Outline

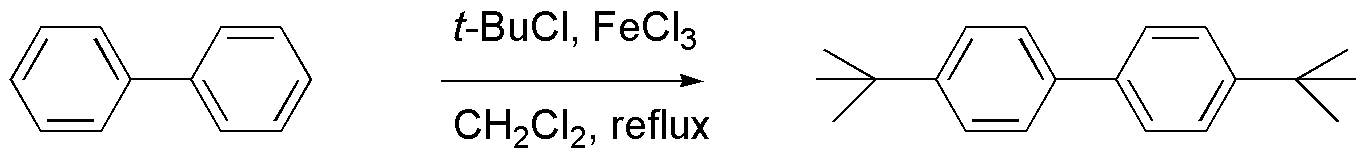

Introduction: The Friedel Crafts reaction provides a way through which aromatic compounds can have an alkyl group added to them so that they may have C-C bonds. The most commonly used solvent is dichloromethane.

Experimental section: This experiment, which involves the preparation of 4,4’-di(t-butyl)biphenyl was done in a duration of three weeks. In the first week, a reflux reaction was done in order to obtain a crude product. Part of the crude product was recrystallized from ethanol and the remaining part was purified by column chromatography in the second week. In week three, both samples were compared and analyzed using thin layer chromatography and IR spectroscopy.

Results: The yield of the crude product was recorded to weigh 4.6260 grams net. The weight of the product collected from the column was found to be 1.5675 grams net. The recrystallized product had a higher melting point and an exact purple spot on the TLC plate.

Discussion: From the results obtained, it was evident that the recrystallized product is purer than the sample purified by column chromatography. Since this experimental procedure was not totally environmentally friendly because of the use of solvents like dichloromethane, more research should be conducted on alternative solvents to be used in the Friedel Crafts reaction.

Introduction

The Friedel Crafts reaction provides a way through which aromatic compounds can have the addition of an alkyl so as to have C-C bonds. One of the most used solvents in this reaction is dichloromethane (Mikami 2005, p87). The aim of this experiment is not only to prepare 4,4’-di(t-butyl)biphenyl but to also obtain a pure product of the same. Purification is done by the use of chromatography, TLC to be more specific. One of the applications of this reaction in the manufacture of dyes. It is also used as a test to give the measure of how aromatic a compound is (Bansal 2001, p71).

Experimental section

Week 1

3.1 grams of the biphenyl, 6.5ml of tert-butyl, 20ml of dichloromethane, and some boiling chips were added into a clean and dry 100ml round-bottomed flask. This mixture was carefully swirled to avoid spillage until a clear solution was obtained. A reflux condenser was fixed onto the round-bottomed flask, but tubing for the water inlet and outlet were not fixed. The pre-weighed iron (III) chloride was added into the mixture quickly and carefully so as to avoid excessive exposure of this compound to atmospheric moisture. The rubber tubing was then connected to the reflux condenser

after which a loose ball of cotton wool was placed at the top of the condenser so as to avoid the entry of the atmospheric mixture. The flask in this setup was then placed in an oil bath which was on a hot plate, after which the cooling water was then allowed to run through the condenser.

The mixture therein was heated to reflux and allowed to continue reacting for half an hour after the reflux had commenced. The flask was then cooled by placing it in a bowl of ice and then the mixture was poured into a separating funnel containing 10ml of 2M hydrochloric acid and 5grams of ice. The flask was rinsed out using a little dichloromethane to avoid sample loss and the contents added into the separating funnel. After stoppering the separating funnel, undue pressure was released by inverting it and turning the tap on. To ensure that all undue pressure was released, this procedure was repeated severally.

The separating funnel was then firmly clamped in an upright position to allow the various layers to separate. After the lower layer was carefully collected, the upper layer was discarded. The lower (organic) layer was then put back into the separating funnel and the above procedure was for three times repeated using 10ml of 2M hydrochloric acid but leaving out the ice. This was followed by pouring the organic layer into a conical flask and adding adequate anhydrous Na2SO4 so as to obtain some free-flowing powder in the flask. The dichloromethane was then filtered into a clean and weighed round-bottomed flask through a filter paper that was folded into a flute shape. This was followed by extracting the solvent on a rotary evaporator so as to obtain the crude product, which is a dark yellow solid. The crude yield was then recorded.

