Introduction

Polypropylene (PP), in another name polypropene, signifies a thermoplastic polymer employed in a broad variety of uses comprising packaging, textile industry, stationery, containers of different kinds, laboratory apparatus, vehicle parts, and banknotes. In the year 2008, the international market for polypropene had a capacity of 45.1 million tonnes that gave rise to revenue of approximately €47.4 billion (roughly $65 billion). The majority of commercial PP is isotactic and possesses a transitional intensity of crystallinity amid the one of high-density polyethylene (HDPE) and low-density polyethylene (LDPE).

In most instances, PP is hard and stretchy, and more so when copolymerized with ethylene. This aspect permits the use of PP as an engineering plastic, outdoing materials like Acrylonitrile Butadiene Styrene (ABS). PP has the advantage of being cost-effective. It could as well be semitransparent when not colored even if it is not easy for it to be made clear like the majority of other plastics. PP is frequently opaque and can be colored by means of pigments. PP has excellent opposition to fatigue. “The melt flow index (MFI) or melt flow rate (MFR) is its determination of molecular weight (MW).”

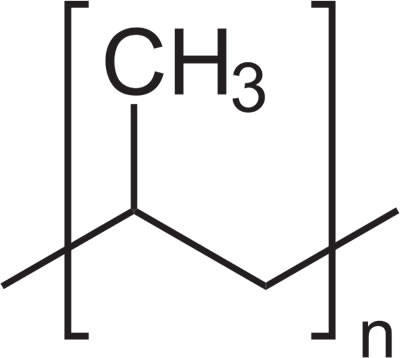

The MFI assists in establishing how simply the molten PP will flow when processing. PP with a high MFI will make the plastic cast full more simply when processing. If the melt flow rises, “a number of physical properties, such as impact strength, reduce.” Characteristically, there is the application of comonomer together with ethylene. When combined with polypropylene, homopolymer, ethylene-propylene rubber raises its temperature strength. Indiscriminately, when polymerized ethylene monomer coalesces with homopolymer of PP, it causes the polymer to be extra-transparent and lessens its crystallinity. The structure of polypropylene is as shown by the figure below.

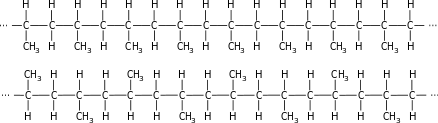

Tacticity is a significant perception in comprehending the association involving the chemical structure of polypropylene in addition to its properties. The comparative position of every methyl (CH3) group comparative to the CH3 groups in adjacent monomer entities has a powerful influence in the capacity of the polymer to make crystals. A given catalyst (for instance, Ziegler-Natta) is capable of controlling the manner of connection of monomer molecules to an intended arrangement.

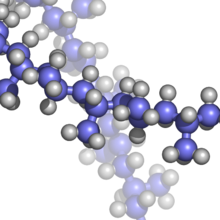

The arrangement could be isotactic if the methyl groups are all positioned at a particular side of the PP chain, or syndiotactic, if the positions of the CH3 groups to the side of the chain interchange. Commercially obtainable isotactic PP uses two kinds of catalysts. One set of the catalysts includes solid catalysts and particular kinds of metallocene catalysts that dissolve. Commercial isotactic macromolecules thus curl to form helical shapes. When the shapes line up, they present isotactic PP with numerous attractive aspects.

In cases where the CH3 groups on a PP chain exhibit an irregular arrangement, they generate an atactic polymer. The atactic PP is a rubbery substance with no definite shape and can be made commercially with some kinds of catalysts. Filtering applications could be observed as air-conditioners or water sieves. In the United States military, as well as in other places, PP was applied in the manufacture of cold-climate base attire like shirts with long-sleeves and long underwear.

