Introduction

Petroleum products are used in different sectors as energy and raw materials for various industries. According to Leffler and Raymond (2006), oil is one of the most important commodities in the world market. It has a massive impact on other sectors of the economy.

In the 19th and 20th centuries, the United States was the leading producer of oil in the world. It has since been surpassed by Saudi Arabia and Russia in production of oil. However, the government has been committing a lot of investment in this sector.

The federal government has been keen to develop the infrastructure in the energy sector in order to boost production of energy. Although other units in the energy sector ,such as hydro, geothermal and wind energy power, have been given focus, attention has always been on the petroleum sector.

The United States has been willing to ensure that it has increased the volume of petroleum products that it produced. This has seen it improve the infrastructure in this sector to great extents.

Recent studies show that the United States has the capacity of becoming the leading oil producer in the world based on the oil reserves that have been identified in the recent past. The focus of this study will be to bring an understanding of how oil exploration, production, storage, transport, and refinement take place.

Exploration

Oil exploration is one of the most complex and very expensive processes in petroleum production. Parkash (2003) defines petroleum exploration as, “The search by petroleum geologists and geophysicists for hydrocarbons deposits beneath the Earth’s surface, such as oil and natural gas.”

This process involves different complex processes that would help in determining the presence of oil in a given region.

In the United States, oil exploration has evolved over the years, from the use of a simple tool to tap petroleum products that were near the surface to complex processes that can help determine the presence of oil in the deep seas. The cost of oil exploration has been the main hindrance to small scale oil exploration in the country.

Oil exploration can take place at onshore or offshore sites. Some of the traditional ways of determining the presence of oil is the detection of oil or natural gas seeps on the surface of the earth. These are the crucial leads to many oil explorers.

According to Parkash (2003), although there are currently many sophisticated tools that are used to detect the presence of petroleum, the seeps still act as crucial leads to the possibility of oil exploration beneath the ground.

Exploration geophysics has been one of the most important tools that are currently used to identify the presence of hydrocarbons deposit.

As a result of the massive cost of drilling oil wells, there has been an increasing need to confirm that there is a substantial amount of oil in a given region before drilling of the wells can begin. Technological advancement has helped develop some tools that can assist in confirming that the amount of oil detected is worth exploring.

This means that when a region is suspected to have oil deposits, it will be subjected to a series of sub-surface geological analyses. The first stage is always to subject the area to gravity survey. Special tools are used at this stage to determine how gravitational force is affected in that particular area.

Significant presence of oil deposits would have an effect on the gravitational force, a fact that could point to the presence of oil. However, presence of ground water may have a similar effect, and this means that a further analysis is needed.

The second stage will be magnetic survey. This is used to determine if the gravitational effect is caused by water or deposits of hydrocarbons. Magnetometer is used at this stage. The next stage would be to conduct a passive seismic survey.

Parkash (2003) says, “Passive seismic is the detection of the natural low frequency earth movements, usually with the purpose of discerning the geological structure and locate the underground oil, gas, or other resources.”

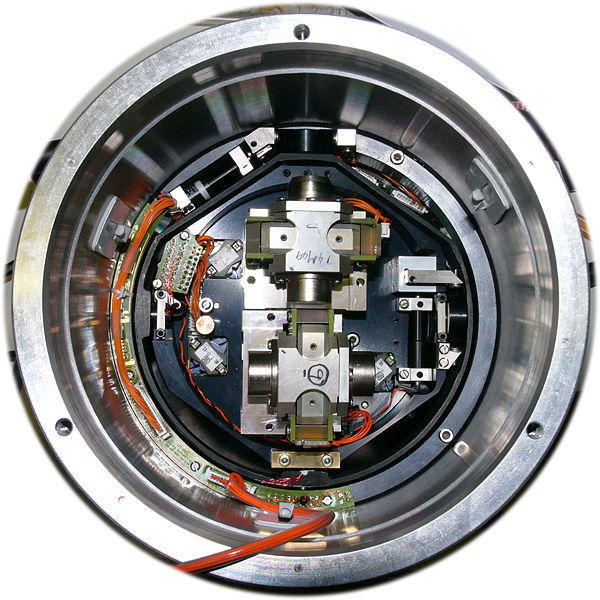

The natural frequency would be measured by close observation of seismic waves with the help of portable seismometers. Below is a picture of seismometer used in monitoring the flow of seismic waves.

Seismometer

When all these processes give a lead to a possible presence of oil in a given location, then it would be considered worth drilling an exploration well that would be the final test that a given region has potential oil deposits.

In the United States, oil explorations have been extensively conducted in Georgia, Virginia, Ohio, New York, Oklahoma, Texas, Louisiana, and many other states in this country.

Offshore exploration, especially in the deep sea, has also been conducted to supplement the supplies found onshore. Although very expensive, offshore oil drilling is currently becoming very popular, especially among large American corporations.

Production

Petroleum production, also known as oil extraction, is the actual process of extracting usable petroleum from the earth. Upon a successful completion of the exploration process, the next step is always the extraction. This is another very costly process that involves numerous risks.

