Introduction

Pre-stressing is one of the methodologies applied by civil engineers to mitigate natural drawbacks of steel concrete structures. The methodology is deployed to produce various structures for commercial utilisation such as floors, bridges, and beams among others.

Concrete withstands more loads while subjected to compressive loads than while subjected to tensile loads. This behaviour implies that, when used to produce columns that are to be subjected to compressive loads, it can withstand more loads relative to when it supports loads that subject it to tension.

A similar scenario is experienced when concrete is deployed to produce a beam. For instance, when a beam is simply supported and loaded, the dead load (load due to the weight of the beam) and the applied load subject the upper portion of the beam to compressive deformation. The lower side is subjected to tensile strains, which otherwise induces tensile stress. Since non-reinforced concrete is stronger in compression than in tension, the beam can only support a limited amount of load in tension.

When the span of a beam is increased, the load, which can be supported, reduces because longer spans buckle more than shorter spans. One way of dealing with this challenge is by providing more supports to the beam. However, this strategy is inconvenient especially when a beam is used to support floors in multi-storey buildings requiring large floor surface areas. Cost also becomes prohibitive.

The amount of concrete used to make a beam to support a given amount of load is also higher than in the case of a reinforced beam. Traditionally, reinforcing was done using steel bars, which provide the required strength in tension. With a reinforced beam, the spans, which can support an equivalent load with a non-reinforced concrete beam with equal cross-sectional dimensions is higher.

The need to increase such spans even higher gives rise to the need of utilisation of pre-stressed concrete. The aim of this paper is to discuss the historical developments of pre-stressed concrete, the basic concepts of pre-stressed concrete, and the manufacturing of the pre-stressed concrete. An effort is also made to discuss the design of pre-stressed concrete together with its new developments.

Historical Development

The current achievements of the utilisation of pre-stressed concrete in civil engineering rest on the undying effort of scientists and engineers within the last 100 years. A San Francisco-based engineer, Jackson, was the first to patent pre-stressed concrete when he applied “patent for construction of artificial stone and concrete pavements in 1886” (Raju 2009: 2).

In his patent, pre-stressing was realised through tensioning. Various rods used for reinforcing concrete were set in the form of sleeves. Two years later in 1888, small beams coupled with slabs were produced in Germany, Dorhring through deployment of tensioned wires that were embedded in concrete for purposes of crack prevention.

In 1886, Mandl introduced the idea that pre-stressing was essential in countering the stress introduced by loads in concrete structures. Later, in 1907, “ Koenen, of Germany, further developed the subject by reporting on the losses of pre-stress due to elastic shortening of concrete”(Raju 2009: 2). However, the significance of the loss of these stresses was identified first by an American Engineer, Steiner, in the year 1908. A Vienna-based Engineer, Emperger, used these findings to produce wire-bound concrete pipes.

According to Raju (2009), these pipes were made by “binding high tensile steel wires on pipes at stresses ranging from 160 to 800 N/mm2” (2). Dischinger first demonstrated that unbounded tendons could also be utilised to make pre-stressed concrete structures in the year 1928. This task was accomplished through construction of deep-girder version of major bridges through use of pre-stressed wires, which were secured inside his girder that did not have any bond.

The losses of pre-stress encountered were taken up by corresponding re-tensioning of wires that were deployed in the concrete structure. Based on these structures and exhaustively studying the steel and concrete properties, in 1928, Freyssinet argued that high-strength steel was advantageous for use in making pre-stressed concrete since more accounting of pre-stress losses could be realised. He singled out that such losses arose principally from shrinkage and creep in steel structures when loaded.

From 1928 to 1933, Freyssinet is recognised for having made the most significant achievement in the development of pre-stressed concrete. These achievements were due to “development of vibration techniques for production of high-strength concrete and the invention of the double acting jack for stressing high-tensile steel wires” (Raju 2009: 2).