Of late, polyester has reinstated PP in these users in the United States military. Another application of PP in the textile field is in making of warm-climate gear like clothing that easily carry sweat off the skin. Even if PP clothes are not simply flammable, they easily melt and thus might give rise to burns in case of a fire catastrophe. Furthermore, in the past, PP apparels kept hold of body smells that posed difficulty in trying to get rid of them. Nevertheless, the present creation of PP eradicated these drawbacks.

Thanks to its precise weight, “of all types of fibers, the lightest fiber is PP yarn.” Manufacturers achieve monetary and environmental benefits when making textiles and attires out of PP yarn. Ultimate users acquire more relieve since the clothes are lighter, which allows them to provide better functioning during their actions and offers them the liberty of movement. PP yarn has exceptionally first-rate insulation aspects and its water uptake is roughly nil. Textiles made of PP yarn carry moisture to the exterior or to a different absorbent coating from where it slowly evaporates.

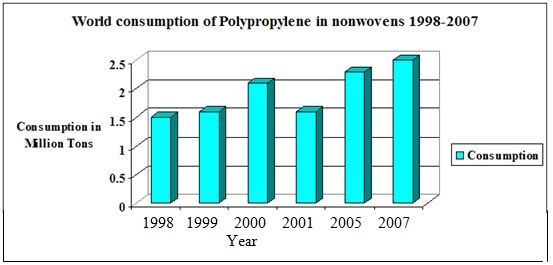

Lately, high-class PP has been established into the textile industry via the effort of designers that have extended specialized practices to make ornaments as well as wearable stuff from PP. PP is exceedingly resourceful as a fiber-making substance, while polyethylene (PE) is not as excellent a fiber-making high polymer substance. From the time when it was initiated into the textile field at around 1950s, the record of successful merchandise and markets for PP yarn has grown significantly. The figure below shows the estimated world use of PP in million tons starting from the year 1998 to the year 2007.

Out of the PP utilized in the United States, over one-third makes fiber as well as fiber-associated merchandise. The decreasing price, the low specific gravity (that gives high covering strength), and increasing developments in the quality of PP resins have been vital aspects in the advancement of new merchandise end uses. This paper discusses the application of PP in the textile field.

Background

PP was introduced in the textile field at around 1950s. Initially, PP was not widely used but its application in the textile industry has progressively increased. Olefin fibers are easily accessible around the globe and a huge number of trade suppliers offer high-quality resins. In addition, continuing developments in catalyst successes have given rise to boosts in PP productivity and advancements in its properties.

Versatility of Polypropylene

A key quality of PP is its capacity to be employed in an extensive variety of fibrous types. The listing of successful merchandise and markets for PP materials is far-reaching. It comprises ropes, carpets, craft fabrics, sieving materials, agricultural objects, vehicle components, leak-cleanout materials, diapers, healthcare substances, and protective clothes. PP is furthermore a forbearing polymer in the practice of extrusion.

Different from several thermoplastic polymers, PP does not necessitate covering with an inert gas when processing or pre-drying for the majority of products. Given that unmodified PP cannot take up dye with ease, pigmentation turned out as the desired means of coloring PP in textile-associated uses. In general, the fastness aspects of pigmented yarns are better as compared to the aspects of dyed yarns.

Pigmented PP yarns have turned into application in carpets, doormats, artificial turf, and many different uses, due to their better fastness aspects. Stabilizers of light have assisted in establishing fresh markets for PP products for outdoor applications. Moreover, advanced stabilizers of heat have enhanced extrusion effectiveness of PP and permitted application of more recycled matter. The fibrous types of PP comprise fasteners, filaments, slit film fibers, and pulps just to mention but a few.

Historical Point of View

Before the Second World War, natural yarns like sisal and manila were broadly employed in rope making. During World War II, nylon was used for making ropes used for towage and many more functions, especially in the military. After the Second World War, artificial yarns of different types became easily obtainable and the majority of the rope makers started using the artificial yarns. When PP resin became easily obtainable, the rope industry was one of the earliest industries in the textile field to extrude PP fibers.