It has been a preserve for the large specialized companies, such as Bio Tech Inc., that have been very successful in most of the oil fields in Texas. The first stage in oil extraction involves drilling of oil well at the site using oil rings. A steel pipe is then placed into the bore to enable the oil to move easily to the surface.

At the top end of the pipe, there are collection valves, also known as Christmas Tree (Leffler, Pattarozzi and Sterling 2011). It helps in controlling the flow and regulating the pressure. The figure below is Pump jack used in the extraction process.

According to Zou (2013), oil extraction takes place in three main stages. The first, also known as the primary recovery stage, takes place when natural mechanisms are used to extract oil deposits into the surface.

At this stage, such natural occurrences as displacement of oil by water and gravitational forces would help in the extraction of oil from the ground. This always takes place in cases where there are large deposits of oil. This stage is common in newly drilled wells.

The second stage, also known as the secondary recovery stage, takes place when the natural forces become too weak to support the extraction process. This is common in cases where the extraction process has been ongoing for some time.

The process involves supplying external energy into the reservoir in order to force oil deposits into the system. Totten (2003) notes that gas lifts are always used to inject carbon dioxide into the reservoir to help in forcing oil products into the drilling pipe.

The third stage known as tertiary recovery is a complex process that uses different approaches to extract oil from the ground. Also known as thermally enhanced oil recovery process, this stage uses steam injection and fire flooding in order to extract oil from the ground.

Sometimes it even becomes necessary to convert oil into electrical energy to further enhance the extraction process. The ultimate amount of oil that can be extracted from a given location depends on a number of factors.

According to Parkash (2003), the most important factor that determines the amount of oil that can be extracted from a given area is the level of oil deposits. Large oil deposits would yield higher amounts of oil. Another important factor is the permeability of the rocks.

Some rocks do not allow for a smooth flow of oil because they are tight. Such rocks inhibit the rate at which oil can be extracted from them.

Finally, the technology used and the level of skills of the workforce will play some part in determining the amount and rate at which oil is extracted from the ground.

Most of the oil extracting companies in the United States are known to use sophisticated tools in order to improve the speed and amount of oil extracted from the ground. This has helped them increase the efficiency of the entire process.

Storage

When petroleum products have been extracted from the ground, they must be temporarily stored before they are transported to the refinery plants. According to Parkash (2003), storage of petroleum products can be analyzed from two perspectives.

The first perspective will analyze the storage process of the crude oil just before it is transported to refinery plants.

The second perspective will be the storage of the processed products that are waiting for transportation to various retailing destinations. Storage of oil always takes place within a short while as it awaits its transportation to the relevant destinations. Storage of crude oil may take place onshore or offshore.

The approach taken to store oil extracted onshore is different from the approach taken to store that which is extracted offshore. Onshore crude oil storage is a simpler process that makes use of large cylindrical tanks constructed above or below the surface.

The size of the tanks will depend on the amount of oil that is extracted per unit time, and the speed of the transportation system. It is important to ensure that the storage tanks are of the standard materials because any leakage of the crude oil may have a devastating effect on the environment.

Several government agencies and environmental organizations have developed requirements that should be followed when designing such tanks. This is meant to enhance environmental protection and security of the employees and infrastructure within the plant or its surrounding.

The petroleum products extracted offshore are always stored with the help of floating production, storage and offloading unit (Zou 2013).

This is a complex unit that does not only help in the production process but also in its storage while it awaits tankers that would be used in the transportation process. The figure below shows the unit on high seas.

When the crude oil has been processed into such products as liquid petroleum gas, petrol, kerosene, or heavy fuels, temporary storage of these products is needed before they can be transported to the market. Storage of these final products is a very complex process that requires a high level of safety measures.

Liquid petroleum gas and petrol are highly flammable products, and their storage at the refinery plants needs specialized equipment. According to Leffler (2008), emerging technologies have helped improvise storage equipment that is efficient in storing refined petroleum products.

Transport

Transportation is the nest stage in this process. Transportation of petroleum products always takes place with the help of pipelines, tank trucks, marine vessels, rail tanks, and many other vessels.

Although crude oil is majorly transported using pipelines and tankers, the refined products require unique transport systems that take into consideration their true nature.

For instance, the transport method used for liquid petroleum gas may not be appropriate when transporting heavy fuels, such as diesel. Each product has its own unique transportation vessel to enhance safety of the people handling the products, the society, and the environment.

Transportation of gasoline must be done through specialized pipelines, tanks, and such other containers that will restrict its exposure to the air. This is so because the product is highly flammable and can have devastating effects when exposed to air and flame.

Liquid petroleum gas is stored and transported at temperatures below -162 degrees centigrade. This helps ensure that the product remains in a liquid state. The main advantage of liquefaction of the product is that it consumes a smaller space than when stored in a gaseous form.

This helps in storing and transportation of a large amount of the gaseous energy in a small container. This also reduces the possibility of the product to evaporate from the containers.

The transportation equipment must have the ability to maintain the temperatures of the product at low temperatures to avoid the possibility of transformation into gas. If the product turns into gaseous form, it can cause a massive explosion as it will be trying to force its way out of the container.

