

The results achieved by the company

Betta Struts has managed to bring several improvements into their major information systems. First of all, we need to discuss the logistics information system of this enterprise. By relying on the information, provided by sales managers they managed to better predict the demand for their products. As a result, they were better able to predict their need for raw materials (Sadler, 2007, p 158).

Moreover, they were able to reduce the inventory turnover by 30 percent. Thus, one can say that their logistics information system has been transformed into a tool that allows to plan production and manage suppliers. It has become essential for cost reduction.

Secondly, we can mention Sales and Distribution System, which enabled them to diminish the cost of purchase orders and made the company more attractive to the customers. Finally, we need to discuss management information system.

It has allowed the company to integrate several departments that were responsible for the management of supply chain. Such departments as “Purchasing”, “Operations” and “Marketing” were able to work together. So, management information system has been turned into a tool that can help business administrators to form cross-functional teams.

This tool is applicable not only to supply chain management but to other business processes such as customer service or R&D.

The main change that occurred witin Betta Struts is that information has become more accessible to the employees and the management was able to better coordinate the efforts of suppliers, manufacturing facilities, and distributors. Most importantly, customers benefit from this innovation because order processing became more time-efficient.

Ways of overcoming challenges

As it has been identified in the literature review, the company that tried to implement IT into supply chain frequently has to struggle with unwillingness to participate in information sharing. Similar problems were faced by the management Betta Struts. The departments of this enterprise were quite separated from one another.

It should be noted that adoption of information technologies often entails radical organizational changes, for instance, many employees may be unaccustomed to working in cross-functional teams. Very often this change is not accepted readily by the staff.

The management avoided this problem by consulting other employees. Again, they offered training courses the end users. These strategies should be taken into account by the enterprises which plan to re-organize their supply chain.

Conclusion

This analysis indicates that effective communication of information is essential for optimization of supply chain. Empirical studies and case studies show that it is essential for the reduction of labor costs, inventory turnover, and expenses of procurement. Additionally, information technologies have become an inseparable part production planning.

Their benefits can hardly be disputed but the implementation of such products requires considerable expertise and experience. The most important thing to remember is that management should avoid the so-called top-down approach. In other words, they should encourage other members of the staff to take part in such projects; otherwise, such attempts are doomed to failure.

On the whole, a managers, who is willing to bring changes into supply chain, should carefully research the best practices adopted by the leading companies. Only by relying on experience of others one will be able to improve the supply chain.

References

Gunasekaran. A. & Ngai E. 2004. Information systems in supply chain integration and management. European Journal of Operational Research. 159, pp 269-295.

Kumar K. 2001. Technology for Supporting Supply. Communication of the ACM. 44, (6), pp 58-61.

McLaren T, Head M, & Yuan Y. (2004). Supply chain management information systems capabilities. An exploratory study of electronics manufacturers. Information Systems and e-Business Management. 2, p 207-222.

Premkumar. G Prem. 2000. Interorganizational Systems and Supply Chain Management – An Information Processing Perspective. ECIS 2000 Proceedings. Paper 198, pp 1-9.

Premus. R & Sanders N. 2008 Information Sharing in Global Supply Chain Alliances. Journal of Asia-Pacific Business. 9 (2), p 174-192.

Sadler I. 2007 Logistics and Supply Chain Integration. London: SAGE.

Tokar. T. Aloysius J. Waller M. & Williams B. (n. d). Retail Promotions and Information Sharing in the Supply Chain a Controlled Experiment. Emerald Group Publishing Limited, pp 1-44.

Williamson E. Harrison. D. & Jordan, M. 2004 Information systems development within supply chain management. International Journal of Information Management. 24, pp 375-385.