The moderately easy extrusion practices and low manufacturing rates for polyolefins allowed the textile industry to change to two turns being made in the fiber for every rotation of the flyer sections on the rope-producing machine. The making of the rope was in curl form all set for shipping. PP products for yarn application were initiated to the United States textile sector in the late 1950s.

Due to its deficiency instability to sunlight and heat and the hardships encountered in the coloring of PP, the early approval of the polymer in the textile field was limited. With the increase of polyolefin resins, advancements in light and heat stabilizers, and improvements of colorants for PP and PE, PP acceptance in the textile industry rose gradually.

Synthetic Carpets

When the tufted carpet sector started rising at around the late 1950s, the United States carpet sector was reliant on cotton or woven jute for the main backing where the fibers were tufted. Due to its cheaper cost and excellent performance, jute quickly reinstated the cotton fabric employed for major and minor backing. Previously, the carpet sector had nearly become fully reliant on jute that came from Arab nations like Pakistan; however, civil commotions, suppositions, and organized strikes of dockworkers brought about periodic scarcities of jute and terrible cost fluctuations.

The unsteady market for jute fabrics promoted the rise of substitute materials. In the year 1971, warfare in Bangladesh affected consignments of jute fabric and in the year 1978, dockworker strikes in India caused high jute fabric costs. These happenings offered the drive for a remarkable attempt to reinstate jute fabric by the carpet sector.

Chamba fabric made by the Chemstrand Company (currently Solutia Company) of the United States, a woven nylon material coated with polyurethane froth, was an early endeavor to advance a major backing. Nevertheless, the high price of the fabric and the bulky formation of the material stopped its marketable success.

Phillips Fibers Company (currently a section of Amoco Fabrics and Fibers Company) acquired the expertise and Loktuft trademark for carpet backing in the early 1960s from a carpet making company. With its use of PP staple yarn and a woven PP fabric prepared from staple fiber, Loktuft was anchored in non-woven practices.

The fabric contributed to the dimensional potency of the material. Loktuft succeeded for just a short period as a carpet backing by having high sales in the period when jute fabrics were in deficiency, but the sales decreased with the resumption of jute supply. One drawback of Loktuft was its thickness in addition to wasted face yarns, which made it acquire better approval in the area of rugs as compared to broadloom carpeting.

In the early 1960s, James Lees & Sons Carpet Company (presently a section of Burlington Industries) of the US started making woven band fabrics from slit PP film. PP was the polymer selected for this fabric due to its effortlessness of change into tape fibers, the naturally excellent properties of PP, and the cost-effective concerns of a comparatively low price and potentially constant resin cost. The woven band fabrics had a plane surface and regular arrangement, which advanced tufting effectiveness and offered a more consistent carpet semblance.

Additional benefits of the synthetic carpet backing comprised opposition of mildew and microbes and the nonexistence of bad odors, which lessens the ease of the carpet getting dirty. In the 1970s, preferences shifted to open carpeting, necessitating the advancement of a new perception in PP backing materials.

In the United States, Amoco Fabrics and Fibers Company (currently a section of BP Amoco) along with Synthetic Industries Company are presently among the major manufacturers of woven PP carpet backing. Secondary carpet backing is formed by combining a PP ribbon fiber warp with a woven PP staple yarn filling. Jute carpet backings are no longer available in the United States carpet business.

Other than PP spun-bonded materials, materials of polyester are obtainable in the US. Nonetheless, PP is so far the main polymer employed in the production of spun-bonded and melt-blown materials. Polyester carpet backings get broadly used in vehicle carpeting since they present better contour capacity than PP.

Melt Blown Nonwovens

In the late 1940s, laboratory amounts of polystyrene fibers were made with the use of polystyrene immersed in cumene. The solution was then transferred into parallel tubes that turned in opposite sides and ultimately formed yarns. Esso Research & Engineering (currently Exxon Research) started the investigation of nonconventional methods of making PP fibers in the year 1965. The melt blowing progression was among the methods examined with constituents of the practice employed as a foundation for the work.

