Introduction

Lloyd Register Group (LRG) is a company that is engaged in high-risk business because their clients work with valuable assets in the industries where mistakes can be costly. Quality improvement (QI) is thus a critical element for ensuring that the services the company provides are excellent. Notably, QI is based on a systemic approach, rather than changes that target a single aspect of operations, which allows businesses to implement tools and techniques of quality assurance across different departments and operational activities. This paper aims to critically appraise the LRG’s strategy for QI, examine the tools and techniques implemented by management, and strategic application of quality.

Range of QI Tools, Methods, and Models Used by LRG

LRG is a multinational company and an industry leader that helps companies ensure that their products and services align with recognized standards. As such, by reviewing the QI process of this company, one can assess the main tools and techniques used by private organizations. In basic terms, QI is possible when the output of operations, in the case of LRG, aligns with the set standard, and in instances where the two are not aligned, actions to correct the process are implemented. LRG achieves this by combining the main methods used in total quality management (TQM) – Six Sigma, Lean, and P30. As the company outlines the results, they can have cohesive documentation and outcome records, a well as retain knowledge and learn continuously to enable improvement.

The main element of QI that LRG developed and implemented is a unified group plan, which is based on non-financial metrics, as opposed to previous performance reviews, which considered only the latter. Before this, the performance appraisals were based mainly on meeting the financial targets of different subsidiaries and groups within this company, which arguably overlooked essential aspects of operations.

By focusing on financials only, the organization fails to account for the number of satisfied clients or the alignment of LRG’s service with the purpose. QI’s goal is not merely connected to a better service provision, the underlying purpose of implementing QI tools is profitability. Better quality translates into lower costs and higher profits. However, when focusing on financial measures alone, the company overlooks essential elements that contribute to the provision and sustainability of high-quality services. Therefore, LRG’s step towards different measurement metrics and techniques that focus on a variety of key performance indicators (KPI)’s.

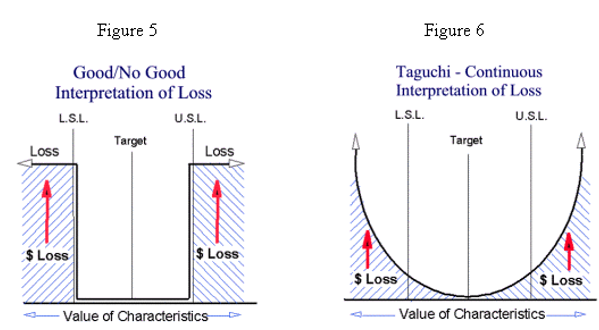

In traditional thinking, investment in quality is not always associated with the enhancement of a firm’s financial performance. However, the Taguchi loss function displayed in Picture 1, demonstrates that the increase of variation leads to a subsequent decrease in client satisfaction. This is an essential concept for understanding quality because providing a service that is consistent and always presents the high-level expertise of LRG’s employees is crucial.

The variation, in this case, is the difference in the quality of services that LRG presents. Lower specification limit (LSP) and upper specification limits (USL) used to be considered as a range across which customer satisfaction does not change, regardless of the ratio. According to Taguchi’s view, any change in quality irrespective of the specifications affects client satisfaction and thus must be addressed. The case study does not explicitly outline how LRG approaches variation. However, one can assume that benchmarks and KPIs are the primary tools allowing for tracking and addressing them.

This case provides an understanding of the methods applicable to QI and used in private organizations. However, both private and public organizations aim to provide excellent quality that aligns with the expectations of individuals using the services while having work efficiency. Hence, the evaluation of LRG allows one to comprehend the applicability of QI tools in both domains. With any type of business or public work, quality is the crucial element of excellence, because it is the reflection of satisfying the client’s needs and expectations systemically.

Continuous improvement is the basis of total quality management (TQM). One example is Deming’s improvement cycle is one element of implementing this, which is manifested through the Plan-Do-Study-Act (PDSA) system. LRG uses PDSA when implementing new projects. LRG uses the “closed-loop improvement cycle” as its approach to continuous enhancement of work, in which the management defines the strategy, objectives quality assurance measures, monitors and appraises outcomes, and finally adopts the plan if it is useful. This is similar to the PDSA, with the main difference being the incorporation of management’s review of performance and business improvement projects that LGR has.

