Nowadays, the rapid advancement of humanity requires businesses to look for appropriate ways to renovate their processes, products and services to stay competitive. The Japanese philosophy of continuous improvement, called “kaizen,” presents one of the ways to enhance efficiency and experience fewer costs. Practical experience shows that this approach revolutionises different industries, from automotive production to healthcare. As such, the application of the mentioned philosophy seems to be a viable idea when it comes to other industries as well. This paper aims to highlight the key concepts related to kaizen and other Japanese instruments, introducing them into the context of Etihad Airways to discuss the ways the company can use to improve continuously.

Organisation Identification

Etihad Airways is the national airline of the United Arab Emirates (UAE) that provides transportation for passengers and cargo around the world. The principal goal of this company is to create a 21st-century global airline with a new view of the concept of hospitality in the field of air transportation (“Building the future,” 2015). Etihad Airways provides its services to passengers from all over the world, operating flights in 61 destinations. The Crystal Cargo department of the company is responsible for cargo transportation flights to 42 countries in Africa, Asia, Europe, North America and Oceania.

The services on board the aircraft include those service on board the aircraft, entertainment and medical assistance. The onboard services of Etihad Airways consist of two parts: flight conditions (for example, the convenience of seats) and the level of service for cabin crew. The services are offered for airline passengers while they wait for a flight at the airport, after the end of the flight and when they are considering the purchase of a ticket. The airline also takes care of passengers who are currently in flight. At many airports in Europe, Etihad Airways has opened exclusive bars with comfortable seats for passengers awaiting their flight. The bars open three hours before boarding, allowing airline customers to wait in comfort for their flight.

Despite its variety of routes and millions of passengers, Etihad faces difficulties, and its revenues decline steadily. Dudley (2019) reports that the idea of buying troubled airlines and returning them to the market proved to be calamitous, negatively affecting passenger and cargo volumes. In comparison to 18.6 million passengers in 2017, the company carried 17.8 million passengers in 2018, and the numbers are likely to decrease further. In addition, the seat load also declined, and the total revenue fell by 2.3%, comprising $5.86 billion per year (Dudley, 2019). In this connection, it becomes evident that the company needs innovative management decisions to enhance its core operating performance. Among other approaches, the Japanese improvement methods suggest gradual change, a focus on quality, communication, employee motivation, and willingness to transform.

Implementing Japanese Concepts into Etihad Airways

Kaizen

Kaizen is a comprehensive concept that encompasses theory, philosophy and management instruments, enabling the achievement of competitive advantages in a given period. Masaaki Imai set forth the ideas of the kaizen system, distinguishing between radical change (innovation) and continuous improvement (Rüttimann & Stöckli, 2016). The latter is a framework that contains five main components: personal discipline, teamwork, quality circles, improved morale and considerations for enhancement. According to kaizen, all enterprise has problems but can resolve them by developing a specific culture. In it, the company tries to guarantee that no problems happen rather than punish employees for creating them. This strategy arises from the recognition that management, whose goal is to make a profit, should set the goal of client satisfaction as its central requirement, acting as a customer-oriented improvement system.

With regards to Etihad Airways, kaizen also follows the fact that all the services of the company should ultimately lead to increased customer satisfaction. The philosophies of serving internal and external clients are different. The kaizen system operates through the creation and constant work of so-called kaizen teams (Rüttimann & Stöckli, 2016). Five main types of teams emerge based on the tasks they perform. The composition of permanent teams that operate every day can include specialists who work on the ground. In turn, problem-solving teams search for answers to a specific issue, and the professions of their members can be diverse. The team consists of participants from several permanent groups. The number of participants in such a team is usually six to eight people, and after making a decision, the team disbands.