A limitation of the method was the creation of the shot in conjunction with the fine yarns. Perfections in the method and introduction of advanced dyes assisted in decreasing the shot progression. Investigation of an extensive variety of product uses for melt-blown nonwovens took place, encompassing cable insulation and filters of cigarettes.

In addition, a broad variety of polymers, comprising of elastomeric fabrics could be melt-blown, in addition to a broad range of yarn sizes being made. In-line merchandise like surgical and engineering masks could be shaped and produced. On both off-line as well as on-line structures, there has been the combination of melt-blown nonwovens with spun-bonds.

In the United States, PP fibers currently form a great proportion of the face yarn applied in rugs and carpets. In the year 1998, the comparatively cheap prices for PP resins were a key aspect in boosting the income for the main United States manufacturers of rugs and carpets. Developments in stabilizers and in manufacturing expertise assist in clarifying why the United States carpet industries have encountered a high extent of achievement in the production of PP carpet fibers.

Advancements in light and heat additives and the coloring are improved by collaboration amid providers and processors of stabilizers and colors. Further advantages come from the accessibility of quick, multicolor weaving paraphernalia, and from workers who are knowledgeable in yarn production. Dense spinning components, enhancements in pace and function of air-entrapping and texturing apparatus, improvements to prototype capacity of tufting devices, and amplified application of systems all assist in the betterment of the product.

With the present overcapacity of PP resins leading to harsh price demands on resin producers, fresh textile-associated uses carry on being developed. The good price for buyers of PP and its effortlessness in processing have roused its application by end-user and industrial merchandise. PP is not observed, nevertheless, as offering a significant challenge to nylon, polyester (PES), and cotton in the clothing business. Some of the hindrances to the success of PP are the low melting point as well as deficiency of convenient dyeability.

It is anticipated that resins intended for particular extrusion structures and relevancies will be made achievable via the application of catalysts. In addition, as additional engineers turn out to be knowledgeable with geotextile functions, their application for woven and nonwoven PP materials will keep on growing and hastening. PP and PES were commonly utilized in the textile industry in the past and currently. Nevertheless, PES is widely used in the clothing industry as compared to PP. The following is a comparison of the properties of PP with those of PES.

PES is obtainable in higher firmness grades than PP. Therefore, for manufacturing textiles with higher required strength, PES will attain the obligations and requirements more effortlessly.

- Unlike PP, PES fibers for making sewing yarns of excellent tenacity are as well available. Due to its low melting point, PP is not commonly applied for sewing yarns.

- The extension is much greater in PP than in PES. This offers PP enhanced elasticity for fabric and advanced molding in molded carpets.

- The density of PP (0.91g/cc) is lesser than that of PES (1.38 g/cc). In this regard, a cross-section of PP fiber is fairly bigger when compared to that of PES fiber of an identical denier. Consequently, thicker and heavier fibers unsuitable for clothing and more appropriate for carpets are produced with PP for a particular count of fiber and density of the material.

- The melting point of PP (165oC) is lower as compared to that of PES (260oC). Fabric made from PP is as a result not appropriate in fire fighting as well as comparable clothing where there are high temperatures. A flameproof compound has to be mingled with PP fabric. This increases costs.

- Resistance to ultraviolet light is lower with PP than with PES. Photo destruction occurs with contact to sunlight in the case of PP. Ultraviolet additive (Carbon black) has to be provided during the making of PP to better its resistance to ultraviolet light. Since geotextiles and upholstery substance are displayed to sunshine constantly, PES is more appropriate than PP.

- Unlike in PES, PP has a tendency of making beads on the needle and wire when carding and demands regular plan for getting rid of the beads. Attainable manufacture rates are thus lower with PP than PES due to card loading.

- When judged against PES, PP is extremely resistant to chemicals. This makes it appropriate for use in fishing nets. PP can also be used in geotextiles for soils with significant levels of acidity or alkalinity. PES, in contrast, should not be applied in alkaline soils because it loses its potency. Leaching as well occurs with PES in aqueous solution making it lose strength.