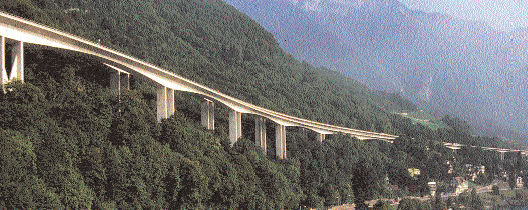

These discoveries marked the beginning of the intensive spread of the practical applicability of the pre-stressed steel as from 1935. In the US and Europe, civil engineers began constructing long-span bridges from 1945 to 1950. A good example of such a bridge is shown in fig.1 below. Christian Menn designed and fabricated it in 1962. The bridge is found in Tamins-Reichenau in Switzerland.

Over the last 50 years, pre-stressed concrete has been used in civil engineering for a variety of applications. They include construction of bridges having long spans, shelf roof for industrial applications, construction of structures used in the marine industry, pressure vessels used in nuclear power plants, and railway sleepers among other applications.

In recognition of these applications of pre-stressed concrete, Raju (2009) reckons, “there is probably no structural problem to which pre-stressed concrete cannot provide solution and often a revolutionary one” (3). In the same line of thought, it can be inferred that pre-stressing is a universal principle in civil engineering, rather than just a technique.

Basic Concepts of Pre-stressed Concrete

The need to use pre-stressed steel arose because of two main reasons. The first one is the need for utilisation of high-strength steel in the making of concrete structures. The basic idea behind this need is that, the stronger the material used in construction, the lighter and smaller the beams to be built without sacrificing strength. Burgoyne (2002) cites the second reason as “the recognition of losses of pre-stresses due to various causes” (548).

In fact, the initial attempts to deploy mild steel in the making of the pre-stressed concrete failed miserably because the working stress of mild steel is about 120N/mm2. This stress is totally, or the better part of it is, lost due to shrinkage and creeping together with elastic deformation. In this regard, Burgoyne (2002) puts the loss of stress in pre-stressed concrete due to these factors in the order of 100 to 240N/mm2.

A material to be utilised successfully for making pre-stressed concrete requires strength in the range of 1200 to 2000N/mm2. Such amount of strength can only be provided by high strength steel. Raju (2009) supports this basic design principle by asserting, “high strength concrete is necessary in pre-stressed concrete, as the material offers high resistance in tension, shear, bond, and bearing” (3). A fundamental question that arises is how the high-strength steel could be used to support tensile loads yet it sags.

The response to the above query underlines the reason why pre-stressing is done while using a high-strength steel to make concrete beams. Perhaps the best way of conceptualisation of how steel functions in a concrete beam to support tensile loads can be done by consideration of an elastic band.

When an elastic rubber band is stretched and force applied mid way, the amount of sag decreases when a constant load is applied as the stretching force is increased. This finding implies that the higher the pre-stressing force, the higher the amount of that load that the rubber band can support. This concept is the basic principle of operation of pre-stressed concrete beam.

The functionality of pre-stressed concrete beam may also be interpreted by consideration of an analogy of carrying books, which are stuck together. Books can be stuck in rows, which can then be lifted up. It is also possible to carry the books by first applying a force to make the rows stick together and then pull the stacked books in rows horizontally.

Upon applying pressure, compressive stresses are induced in the books so that they become easier to move from place to place at once. Using the same concept, pre-stressing concrete helps to eliminate a number of design challenges associated with reinforced concrete.

Burgoyne (2002) supports this importance of pre-stressed concrete by asserting, “Pre-stressing removes a number of design limitations that conventional concrete places on span and load by permitting the building of roofs, floors, bridges, and walls with longer unsupported spans” (551).

Consequently, engineers and architects are given an opportunity to come up with designs for beams, which can have longer, lighter, and shallower spans while paying critical attention to the need of the high strength required for utility performance in structural components of roofs and bridges.

Manufacturing of Pre-stressed Concrete

Manufacturing of pre-stressed concrete is done at a pre-stressing concrete plant. During manufacturing of the pre-stressed concrete, civil engineers apply two ways for inducing compressive stresses in pre-stressed concrete. The first one is pre-tensioning while the second one is post-tensioning. Pre-tensioning is a method whereby concrete is placed after stretching of tendons. Fig. 2 below shows the tendons used in the manufacture of pre-stressed concrete.