These decision-making teams should change depending on the situation. For example, the airline serves its customers free of charge when the flight delays for an extended period. An example of such a service is the situation in which airlines could not operate during a volcanic eruption in Iceland. In this case, team-based decision-making is a suitable method to discuss the critical situation occurred and choose the coping strategies that would best meet the needs of passengers. Cross-functional teams, another type of kaizen team, gather to assess the current processes of the organisation and search for opportunities to improve them (Bouchereau, 2016). The composition of the team can involve ordinary specialists and managers from various departments.

Solution implementation teams can be useful for Etihad to introduce developed process improvements. These teams consist of participants of other groups, a trait that simplifies the application of specialised or innovative processes. The composition of the team includes grassroots specialists (workers, performers) and heads of units from permanent and problem-solving teams. The teams work in kaizen sessions, which usually last for 2-5 days (Bouchereau, 2016). Each session aims to solve a specific business problem, and the organisation of work within the framework of the kaizen session uses the principle of the plan-do-check-act (PDCA) cycle. In the case of a disaster such as that above, the described system of response can promptly address the consequences and maintain high service quality.

Visual Management

The internal arrangement of the aircraft is another area that may benefit from kaizen. For the convenience of customers, Etihad’s aircraft feature the latest technology, yet there is a significant disparity in quality. The airline offers passengers three classes of service: first class (Diamond First Class), business class (Pearl Business Class) and economy class (Coral Economy Class). The implementation of visual management can be an appropriate strategy that can noticeably improve service quality and promote cost-effectiveness. Visual management is a clear statement of all the standards, goals and working conditions in the field (Eaidgah, Maki, Kurczewski, & Abdekhodaee, 2016). It is an opportunity to compare the actual situation with the requirements for production efficiency provided to each of the employees so that any participant in the process can evaluate the state of the system. Visual management can improve through the use of Kanban, 5S, 5M, problem analysis visualisation (Pareto diagram, fishbone structure, et cetera), key performance indicators and other standards.

The passengers flying with Etihad Airways can order services via the Internet when buying a ticket for first or business class. They can request transportation to the airport of departure and from the airport of arrival in a limousine. After fulfilling his or her direct duties, the driver will show the client to the registration desk and departure hall while answering any questions. Also, many airports where Etihad operates have select areas where one can play with children or leave them with workers who have the necessary competencies in dealing with children. Visual management may help notify customers of the mentioned services. For example, brief videos of services available, staff training certificates and company-specific indicators can improve customer satisfaction.

There are many different examples of how visual management can be used to improve service quality, brand recognition, and customer satisfaction in airports and planes. Airport monitors are a well-known method of conveying large amounts of critical information in a compact and easily understandable format. Signs positioned where people can see them easily, even in a crowd, are essential for navigation through large airport buildings. “Japan Airlines” (2019) remarks on the Japanese company’s careful usage of colours, logo placement, and other characteristics such as grain, stitching, and leather wrapping in its first-class cabin interiors. Visual management can express itself in both highly visible signs and subtle indications, all of which contribute to the improvement of the customer’s experience.

The literature suggests a set of stages that implement visual management tools in practice. The first step consists of work organisation, preferably with the use of the 5S system, which will be discussed later in this paper. In the second stage, information collection focuses directly on the workplace, comprising quality, equipment usage, equipment safety rules compliance and others (Bititci, Cocca, & Ates, 2016). Etihad should collect data about the customers that would benefit from the services described above and assess their needs. At the third stage, the results and performance indicators of the process undergo an evaluation. The preliminary customer satisfaction outcomes produced by visual management should go to Etihad management for analysis. The fourth stage is the implementation of necessary measures based on the collected information.

With regards to the forms of visual management that Etihad Airways can use, the creation and implementation of methods, quality, maintenance and service quantity standards is essential. Also, the identification of employee goals (workplaces, quality, productivity, costs and delivery times) is critical, as they inform a large portion of overall customer satisfaction (Eaidgah et al., 2016). By monitoring and posting the achieved results, the company can approach its planned performance. In the case of problems and accidents, a visual and acoustic warning should occur, and, most importantly, the information posted should relate directly to specific jobs/processes (Bititci et al., 2016). The posting of unstructured information is inadequate because employees must then analyse it and find their portion, creating inefficiency.