- PES possesses a higher creep resistance (maintenance of tensile aspects for a long time) as compared to PP. This gives PP a distinct benefit in geotextiles employed for fastening of soils and comparable uses.

- In clothing material, there is the reputation of PES/cotton and PES/viscose blends due to the great strength in addition to wearing resistance of PES and better moisture absorbance, skin kindliness, and comfortableness of cotton. On the other hand, PP is commonly not blended with viscose or cotton.

State-of-the-art

PP fibers hold a number of excellent properties in the textile industry when judged against other fibers. In spite of these attractive properties, PP fibers in the past have endured major shortcomings that have limited the approval of PP in textile apparel uses. As opposed to other yarns, conventional PP fibers could not be dyed. As an alternative, the color had to be added at the yarn extrusion stage via bunch coloration or dyeing with the use of the solution. The practice required the inclusion of heat steady pigments at some stage in the melt whirling of the yarn.

The colors used were not commonly miscible with PP. Therefore, the colorings were evident as detached particles in the yarn, and the pigment imparted turned out to be permanent in the yarn. Whereas this aspect has the advantage of great colorfastness, it is associated with some noteworthy demerits. For instance, introducing new dyes engages a moderately complex pigment-matching stage. This signifies that huge lots of yarn are prepared for each new dye and the period needed to depart from a new dye impression to the ultimate material or fabric can be lengthy.

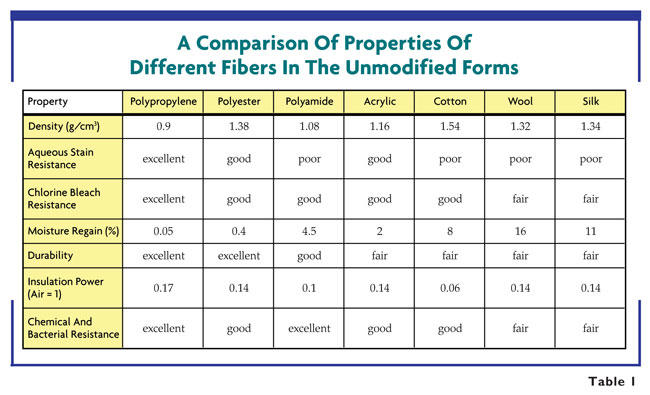

Currently, there is a long-standing concern in the commercialization of PP fibers that are easy to color. Preferably, PP should have a coloring profile close to or well match with large-quantity fibers like cotton, PES, or nylon, so that it is well suited with the coloring and associated practices that are already fixed. In addition, it should not vary the important advantages of PP fibers outlined in Table 1 below, particularly less density, and less surface energy.

Past several efforts to produce dyeable PP fibers had not been doing well since the resultant product did not attain these standards. FiberVisions (a company based in the US) is currently working to produce a revolutionary new PP yarn, CoolVisions colorable PP yarn, which attains the requirements of superficial coloring and PP fiber features by integrating a chemical addition within the PP fiber. The yarn can be colored by use of usual disperse colors in a way comparable to that employed for PES fibers. The PP yarns now possess a broad collection of inherent advantages and features comprising the following.

- Light heaviness and comfortableness

- Cottony gentleness

- Stain resistance

- Easy concern, easy put on

- Wetness management

- Durability

- Heat insulation

- Breathability

Light heaviness and Comfortableness

With the current improvements of the entire commercial yarns, PP fibers are one of the lightest in heaviness. The augmented number of PP yarns for each kilogram of material provides benefit as compared to several other yarns giving rise to advanced coverage for an identical heaviness range or equivalent coverage in textiles of lesser weight for comfortable clothing. Additionally, improved yarns are naturally gentler when compared to traditional PP fabrics. The softness of the improved yarns results to their added comfortableness. The aforementioned improvement in softness makes attractive clothing from PP yarns.