Week 2

The sample obtained from the previous section was divided into two equal portions. One of the portions was recrystallized from ethanol. This was done by placing the portion into a clean conical flask on a steam bath and adding adequate boiling ethanol so as to dissolve the solid. Some boiling chips were added as this sample was kept boiling. In the meantime, a second conical flask was placed on a steam bath and a funnel that is un-stemmed was placed on it. A fluted filter paper was placed in the funnel and the paper and funnel were warmed bypassing a little boiled ethanol through the funnel. The hot solution was now filtered carefully with the addition of boiling ethanol in case of the formation of any crystals on the filter paper.

The filtrate was allowed to cool until some crystallization occurs. For complete crystallization, the flask was placed in ice after which the contents were filtered using a sinter funnel on a Buchner flask. The crystals were allowed to dry by causing air to pass through them on the sinter funnel and simultaneously mixing them using a spatula. After the crystals were completely dry, their weight was recorded.

The second portion of the sample collected in part one is purified by column chromatography. Alumina that weighed six times the weight of the portion was added into a small beaker. The alumina was soaked in a small beaker containing just enough hexane to cover the alumina. This was then added as slurry into a short chromatography column. The solid was allowed to settle and the tap was then opened after which some hexane was allowed to run through until the top of the hexane reached the top of the alumina. This was done to ensure that the column was ready to be used.

The product was dissolved in a very small quantity of hexane. Using a Pasteur pipette, the resulting solution was added onto the surface of the alumina. This was done with caution so as not to agitate the column surface. This solution was allowed to flow slowly through the column just until it reached the top of the column, though it was ensured that the column did not run dry. After the absorption of the solution, the flask was washed out with approximately 5ml of hexane, and this solution was carefully added to the column. Care was taken to ensure that the solvent flowed to a point where it was just above the alumina level. Hexane was carefully added to the top of the column, and the level of this solvent was ensured to be topped up always. Any solution that eluted was collected into a conical flask.

Periodically, a drop of the eluting solution from the column was collected on a watch glass. The drop was then evaporated gently by blowing on it. The collected drop no longer having any solid was an indicator that the compound had eluted to completion and that it was okay to remove the hexane by transferring the solution from the conical flask to a weighed round-bottomed flask and then using the rotary evaporator. The solid was then scraped off onto a large weighing boat then into a labeled vial.

Week 3

The purity of each sample was checked by means of the melting point, thin layer chromatography, and IR spectroscopy. This was done by placing the two samples in separate melting pint tubes, placing the side of the tubes by side, and then melting the samples simultaneously. Also, the two samples were placed side by side on the same thin layer chromatography plate and a spot of starting material, which in this case was the biphenyl. A few crystals of each were collected on a separate watch glass and ten drops of hexane were added to each.

Some of each sample was drawn up using a clean capillary and a small spot of about 1cm made from the bottom of the silica TLC plate. The three spots were dried by blowing on them and then the TLC plate was placed in a developing tank containing 0.5 milliliters of hexane. To allow the hexane to rise up the plate by capillary action, the jar was capped. After the hexane had risen to a level that was about 1cm from the top, the plate was removed and a pencil line was drawn matching the solvent front. After the plate was dried by blowing on it, it was placed under UV light. Any notable spots were circled and their color noted. An IR spectrum of the purer sample was run and this sample was confirmed to be the 4, 4’ isomer by assigning the relevant bands.

Results

Wk 1

Exactly 3.1245 grams of biphenyl was used. A dark purple solution was obtained after iron(III) chloride was added. Following the reflux, the solution turned to light green, but upon shaking it changed to yellow-orange. The yield obtained, which was a yellow crude product, amounting to 4.6260 grams net.

Wk 2

2.1250 grams of the crude product was used for recrystallization of the sample and 2.5010 grams of the product were used for the TLC. After recrystallization, 0.4692 grams of the filtered sample was obtained. 0.7032 grams of the pure sample from week one was left on the filter paper. A light yellow product weighing 1.5675 grams net was collected from the column sample.

Wk 3

Discussion

The results obtained from the thin layer chromatogram indicate that the recrystallized product is purer than the un-recrystallized one. The recrystallized product gives one clear purple spot, showing that it is pure and it comprises only one compound (Bansal 2001, p 589). The IR spectra obtained show that the recrystallized sample is closer to the standard literature values than the peaks obtained from the column product. From the melting points, the recrystallized product exhibited a higher melting point than the column product, showing that the former is purer than the latter. The column sample may have had some traces of unreacted crude elements.