There is considerable room for improvement in many aspects of Etihad Airways’ visual design. As can be seen in Figure 4, the company’s first-class seat cabin appears to be much less spacious and premium than that of Japan Airlines seen in Figure 1, though this is not necessarily the case. There are large amounts of plastic that constrain the walkways and make them seem narrow, creating an overall appearance of wasted space. The passengers have better isolation from outside onlookers, but they also cannot see beyond their space, which can give it a constraining feeling. A change in seat design may reduce the cramped aesthetic and make the area appear, and possibly be, more comfortable than it is now.

5M and 5S Techniques

According to the 5M framework, the causes of problems arise from one of five elements: manpower, machines, materials, methods and management. Materials include internal components as well as services of external organisations that are used by the central company (Mansor, Ismail, Hamran, & Sarifudin, 2018). In the case of Etihad, the external materials are fuel supplies, catering and cleaning services, and others. Machines, or machinery, are equipment, tools and units that see usage across the processes and procedures carried out by Etihad. The technologies and approaches to the organisation of production compose the methods element, and measurement refers to the evaluation of characteristics relevant to consumers for shaping product quality. Lastly, the manpower aspect includes all people who, in one way or another, participate in the service provision processes.

For instance, Etihad has the opportunity to decrease its costs by increasing the time of landing to use less fuel, a practice introduced by several US-based companies. A few minutes longer flight is regarded as the strategy that can save millions in a year by slowing down the landing procedure. This solution is attractive because it does not create any inconveniences for customers. Another recommendation is to change the catering inventory, namely, the soft drinks that the company offers on board. Overall, Etihad Airways can improve the quality of its services both in the airport and on board its aeroplanes by identifying and resolving issues through the use of 5M. The author of this work does not have access to sufficient information to highlight specific issues, but the framework can always help a company improve with proper application.

The steps in the 5S methodology include a set of interconnected components. When following seiri (sort), managers need to single out items and processes that do not contribute enough (Dandawate, Raut, & Talamale, 2015). The component of seiton (set in order) states that one needs to arrange everything necessary for work productively. Next, to fulfil seiso (shine), the workplace and all equipment must be clean. Etihad needs to follow this requirement with particular care since airlines are an area that benefits significantly from waste reduction and resource conservation (Jaca, Viles, Paipa-Galeano, Santos, & Mateo, 2014). Seiketsu (standardise) explains the importance of the standardisation of the first three steps, which is expected to turn them into everyday practice. Lastly, shitsuke (sustain) refers to the continued maintenance of established workplace management practices. A well-structured system is essential to monitor the performance of organised and standardised jobs.

Etihad Airways planes may sometimes rely on an aesthetic that emphasises the UAE’s beauty and wealth too much. Schlappig (2014) describes the company’s approach to design as “style over substance” and complains about unnecessary additions such as a minibar with room temperature water. Seiri requires that the design does not feature such nonessential items, freeing space for better allocation of the critical aspects as per seiton. More straightforward and spacious layouts would also make cleaning easier, leading to better results when observing seiso. The idea of seiketsu mandates that the company develops the best approach as a global standard and applies it across all of its planes. Lastly, shitsuke means that the company has to review its visual design continuously and repeatedly, trying to isolate critical improvement ideas and implement them. Through determined attempts to enhance its services, Etihad Airways will stay relevant worldwide and potentially become an industry leader.