Wetness Management

In accordance with FiberVisions, CoolVisions PP yarns surpass every other dyeable yarn in low-wetness-absorption assessments. Additionally, textiles produced from PP have a tendency of having a high wetness-vapor-spread rate, which is significant in comfortableness, particularly when the wearer needs the skin to remain dry and cool.

Mechanical features of PP fibers are not influenced when the textile is damp, which is a natural benefit when judged against yarns like rayon that can lose potency significantly. Similar to traditional PP, CoolVisions presents desirable resistance to chemicals as well as aqueous stains. Household cleaning agents such as bleaches do not have a negative effect on PP yarns. Microbes like bacteria, mold, and mildew do not affect the fibers. Dyeable PP fibers are appropriate for clothing end-uses such as uses in water sports.

Dyeing Characteristics

CoolVisions colorable PP yarns can be colored using generally obtainable PES high-energy disperse colors and in normal high-pressure coloring practices employed for PES yarns, but with lower coloring temperatures achievable. The color variety and color-harmonizing procedure are comparable to those for PES fibers. The capacity to color garments gives rise to numerous benefits as compared to solution-dyed garments as done in the past.

A number of the value-chain advantages comprise the capacity to amass greige merchandise, equate colors fast, create smaller lot quantities, serve a function or fashion-associated color lines, act rapidly in response to market demand, and provide a wider variety of colors devoid of significantly mounting on inventory costs. The improvements have brought about added monetary gains from decreased operational capital requirements and condensed manufacture times.

Styling gains consist of a decrease in inconveniences presented by solution-dyed garments and the need to apply dye inks in place of pigment inks. Garments printed with dye display a softer offer and superior colorfastness as compared to pigment-printed garments. There is further improvement of CoolVisions yarns going on to give them natural cotton and gentle feel not prevailing in PP fibers in the past.

As aforementioned, CoolVisions fibers include a stabilizer that operates as a dye receptor. The chemical additives are present in the garments as infinitesimal fields that take up the disperse dyes all through the dyeing period. At heat greater than the boiling level of water, the dyes diffuse willingly into the PP fabric in the capsulated fields of the chemical additives.

Under normal fabric use states, which comprise inferior heats, the dispersal of the dyes, and its pullout from the fiber is highly reduced, giving rise to excellent colorfastness. Similar to PES yarns, rich disperse dyes ought to be applied to attain the finest colorfastness. The advance of enclosing the stabilizer within the PP fiber has numerous advantages. The face of the yarn is fundamentally unchanged, bringing about outstanding ability to withstand aqueous stain and low water uptake.

The PP fiber as well serves to guard the dyes against compounds like chlorine, giving rise to exceptional bleach stronghold. Given that the capacity to dye the PP fiber is conveyed by the inclusion of a stabilizer, the intensity of the stabilizer influences the strength of shade and therefore giving PP a couple of advantages. The stabilizer intensity can be managed fairly well, giving rise to decreased shade sensitivity to manufacturing states.

Additionally, the extent can be deliberately altered to create fabrics that dye to diverse depths, thus presenting an extra styling device. Numerous corporations in the textile industry are making use of PP fabrics to establish fresh apparel styles. Actions are in progress to establish air-jet spun in addition to filament-brand products to widen the variety of styling devices.

Discussion

The most significant feature of PP is its versatility; that is, it can be modified to fit a number of production methods and uses. Outstanding resistance to chemicals, low density, high melting point (for olefin yarns), and reasonable cost makes PP a vital fiber in the textile industry. Nevertheless, the reduced dyeability in addition to texturizability restricted the uses of PP in conventional textile manufacturing.

Through the establishment of yarn denier textured fiber, the use of PP in the apparel industry is turning out to be unavoidable in conjunction with its major channel in the engineering sector. When PP was initially initiated into the market at around 1950s, the merchandise was not crystallizable, which gave rise to the low melting point. Following the establishment of isotactic marketable PP, a significant boost in the crystallinity along with the melting point was realized.