Benchmarking is another concept of TQM that LRG employed by developing and adapting balanced scorecards as a part of performance evaluation. This model was developed by Kaplan and Norton, and it allows critically appraise the outcomes of work based on quantifiable measures. Other methods, such as “Road Map,” “Results Onion,” and “Strategic Objectives” help outline the aim of the company and measures used to determine if those were reached. In general, this should positively affect efficiency and quality since it creates an alignment between quality goals and workflow.

Hence, the purpose of LRG’s case study is to illustrate the real-life use of QI tools and techniques applied by the organization. Moreover, this case study demonstrates the rationale for choosing specific approaches and the expected results. For example, the closed-loop model enables continuous improvement and allows the management to see performance gaps, and therefore address them when developing a strategy, as well as set benchmarks for certain performance elements.

Six Sigma specifically targets efficiency, and as a result, LRG should have an output of 99.9% work effectiveness. LRG states that their new approach to managing different groups allowed them to achieve decentralization, following the implementation of the six-sigma on a small scale. Picture 2 presents an overview of processes according to this concept, which incorporates the essential steps of this concept, such as analysis, control, the definition of a problem, and others.

In essence, the main aim of this approach is to examine variation within customer expectations and output. LRG claims to use Six Sigma in combination with other methods and tools. Similar to Taguchi’s approach, the reduction of variability is the crucial aspect of this method, and an important notion is that there is a notable distinction between the level of errorless of 99% and 99.9%, hence Six Signa is essential. The case study does not outline which methods LRG uses, however, DMAIC may be applied for existing projects, which focuses on improving current capabilities.

Next, Lean is another critical concept of QI, together with Six Sigma, which emphasizes the minimization of waste and maximizing the customer value of LRG’s services. The central question of Lean is the constant questioning of the existing workflow to determine how the services can be improved from the perspective of a customer. Root causes of issues, performance improvement, the image of an ideal process, and evaluation of results are all elements of Lean. Firstly, this approach requires mitigating the tasks that are of minimum value and automating those that repeat. From LRG’s strategy, one can argue that a clear line of sight and environment for improvement are key elements that allow LRG to leverage Lean.

Notably, LRG uses a combination of Lean and Six Sigma, which is a valid approach since the two are complementary and not mutually exclusive. LRG references an emphasis on accountability, which is one of the center elements of Lean, and arguably, its approach to measuring process performance displays the importance that processes have in general. SMART goals is another lean tool that leverages data-driven decision-making and that LRG uses. Therefore, LRG successfully implements Lean in its operations.

Training and empowerment of personnel are critical for quality improvement. LRG’s case study presents several examples of this QI concept, including the recruitment of the best talent and the provision of training programs to the interested individuals. The critical element here is the idea that the company does not impose the need to participate in training for all individuals. Instead, it provides this opportunity only to those who want to be further educated.

On the one hand, arguably, LRG can reduce costs allocated to training and development of human resources, while on the other, it is unclear what is the ratio of people wanting to participate compared to those who avoid additional training and how LRG is affected by the latter group. “Lunch Learns,” “Local Briefings,” are used as educational strategies for LRG, which help transfer knowledge across the organization and thus help improve the quality.

Analysis and Recommendations

There are several well-established approaches to QI that can further improve LRG’s performance and efficiency. It should be noted that quality, as a concept, can be challenging to define precisely, as it can mean different things for different products, services, or organizations. However, across all of the mentioned elements, quality results in efficiency, durability, reliability, and other aspects that allow a business to reach its strategic objectives. Juran’s definition suggests that quality is when the offer meets the purpose of the product or service.

Moreover, since quality is a systemic matter, the final output must consistently align with the expectations, which is aided by a variety of QI tools and methods. QI is an approach that focuses on all elements of operations, the entirety of the supply chain, and product delivery to the client, which is why it is an essential change for LRG to include a more cohesive strategy and KPI’s into its planning and performance review.