Muda, Mura and Muri

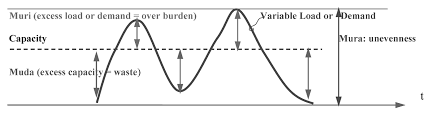

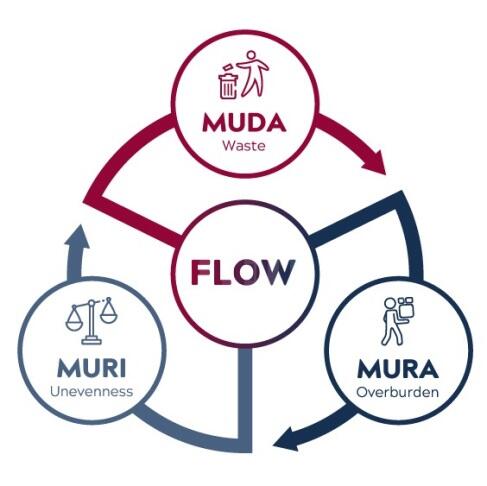

Muda, which means “loss” in Japanese, is any activity that takes resources but does not create value. According to Taiichi Ohno, the founder of the Toyota production system, there are seven types of losses: waiting, overproduction, inventory, transport, defects, over-processing and motion (Smith, 2014). In the case of Etihad, baggage handling and the associated waiting times may be considered muda. The solution is to apply the lean process of accelerating the baggage loading process. When the aircraft lands in the airport, the cargo doors should open, and the baggage should leave the aircraft before the passengers start getting up. Such an approach would reduce time wastage since the customers would be able to retrieve their baggage from the carousel as soon as possible.

In the case of Etihad Airways, the presence of muda expresses itself in a design aesthetic that emphasises luxury over efficient space usage. Klint (2018) highlights the presence of a large lounge in the first-class cabin of his flight while also expressing concern over the storage container’s inability to fit his bag, self-described as small. The design uses much space for accommodations that not all passengers will need while failing to provide a service that most of them find essential. Due to the small number of first-class compartments on board the aircraft, it should be simple to alter the design so that the lounge is slightly smaller and the individual cabins can store larger bags.

Mura is unevenness in the workload; it arises due to differences in scheduling, planning and speeds for various operations. Sunjka and Murphy (2014) state that mura can result in an untimely delivery of components, necessary data not being collected on time, an inability to provide the required number of workers or equipment, and other issues. The critical factors for the successful implementation of the principles of lean manufacturing and the elimination of mura are thoughtfulness, expediency and phasing. Etihad should develop an approach that would enable efficient work and minimise downtime. As a result of transparent and well-designed planning that takes all aspects of operations into account, mura should disappear naturally.

Etihad Airways is sometimes prone to planning and preparation issues. Klint (2018) praises the airline for its commitment to providing extensive menus and high-quality meals but also notes that it tends to run out of first-class food, recommending readers to order early to avoid being left hungry. Etihad can estimate the dietary requirements of an average passenger based on the length of the flight and prepare sufficient ingredients in advance. Wastage issues may arise if the plane stocks enough food to provide each passenger with every meal on the menu on demand. However, such problems can become less prominent through customer preference analysis or the usage of meals that share numerous ingredients.

Muri is overburdening of equipment or operators that appears due to inadequate resource allocation. If the management is unable to equalise the loads of personnel and production capacities, then workers will be either idle or overloaded with work at most times (Sunjka & Murphy, 2014). To avoid muri, one has to stabilise the processes in order to eliminate unevenness (mura), standardise the rules of work and eliminate the losses caused by the previous unevenness. For example, Etihad may reduce the costs of its flights by minimising the time its planes stay on the ground, reducing its costs and removing some of the burdens on airports.

Etihad Airlines is known for providing excellent food quality, particularly to its first-class passengers, with excellent chefs working on their planes. However, as Klint (2018) notes, the size of the menu, combined with the complexity and number of various items, creates a massive workload for cooks and flight attendants, especially on shorter flights. With that said, this issue can likely reach a partial or full resolution through the methods proposed above. Reduced and simplified menus would reduce the stress on staff by making it easier to prepare several meals at once. Moreover, the improvement would achieve this target without compromising food quality with subpar ingredients.

Kanban

This system uses the just-in-time system, which revolves around the timely delivery of the minimum necessary quantities of product where they are needed, as the basis. The essence of the kanban system is in the fact that all the production sites of the enterprise, including the final assembly lines, work on an exact schedule, using specific amounts of raw materials (Mansor et al., 2018). This precision is necessary for rhythmical production, where items move through production without stopping.