PP has recorded improved international market share expansion in current years and it is expected that its use will still increase as PP is progressively utilized as a replacement for other fabrics like PES and a number of engineering plastics. Some of the difficulties that should be overcome to improve the production of PP include:

- The low melting point that stops it from ironing like cotton

- Difficulty in dying after manufacturing not unless after significant treatment and alteration

- High crystallinity along with poor heat conductivity causing limited texturizability

- Poor ultraviolet and heat stability that necessitates the addition of costly ultraviolet additives and antioxidants to rise above this difficulty

- Inflammable and thus burns or melts similar to wax

- Poor hold to latex and glue

Heat setting eliminates the remaining strains and creates an imperfection-free and steady crystalline arrangement to make materials dimensionally constant. It as well advances the proportion of general crystallinity. The smectic organization adjusts to the more ideal monoclinic configuration when the progression of heat setting is at temperatures exceeding 70oC. When the temperatures reach 145oC, the change is nearly complete. As compared to primarily smectic type, the monoclinic type does not go through any main modification in the crystalline configuration in the process of heat setting.

Dyeability

Physical characteristics along with chemical aspects determine the ease of dying fabrics. Easy dyeability is observed in fabrics whose molecular units contain polar groups. Through making chemical links, the polar groups present the advantage of acting as locations for the combination with dye particles. The dye particles do not chemically combine with PP yarns, as they do not contain required polar groups.

Owing to hydrophobic characteristics of PP yarn, the dye particles are not powerfully combined with the yarns. As a result, the adsorbed particles that intermingle with the yarn surface through weak van der Waal’s forces are simply washed off. Additionally, PP yarn has high crystallinity that somewhat contributes to its extremely low dyeability.

Yarn improvements have been examined to make PP easy to dye. The improvement comprises copolymerization in bid to ensure dyeability of the yarns. Bromination of PP yarns gives them an attraction for necessary dyes. These techniques led to the noteworthy decline of some attractive properties of PP fibers. In current years, face adjustment of hydrophobic yarns by plasma action unlocks new potentials in this sector. Plasma action is currently employed in initiating functional groups onto the PP yarns.

The polar level on the face of the yarns advances their wettability as well as their magnetism for aqueous particles and more so those of the dye. Following reaction with the polar groups that are established by plasma action, molecules of the dye are fastened on the yarn surface. Since plasmas do not interrelate with the inside section of the yarn, this method might not significantly change the mechanical features of the treated yarn.

Generally, PP yarn has outstanding chemical resistance concerning alkalis and acids. PP yarn is as well simple to process and economical when judged against other synthetic fibers. Due to its better performance attributes and low-cost, PP yarn finds far-reaching application in the nonwoven sector. Applications of PP in baby diapers along with comparable products will bring about noticeably increased application of PP. The softness in feel and hydrophobic features facilitate the use of PP in hygiene merchandise in addition to diapers.

Chemically, PP is very comparable to polyethylene, containing carbon as well as hydrogen atoms. Among the attractive aspects of PP is its cost-effectiveness, which is because of a comparatively effortless production from the inexpensive petrochemical propylene. For PP to be functional in a broader variety of uses, PP is frequently copolymerized using polyethylene, producing a fabric with high resistance to temperatures, and that has rigidity, and potency of PP but improved impact resistance facilitated by the bendable polyethylene connections.

Copolymer or homopolymer must be stated in cases where PP is recorded in scientific writing. PP cannot withstand heat or ultraviolet instigated deprivation as PE and Carbon black works as an excellent ultraviolet additive. Even under a stabilizer, PP is commonly not employed in outdoor uses, with the exception of black colors.