Strategic application of quality relates to the alignment of QI with the businesses’ strategy and activities. The holistic view of quality and business excellence strategy, theory, process, structure, and systems is applied by LRG since the organization creates a unified vision of QI through its continuous improvement loop while allowing for autonomy and development of projects. In synthesizing the purpose, design, functions, and character of quality and business excellence, a company can achieve maximum efficiency, or in the case of Six Sigma, the 99.9% effectiveness of operations. Therefore, QI tools are essential for achieving operational excellence.

The purpose of methods used by LRG is to analyze the performance, with a focus on no-financial indicators, and create a system that will allow achieving the best performance possible repetitively. One should note that the financial element of operations is essential and can indicate a certain level of quality; however, it does not reflect the full spectrum of quality. For instance, LRG may be failing some clients in regards to the expectations of responsiveness or reliability, while still receiving a decent profit. However, in the long0term perspective, the clients that do not see the value of LRG’s product will choose to shift to a different service provider. Hence, the primary purpose of the tools and techniques implemented by LRG is to address this gap between quality and current performance, by designing approaches relevant to the specifics of this organization and aligning their functions with objectives. Notably, the character of quality affects the business performance, since, this notion is multidimensional and incorporates a variety of elements that will be reviewed in the next section.

Appraisal of Tools and Techniques for QI

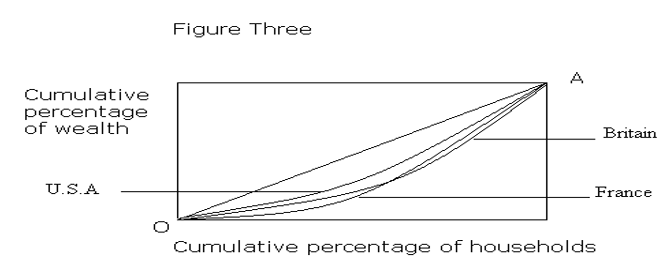

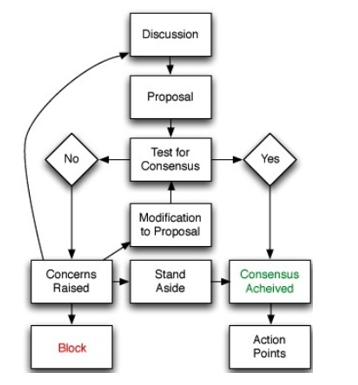

From the case study, one can conclude that FRG uses process maps and other visualization tools to improve its operations. One example is Picture 3, where the elements that affect LRG’s operations are displayed. While this is not a normal process map that outlines one specific activity with the inputs, decisions, and process activities, it nevertheless provides a brief outline of the workflow. Thus, one recommendation to FRG is to use standard process mapping to ensure regular performance across its groups. Picture 4 depicts a process map for the service industry that FRG can use.

In comparison with the TQC concepts and QI tools, LRG successfully uses the main principles to improve its operational efficiency and quality. Histograms and check sheets help create an evidence-based representation of issues and the frequency of their occurrence. LRG uses Tally sheets, which are all methods for obtaining and examining quantifiable data of performance and quality, however, it is not clearly outlined which processes incorporate these tools.

Alternatively, LRG can use scatter diagrams that help determine the correlation between variables and thus examine the causes of problems that obstruct the quality of performance. The analysis suggests that the root cause aspect of quality improvement is not emphasized by LRG. Thus another recommendation is to use a fishbone diagram to determine the problems that may affect quality.

In general, FRG’s process of developing a systemic approach to QI is an example of successful and targeted improvement. The main strength of LRG’s approach to QI is a cohesive strategy that reviews the organization and quality performance from a systemic perspective. The weakness is that the organization does not employ essential tools such as root cause analysis, which are useful in planning and evaluating the day-to-day workflow.

Conclusion

Overall, this paper examined the case study of LRG and the QI approach the company adopted. The main positive change implemented by LRG that allows the company to advance the quality of its services is the adoption of a systemic view, where the strategy is created for all groups and the review of non-financial indicators. This is manifested through the continuous improvement loop, which allows developing a plan, creating benchmarks, testing, analyzing, and implementing it. Additionally, LRG successfully uses Lead and Six Sigma and the main principles of these techniques.