Introduction

Maglev trains or magnetic levitation trains were opened up for commercial transport in 1984 when they operated between Birmingham airport and the main railway. Britain was the first country to develop these trains, although other countries developed their sns and used them to transport mainly people.

Maglev trains are based on the principle of electromagnetism to be levitated and propelled. The car has no contact with the rail, an advantage that affords them to move without friction, and therefore move at very high speeds of almost 500 kilometers per hour. The cars have no engines or any moving parts, though they need a lot of electricity to create the desired powerful electromagnets on the tracks. The basic principle that is applied in maglev trains is that of the magnetic like poles which repel while opposites attract.

Working principle of maglev trains

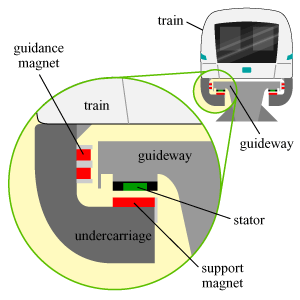

The trains have attached magnets that are very powerful to create a high density of magnetic field at the bottom. The tracks have electromagnetic magnetic field that repels this magnetic density on the bottom, and thus the car is propelled forward. These are the U-shaped guide way that has individual coils to which an alternating current is applied in order to create repulsion between magnets.

It is the force that is created to achieve both goals, to propel the car and levite it vertically at the same time. The gap between the train and the trucks is about 2 and 3 cm for Indatruck models, or 1 cm for Transrapid Internatioanal model. Meissner effect is used to create bearings without the train coming into contact with the trucks. Thus, the train can climb steep hills or even ice-covered trucks without losing speed considerably.

Efficiency is thus increased in this technology, although these trains tend to quite pricey compared to conventional trains (Blundell, 2009). Other developments introduced another set of coils in which alternating current passes to create electromagnets. Two sets of coils achieved the function of checking the lateral movement, while the other levitated the car. This is done by placing guidance magnets on the left side so that the train moves forward and does not hit the sides.

“Transrapid international” or Electromagnetic Suspension (EMS)

To create large magnetic fields, superconductors are used to produce stronger magnetic fields, although it was noted that these strong magnetic fields are produced by rare earth magnets, other than iron and ferrite. Neodymium-iron-boron is used to create the desired high magnetic field. The material used must be thick, have low resistivity and possess the ability to change fields quite fast. According to the author, the train is propelled forward after it is levitated by the repulsion of magnetic forces.

The truck has several coils which use alternating current to change polarity at a high frequency. The change of polarity by the coils makes them propel forward. Vertical magnetic forces that provide levitation make the car to balance in suspension and is stabilized by the horizontal magnetic forces so that the car is centered and does not drift to any side.

According to Gibilisco (2006), such an arrangement requires the acceleration and braking to be provided by linear motors and additional electromagnets to be in place in the track. Higher levitation speeds were achieved in the Japanese models by positioning upper and lower coils, such that they created field currents of figure of eight.

This arrangement is called Halbach array whose main purpose is concentration of magnetic field above the car. While the lower coils produced repulsive forces for levitating the train, the lower coils provided the “push-pull effect” together with linear motors in the tracks which propel the car forward at higher.

Indutrack models

The train has other features that make it to be safe, given that some can reach high speeds of 522 km/h. Electric power is used to accelerate the train until full levitation is reached. The reason to use the superconductors, besides the high magnetic field potential, is that they can retain this field for some time even after power have failed. Power can fail, and modern maglev trains have auxiliary wheels that help them decelerate until they stop.

Computers are used to monitor levitation distance to ensure the speeds and movements are safe so that in case of any anomaly, the train is automatically halted and corrective actions are taken. Some models have batteries for electricity back up in case power supply is interrupted.

Conclusion

There is really little difference between the models of producing motion in the maglev trains, although depending on the arrangement of electromagnetic coils and force that is used to provide first acceleration, top speeds attainable can vary. For example, maglev trains that are based on Electrodynamic Suspension (EDS) use rubber wheels for the first 100 km/h after which coils are activated and move by levitation propulsion after which they can reach top speeds of 522 km/h.

List of References

Gibilisco, S. (2006). Alternative energy demystified. New York: McGraw-Hill Professional.