Large tankers have been widely used in the transportation of liquefied petroleum gas in the mainland. The figure below shows a large track used to transport LPG from the refinery to various consumer outlets in the United States.

In the United States, pipelines have been popular when transporting petrol and other heavy fuels, such as diesel and kerosene. Pipelines are efficient because of their speed and cost-effectiveness.

This eliminates the need for large tank tracks that are associated with more labor cost, raised negative effect on the environment, destruction of roads, and increased rates of the traffic jam.

However, it needs close monitoring and evaluation to ensure that any leakage is detected and corrected before it can cause negative effects on the environment.

Some of the widely used pipelines include flow lines, gathering and feeder lines, crude trunk lines, and petroleum product trunk lines (Leffler, Pattarozzi and Sterling 2011). Other heavy products, such as bitumen are transported in sizable drums.

Refinement and distribution of oil throughout the U.S

Refinery of petroleum products is a complex process that involves a series of activities within the refinery plant.

Zou (2013) defines refinery process as, “A series of chemical engineering processes that are used to transform crude oil into useful products such as liquefied petroleum gas (LPG), gasoline or petrol, kerosene, jet fuel, diesel oil and fuel oils.”

The scholar says that the processes that take place during the refinery are so complex that it may not be easy to describe them in a layman’s language.

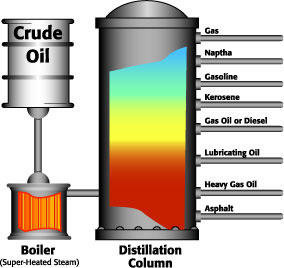

However, the process can be summarized into some of the general stages that crude oil is subjected to before it can produce the desired products. The figure below is a simple diagrammatic representation of what takes place in a refinery plant.

As shown in the diagram, crude oil is a combination of several products that are needed in various sectors to provide energy. In the refinery plant, crude oil is poured into a large boiler. The boiler is connected to a distillation chamber as shown in the above diagram.

The boiler is superheated, forcing its content into the distillation column. At this distillation column, different products will be obtained based on their boiling points in a process known as fractional distillation.

Light petroleum products, such as liquid petroleum gas, will be collected first because of their low boiling points. Gasoline and kerosene will follow.

Heavy petroleum products, such as asphalt, would come out of the distillation chamber last. Although the diagram shows a simple process, the actual refinery process is complex and involves the use of a series of machines.

Some of the leading oil refinery plants in the United States include Cherry Point in Washington, Whiting in Indiana, Toledo in Ohio, Cooper River, Texas City in Texas, and Decatur in Alaska.

These products are then sold to some of the major distributors of petroleum products using the above mentioned transport methods. These distributors will make the products available by any appropriate means.

Security measures in place to ensure safety of the oil sector

Oil sector is the backbone of all other industries in the American economy. Accidents in this sector or acts of terrorism targeted towards it may have devastating effects.

For this reason, security measures are crucial to ensure that this sector operates without any threat of accidents or terrorist actions. Measures and codes of conduct have been put in place to enhance security and safety of this sector.

These measures were under review, especially after the Texas City Refinery explosion in 2005. The diagram below shows the massive destruction that was caused by this explosion. Fifteen people died while over 170 others sustained serious injuries.

The security measures define the standards and codes of conduct that should be observed in all the stages defined. According to Mora and Cooney (2007), dangers in this sector begin during the exploration process, to the time the product is finally consumed.

Government bodies have set standards that seek to ensure that exploration is done in a way that does not expose dangers to the environment. The policies define tools that should be used in the exploration and drilling processes.

The recent deep sea oil spillage involving BP is a clear indication of dangers that may occur when these policies are ignored. At the refinery plant, there are guidelines that define the infrastructure to be used and code that must be followed during the processing of the products.

The government has also established tough laws to regulate the transportation of these products, such as the Safety Standards for Conveyers and Related Equipment.

Conclusion

Petroleum products are very important to many sectors of the economy because they offer the energy needed to drive various machines and instruments.

The process of coming up with these products is very complex. It starts with the exploration, extraction, transport, refinery, storage, and finally distribution to various outlets within the country and in other overseas markets.

References

Leffler, W. L. (2008). Petroleum refining in nontechnical language. Tulsa, Okla: PennWell.

Leffler, W. L., Pattarozzi, R., & Sterling, G. (2011). Deepwater petroleum exploration & production: A nontechnical guide. Tulsa, Okla: PennWell Corp.

Leffler, W. L., & Raymond, M. (2006). Oil and gas production in nontechnical language. Tulsa, Okla: PennWell Corp.

Mora, F. O., & Cooney, J. W. (2007). Paraguay and the United States: Distant allies. Athens [u.a.: Univ. of Georgia Press.

Parkash, S. (2003). Refining processes handbook. Amsterdam: Gulf Professional Pub.

Totten, G. E. (2003). Fuels and lubricants handbook: Technology, properties, performance, and testing. West Conshohocken, Pa: ASTM International.

Zou, C. (2013). Volcanic reservoirs in petroleum exploration. Amsterdam: Elsevier.