Some possible sources of errors included contamination of the product by particulates and moisture from the atmosphere during blowing. This experimental procedure was not totally environmentally friendly because of the use of solvents like dichloromethane. More research should be conducted on alternative solvents to be used in the Friedel Crafts reaction.

Answers to questions

Q1: Nitrobenzene is sometimes used as a solvent for the Friedel-Crafts reaction and yet it doesn’t react with the electrophile (in this case t-butyl chloride / FeCl3). Why does it not interfere with the desired reaction?

A: The nitro group in nitrobenzene causes the aromatic compound not to be inclined to electrophilic substitution. This is because of resonance stabilization of the nitro group, which causes almost all of the electrons to be concentrated around it (Hanson 2002, p79). Nitrobenzene does not react with iron (III) chloride, but the use of iron chloride increases the reaction rate because of reduced selectivity. The iron (III) chloride is Meta directing, but the desired reaction is still achieved because the quantity used is not merely catalytic (Bruckner 2002, p 379).

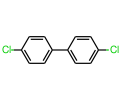

Q2: The monochlorination of biphenyl occurs at a much greater rate than the chlorination of benzene under the same conditions. Explain this observation and suggest which chlorobiphenyl isomer would be formed preferentially. Draw the dichorobiphenyl isomer that would result from chlorination of this preferred chlorobiphenyl isomer.

A: The delocalization in biphenyl is more than that in benzene, making it easier for the positive ion to stabilize in the biphenyl. This occurs on the condition that the substitution occurring is either directed to the ortho or the para position (Carey 2000, p519). The most stable and preferential isomer obtained from the monochlorination of biphenyl is the 4-chlorobiphenyl isomer. This shows that between the ortho and para substitution, the latter is preferred because of stability and low steric hindrance. The chlorobiphenyl isomer (C12H9Cl) can be chlorinated to form a dichlorobiphenyl isomer (C12H8Cl2) (Sartori 2009, p111). Chlorination of the 4-chlorobiphenyl isomer results in the formation of 4, 4′-dichlorobiphenyl isomer:

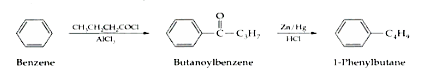

Q3: The Friedel-Crafts reaction of 1-chlorobutane with benzene is not a good method for making 1-phenylbutane. Why not? What other products can form? Suggest a better method for making this compound from benzene.

A: It is not a suitable method because other products which can form are those which are from 2° and dissociated C+ ions, and such products are very impure. A better method for making 1-phenylbutane is by reacting benzene with CH3CH2CH2COCl in the presence of aluminum (III) chloride to form butanoylbenzene. The next step is cracking butanoylbenzene with zinc or mercury in acidic media (preferably HCl) to obtain 1-phenylbutane (Carey 2000, p480).

Q4: How could you make 4-t-butylbiphenyl without contamination by 4, 4’-di(t-butyl)biphenyl (Hint: use a reaction other than the Friedel-Crafts reaction).

A: To synthesize a pure and uncontaminated mono substituted 4-t-butylbiphenyl, a highly selective method will be required. The most commonly used catalyst for this is a Pd intricate compound. This is unlike the chloride used in the Friedel crafts reaction. It should also be done under temperatures between 60-68 degrees Celsius and in a basic medium (preferably NaOH) (Bansal 2001, p377)

References

Bansal (2001). Organic Reaction Mechanisms (3rd Ed.). New York: Tata McGraw-Hill.

Mikami, K. (2005). Green reaction media in organic synthesis. California: Wiley-Blackwell.

Hanson, J. R. (2002). Organic synthetic methods. London: Royal Society of Chemistry.

Sartori, G. (2009). Advances in Friedel-Crafts Acylation Reactions: Catalytic and Green Processes. New York: CRC Press.

Carey, F. A. & Sundberg, R.J. (2000). Advanced Organic Chemistry: Structure and mechanisms. London: Springer.

Bruckner, R. (2002). Advanced organic chemistry: reaction mechanisms. New Jersey: Academic Press.