The force used to pre-stress concrete is transferred via a bond to the concrete. In the pre-tensioning method, concrete is placed upon stretching steel. “In order to strengthen the beam, steel tendons with high strength are put in between two abutments to be tensioned to around 70 to 80 percent of their overall strength” (Mutsuyoshi & Hai, 2010, p.167). The concrete is allowed enough time to cure to gain the necessary strength.

Tensioning forces are now released. Steel produces a reaction after attaining the required strength from the concrete making it gain the length that it had before. Consequently, tensile stresses are converted into transformed into compressive stresses, which upon complete curing are now very firm. Fig .3 below shows an example of a beam used for bridge contruction manufutured through pretentioning.

Post-tensioning is a pre-stressing methodology in which the concrete put after the tendons is tensioned and hardened before the steel is stretched. “The pre-stressing force is moved through the end anchorages to the concrete” (Mutsuyoshi & Hai, 2010, p.171).

Concrete is then cast around. Normally, an engineer makes ducts in the concrete body as the process progresses. This case is done with the help of steel rods, which are later removed. In the next step, with regard to Raju (2009), “After the concrete is hardened until it gains the required strength, engineers place and stretch the steel tendons towards the end of the unit” (p.57).

Concrete that has been post-tensioned has a myriad of applications ranging from making of large girders, slabs, and roofs to pavements among other applications. Both pre-tensioning and post-tensioning produce good pre-stressed concrete. However, they are different. One of the striking differences is that post-tensioning is only possible to do in a manufacturing plant. Post-tensioning is done on the job site using applications, which are cast in place.

Design of Pre-stressed Concrete Beams

The pre-stressed concrete design initiates by determining the required load to be supported and the mechanism of loading the resulting beam. However, while designing, it is important to remember that a beam has its own weight. In the most simplistic scenario, it is uniformly distributed. Supporting conditions also determine the dimensional and sectional properties of the pre-stressed concrete beam that is selected for a given application.

The simplest support conditions are the cart livered beams or simply the supported beams. For pre-stressed concrete beams, having multi supports such as the ones shown in making the bridge shown in shown in fig .4, the calculation involved requires advanced techniques to obtain solutions for deflections, and the tensile and compressive stresses and strains on the loaded beam. Such techniques involve numerical methods and other methods for obtaining parametric solutions.

It is important to note that, with the development of software applications, there is a specialised commercial software application that helps designers to handle these often-tedious calculations. However, for the software to give practical solutions, there must be inputs such as loading conditions and sectional properties such as the modulus of elasticity, the permissible bearing, shearing, compressive and even tensile stresses that would be induced on the beam.

Normally, a designer has at his or her disposal the material properties, which are often tested and documented in the form of standards such the required loading and span. Depending on the required aesthetic properties of the concrete structure, the cross-sectional shape may also be known. The design challenge is then to find the member size, which is required together with the tendon profile and forces required for pre-stressing.

Determination of the member size requires designers to conduct an analysis of the pre-stressed members, which can be “different for different stages of loading” (Burgoyne 2002: 549). There are three main stages of loading.

They are initial, intermediate, and final loading stages. The initial stage is further divided into two main sub-stages. These are “tensioning of steel and the transfer of pre-stress to concrete” (Raju 2009: 98). In case of the intermediate stage, the designer considers the loads acting on the members during transportation, handling, and during erection of members that are pre-stressed. In the final stage of design of the pre-stressed concrete beams, two main considerations are made.

These are the response of the members during operation and the ultimate performance of the members during extreme conditions. Since a pre-stressed member is built to withstand even extreme forces, for instance intense forces impacted on members during high water waves or during earthquakes, the designer is most interested in the analysis of the failure of the structure during such scenarios.

As argued before, the design process of pre-stressed concrete yield parametric solutions. Therefore, the designer is involved in the intersection between decision-making and numerical calculations. In this regard, Burgoyne (2002) argues, “the human designer alternates between decision-making and computational challenges until the design is complete” (p.549).

However, simple calculations are conducted first since they are repeated again in case the design fails to work. Complicated calculations are normally executed last when the design engineer is completely sure that the design will work.