Instead of a large number of small tasks, Etihad should set up several large ones and divide them into steps. This change should reduce production time and eliminate overproduction, lowering catering and waiting delays. The task should gradually move between teams or individual members. For example, a manager proposes a flyer or visual management placement layout and passes the idea to a designer, who sends the samples for testing upon completion. At each stage, specialists solve one problem and move on after transferring it to the next team. The product’s assembly will resemble a conveyor in its structure as a result. However, the elements of this conveyor work when necessary, reducing unnecessary labour: the teams work on current tasks and not future ones.

Conclusion

Today, the service sector has become the most significant in the world economy. Etihad Airways services distinguish themselves through intangibility, non-standard approaches and instability in demand and supply, which create specific problems in management approaches. Service organisations feature large-scale usage of the human component, and Etihad Airways is no exception. Since personnel is a crucial asset of the airport, the application of internal Japanese improvement management, particularly for human resources, is a way to achieve better results. The central idea of these approaches is that satisfied employees improve the experience of the company’s customers. After analysing the activities of Etihad Airways, the author concludes that the company occupies a leading position in the global aviation services market. Although it offers a wide range of services and has excellent potential for further development, its processes need to be enhanced. Continuous improvement based on kaizen, Kanban, 5M, 5S and visual management can lead to significant improvement in results.

References

Baby rooms[Image]. (2017). Web.

Bititci, U., Cocca, P., & Ates, A. (2016). Impact of visual performance management systems on the performance management practices of organisations. International Journal of Production Research, 54(6), 1571-1593.

Bouchereau, F. (2016). Kaizen kanban: A visual facilitation approach to create prioritized project pipelines. Milwaukee, WI: ASQ Quality Press.

Building the future. (2015). Web.

Dandawate, S., Raut, L. P., & Talamale, P. (2015). Implementing ‘5-S methodology’ as tool for improving efficiency & performance of delivery and production operations at Bajaj Steels Industries Ltd. International Journal for Scientific Research & Development, 3(3), 214-220.

Dudley, D. (2019). Etihad Airways claims progress with restructuring while reporting another huge loss.Forbes. Web.

Eaidgah, Y., Maki, A. A., Kurczewski, K., & Abdekhodaee, A. (2016). Visual management, performance management and continuous improvement: A lean manufacturing approach. International Journal of Lean Six Sigma, 7(2), 187-210.

Jaca, C., Viles, E., Paipa-Galeano, L., Santos, J., & Mateo, R. (2014). Learning 5S principles from Japanese best practitioners: Case studies of five manufacturing companies. International Journal of Production Research, 52(15), 4574-4586.

Japan Airlines unveils new cabin design. (2019). Trade Arabia. Web.

Kishi, D. (2019). Arrivals departure board in Narita Airport, Japan[Image]. Web.

Klint, M. (2018). Review: Etihad A380 First Class Apartment [Blog post]. Web.

Mansor, M. A., Ismail, A. R., Hamran, N. N. N., & Sarifudin, M. S. (2018). Knowledge management to boost productivity in manufacturing. Journal of Fundamental and Applied Sciences, 10(3), 19-31.

Rüttimann, B. G., & Stöckli, M. T. (2016). Going beyond triviality: The Toyota production system — Lean manufacturing beyond Muda and Kaizen. Journal of Service Science and Management, 9(02), 140-149.

Schlappig, B. (2014). Review: Etihad Airways first class A340-500 Abu Dhabi to Los Angeles [Blog post]. Web.

Smith, S. (2014). Muda, Muri and Mura. Lean & Six Sigma Review, 13(2), 36-37.

Sunjka, B. P., & Murphy, S. F. (2014). Lean implementation within South African aircraft maintenance organisations. International Journal of Lean Enterprise Research, 1(1), 59-80.