An exceedingly popular aspect of PP is the living hinge result. In slender parts where the constituent parts are oriented, the garment could be bent nearly for an indefinite period devoid of malfunction. The PP yarn is employed in upholstery and carpeting because of its chemical resistance and ability to withstand wear. Ordinary molded uses comprise pipe, and bottles because of chemical resistance. Given its inexpensive cost, PP finds countless applications like in toys and housewares. In summary, PP is a resourceful polymer that is becoming more desirable with improvements through new expertise and because of the cheap base polymer.

Conclusion

Polypropylene denotes a thermoplastic polymer employed in a broad variety of uses in the textile industry as well as in many other fields. The majority of commercial PP is isotactic and possesses a transitional intensity of crystallinity. From the time when it found its way into the textile field at around 1950s, the evidence of flourishing merchandise and markets for PP yarn has grown considerably. Attributable to its insufficiency instability to sunlight and heat and the hardships encountered in the coloring of the PP, the early appreciation of the polymer in the textile field was limited. With the augment of polyolefin resins, advancements in light and heat stabilizers, and perfections of colorants for PP, its acceptance in the textile industry rose gradually.

A key quality of PP is its capacity to be employed in an extensive diversity of fibrous types. The products of PP in the textile field comprises ropes, carpets, craft fabrics, sieving materials, vehicle components, leak-cleanout materials, diapers, healthcare substances, and protective clothes. PP is moreover a forbearing polymer in the practice of extrusion.

The good price for consumers of PP and its effortlessness in processing have roused its application by end-user and industrial merchandise. Increased potential for spunbonded in addition to melting-blown PP merchandise will be key contributors to numerous of the new uses in the textile industry such as making clothing like shirts and coats. PP resins are applied for melt-blown merchandise. Finally, PP will become even more desirable with continued improvements through new expertise.

Bibliography

Aizenshtein, EM, ‘Polyester fibres continue to dominate on the world textile raw materials balance sheet’, Fibre Chemistry, vol. 41, no.1, 2009, pp. 1-8.

Aizenshtein, E & V Efremov, ‘Production and use of polypropylene fibres and yarn’, Fibre Chemistry, vol. 38, no. 5, 2006, pp. 345-350.

Athalye, AS, ‘Non-woven PP Fabrics in Medicare, Hygiene and Healthcare’, Popular Plastics & Packaging, vol. 55, no. 10, 2010, pp. 24-27.

Genis, A, V Usov & V Razboeva, ‘Status of production and use of polypropylene spunbond in Russia and abroad’, Fibre Chemistry, vol. 39, no. 1, 2007, pp. 1-6.

Gokarneshan, N, B Varadarajan, CB Sentil, K Balamurugan & A Rachel, ‘Engineering knits for versatile technical applications: Some insights on recent researches’, Journal of Industrial Textiles, vol. 42, no. 1, pp. 52-75.

Kiselev, S, A Prosvirnitsyn, G Slutsker, & A Stalevich, ‘Creep and recovery of polypropylene nonwoven material’, Fibre Chemistry, vol. 39, no.1, 2007, pp. 87-90.

Kissin, YV, Alkene Polymerization Reactions with Transition Metal Catalysts, Elsevier, Amsterdam, 2008.

Korobova, G & N Nozdrina, ‘Determination of the critical twist for polypropylene yarn’, Fibre Chemistry, vol. 38, no. 6, 2006, pp. 527-531.

Ma, G, J Zhai, B Liu, D Huang & J Sheng, ‘Plasma modification of polypropylene surfaces and grafting copolymerization of styrene onto polypropylene’, Chinese Journal of Polymer Science, vol. 30, no. 3, 2012, pp. 423-435.

Moore, EP, Polypropylene Handbook. Polymerization, Characterization, Properties, Processing, Applications, Hanser Publishers, New York, 2000.

Ray, H & RT Mathers, Handbook of Transition Metal Polymerization Catalysts, John Wiley & Sons, New Jersey, 2010.

Tomlinson, J, ‘Managing Decline: The Case of Jute’, Scottish Historical Review, vol. 90, no. 2, 2011, pp. 257-279.