New Developments in the Pre-stressed Concrete

For many decades now, pre-stressed concrete has been used in the construction of structures such as bridges all over the world. Pre-stressed concrete has dramatically grown due to the rise of its advantages such as higher lifecycle and the initial cost of making the concrete bridge.

Pre-stressed concrete has great features over steel bridges because of its huge characteristics in aesthetic and economic aspects compared to concrete bridges, which have been reinforced. Recently, most pre-stressed concrete bridges have deteriorated before serving their estimated life span. This situation is caused by various factors such as environmental factors and corrosion. Consequently, concerns have been raised in the design and construction of pre-stressed concrete and its long-term durability (Mutsuyoshi & Hai 2010).

Therefore, civil engineers have adopted and applied a number of innovative technologies of pre-stressed concrete during the actual construction of projects as well as in their developments. In addition, some structures used in the construction of pre-stressed concrete have been presented to represent state of the art technologies.

Development of new structures for pre-stressed bridges requires using an external pre-stressing technique, which produces externally pre-stressed concrete bridges that are designed using pre-stressing tendons, which are placed outside the section with concrete but within the boundaries of the cross-section of the girder.

The idea behind external pre-stressing is widely advantageous. It is now becoming more popular in the building of medium and long-span bridges. Some of the advantages are the ability to control and adjust tendon forces, ease inspection of tendons while they are built, and reduction in thickness of the web. To increase performance of pre-stressed concrete bridges, new innovative technologies have been adopted to make this possible.

These technologies include PC bridges, which have tendons that are highly eccentric externally. Although, externally pre-stressed PC bridges are well known and are highly advantageous, their flexural strength is lower compared to that of internally bonded tendons because of the eccentric tendons being smaller and limited by the ties of the girder section as well as the reduced eccentric tendon at the definite flexural failure.

Extra-dosed PC bridges comprise a type of system that is structured in a way that tendons have been installed outside and above the major girder with a short deviation of towers being situated at supports. With regard to Virlogeux (1998) argues, “Extra-dosed PC bridges have a girder height that is lower than that of the ordinary girder bridges” (p.19).

This case reduces the weight of the structure. Thirdly, bridges made from pre-stressed concrete and possessing webs from steel possess grooved steel plates with less weight. These are better instead of using the concrete web because corrugated steel can withstand shear forces while not absorbing the unwanted stresses brought by pre-stressing thus efficiently enabling pre-stressing of up and down concrete deck slabs (Virlogeux 1998).

In fact, corrugated webs made form steel are known to possess incredible shear resistance coupled with buckling résistance. Raju, (2009) develops this argument further by stating, “Lightweight corrugated steel web plates cause about 25% reduction in self-weight of main girders enabling the usage of longer spans” (p.93). They also reduce the cost of construction.

Conclusion

Pre-stressed concrete offer a myriad of advantages compared to the reinforced concrete. From the discussions of the paper, these merits range from increased spans length of a beam that can be simply supported to reduction of the dimensions of the beam without sacrificing the strength of the structure constructed using the pre-stressed concrete beams. Since the weight of a beam is also less, the strength of the supports required is also reduced.

The paper held that the advantages have prompted hefty research on how such beams can be cheaply manufactured since they are currently finding wide range of applications in a variety of fields such as nuclear power plants, rails, and road bridges having long spans and even in construction of roofs for building requiring large floor areas.

Bibliography

Billington, D, ‘Historical Perspective on Prestressed Concrete’, PCI Journal, vol. 1, no. 3, 2004, pp. 14-30.

Burgoyne, C, Design of Prestressed Concrete Beams Using Expert Systems, Imperial College of Science and Technology, London, 2002.

Mutsuyoshi, H & N Hai, Recent technology of pre-stressed concrete bridges in Japan, Saitama University, Tokyo, 2010.

Raju, K, Pre-Stressed Concrete, McGraw Hill, New York, 2009.

Virlogeux, M, Non-linear Analysis of Externally Prestressed Structures, Proceedings of FIP Symposium, London, 1998.